An ecological cycle treatment method for livestock farm wastewater

A technology of ecological cycle and treatment method, which is applied in the fields of animal husbandry wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc. problems, to achieve the effect of saving ration, improving the structure of the ration, and improving the economic utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

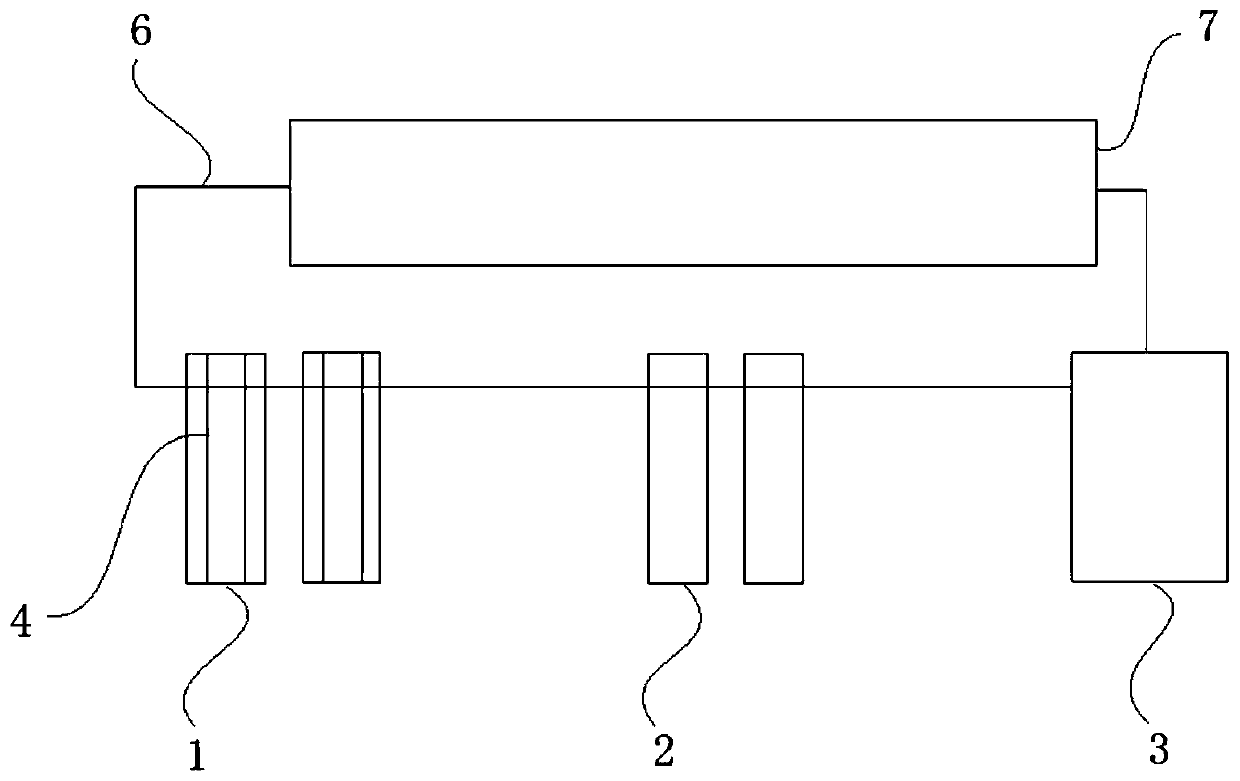

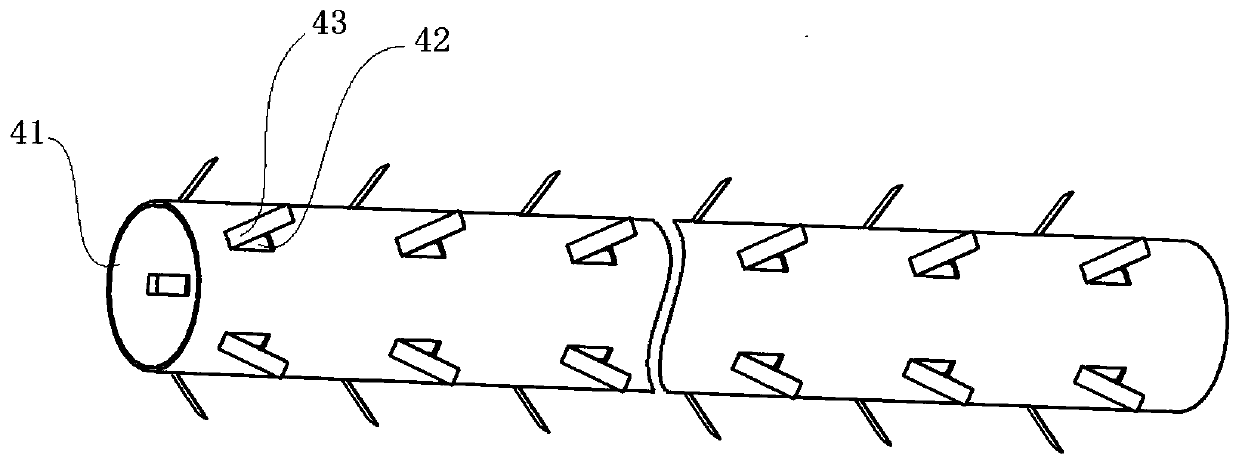

[0035] Such as figure 1 As shown, an ecological cycle treatment method for farm wastewater includes anaerobic treatment and three-stage biological purification, and the wastewater after anaerobic treatment is then subjected to three-stage biological purification. Anaerobic treatment adopts existing technical means, which are widely used in sewage treatment and biogas production. Under anaerobic conditions, organic matter in sewage is decomposed, metabolized, and digested by anaerobic bacteria, which greatly reduces the content of organic matter in sewage. At the same time Generate biogas. The three-level biological purification equipment includes a first-level purification pool 1 , a second-level purification field 2 , a third-level purification pool 3 , and a pipeline 4 . Such as image 3 As shown, one end of the pipeline 4 is open 41, and the other end is closed. The side wall of the pipeline 4 offers some outlets 42, and a flexible baffle 43 is set near the outlet 42. The...

