Patents

Literature

46results about How to "Eliminate coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

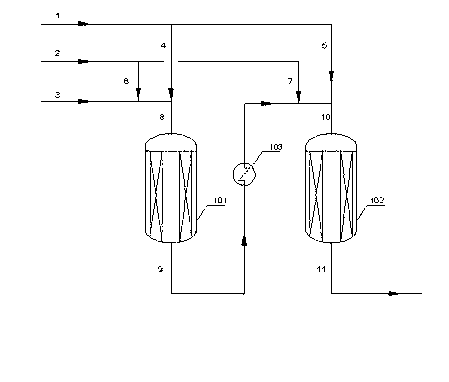

In-situ regeneration method of butylene oxy-dehydrogenation catalyst

InactiveCN103071544AReduce steamPromote crystal phase transitionCatalyst regeneration/reactivationHydrocarbonsPtru catalystButadiene Dioxide

The invention relates to an in-situ regeneration method of a butylene oxy-dehydrogenation catalyst, which mainly solves the problems that the in-situ regeneration effect of the butylene oxy-dehydrogenation catalyst is poor, so that the life of the catalyst is shortened, the conversion rate and yield of reaction are reduced, and the change of the catalyst results in long stopping time of a device and influences the output of the device in the prior art. The method comprises the following steps of: a) stopping feeding of oxygen-containing gas and then a butylene raw material, purging the catalyst with 300-500 DEG C superheated water vapor for 0.2-56h, b) gradually reducing the amount of the water vapor till the airspeed of the water vapor is 500-2000h<-1>, filling in air till the molar ratio of the air to the water vapor is 0.05-0.2, controlling the regeneration temperature at 360-450 DEG C, conducting regeneration of the oxy-dehydrogenation catalyst, and c) reducing the amount of the vapor, allowing the temperature rise of a bed to be reduced gradually till the temperature at an inlet and an outlet of the catalyst bed keeps constant, and accomplishing the technical scheme of catalyst regeneration. The method solves the problems better, and can be used for industrial production of preparing butadiene through butylene oxy-dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

