Industrial production method for toluene sulfonamide

A technology of p-toluenesulfonamide and p-toluenesulfonyl chloride, which is applied in the field of industrial production of p-toluenesulfonamide, can solve the problems of high labor intensity, large amount of ammonia nitrogen, low yield, etc., to reduce labor intensity, reduce COD emissions, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

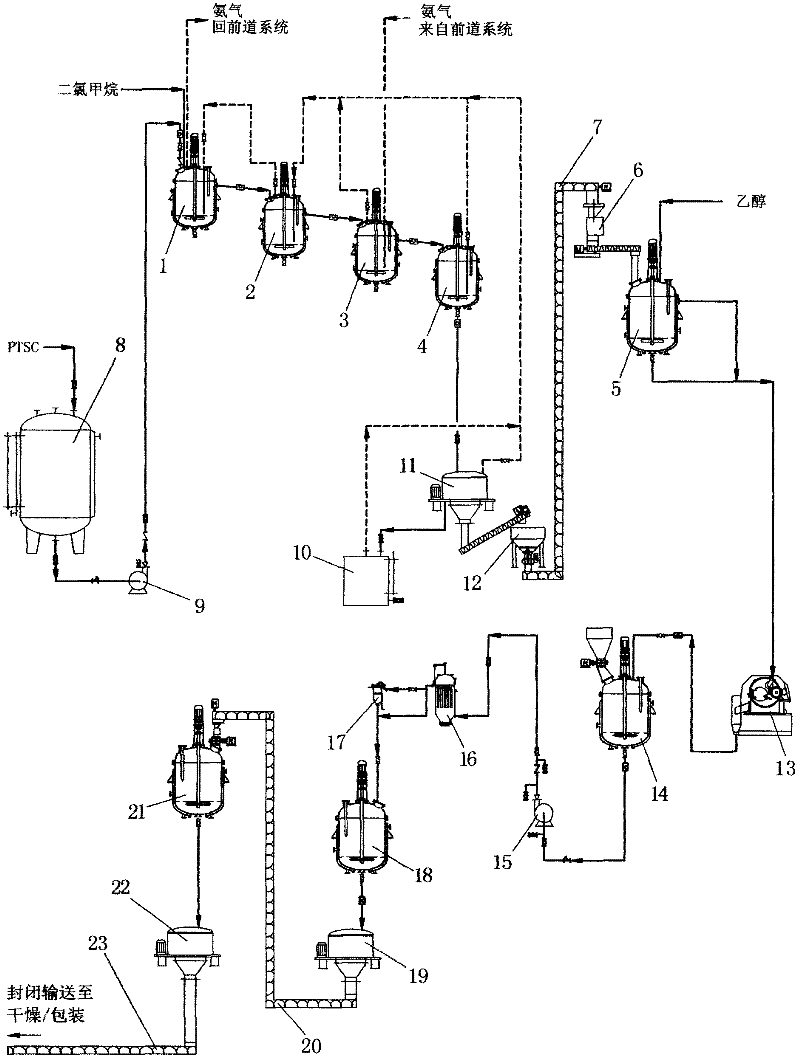

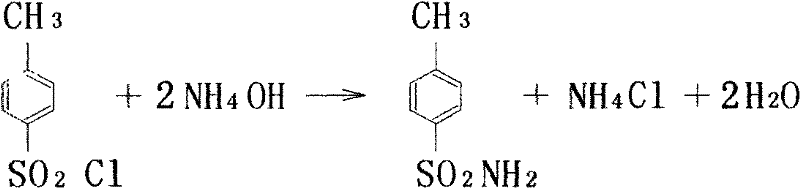

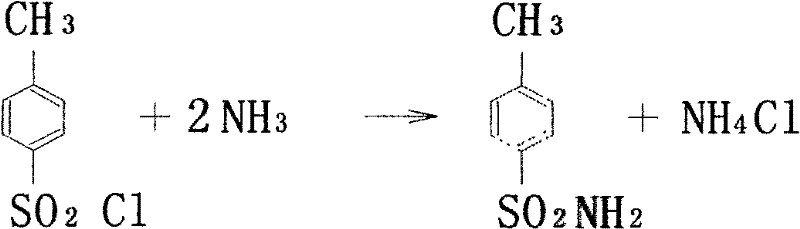

Method used

Image

Examples

Embodiment 1

[0042] The dichloromethane solution of p-toluenesulfonyl chloride is sent from the acid chloride workshop to the intermediate storage tank. Then the dichloromethane solution of p-toluenesulfonyl chloride is injected into the first-level amination still with the speed of 300kg / h by delivery pump, and puts into the first-level amination still with the dichloromethane from head tank at the speed of 450kg / h simultaneously . Through the side outlet of the primary amination kettle, it enters the secondary amination kettle in the form of overflow, and then enters the third-level amination kettle in the form of overflow through the side outlet of the second-level amination kettle, and then enters the fourth-level amination kettle in the same way. grade amination kettle. Then it enters the centrifuge through the lower outlet of the fourth-stage amination kettle. Reactor temperature control is 20~35 ℃.

[0043] Ammonia gas enters from the three-stage amination kettle with a flow rate...

Embodiment 2

[0050] Process is identical with embodiment 1, and each process parameter is:

[0051] The dichloromethane solution of p-toluenesulfonyl chloride is squeezed into the primary amination still with the speed of 560kg / h,

[0052] Dichloromethane is put into the primary amination kettle from the head tank at a speed of 840kg / h,

[0053] The temperature of the amination reaction is controlled at 20-35°C,

[0054] The flow rate of the ammonia entering the three-stage amination kettle is 51kg / h,

[0055] The temperature of the dissolution tank is controlled at 70-80°C,

[0056] The temperature of the decolorization kettle is controlled at 70-80°C,

[0057] The temperature of the crystallization tank is controlled at 5-15°C,

[0058] The washing temperature of the washing tank is 25-40°C.

[0059] After the system operated for 195 hours, 48.882t of p-toluenesulfonamide was obtained, and the output rate was 251kg / h.

Embodiment 3

[0061] Process is identical with embodiment 1, and each process parameter is:

[0062] The dichloromethane solution of p-toluenesulfonyl chloride is injected into the primary amination kettle at a speed of 1000kg / h,

[0063] Dichloromethane is put into the primary amination kettle from the head tank at a speed of 1500kg / h,

[0064] The temperature of the amination reaction is controlled at 20-35°C,

[0065] The flow rate of the ammonia entering the three-stage amination kettle is 90kg / h,

[0066] The temperature of the dissolution tank is controlled at 70-80°C,

[0067] The temperature of the decolorization kettle is controlled at 70-80°C,

[0068] The temperature of the crystallization tank is controlled at 5-15°C,

[0069] The washing temperature of the washing tank is 25-40°C.

[0070] After running the system for 288 hours, 128.921t of p-toluenesulfonamide was obtained, and the output rate was 447kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com