Method and equipment for preparing caprolactam from cyclohexanone oxime

A technology of cyclohexanone oxime and caprolactam, which is applied in the field of preparing caprolactam, can solve the problems of uneven bed temperature, high operation cost, short operation period and the like, and achieves the effects of reducing temperature rise, eliminating coking and increasing relative content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

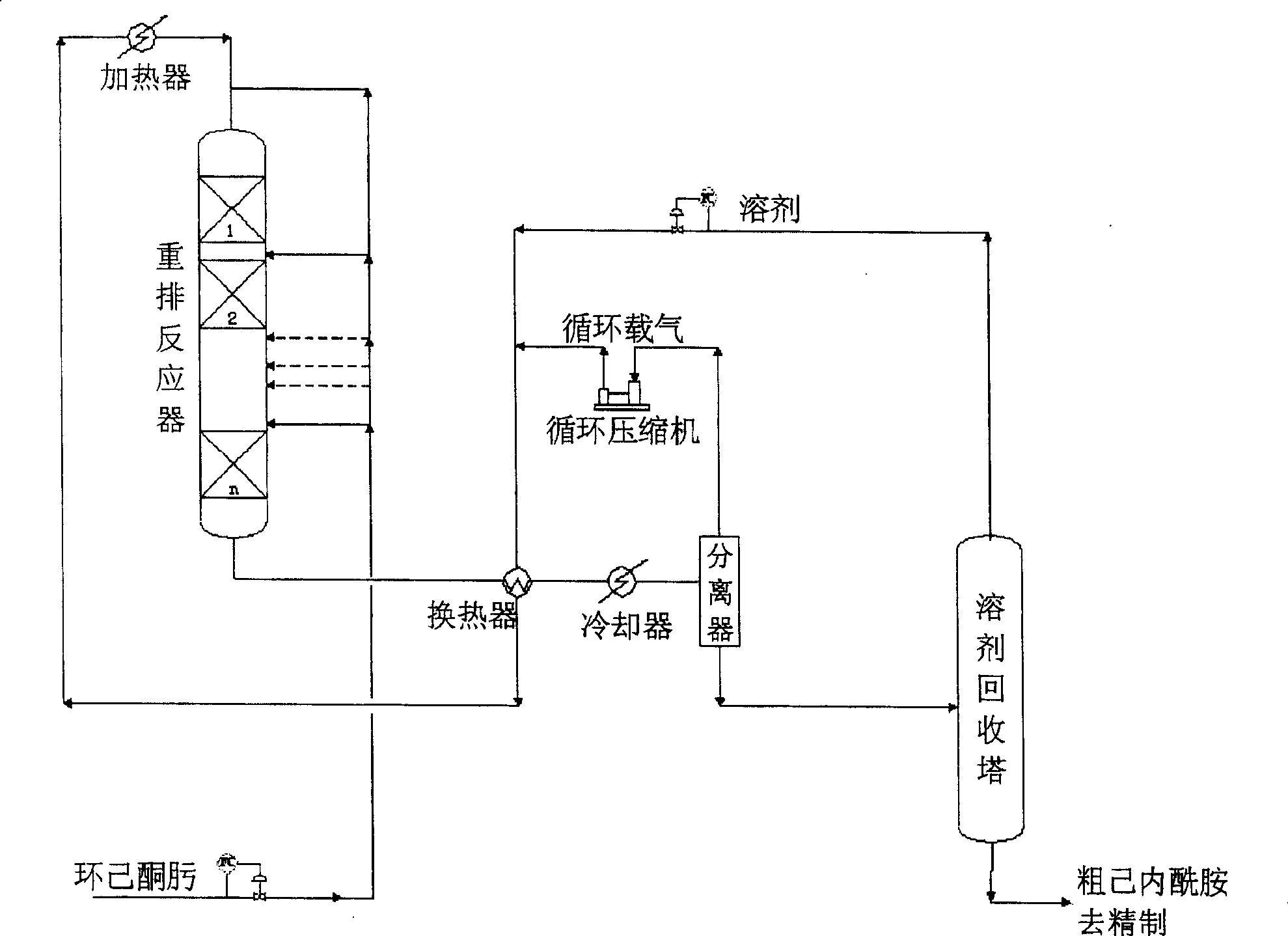

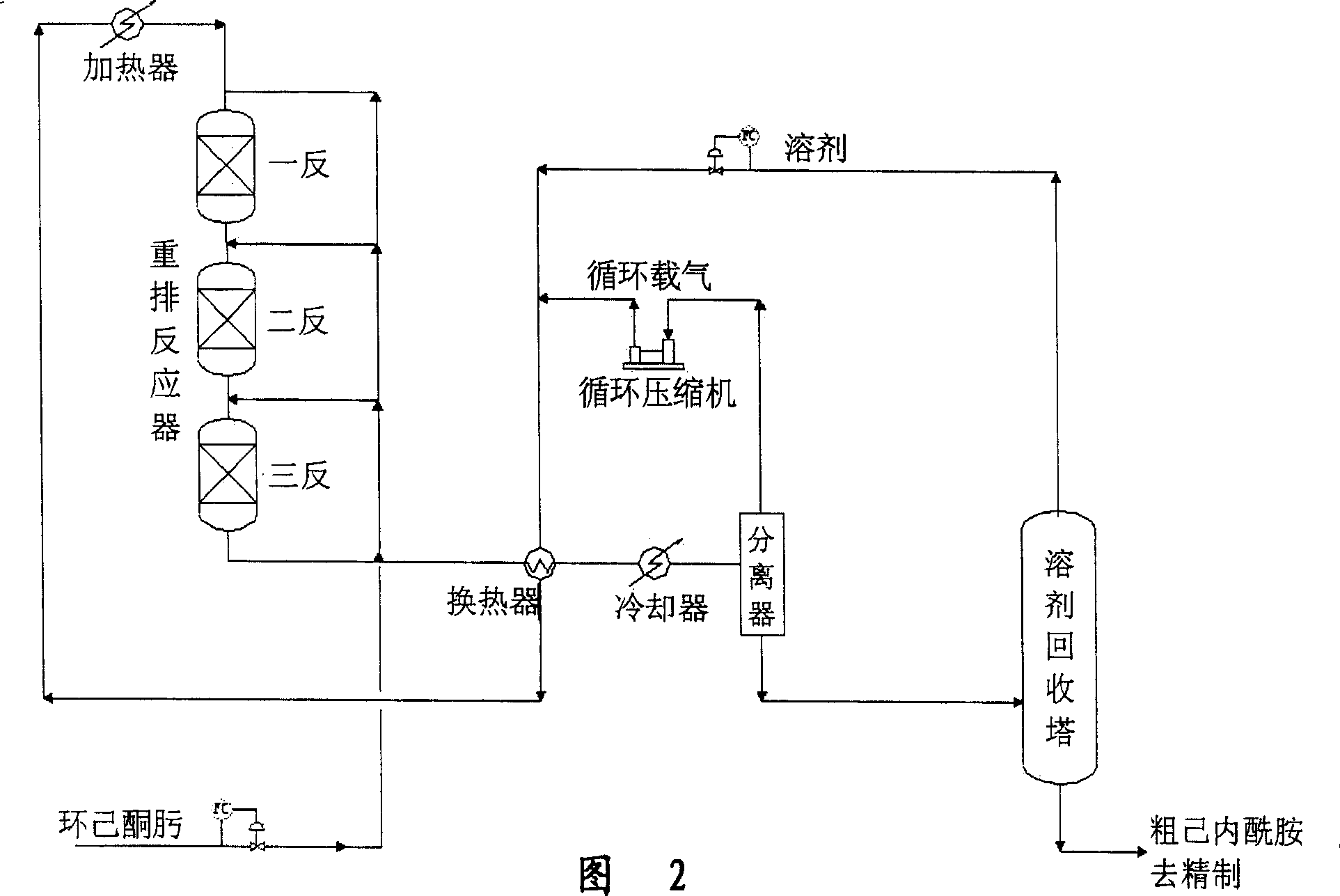

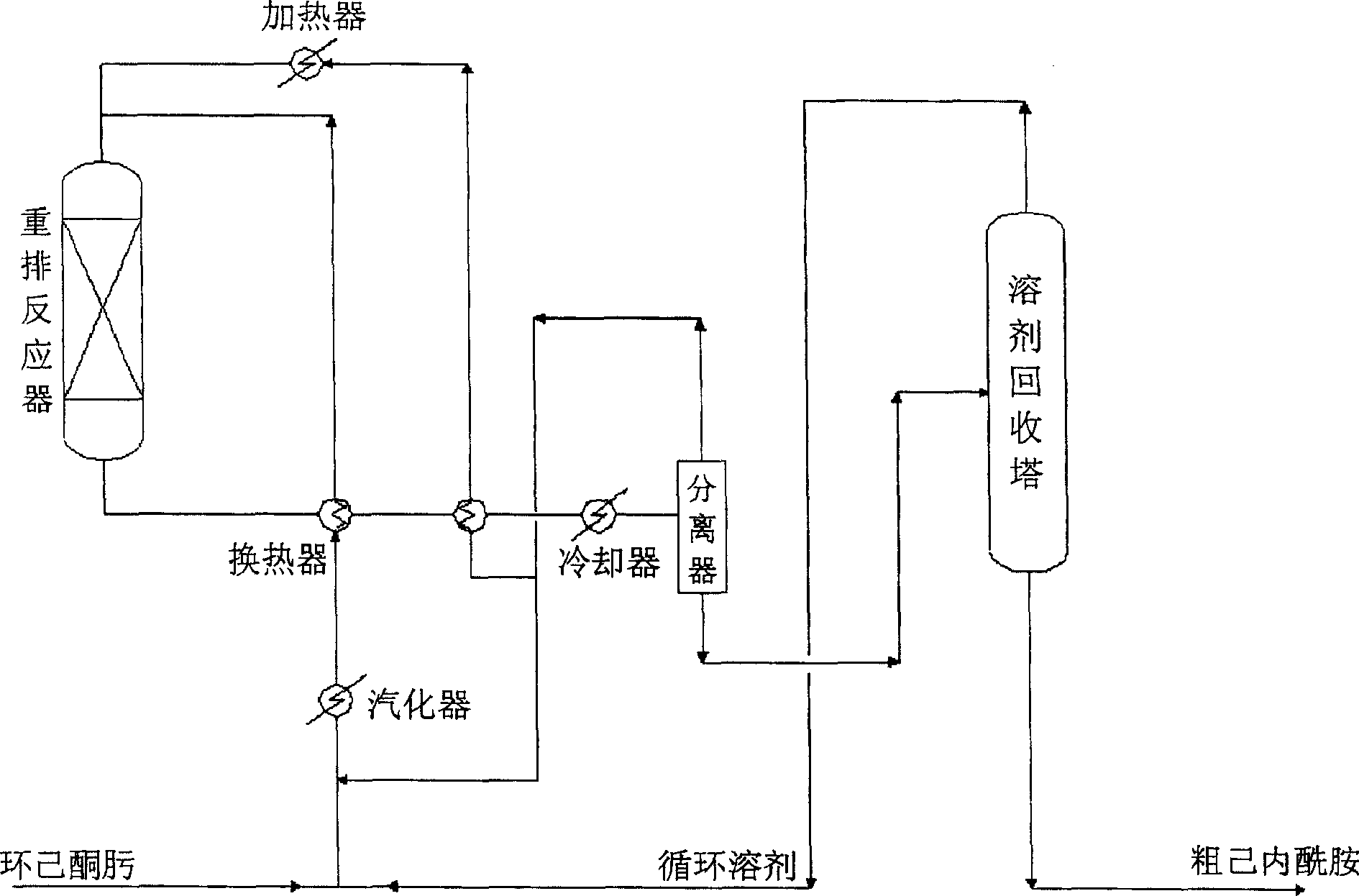

Method used

Image

Examples

Embodiment 1

[0046] Three fixed-bed reactors are connected in series as a multi-stage series reactor, and φ10, φ3 inert ceramic balls and 25kg of catalyst are respectively loaded from bottom