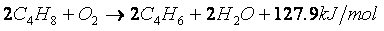

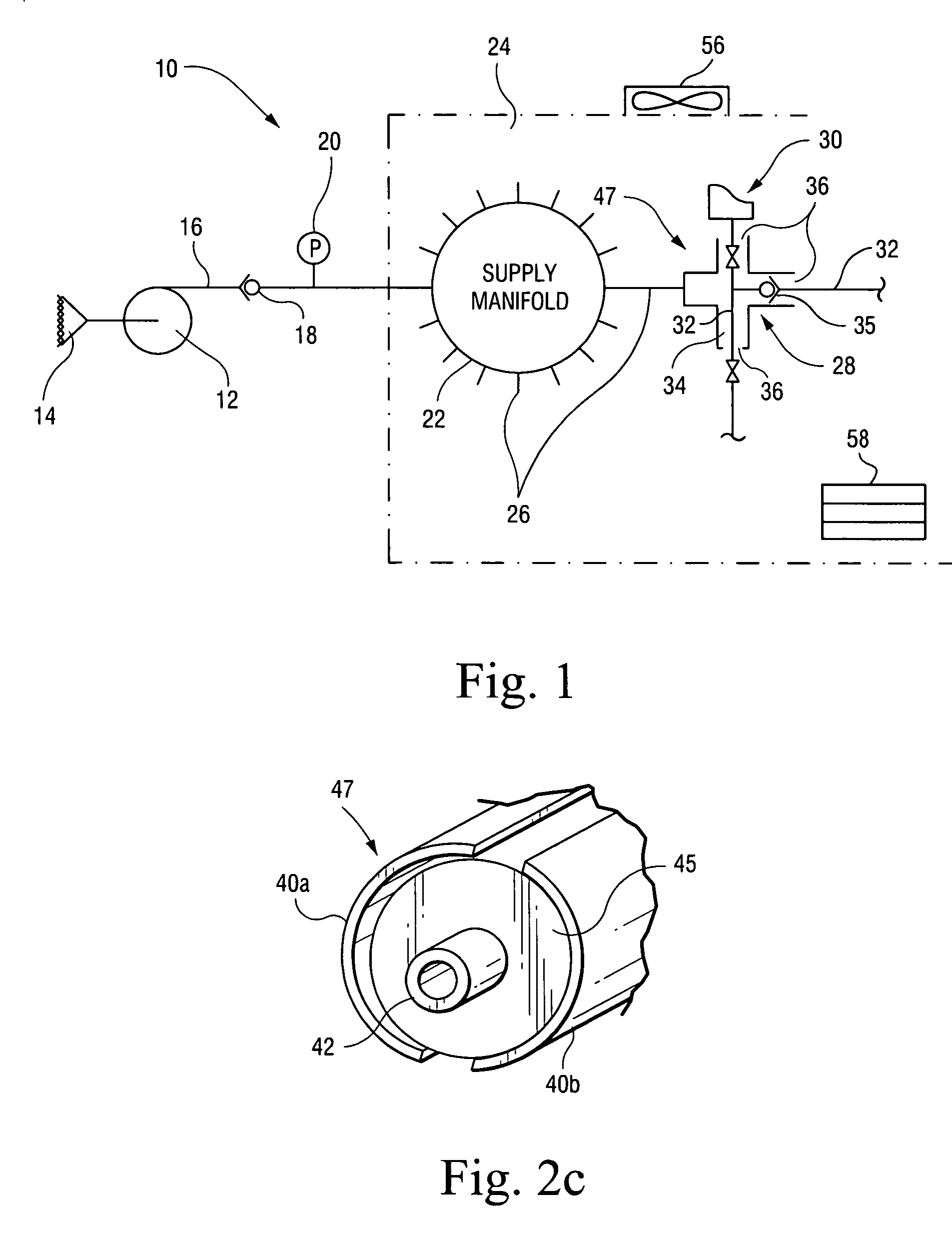

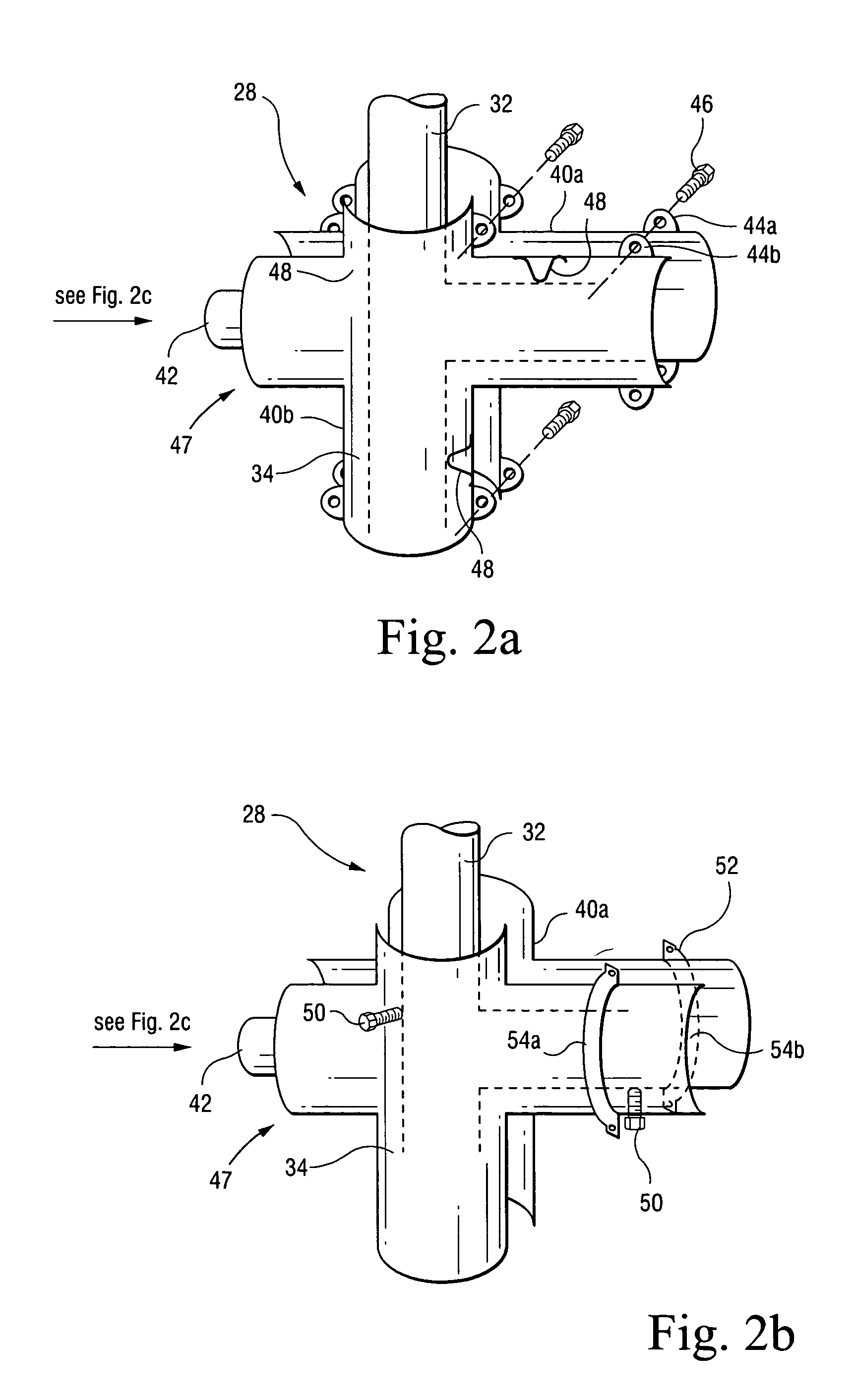

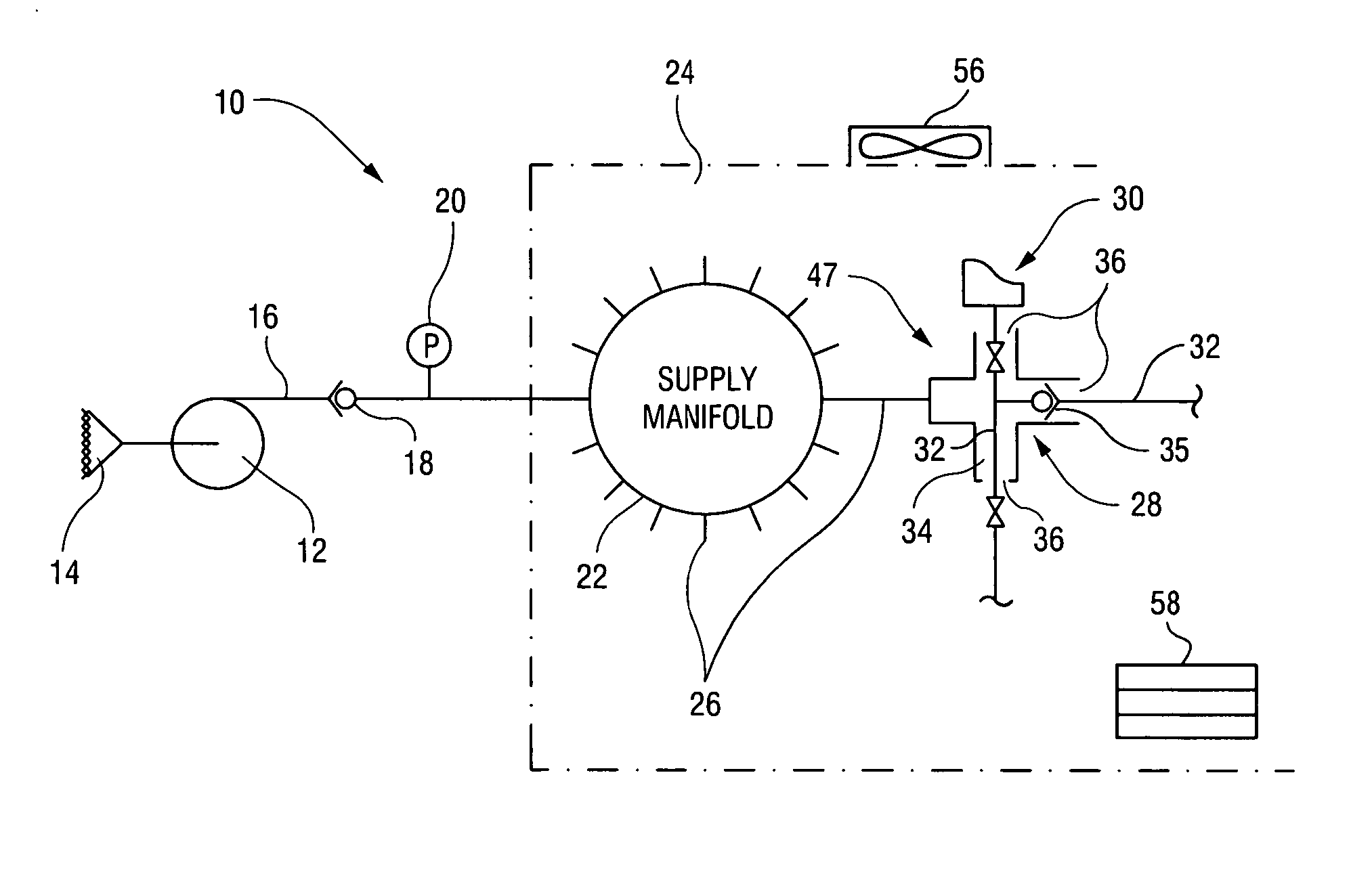

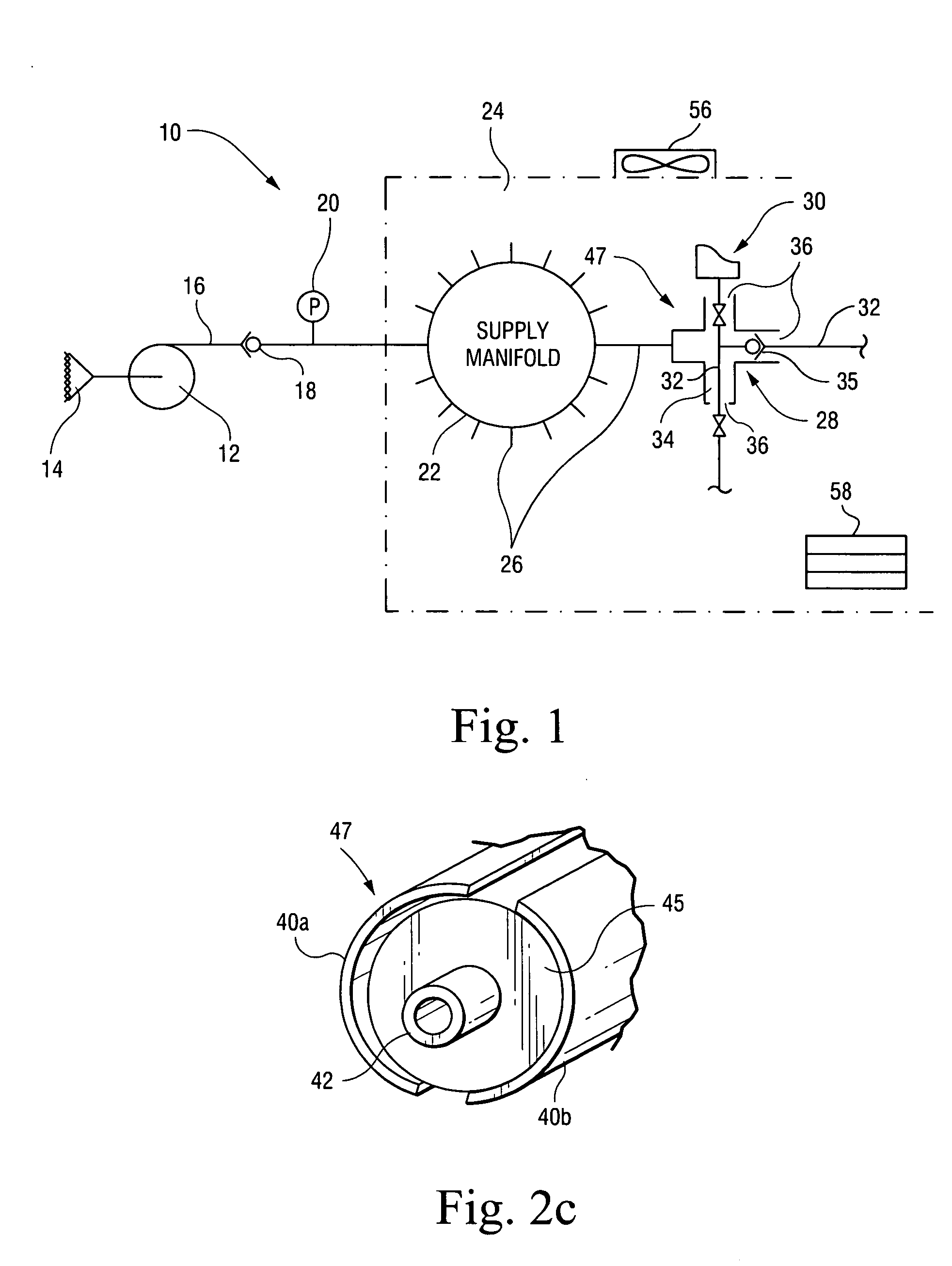

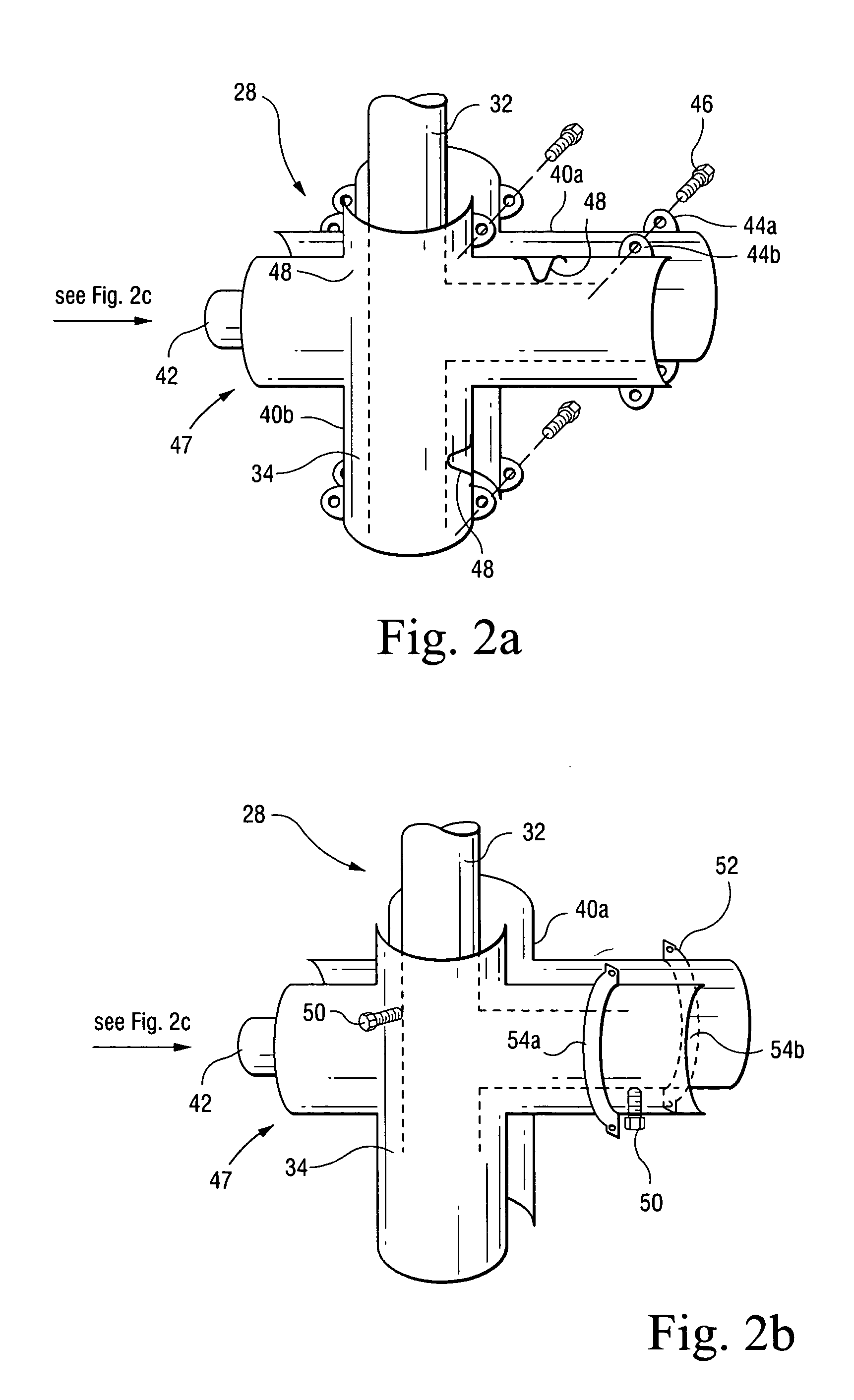

Cooling of liquid fuel components to eliminate coking

InactiveUS7117675B2Reduce the temperatureEliminate cokingBurnersTurbine/propulsion engine coolingEngineeringLiquid fuel

Owner:GENERAL ELECTRIC CO

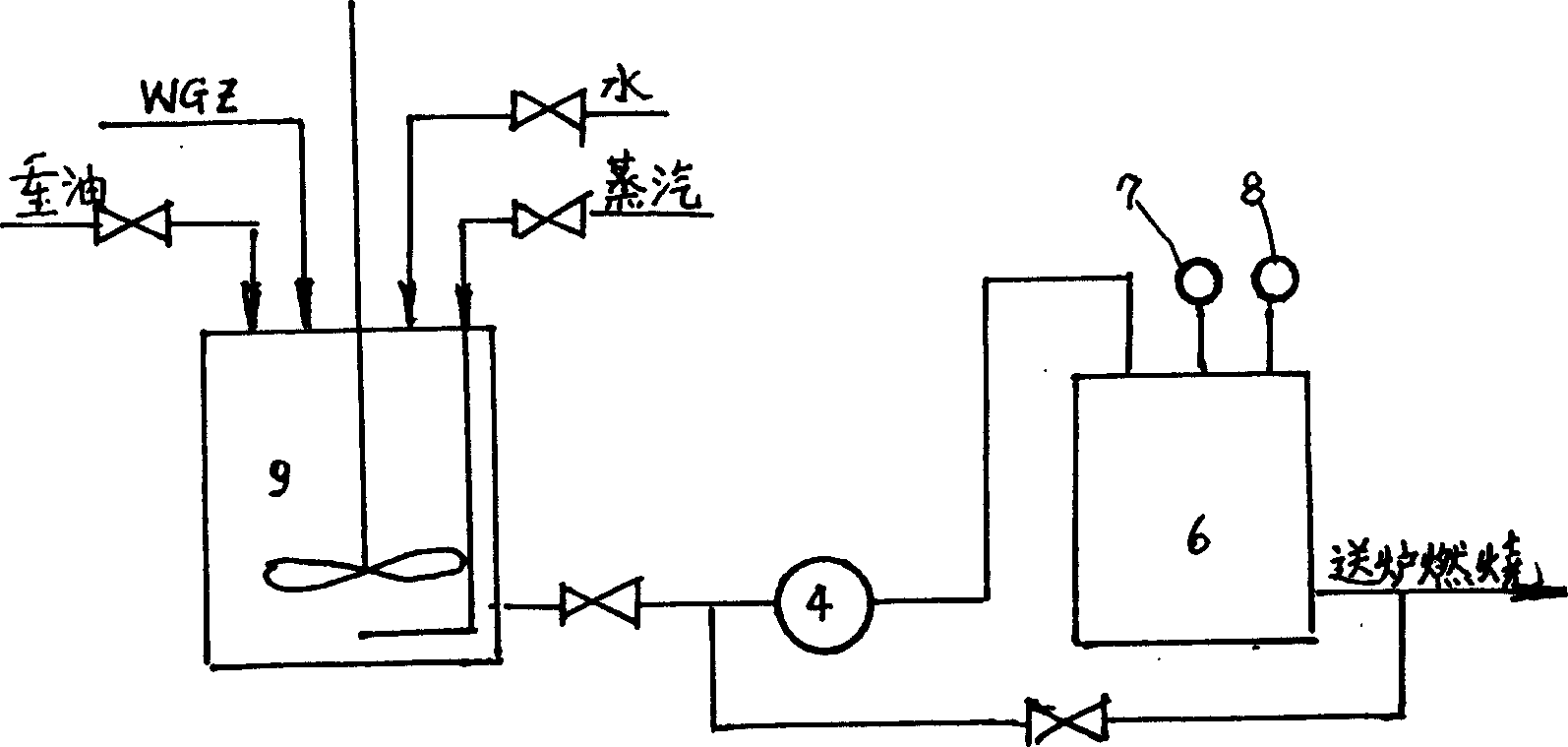

Multifunctional heavy oil and fuel oil additive, preparation and use thereof in preparing emulsified oil

InactiveCN1401745AWide emulsification rangeMix well and evenlyLiquid carbonaceous fuelsFuel oilDisperser

An oil-soluble multifunctional additive for heavy oil or fuel oil contains more surfactants, composite catalytic combustion adjuvant and detergent disperser, and is characterized by saving oil by 10-25%, increasing added water to 10-30% and eliminating black smoke. A process for preparing emulsified heavy oil or fuel oil is also disclosed.

Owner:WUHAN UNIV OF TECH

Physical generating apparatus for fuel-oil additive

InactiveCN101070487ALow viscosityReduce surface tensionHydrocarbon oils refiningSupersonic wavesPhysical chemistry

The invention relates to a multiple physical technical disposal device which coul provide activated material and energy to fuel. It adopts four physical techniques which includes magnetization, fluctuation, supersonic wave and far infrared ray to deal with fuel, and makes physical oil adjunct. After dealed, put it with oil together, resonate with oil molecule, decrease the condensation, and the oil molecule crystalline constitution metamorphosis, then the oil viscidity and surface tension decline. The mixed mass of fuel and air increases, the air factor decreases, the burning velocity of oil, the temperature of burning area, and the viscidity of complete burning increase, ehile on the other hand, disposed fume decreases, the coking of spray nozzle is eliminated. Thus, the flow ability, flammability, cleaning ability are improved.

