Mixture gas catalytic deoxidation process containing combustible gas

A technology of mixed gas and catalytic deoxidation, which is applied in the fields of gas fuel, fuel, petroleum industry, etc., can solve the problems of high energy consumption, large investment and high cycle ratio of circulating compressors, and achieve the effect of saving energy and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

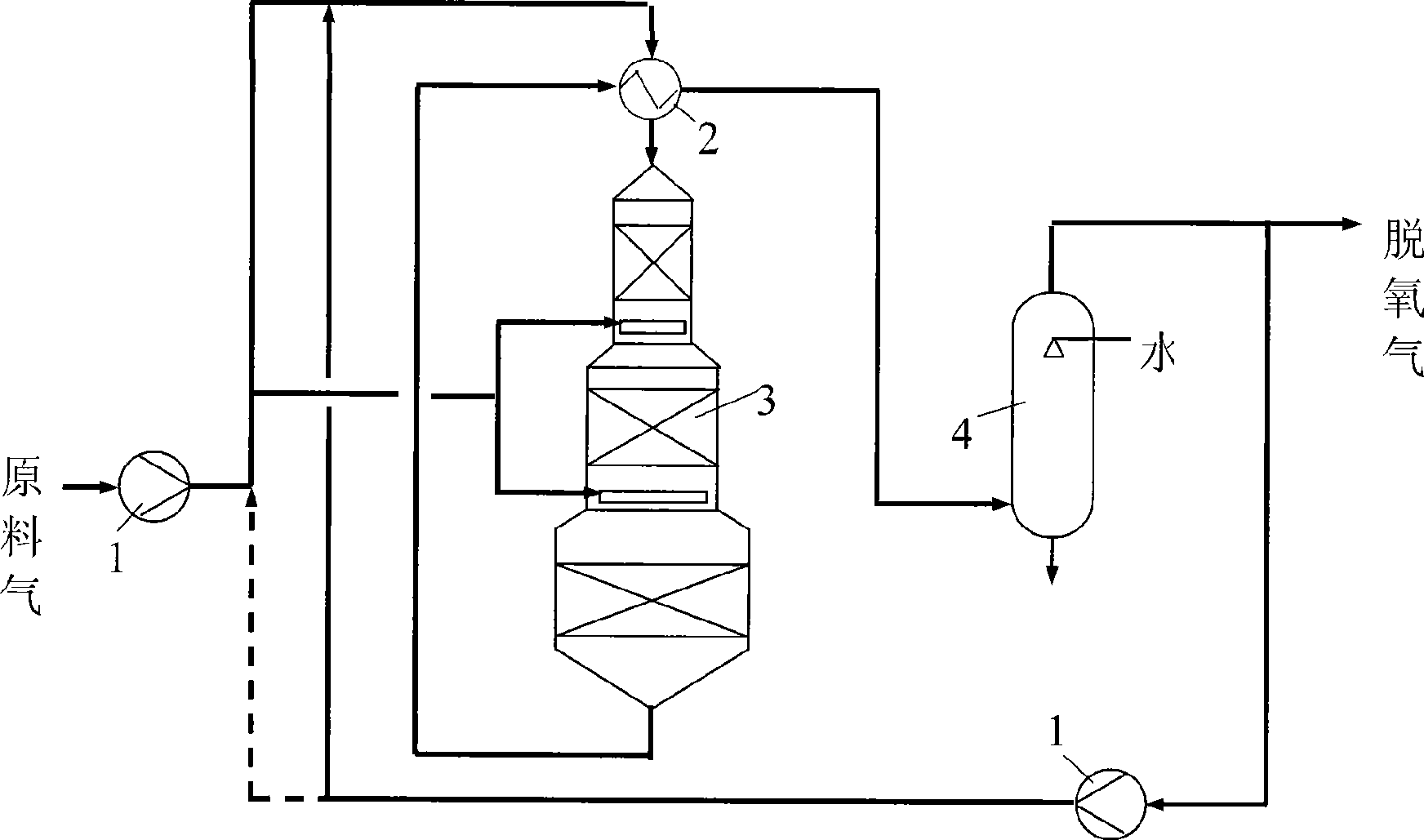

Embodiment 1

[0033] The raw material mixed gas is divided into two streams after being pressurized by the compressor, and the gas volume of the first raw material mixed gas is 1087Nm 3 / hr is mixed with part of the circulating gas, and the amount of circulating gas is controlled to keep the oxygen content of the mixed gas at 4.1%. Afterwards, the mixed gas is preheated to about 450°C by the raw material mixed gas preheater, and enters the first-stage reactor from the upper part to react and deoxidize. The oxygen content of the reacted gas is 0.2%.

[0034] Another stream of raw material mixed gas is mixed with part of the recycle gas, and the amount of recycle gas is controlled so that the oxygen content of the mixed gas is 6.83%. This part of the mixed gas is divided into two streams, one with a volume of 3859Nm 3 The / hr mixed gas is mixed with the deoxygenated gas from the first-stage reactor in the pipeline, enters the second-stage reactor from the upper part, and deoxidizes in the se...

