Preparation method for high melt strength poly lactic acid, and extruder thereof

A high-melt-strength, extruder technology is applied in the field of preparation of high-melt-strength polylactic acid, which can solve the problems such as the inability to significantly increase the material residence time, the low molecular weight of long-chain branched PLA, and the short residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

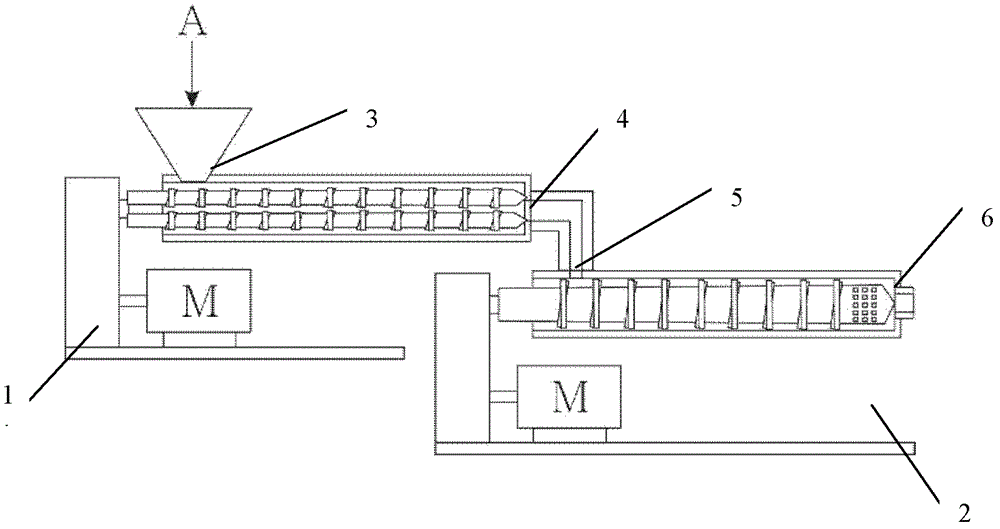

[0020] Such as figure 2 As shown, the present invention provides an extruder, which includes a first-stage extruder 1 and a second-stage extruder 2, the first-stage extruder 1 is a twin-screw extruder, and the second-stage extruder 2 It is a single-screw extruder, the first-stage extruder has a first material inlet 3 and a first material outlet 4, the second extruder has a second material inlet 5 and a second material outlet 6, and the first The material outlet 4 is connected to the second material inlet 5 . Preferably, the diameter-to-length ratio of the first-stage extruder is 1:45, and the diameter-to-length ratio of the second-stage extruder is 1:65. Of course, the diameter-to-length ratio can be changed according to requirements. Above-mentioned twin-screw extruder and single-screw extruder are existing equipment. The invention combines the two, the equipment modification is simple and quick, and the effect of chain extension is quite different, which is an innovation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com