to top, and the total catalyst loading capacity is 75kg. Nitrogen is used as the carrier gas, and the flow direction of the carrier gas and reaction raw materials is downward. Purge the system with nitrogen until the oxygen content is less than 0.3 %, and pressurized to a reaction pressure of 0.28MPa (g), start the circulating carrier gas compressor, and control the total flow of circulating nitrogen entering the reactor to be 410Nm 3 / h. After the system is stable, start the carrier gas heater to heat the carrier gas to 380-400°C. Add circulating methanol solvent to the circulating carrier gas at a flow rate of 75kg / h, and continuously inject 0.63L / h deionized water from the inlet of the first reactor. Divide into 3 equal parts, enter the inlet pipelines of three reactors respectively, mix with th...

Embodiment 2

[0048] According to the same method of embodiment 1, the feed flow rate of cyclohexanone oxime is increased to 150Kg / h by 75kg / h, and the water injection rate is increased to 1.2L / h by 0.63L / h, and other conditions are the same as embodiment 1, corresponding The changes of space velocity, total nitrogen oxime ratio, alcohol oxime ratio and reaction results are summarized in Table 1.

Embodiment 3

[0050] According to the same method of embodiment 1, the feed flow rate of cyclohexanone oxime is reduced to 45Kg / h by 75Kg / h, other conditions are identical with embodiment 1, the change of corresponding space velocity, total nitrogen oxime ratio, alcohol oxime ratio and The reaction results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com