Double series reactor process for preparing polyethylene

A series reactor, polyethylene technology, applied in the double series reactor process field, can solve the problems of low activity, difficult to control, high polymerization rate, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of composite catalyst:

[0038] A: Preparation (BuCp) 2 ZrCl 2 -M-1 composite catalyst

[0039] For the preparation method of the supported Ziegler-Natta catalyst, refer to the M catalyst obtained from the patent EP688794. Under the protection of nitrogen, 3g of M catalyst was added into a stirred reaction flask. Add 30ml of styrene-acrylic acid copolymer (-COOH content in the copolymer: 3.5mmol / g polymer) in tetrahydrofuran (containing 0.025g polymer / ml solution) to the reaction flask, and stir at 0°C for 30min. Then add 50ml of isopentane into the reaction flask at a rate of 1ml per minute. After stirring was stopped to allow the solids to settle, the supernatant was removed and the residue was washed with isopentane (30ml / time) and then purged with nitrogen at 70°C until a free flowing powder was obtained. Take another mixing bottle and add 30ml (BuCp) 2 ZrCl 2 Add 8.6ml of MMAO in heptane solution (1.9mmol / ml) to n-hexane solution (3.75mmol / ml), a...

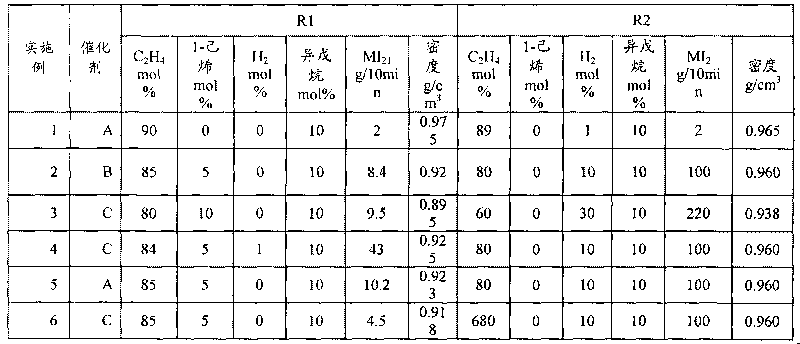

Embodiment 1-6

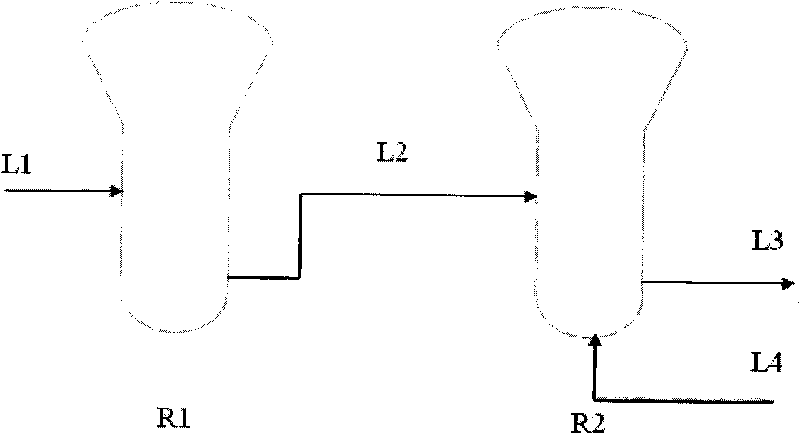

[0045] use as figure 1 The two-reactor setup shown,

[0046] R1 is the first reactor;

[0047] R2 is the second reactor;

[0048] L 1 It is the first reactor reaction material ethylene, comonomer feeding line;

[0049] L 2 It is the discharge line of the reaction material of the first reactor, and this discharge is directly added to the second reactor;

[0050] L 3 It is the discharge line of the second reactor;

[0051] L 4For the second reactor, the reaction materials ethylene and hydrogen enter the feed line.

[0052] Replace the Φ76×700mm adiabatic fluidized bed polymerization reactor several times with nitrogen gas, and then use ethylene gas in the industrial device to maintain the flow replacement of the reactor for more than 2 hours. Into the reactor, add 2.1Mpa of fresh ethylene gas, 3.8Mpa of butene-1 partial pressure, the initial reaction temperature is 60°C, take 0.1g of the above catalyst, and carry it into the first reactor with high-pressure nitrogen (3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com