Embodiment 2

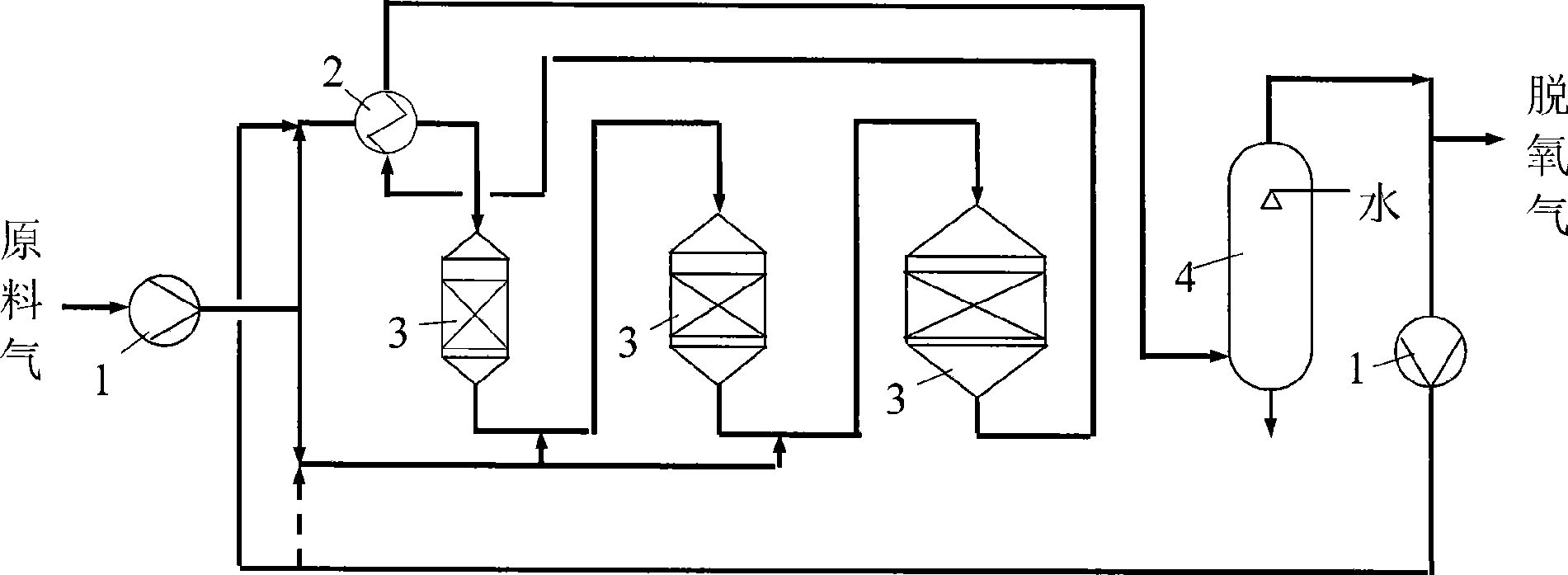

[0043] 10000Nm 3 / hr The raw material mixed gas is divided into three strands after being pressurized by the compressor, of which the gas volume of the first raw mixed gas is 989Nm 3 / hr is mixed with the circulating gas, and the amount of circulating gas is controlled so that the oxygen content of the mixed gas is 4.4%. The mixed gas is preheated to about 325°C by the raw material mixed gas preheater, and enters the first catalyst bed of the reactor from the upper part Reactive deoxygenation. The gas volume of the second raw material mixed gas is 9011Nm 3 / hr, from the side line of the reactor into the upper part of the second catalytic bed. The third remaining raw material mixed gas enters the upper part of the third catalytic bed from the side line of the reactor. The deoxygenated gas from the bottom of the reactor enters the raw material mixed gas preheater to preheat the mixed gas entering the first layer of reactor. The temperature, flow rate and oxygen content of ea...

Embodiment 3

[0052] 10000Nm 3 / hr The raw material mixed gas is divided into three strands after being pressurized by the compressor, of which the gas volume of the first raw mixed gas is 2031Nm 3 / hr is mixed with the circulating gas, and the amount of circulating gas is controlled so that the oxygen content of the mixed gas is 3.5%. The mixed gas is preheated to about 150°C by the raw material mixed gas preheater, and enters the first catalyst bed of the reactor from the upper part Reactive deoxygenation. The gas volume of the second raw material mixed gas is 3183Nm 3 / hr, from the side line of the reactor into the upper part of the second catalytic bed. The third remaining raw material mixed gas enters the upper part of the third catalytic bed from the side line of the reactor. The deoxygenated gas from the bottom of the reactor enters the raw material mixed gas preheater to preheat the mixed gas entering the first layer of reactor. The temperature, flow rate and oxygen content of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com