Device for preparing sulfur dioxide by directly burning raw sulfur

A technology of sulfur dioxide and sulfur generation, which is applied in the direction of sulfur compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of sulfur generation that is not easy to burn, sulfur generation is amorphous, and is not easy to burn, so as to achieve good economic prospects and good social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

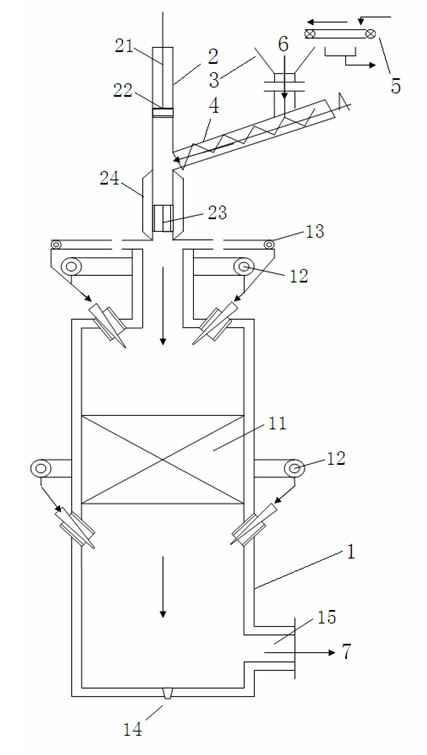

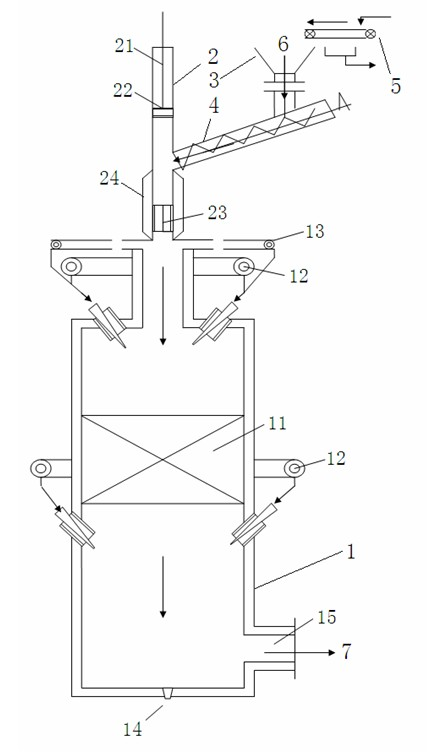

[0017] The present invention will be further explained below in conjunction with the accompanying drawings.

[0018] As shown in the accompanying drawing, it is a device for producing sulfur dioxide by direct incineration of sulfur in the present invention. The device uses a feeder to squeeze raw sulfur into the incinerator to form thin noodles. In the high-temperature incineration furnace, the fine sulfur noodles are quickly dried and burned under the oxidizing gas. The device includes five parts, namely: vacuum filter 5, raw sulfur hopper 3, push feeder 4, sulfur noodle extrusion molding machine 2 and sulfur raw continuous incinerator 1, wherein, push feeder 4, sulfur noodle Extrusion molding machine 2 and sulfur generation continuous incinerator 1 are core devices. The function of the vacuum filter 5 is to dehydrate the sulfur bubbles to make sulfur paste; the function of the raw sulfur hopper 3 is to store and transfer raw sulfur; the function of the push feeder 4 is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com