Owner:姜国常

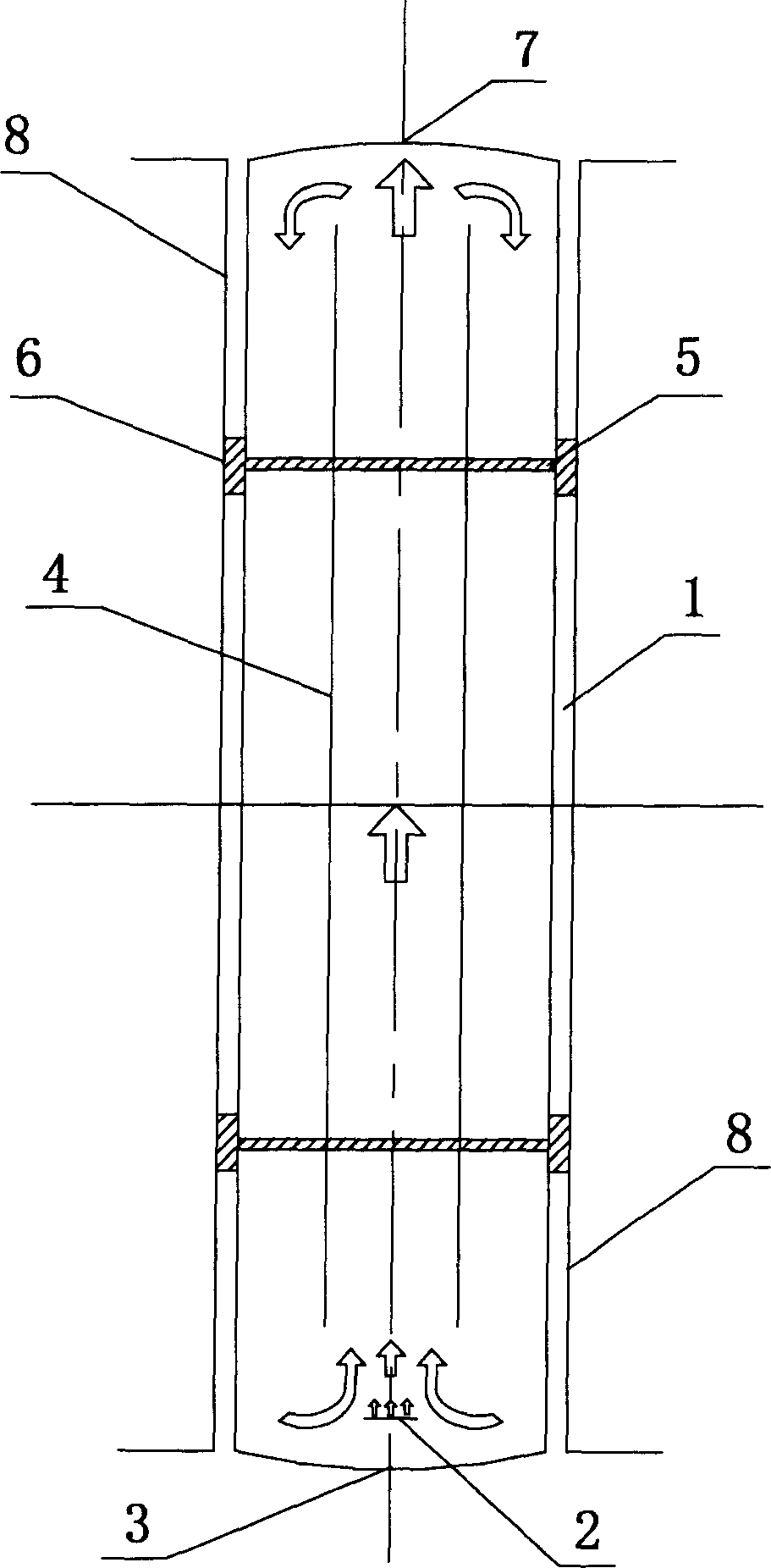

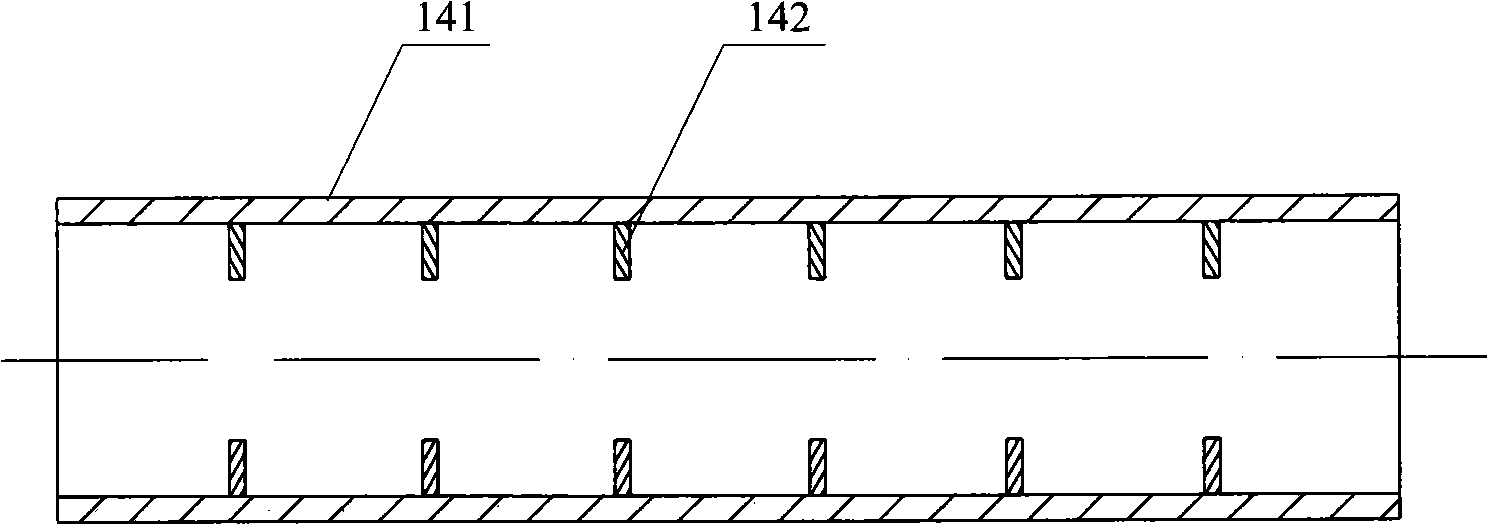

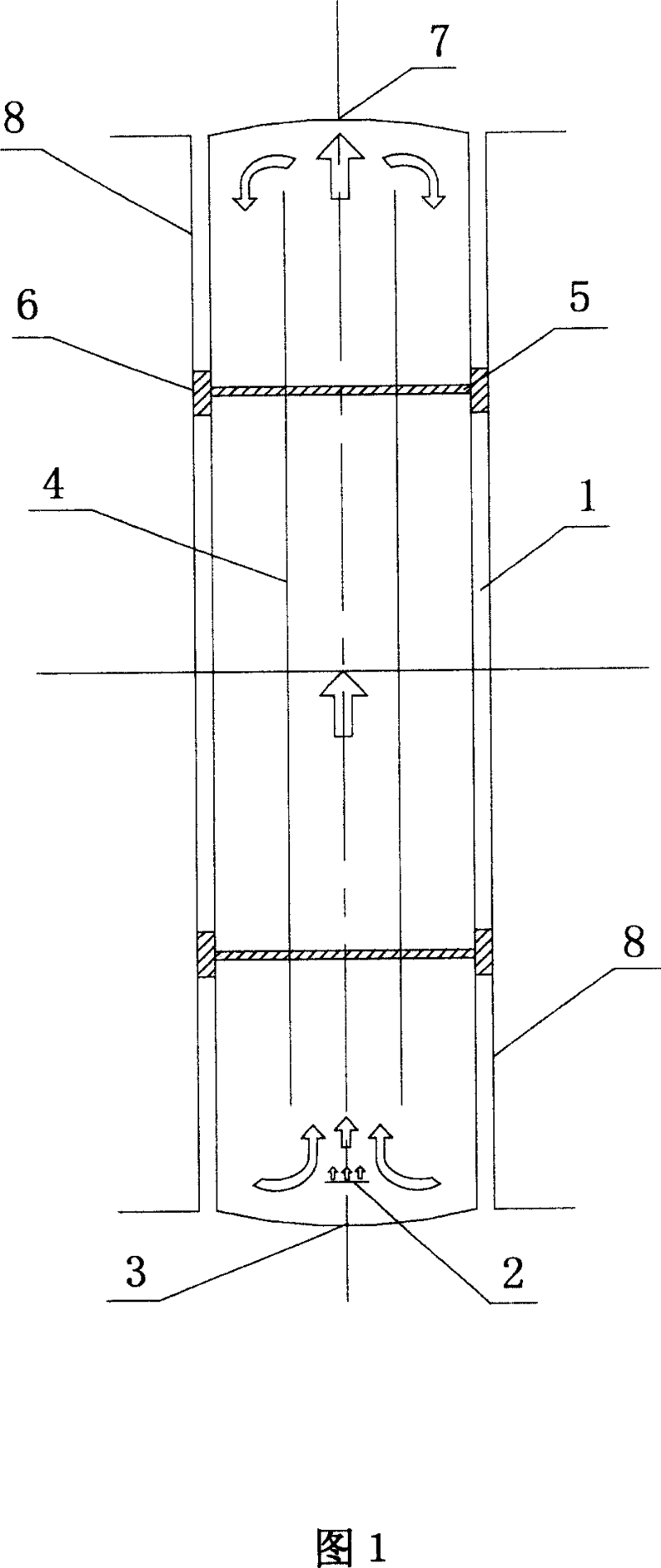

Magnetic scraper loop reactor for coal direct liquefaction and coal direct liquefaction method thereof

InactiveCN1803985AReduce contentEasy to operateLiquid hydrocarbon mixture productionMagnetic tension forceProcess equipment

The related loop reactor for coal direct liquefaction comprises: an outside cylinder, a central tube, a gas distributor, a plurality of magnetic scrapers arranged equally between the cylinder and tube, a magnetic draw device, and a device frame. This invention improves material loop speed and turbulence strength to avoid coking and raise heat / mass transfer efficiency for wide application.

Owner:CHINA COAL RES INST +1

Regeneration method of olefin isomerization catalyst

ActiveCN103537271AAvoid sintering and even structural collapseRestore performanceHydrocarbon by isomerisationCatalyst regeneration/reactivationIsomerizationOxygen content

The invention relates to a regeneration method of an olefin isomerization catalyst. The problems that the catalytic activity is reduced after the olefin isomerization catalyst in the prior art is regenerated, and the olefin isomerization catalyst cannot regenerate in an apparatus and regenerate for a plurality of times are mainly solved. The regeneration method orderly comprises the following steps: a) leading in a gas which is inert to reaction in a reactor after reaction is stopped, and pre-purging the catalyst for 2-10 hours at 200-400 DEG C; b) leading into an oxygen gas until the oxygen content is 0.1-1mol%, burning until the temperature stops rising; c) heating to 420-500 DEG C, increasing the flow of the oxygen gas until the content of the oxygen is 1.5-5mol%, and burning until the temperature stops rising; d) heating to 520-600 DEG C, continuing to increase the flow of the oxygen gas until the content of the oxygen is 5.5-15mol%, and burning until the temperature stops rising; e) stopping leading in the oxygen gas, and continuing to purge the gas which is inert to the reaction via heat. By adopting the regeneration method, the problem is better solved; the regeneration method can be applied to regeneration of the olefin isomerization catalyst in industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cooling of liquid fuel components to eliminate coking

InactiveUS20050081525A1Reduce the temperatureEliminate cokingBurnersTurbine/propulsion engine coolingEngineeringLiquid fuel

A system for cooling at least one gas turbine liquid fuel component located in a high temperature environment to eliminate coking in the component is disclosed. The system includes a sleeve surrounding the liquid fuel component, a device for providing a current of cool air, and a conduit connected between the cool air device and the sleeve to direct the current of cool air into the sleeve to cool the liquid fuel component. The system can also include a manifold connected to the conduit and a plurality of second conduits for connecting the manifold to a plurality of sleeves surrounding a plurality of liquid fuel components, each sleeve being connected to a corresponding second conduit. Each sleeve includes a plurality of spacing devices for centering the sleeve around the at least one liquid fuel component so as to form an annulus between the sleeve and the liquid fuel component through which the current of cool air flows. The system can alternatively use a supply of cool liquid pumped by a pump through a conduit adjacent to a liquid fuel component to cool the component.

Owner:GENERAL ELECTRIC CO

Desulfurization and denitrification combustion improver and application thereof in fuel coal

InactiveCN106190430AReduce processing costsReduce pollutionSolid fuelsFuel additivesSodium phosphatesNuclear chemistry

The invention discloses a desulfurization and denitrification combustion improver and application thereof in fuel coal. The desulfurization and denitrification combustion improver is prepared from, by mass, 40%-70% of rapeseed cakes, 10%-15% of carbon ammonium, 2%-6% of acidized coal gangue, 0.3%-1% of sodium nitrate, 0.1%-0.5% of potassium permanganate, 3%-6% of aluminum sulfate, 1%-10% of sodium chloride, 2%-8% of potassium chlorate, 0.3%-0.7% of manganese dioxide, 3%-5% of sodium phosphate and 5%-10% of soda. Application of the combustion improver is implemented through the steps that the desulfurization and denitrification combustion improver of which the mass accounts for 0.5%-2% of that of the fuel coal is added and then combusted in a combustion furnace, wherein the combustion temperature is controlled at 800 DEG C-1,400 DEG C. According to the desulfurization and denitrification combustion improver, the removal rates of SO2 and nitrogen oxide (NOx) in flue gas obtained after combustion can both reach 80% or above, smoke can be reduced by 70% or above, and the decoking effect and the corrosion inhibition effect can both reach 90% or above.