Embodiment 2

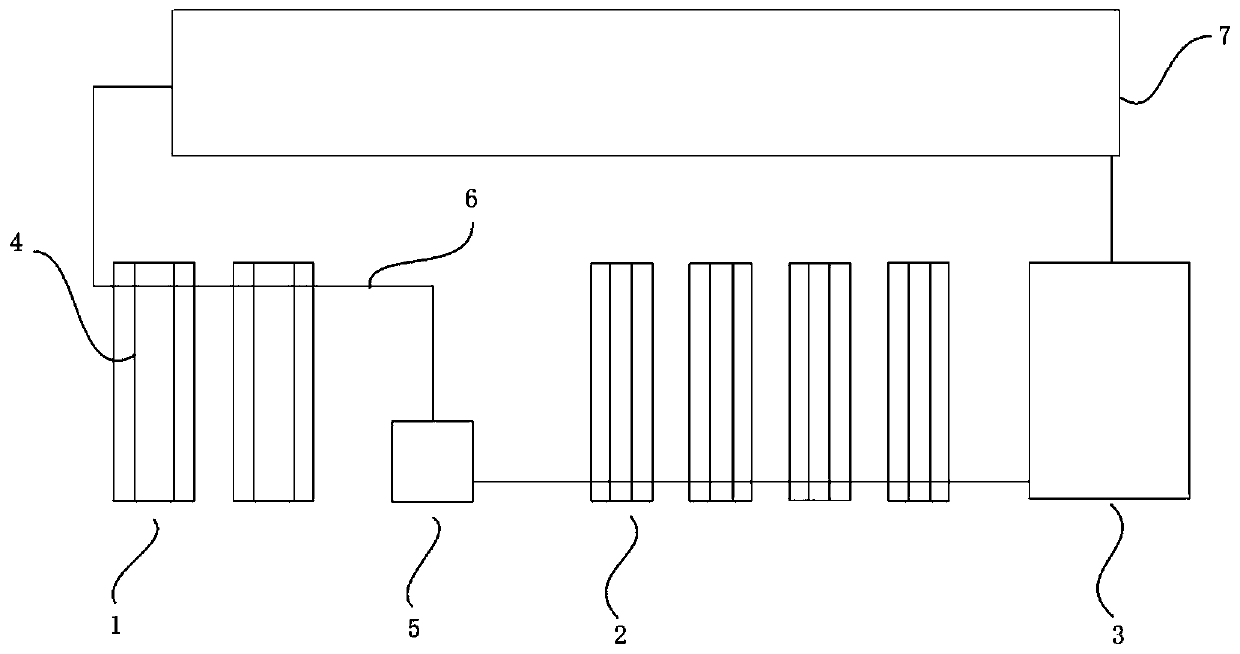

[0041] Such as figure 2As shown, in this embodiment, on the basis of the previous embodiment, there are two primary purification pools 1, and the ryegrass planting time in the two primary purification pools 1 is staggered, and the irrigation is used in turn, and the water flow is maintained by reasonable water distribution. Time and stable purification.

[0042] In this example, if Figure 4 As shown, several outlets 42 on the pipeline 4 form a helical shape along the axial direction of the pipeline 4, and further several outlets 42 can be set to communicate with each other to form a helical outlet around the side wall of the pipeline 4 (the outlet is closed in the figure, and is closed by a flexible baffle. 43 cover). At this time, the several flexible flaps 43 preferably form a spiral shape along the several outlets 42 . The helical outlet increases the outlet area, and the helical flexible baffles are integrated into one body, so that the opening or closing force is mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com