Industrial production method for continuously preparing Dailon

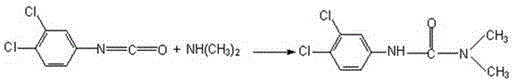

A production method, the technology of Diuron, is applied in the field of industrialized production of continuous preparation of Diuron, which can solve the problems of great impact on product quality and low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

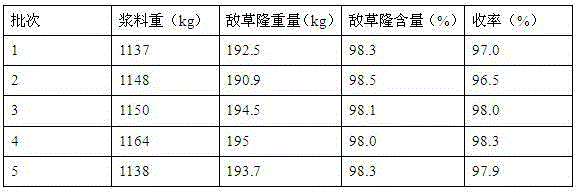

Examples

example 1

[0023] 1. Preparation:

[0024] Prepare 3,4-dichloroisocyanate in toluene as a 15% toluene solution of 3,4-dichloroisocyanate in mass percent for use.

[0025] Mix dimethylamine and water to form a 40% aqueous solution of dimethylamine by mass, and set it aside.

[0026] The three-stage reactors are sequentially connected in series by switching valves, and the material overflow of the third-stage reactors is connected to the collection kettle through the valves. The volumes of the continuous first, second and third stage reactors are 500L, 1000L and 1000L respectively.

[0027] 2. Production control:

[0028] Add 300L of toluene to the reactors at all levels, raise the temperature, and control the reaction temperatures of the first, second and third reactors to be 15-20°C, 25-30°C, and 27-32°C, respectively.

[0029] At the same time, the toluene solution of 3,4-dichloroisocyanate and the aqueous dimethylamine solution are pumped into the first-stage reactor, and the feed f...

example 2

[0035] The flow rate of the dimethylamine aqueous solution in Example 1 is adjusted to 20 L / hr, the pH value of the material in the first-stage reactor is 7, and the others remain unchanged. The average yield of Diuron is 88% and the content is 91%.

example 3

[0037] The concentration of the toluene solution of 3,4-dichloroisocyanate in Example 1 is adjusted to 25%, the flow rate is constant (218 L / hr), the flow rate of the dimethylamine aqueous solution is adjusted to 41 L / hr, in the primary reactor The pH value of the material was determined to be 10, the overflow in the reaction process was difficult, easy to block, and the continuous process could not be carried out normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com