Owner:郴州回康科技有限责任公司

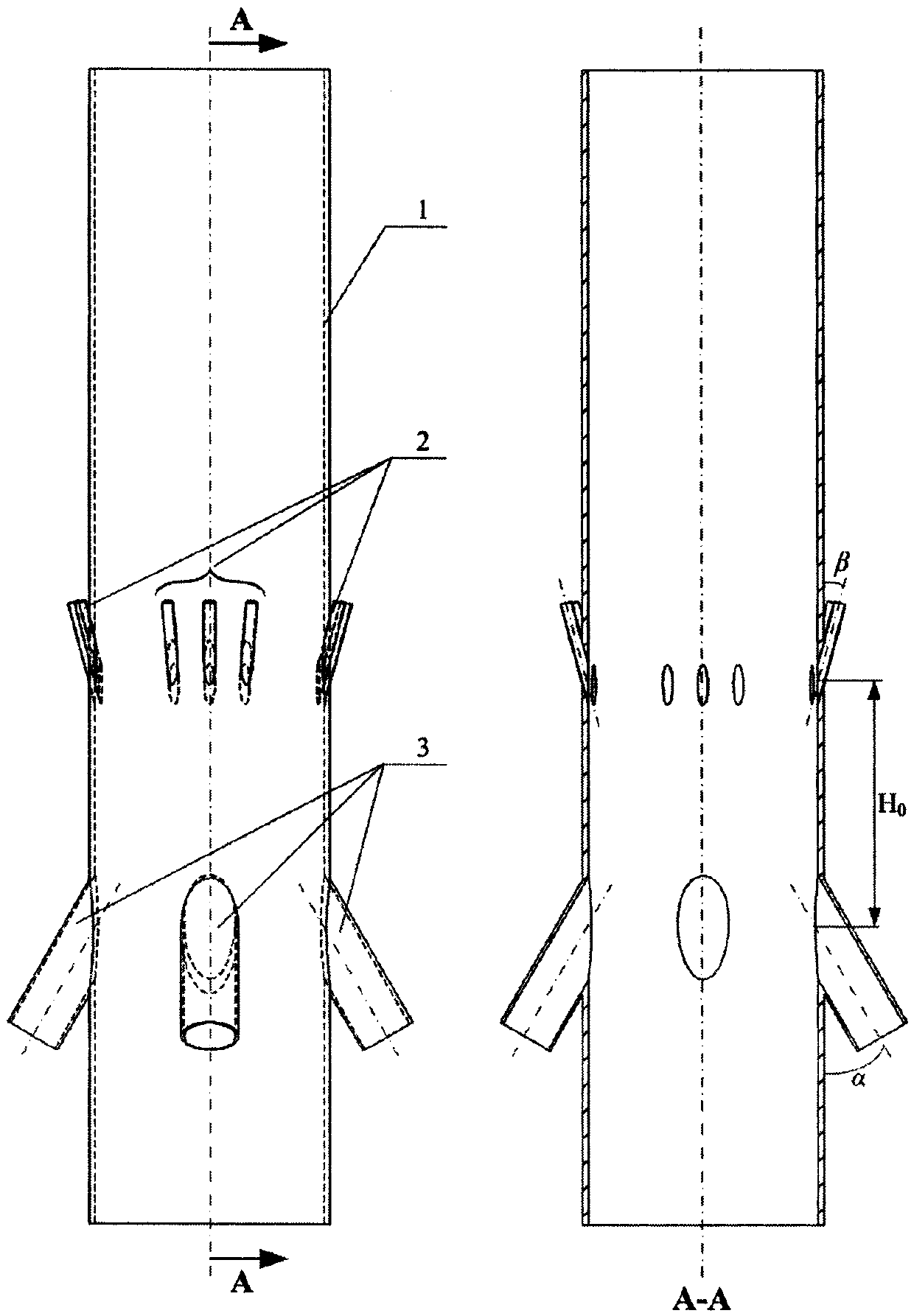

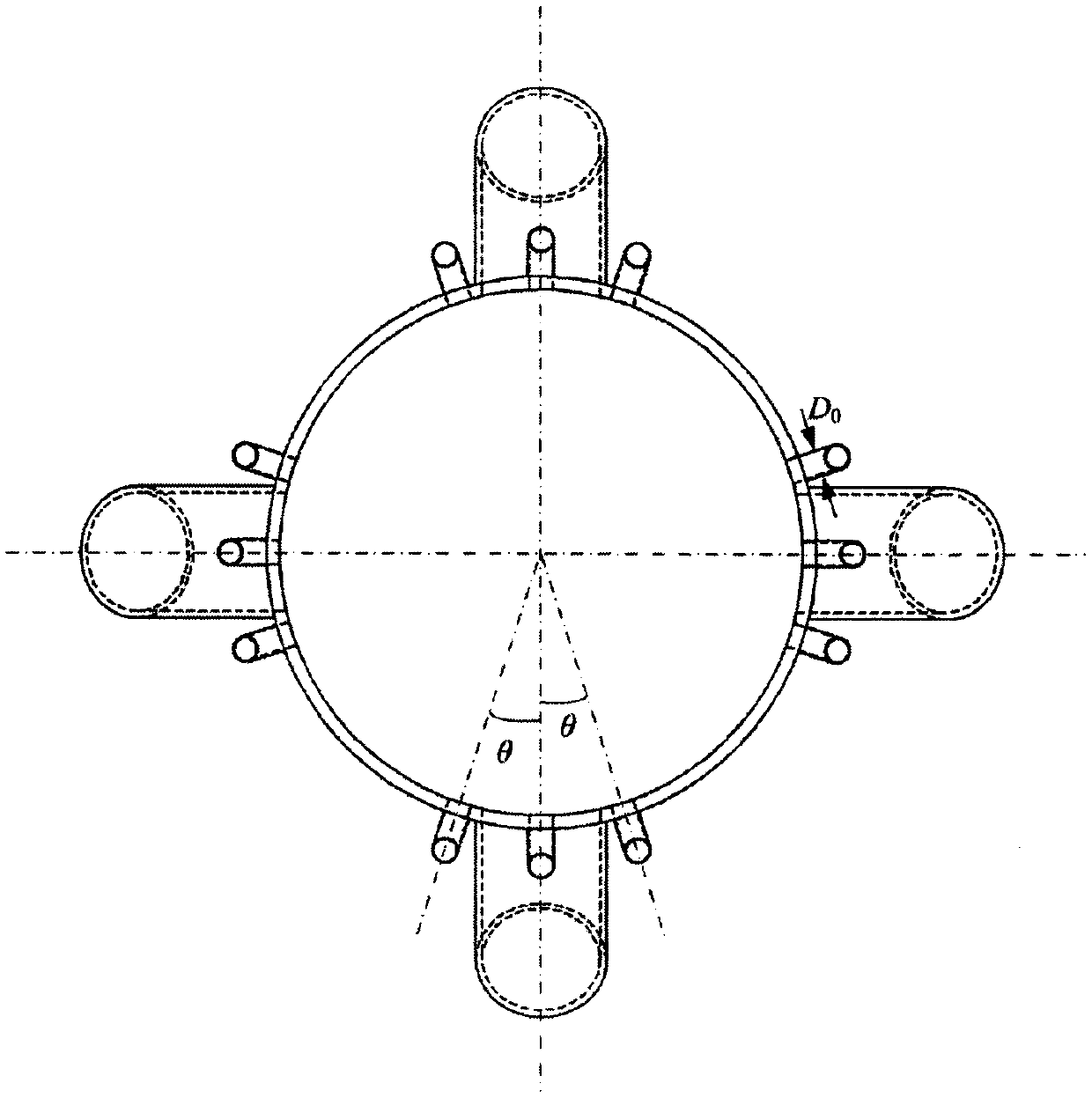

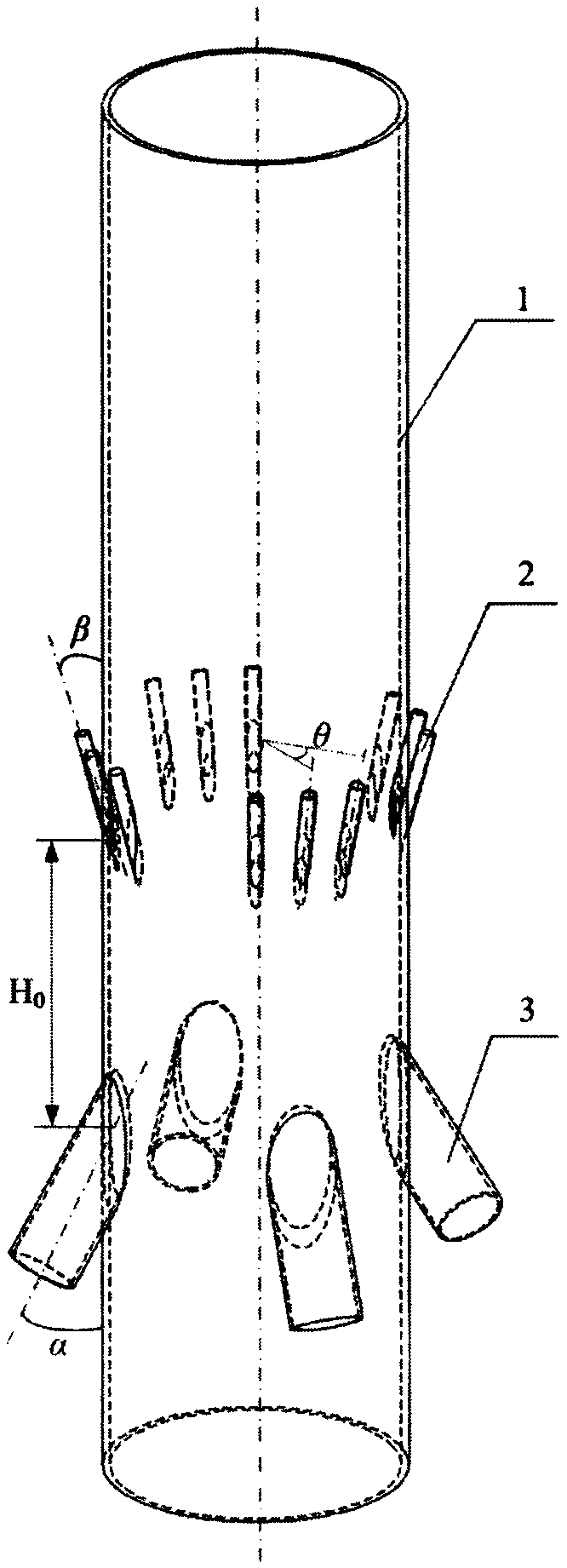

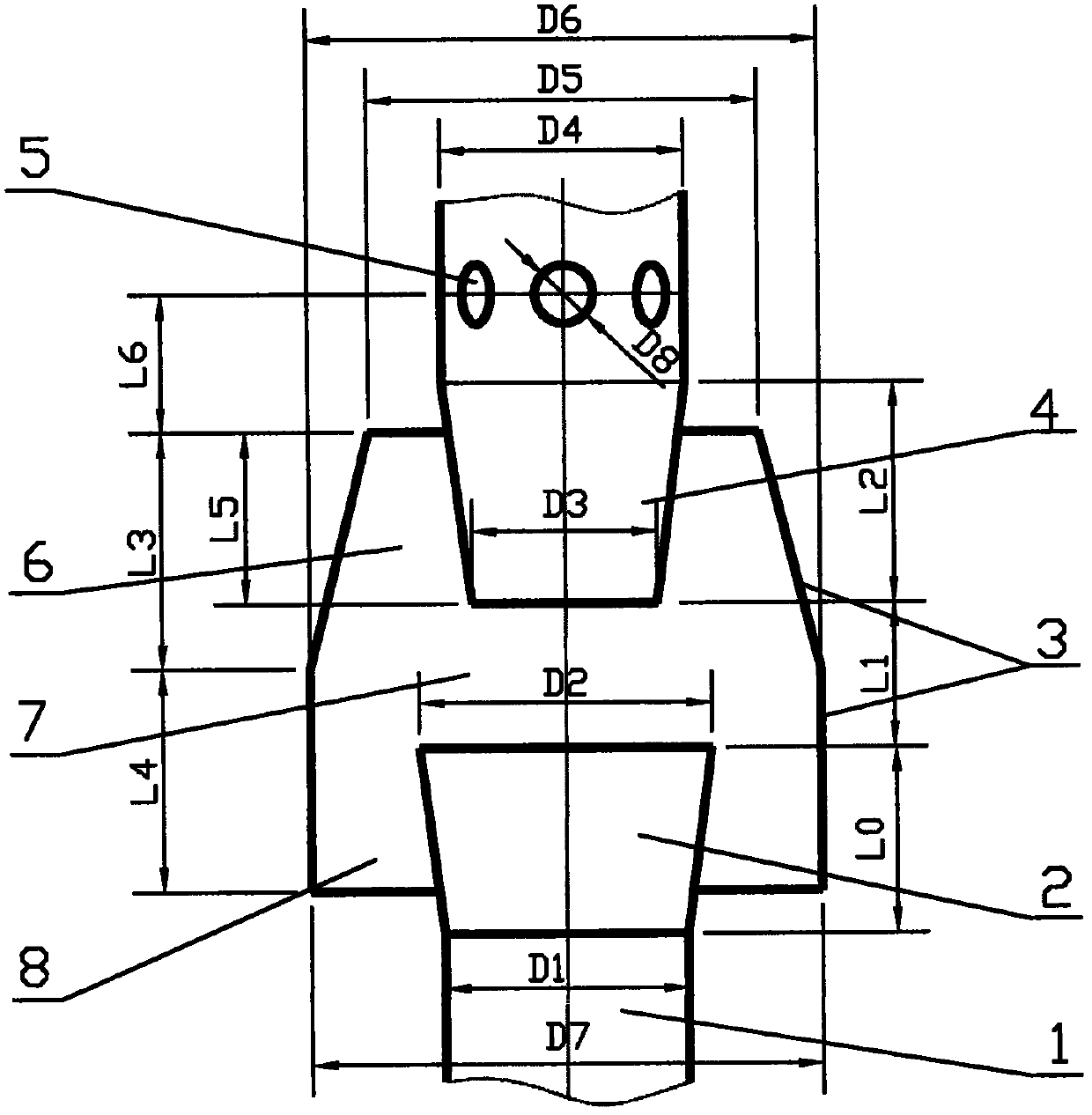

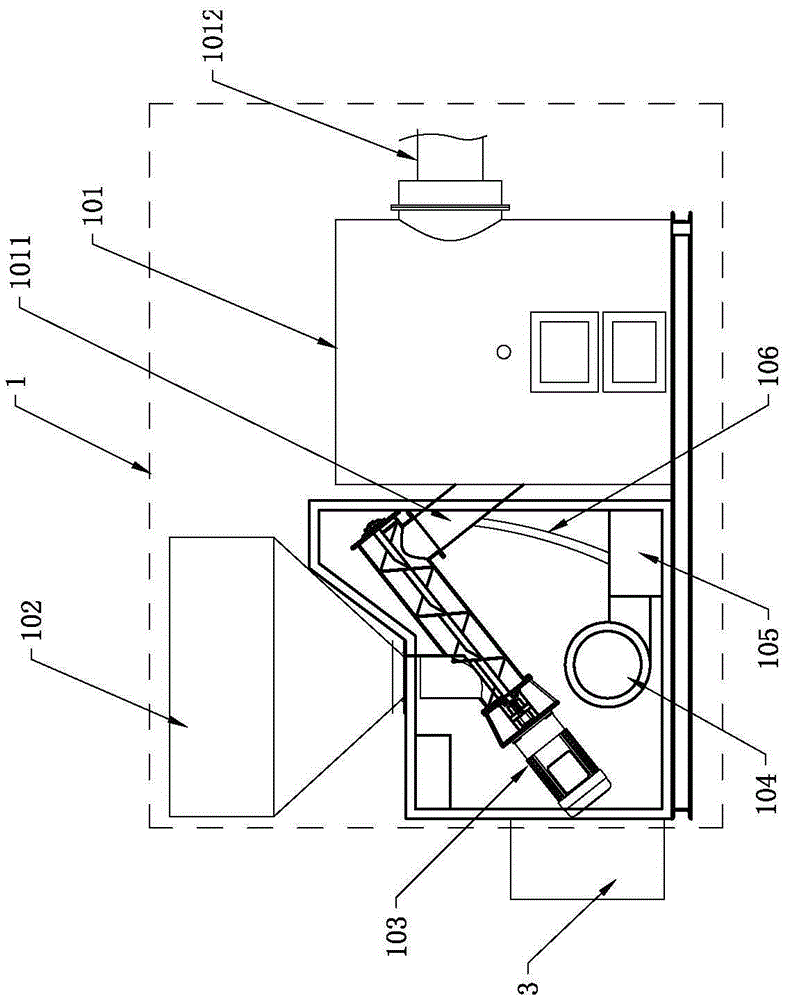

Novel flow aid technology promoting mixing of raw oil and catalyst in catalytic cracking riser feeding area

PendingCN105368479ASufficient diffusion rangeSufficient impact strengthCatalytic crackingFeed devicesSprayerSpray nozzle

The invention is mainly used for the field of petrochemical engineering and relates to the flow aid technology which promotes mixing of raw oil and catalysts and eliminates the problem that the inner wall face of a riser feeding mixing section (1) cokes in the catalytic cracking process. The technology includes the type and the flow of a flow aid, the sizes of flow aid nozzles, distribution of the flow aid nozzles, and the installation height and angles of the flow aid nozzles. The injected flow aid can inhibit formation and development of secondary flow at a raw oil sprayer, strong backmixing of oil on the wall face is eliminated, and coking is reduced. Besides, the jet injecting angle of the raw oil can be changed, part of the raw oil is made to be quickly separated from the edge wall and diffuse to the center, quick contact and mixing of the raw oil and the catalysts are achieved, and reaction efficiency is improved. The flow aid only has the function of promoting mixing of raw oil and catalyst, does not react in a system, and the flow is proper. The flow aid nozzles (2) are installed at the proper height of the upper portion of a raw oil atomizing nozzle installation sleeve (3). Besides, the reasonable nozzle size, the distribution mode and the installation angle are adopted to guarantee that the flow aid has the enough diffusion range and collision strength.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

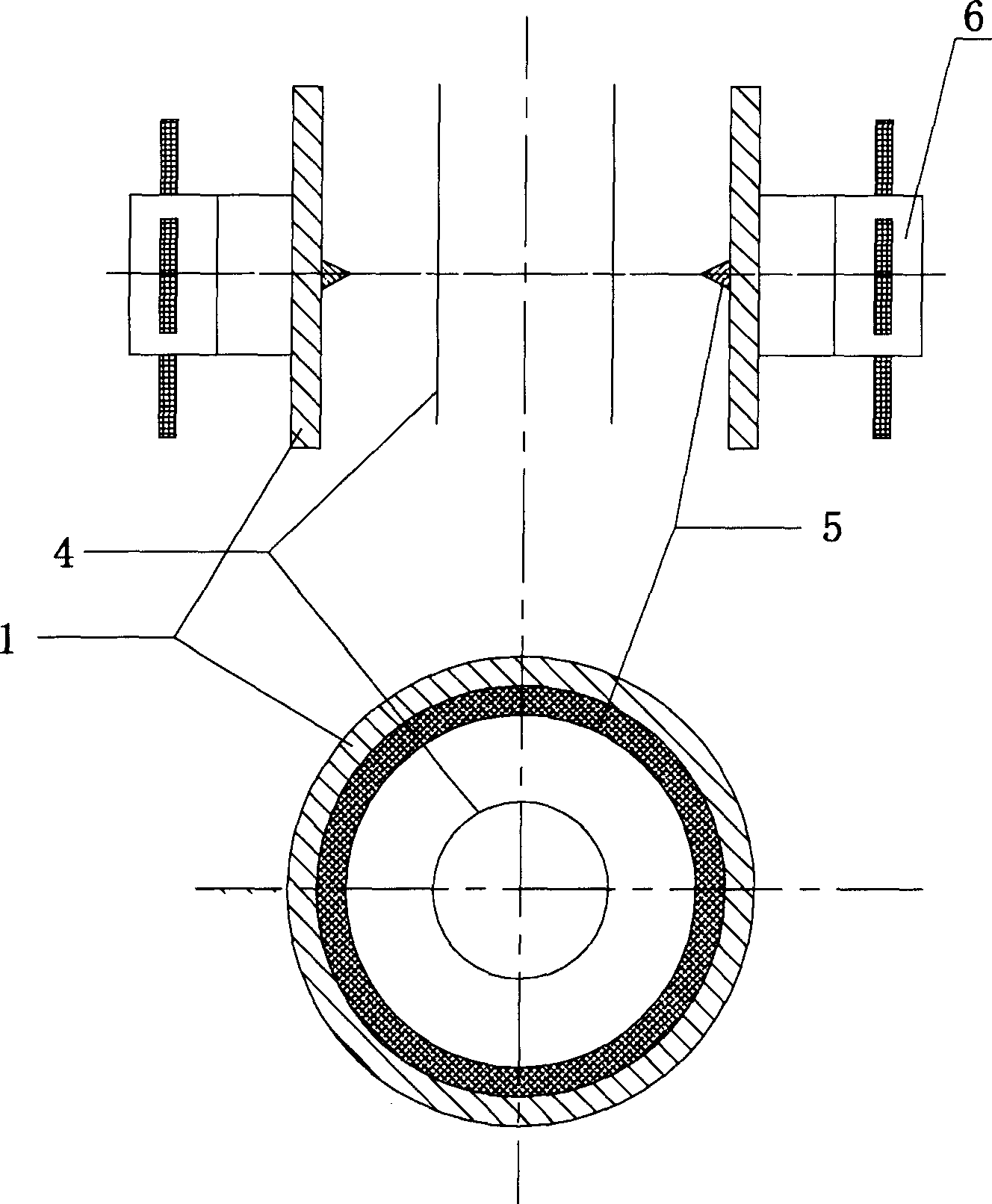

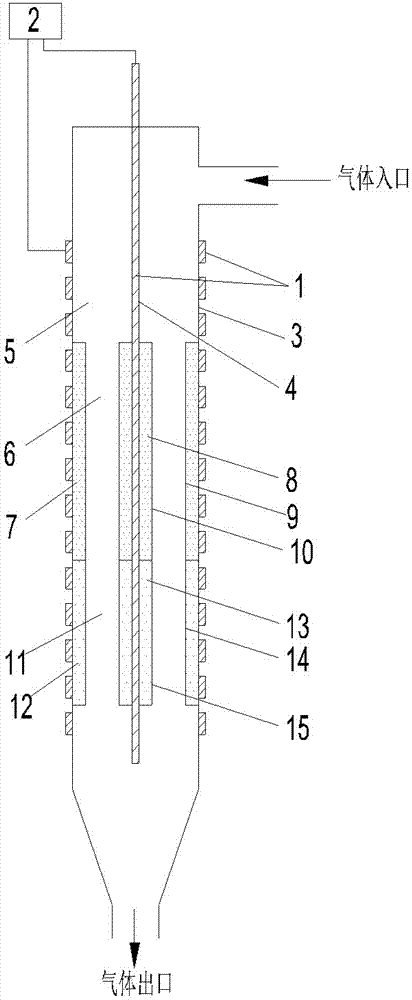

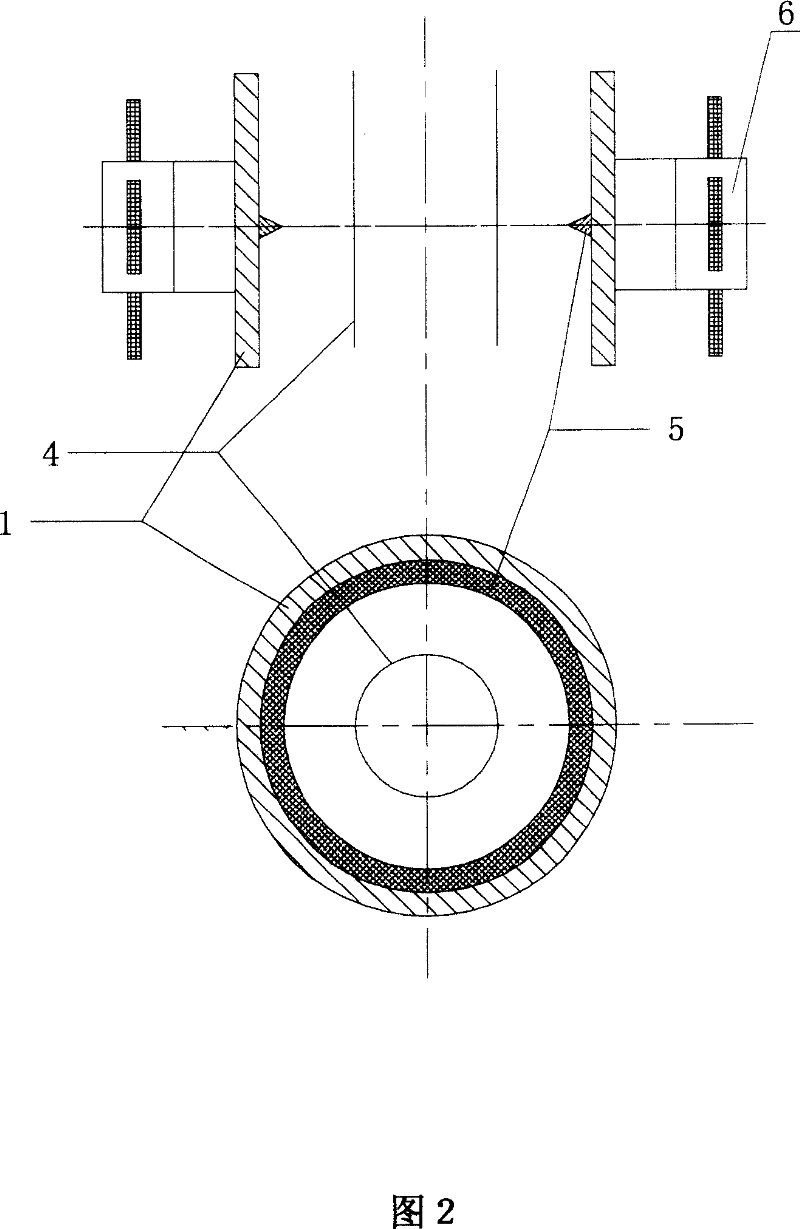

Device for decomposing trimethylamine malodorous gas

ActiveCN106881013AAvoid cokingImprove purification efficiencyGas treatmentDispersed particle separationOptical radiationKrypton

The invention belongs to the technical field of waste gas purification, and particularly relates to a device for decomposing trimethylamine malodorous gas. The device comprises a DBD (dielectric barrier discharge) gas discharging area, a deep ultraviolet light radiation area and a shallow ultraviolet light radiation area; the DBD gas discharging area consists of an inner dielectric layer, an outer dielectric layer, an inner electrode and an outer electrode; the inner electrode and the outer electrode adopt stainless steel spring structures; the deep ultraviolet light radiation area comprises an inner area airtight cavity and an outer area airtight cavity; the cavities are filled with argon and halogen mixed gas correspondingly, or are filled with rare gas xenon, and are mainly used for generating short-wavelength ultraviolet light with wavelength of about 200 nm or below; the shallow ultraviolet light radiation area is divided into an inner area airtight cavity and an outer area airtight cavity; the cavities are filled with krypton and halogen mixed gas correspondingly, or are filled with argon and mercury, and are mainly used for generating long-wavelength ultraviolet light with wavelength of about 250 nm. The device is compact in structure, can degrade trimethylamine gas, and has high efficiency, low energy consumption and high applicability.

