Method for conversion of C10+ heavy aromatics into light aromatics by virtue of hydrogenation

A technology for lightening and heavy aromatic hydrocarbons by hydrogenation, which is applied in the directions of hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of low content of heavy aromatic hydrocarbons, poor stability of catalyst activity, etc. The product is flexible and the effect of reducing the speed of carbon deposition and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of prehydrogenation catalyst: Take 400g of macroporous pseudo-boehmite, add 360mL of 3% dilute nitric acid solution, 12g of scallop powder, knead, shape, dry at 120°C for 8h, and roast at 550°C for 4h to obtain γ-Al 2 o 3 Carrier 320g; Dissolve 72g of nickel acetate and 20g of citric acid in deionized water to prepare 360mL of impregnation solution; load the impregnation solution on the carrier by saturated impregnation method, then dry at 120°C for 8h, and roast at 600°C for 3h to obtain pre-added 356g of hydrogen catalyst; wherein the content of active metal Ni in the catalyst is 10wt%.

[0030] Preparation of hydrocracking catalyst: Take 280g of modified Y molecular sieve, add 40g of binder kaolin, 16g of scallop powder, 400mL of 3% dilute nitric acid solution, knead, shape, dry at 120°C for 8h, and roast at 600°C for 4h Prepare the molecular sieve carrier; take 3 g of metal Pt nitrate and add deionized water to make an impregnating solution 290 mL, plac...

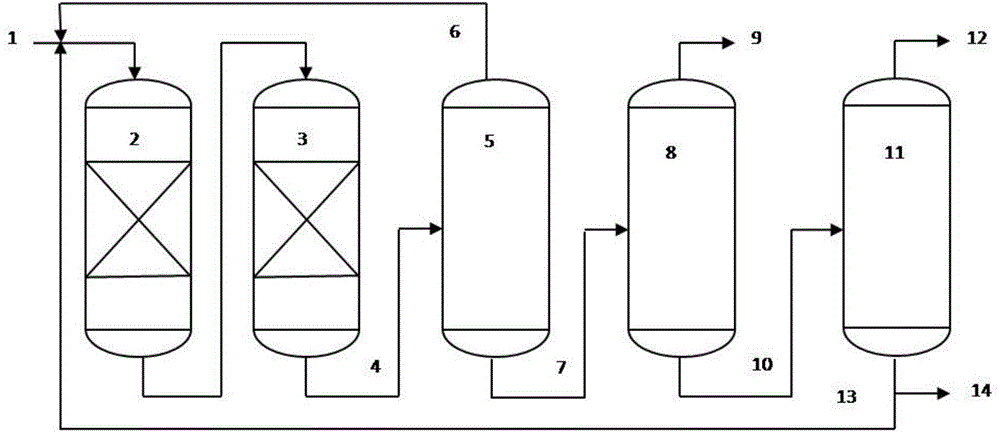

Embodiment 1

[0033] Take the by-product C from a refinery reforming unit 10 + The heavy aromatic fraction is used as raw material, and the properties of the raw material are shown in Table 1. After the raw material is mixed with hydrogen, it passes through the pre-hydrogenation reactor and the hydrocracking reactor in sequence, and the feed volume space velocity is 1.0h -1 , the hydrogen hydrocarbon volume ratio is 1000:1, the reaction temperatures in the middle of the two reactor beds are 350°C and 360°C respectively, and the reaction pressure is 2.5MPa. After the product is separated by the No. 1 rectification tower, the bottom material enters the No. Distillation tower, the fraction before 205°C was extracted from the top of the tower, and the material at the bottom of the tower was recycled to the reaction system. The product analysis data are shown in Table 2.

Embodiment 2

[0035] Experiment with the same raw materials as in Example 1. After the raw material is mixed with hydrogen, it passes through the pre-hydrogenation reactor and the hydrocracking reactor in sequence, and the feed volume space velocity is 1.0h -1 , the hydrogen hydrocarbon volume ratio is 1000:1, the reaction temperatures in the middle of the two reactor beds are 340°C and 355°C, and the reaction pressure is 3.0MPa. After the product is separated by the No. 1 rectification tower, the bottom material enters the No. 2 rectifier Distillation tower, the fraction before 205°C was extracted from the top of the tower, and the material at the bottom of the tower was recycled to the reaction system. The product analysis data are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com