Owner:FUDAN UNIV

Cleaning method of cationic partially oriented yarn (POY) spinning box

InactiveCN102605443AProduction improvedEasy to produceSpinnerette packsArtificial thread manufacturing machinesYarnCleaning methods

A cleaning method of cationic partially oriented yarn (POY) spinning box adopts container with heating function as intermediate tank, triethylene glycol as cleaning medium and centrifugal pump as transport power source. The method comprises filling triethylene glycol into the intermediate tank, starting heating function to heat triethylene glycol to 120 DEG C, self-circulating triethylene glycol in bypass until reaching 270 DEG C, and controlling activation of switching valve to circulate triethylene glycol in circulation pipeline. Triethylene glycol enters the spinning box from its outlet, and leaves the spinning box from its inlet. The inventive cleaning method utilizes high-temperature centrifugal pump to circulate high-temperature triethylene glycol (270 DEG C) between the intermediate tank and spinning box, effectively dissolves pipe wall coke of spinning box to allow coke to flow out together with triethylene glycol, thereby effectively removing box interior coke, and achieving better cleaning effect and higher working efficiency.

Owner:桐昆集团浙江恒盛化纤有限公司

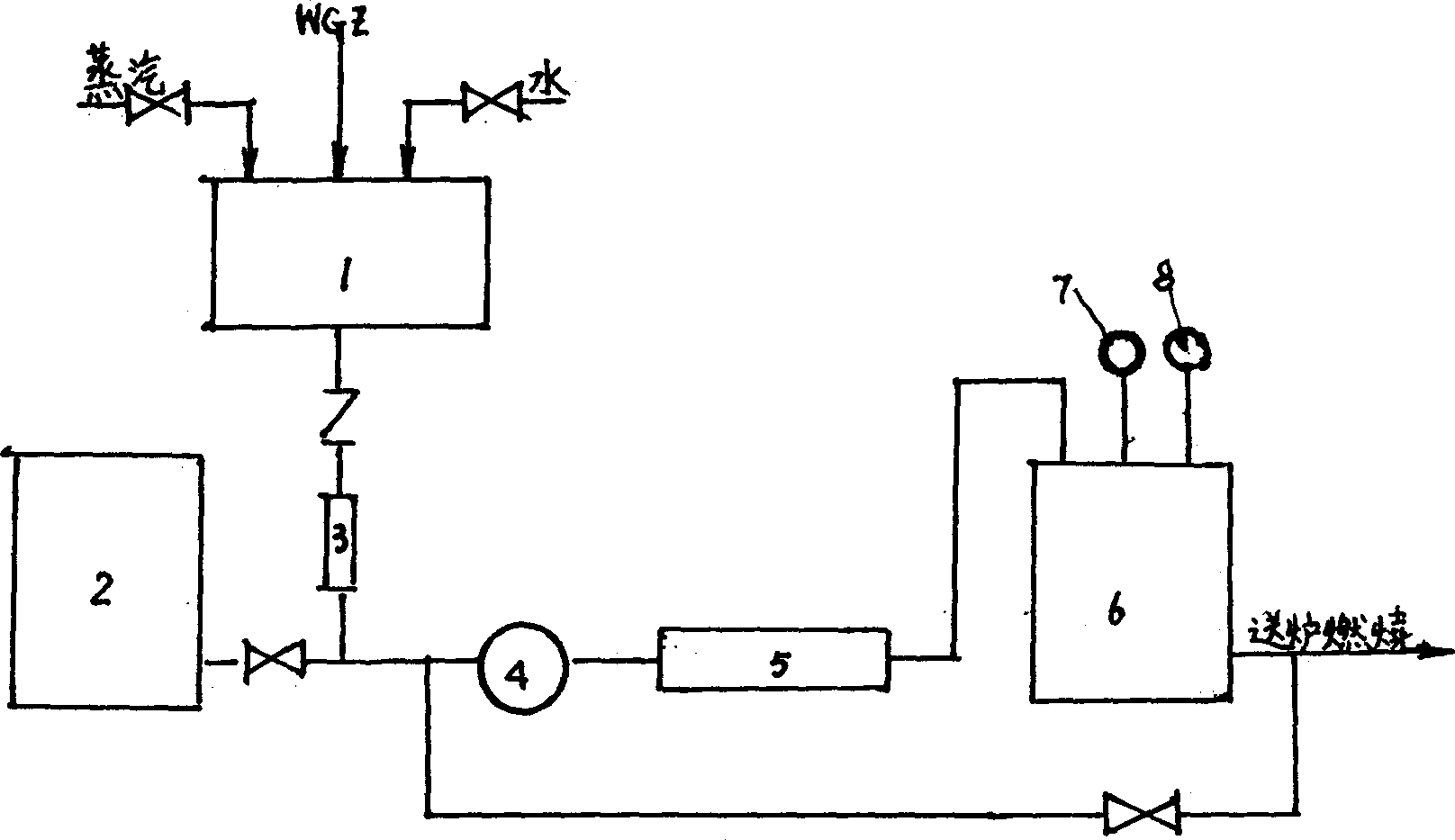

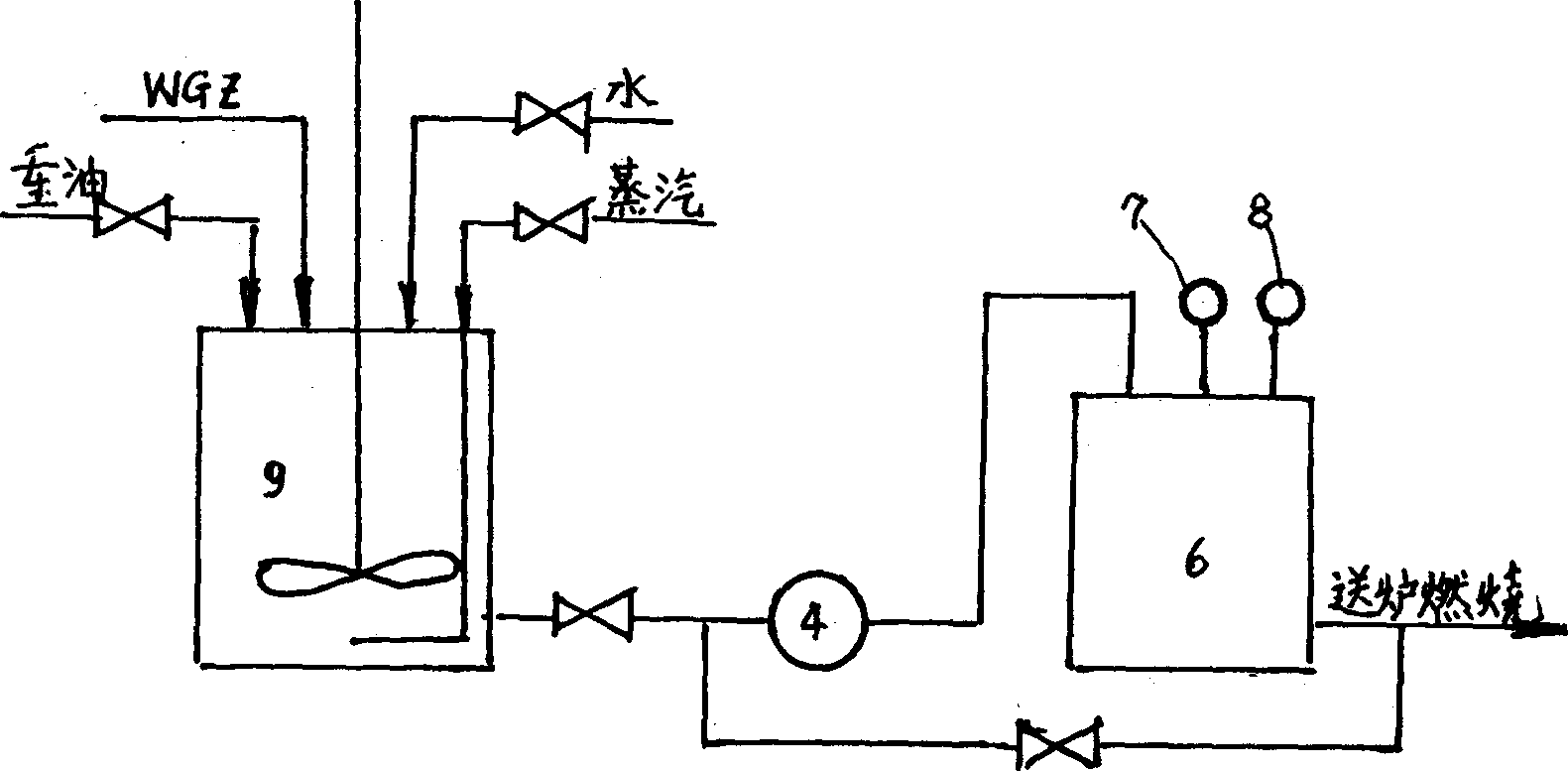

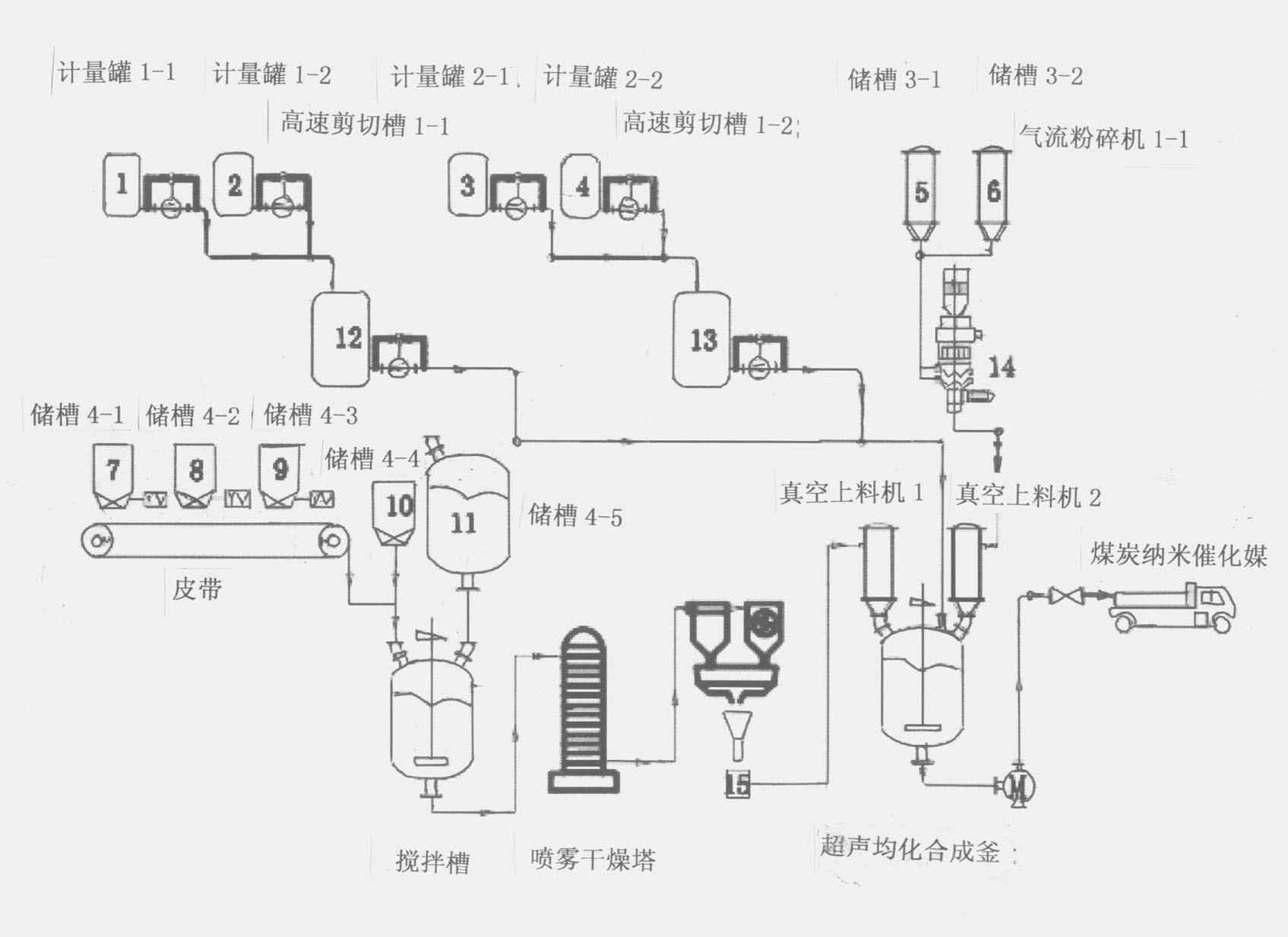

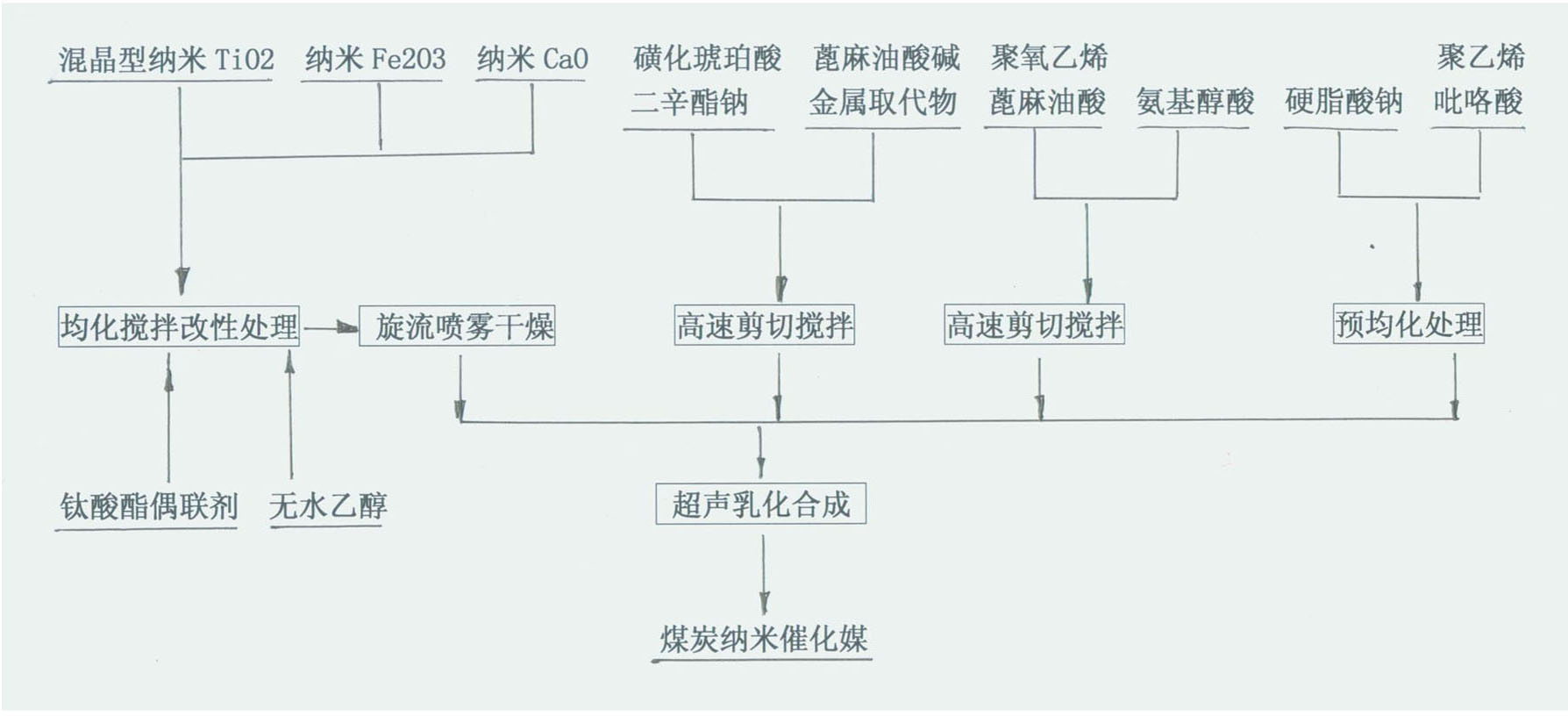

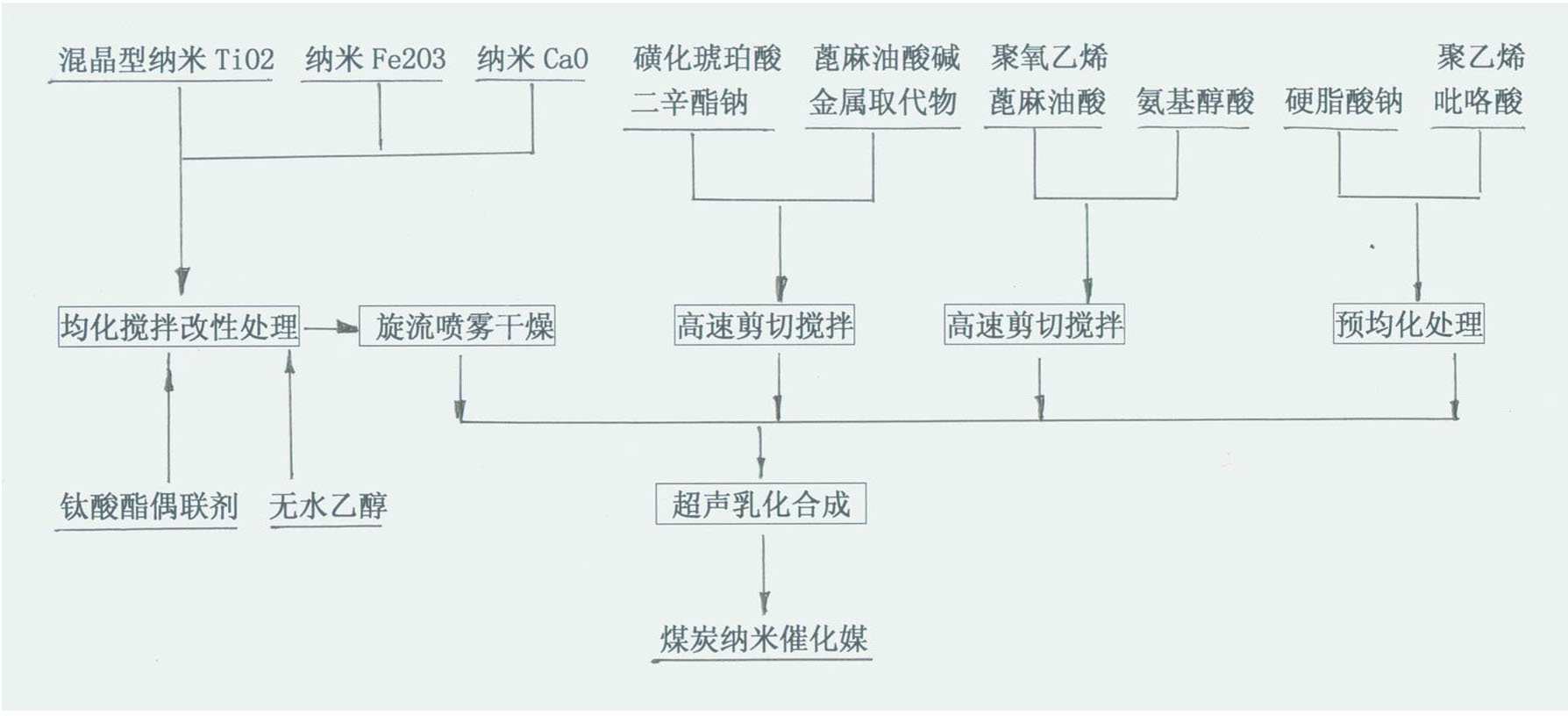

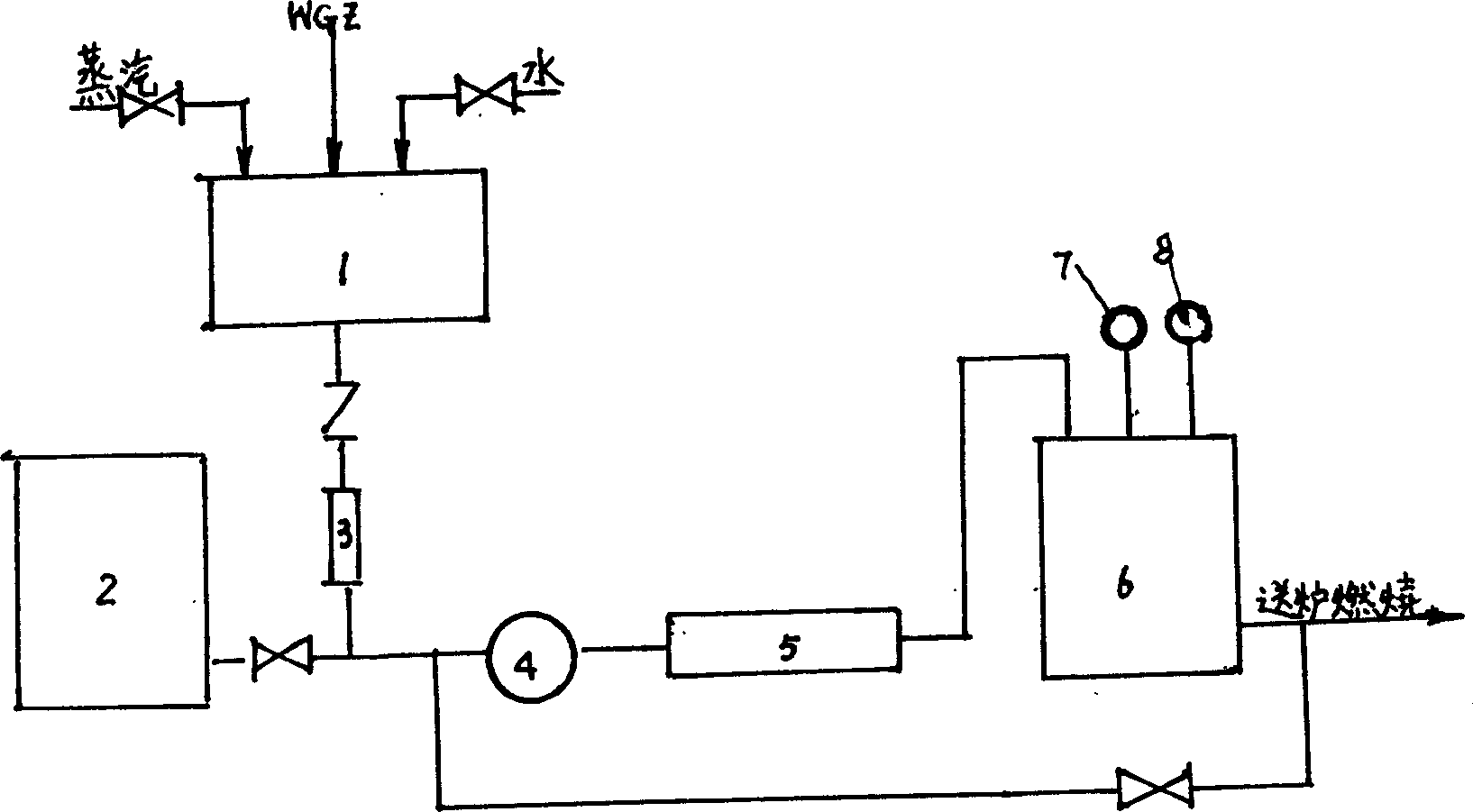

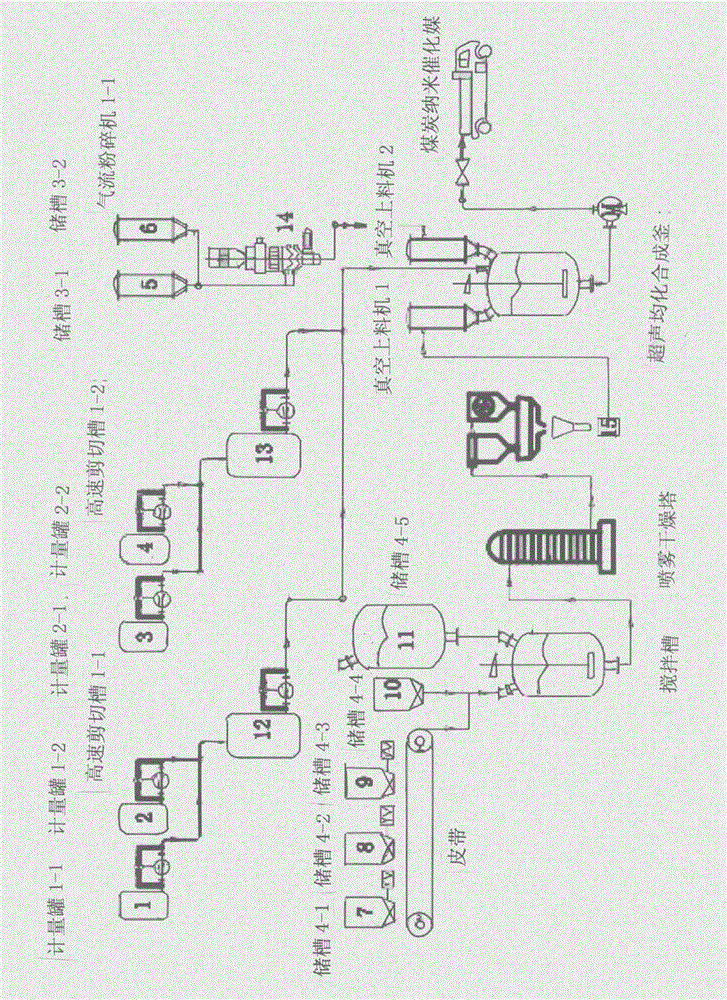

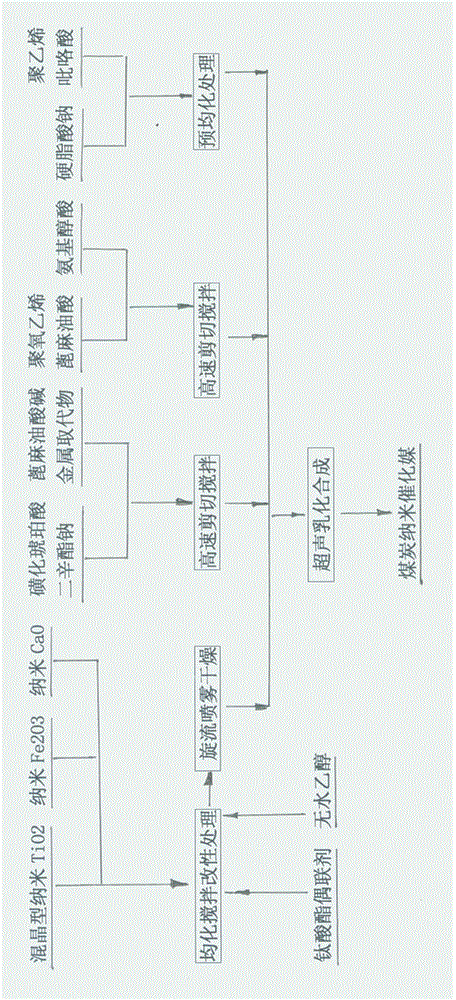

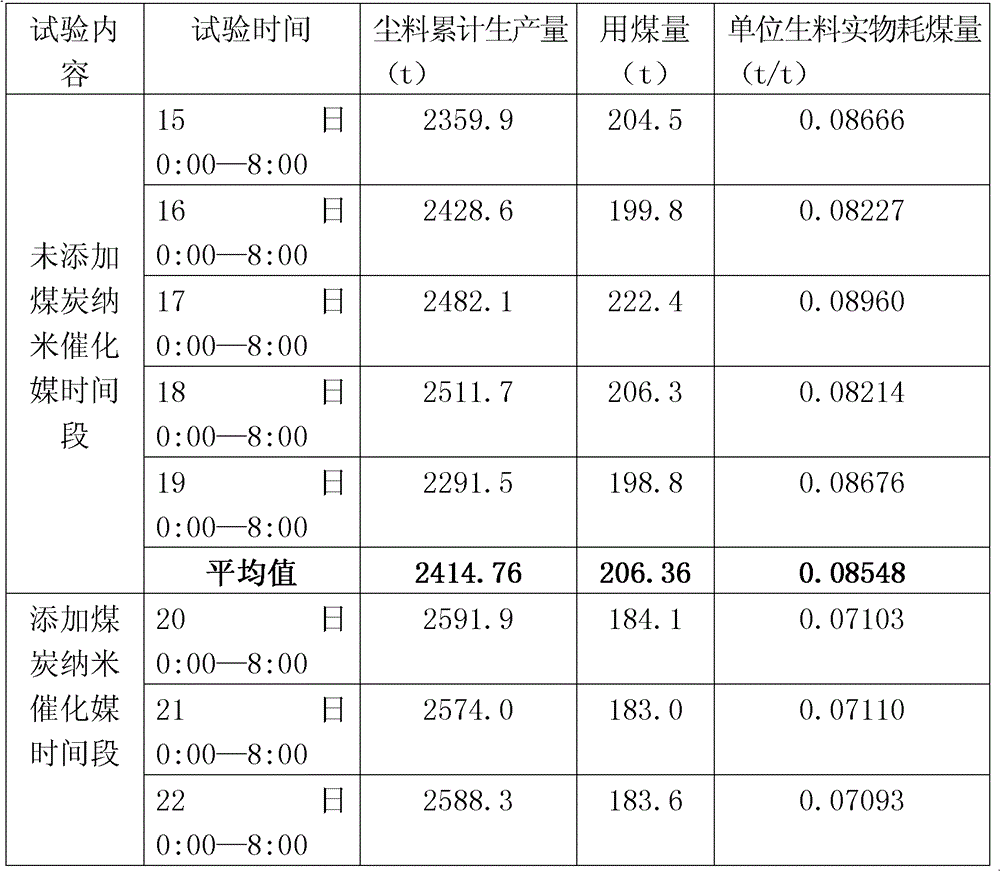

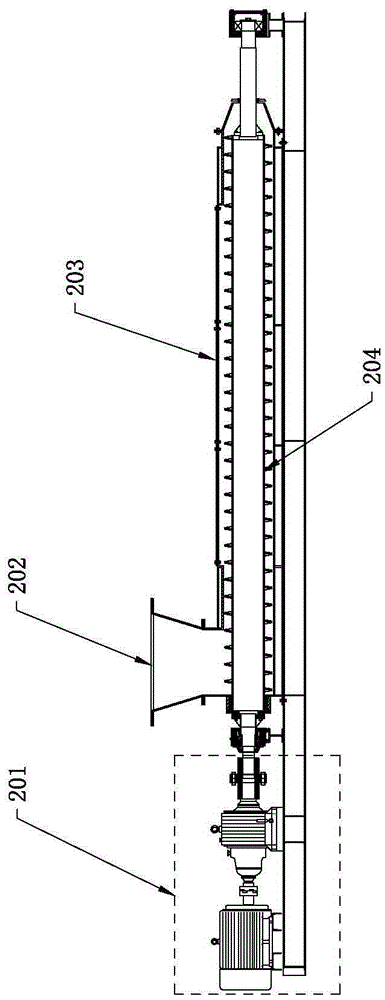

Coal nanocatalysis medium and synthesis process thereof

The invention discloses a preparation technology of a nanocatalysis medium for increasing coal combustion efficiency. The prepared catalysis medium is an oily liquid which is insoluble in water, has stable properties in the air, does not contain any explosive component or heavy metal component, and does not cause any damage to combustion equipment. The catalysis medium is characterized by consisting of a continuous solvent carrier phase component, a continuous solute carrier phase component, a continuous solute promoting phase component and a high-activity nanocatalysis medium dispersed phase. Due to the adoption of the coal nanocatalysis medium prepared with the technology, pulverized coal combustion can be promoted, the amount of fly ash, non-combusted carbon particles and residues is reduced, the using amount of coal is lowered, catalytic coal saving rate is up to 11-18 percent, the emission of pollutants such as Sox, NOx and the like is lowered effectively, the phenomena of cokingand skin formation in a furnace are eliminated, stable combustion of pulverized coal is promoted, the flowing activity of oxygen is increased, the utilization ratio of oxygen is increased, the introducing amount of primary air is reduced, and energy loss caused by the introduction of inert gases is lowered.

Owner:郯城华彩混凝土有限公司

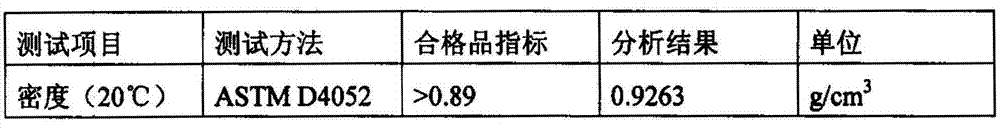

Preparation method of environment-friendly C9 fuel oil

InactiveCN103173244AReduce pollutionImprove pollutionTreatment with plural serial refining stagesWater bathsFuel oil

The invention relates to a preparation method of environment-friendly C9 fuel oil. The preparation method of the environment-friendly C9 fuel oil comprises the following steps of: based on a fraction with the boiling range of 80 to 190 DEG C in the byproduct C9 fraction from ethylene cracking as a raw material, adding an extraction agent, placing in a water bath with the constant temperature of 30 DEG C, stirring for 1h, standing and layering for 1h, adding an additive in the separated oil, and continuing stirring for 1h to obtain the environment-friendly C9 fuel oil. In comparison with the prior art, the environment-friendly C9 fuel oil has the advantages of less sulphur content, good dispersibility and the like.

Owner:SHANGHAI BOHUI CHEM

Regeneration method of dehydrogenating catalyst of alkyl benzene

ActiveCN101306392ARestore performanceExtended service lifeOrganic chemistryCatalyst regeneration/reactivationDehydrogenationSuperheated steam

The invention relates to an in-reactor generative method of an alkyl benzene dehydrogenation catalyst, and mainly solves the problems that the in-reactor generative method of alkyl benzene dehydrogenation catalyst in the unsaturated aromatic hydrocarbon production method is not related in the former documents or the generative method introduced in the former document is poor in the generative effect, therefore the prolonging of the service life of the catalyst, the reaction transformation ratio and the reaction yield coefficient are influenced, and the long down time of the device caused by the catalyst replacement influences the output of the device. The method better solves the problems by adopting the technical proposal that firstly the catalyst is swept by superheated steam at 350 to 600 DEG C and then swept by the gas mixture of air and aqueous vapor, then the amount of the aqueous vapor is gradually reduced while the amount of the air is increased, and the generation is performed to the dehydrogenation catalyst in a reactor. The method can be applied to the industrial production for preparing the unsaturated aromatic hydrocarbon by performing dehydrogenation to alkyl aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

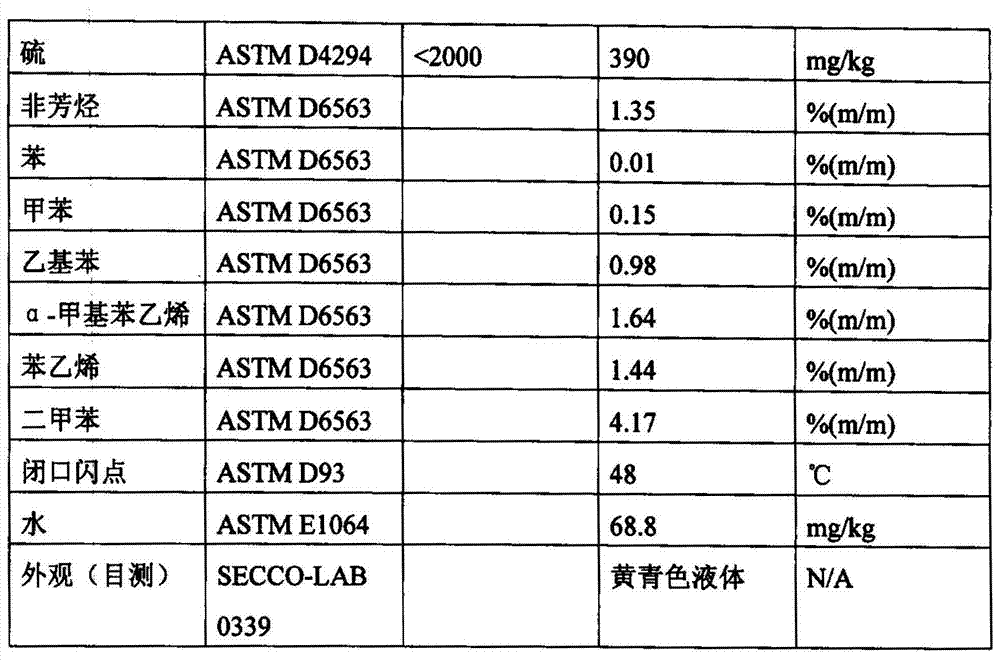

Production process of polyester FDY multi-roll oil-free full-draft fibers

InactiveCN107034533AAvoid slipping and shakingGuaranteed spinnabilityArtificial thread manufacturing machinesFilament manufacturePolyesterDistributor

The invention discloses a production process of polyester FDY multi-roll oil-free full-draft fibers. The production process includes the following steps that polymerization is conducted in a final polymerization autoclave, raw materials are then processed by means of a melt conveying pump, a melt distributor and a melt booster pump in sequence, the obtained melt is conveyed and then processed by means of a melt cooler, a static mixer, a melt distribution valve and a spinning box in sequence, then the melt is extruded in a metering pump and processed by means of a spinning assembly, fiber cooling and molding is conducted, then semi-finished fibers are processed by means of a U-shaped ceramic piece, a secondary network, a spinning channel, a first additional U-shaped ceramic piece1, a second U-shaped ceramic piece 2, a first silk guide roller, a first-level hot pulling roller, a second-level hot pulling roller, a third-level hot pulling roller and a heat-setting hot roller in sequence, a lubricating nipple is used for oiling, and the obtained fibers are processed by means of a second silk guide roller, a primary network, a third silk guide roller and a guide wheel and subjected to coiling, doffing, quality testing and packaging. According to the production process of the polyester FDY multi-roll oil-free full-draft fibers, the product quality is improved, the running environment of equipment and the working environment of workers in a FDY production place are optimized, yarn path operation is simplified, and energy conservation and high efficiency are achieved.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

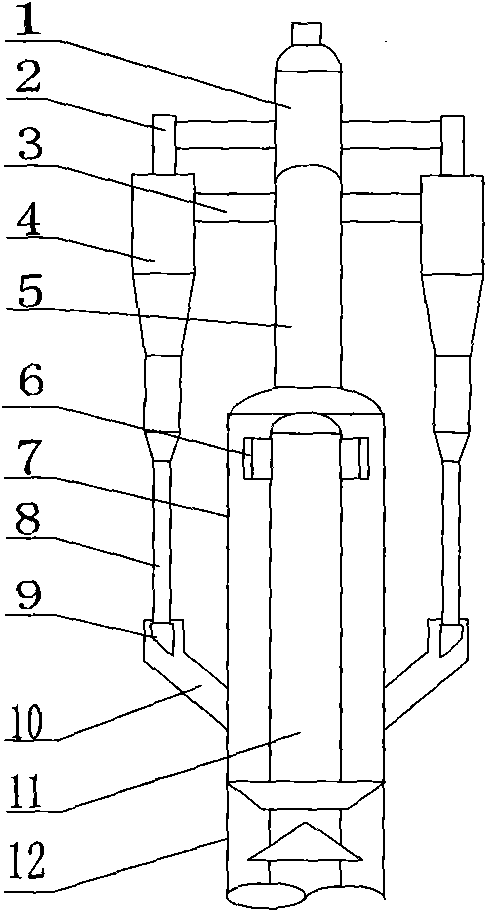

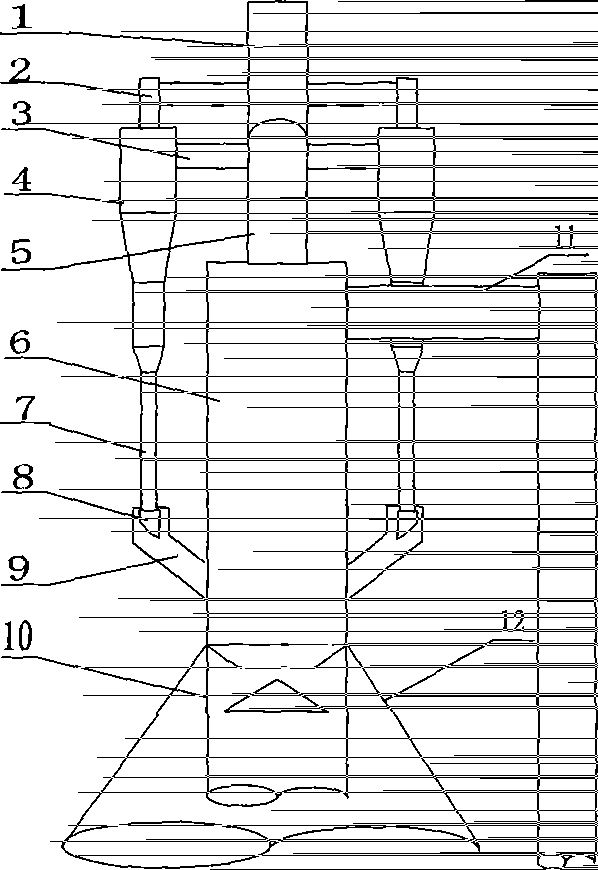

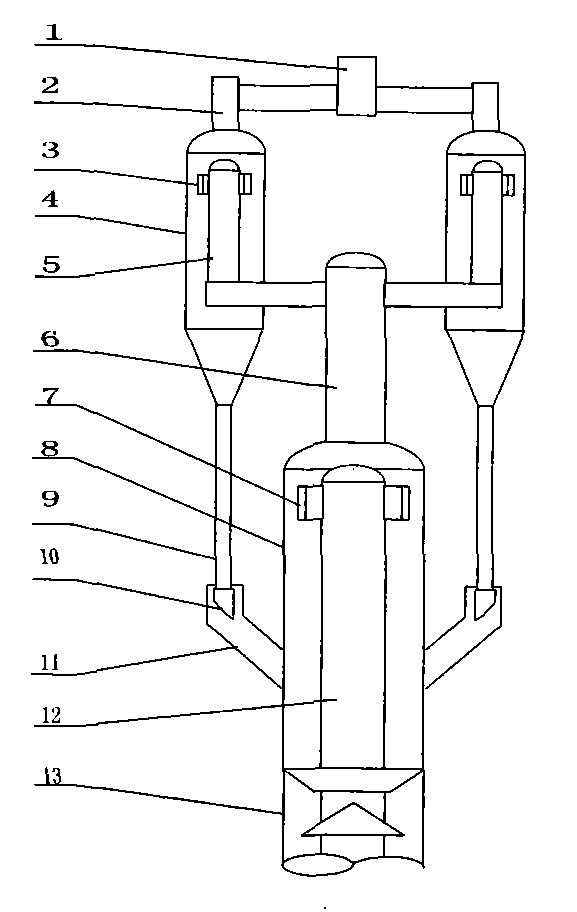

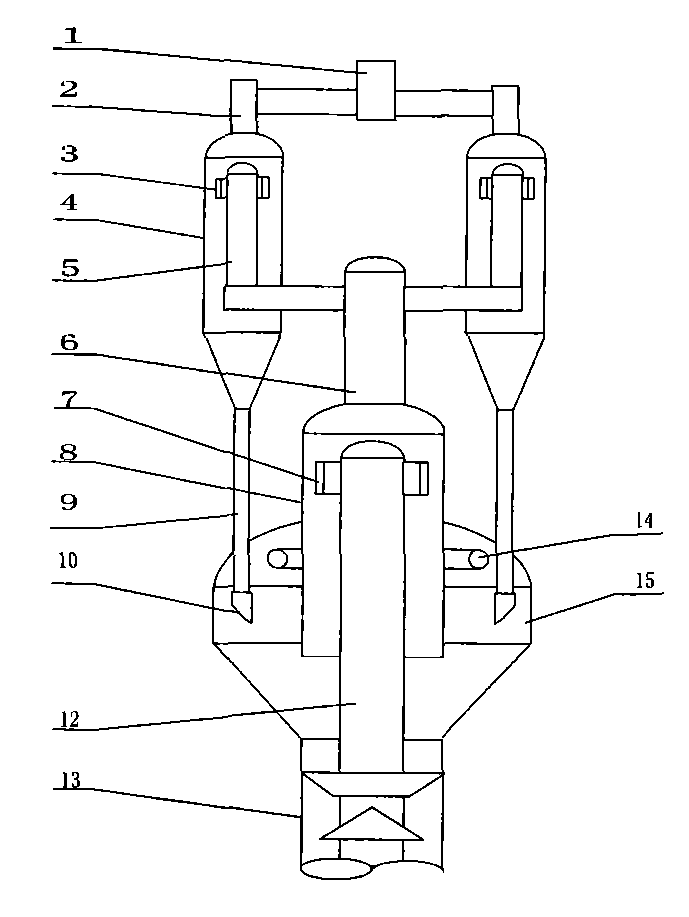

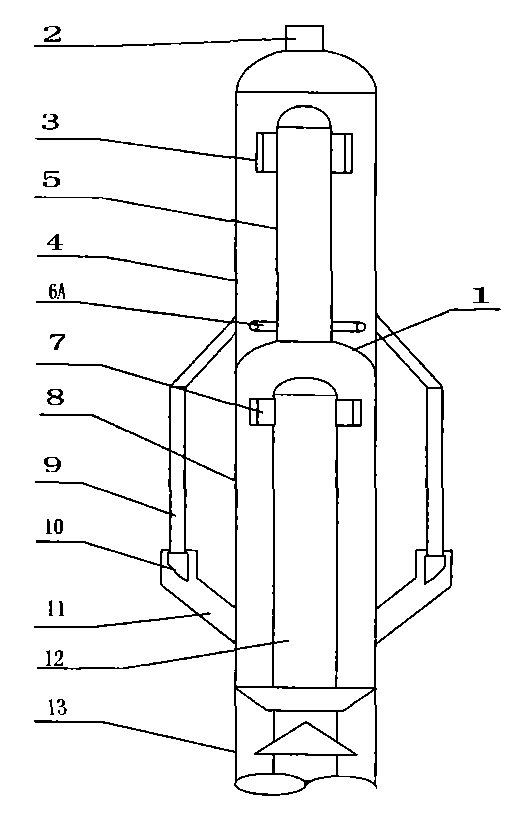

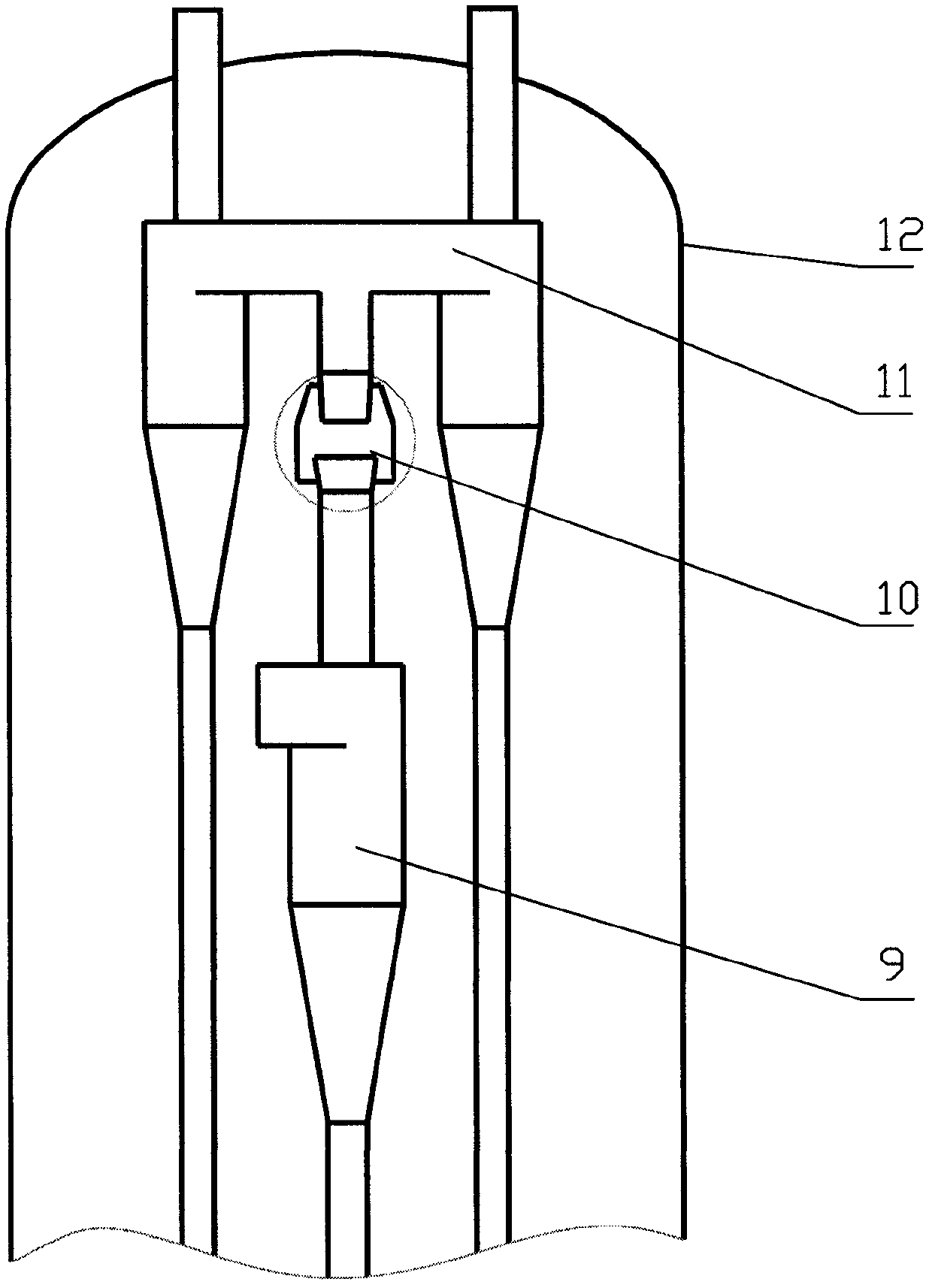

Settler-free gas-solid separation method and equipment

InactiveCN104275036AEliminate cokingReduce oil and gas excessive thermal cracking reactionCatalytic crackingDispersed particle separationChemistryDry gas

The invention relates to a settler-free gas-solid separation method and belongs to the technical field of petrochemical engineering and fluidization. The method is used for solving the problems of reaction that settlers undergo coking and excessive oil vapor thermal cracking. The method comprises the processes of rapid gas-solid separation, second-stage separation, dipleg flutter valve discharge and oil vapor lead-out and is characterized in that due to a settler-free design, closed rapid cyclone separation is adopted to be mated with second-stage cyclone separation, catalyst diversion facilities are arranged, the catalyst diversion facilities are connected with the rapid cyclone separation and the second-stage separation, so as to form a closed separation system, and a catalyst and oil vapor, which are discharged from second-stage flutter valves, are closely guided to the closed separation system. The method has the advantages that the coking of the settlers is eliminated; due to closed rapid cyclone separation, the gas-solid separation efficiency reaches over 98%, and the retention time of the oil vapor is shorter than 5 seconds, so that the reaction of excessive thermal cracking of the oil vapor is obviously reduced, the yield of dry gas is lowered, and the yield of products is increased; the discharging of diplegs is smooth, so that blow-by is avoided; the equipment maintenance is facilitated, and the equipment investment is greatly reduced. The invention further provides an external closed rapid cyclone separator, an external second-stage separator and external catalyst diversion equipment, which are used for implementing the method disclosed by the invention. The method and equipment are applied to devices for catalytic cracking, catalytic pyrolysis and the like.

Owner:刘英聚

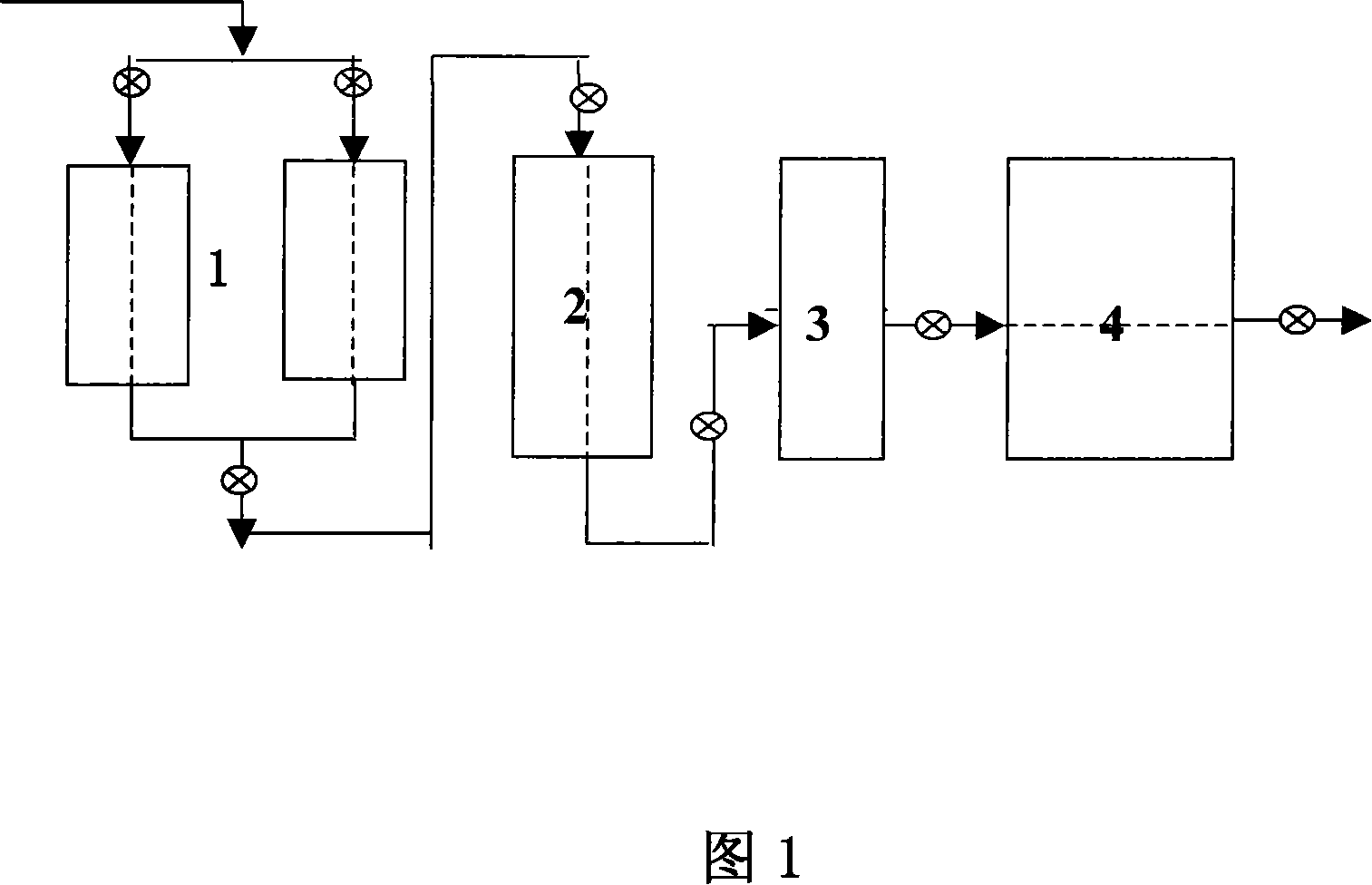

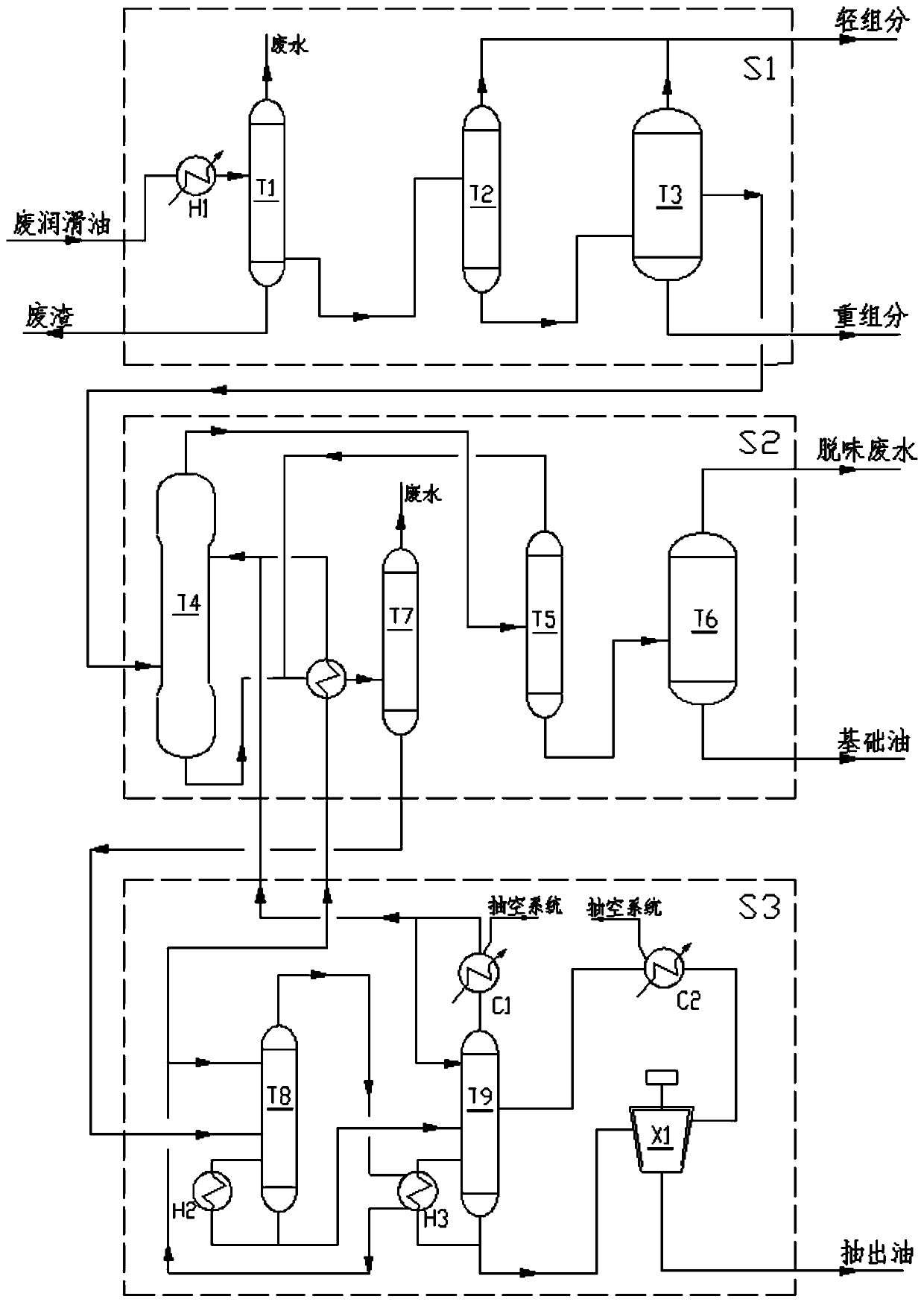

Waste lubricating oil regeneration method and system

ActiveCN110804486AReduce consumptionImprove energy savingLubricant compositionProcess engineeringBase oil

The invention discloses a waste lubricating oil regeneration method and system. The regeneration system comprises a pretreatment system, an extraction and refining system and a regenerative system. According to the process of performing waste lubricating oil regeneration by the adoption of the regeneration system, waste lubricating oil is pretreated to obtain basic distillate oil, the basic distillate oil is subjected to solvent extraction and refining to obtain a lubricating oil basic oil product, an extraction phase obtained after extraction and separation is subjected to two-effect solventregenerative rectification, a heavy component obtained after two-effect regenerative rectification is subjected to first evaporation treatment, an evaporated solvent is used as an extraction solvent cyclically, and extracted oil obtained through extraction is used as a by-product. According to the method, by adjusting running parameters of the two-effect regenerative rectification and the first evaporation, the solvent regeneration effect is improved, solvent loss is reduced, operation energy consumption is lowered, and running stability is improved; and compared with the prior art, under thesame regenerative effect, energy can be saved by 40% or above, the solvent content in the heavy component is not greater than 0.5%, long-term stable running can be realized, and the method and systemare suitable for industrial large-scale production and utilization.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

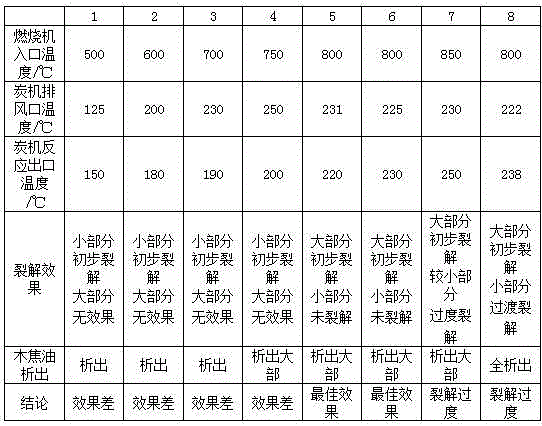

Biomass combustion utilizing method used for butted boiler and heat exchanger

InactiveCN103557515AAvoid burning and cokingGuarantee continuous and stable operationSolid fuel combustionNon-combustible gases/liquids supplySlagVapor generator

A biomass combustion utilizing method used for a butted boiler and a heat exchanger comprises the following steps: (1), preliminary pyrolysis; (2), feeding combustion; and (3) water vapor combustion support. A biomass raw material is subjected to preliminary pyrolysis to precipitate tar oil to obtain biomass fuel with low tar oil content, so that the condition that combustion coking in a furnace chamber is effectively prevented, the frequency of slag removal by blowing down is effectively reduced, the work efficiency is improved, and the service life of equipment is prolonged; meanwhile, a vapor generator is used for spraying water vapor into the furnace chamber so as to support combustion; and experiments prove that the temperature of a flame in a fire hole of a common biomass combustion machine is lower than 800 DEG C, and the temperature of the flame in the fire hole with introduced water vapor is about 100 DEG C higher than that of the flame in the fire hole without introduced water vapor under the condition of the same feeding amount and the same ventilation amount. The combustion flame is ejected out through the fire hole, is used for heating the butted boiler, the heat exchanger, a heat supply system, a heat generator and other thermal utilization equipment, is not limited to boiler heating, and can be extensively applied to various equipment with naked fire heating requirements.

Owner:黎明 +1

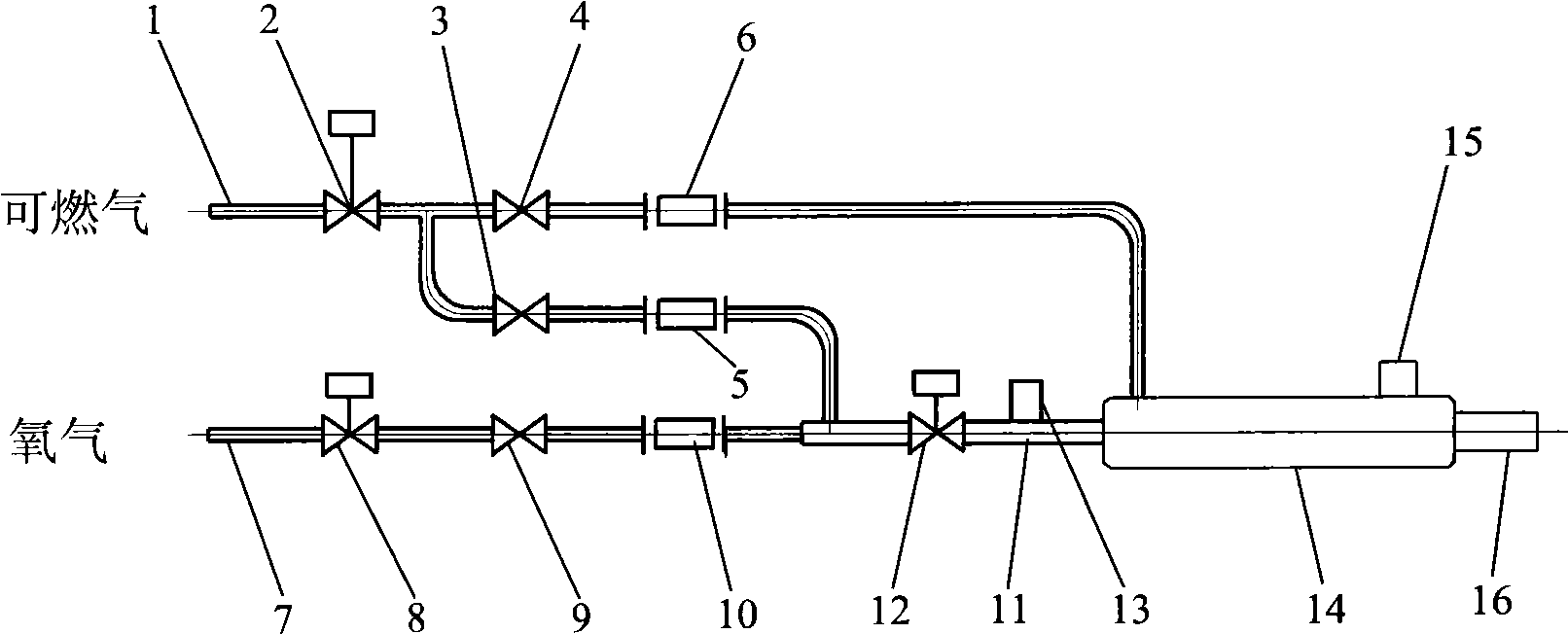

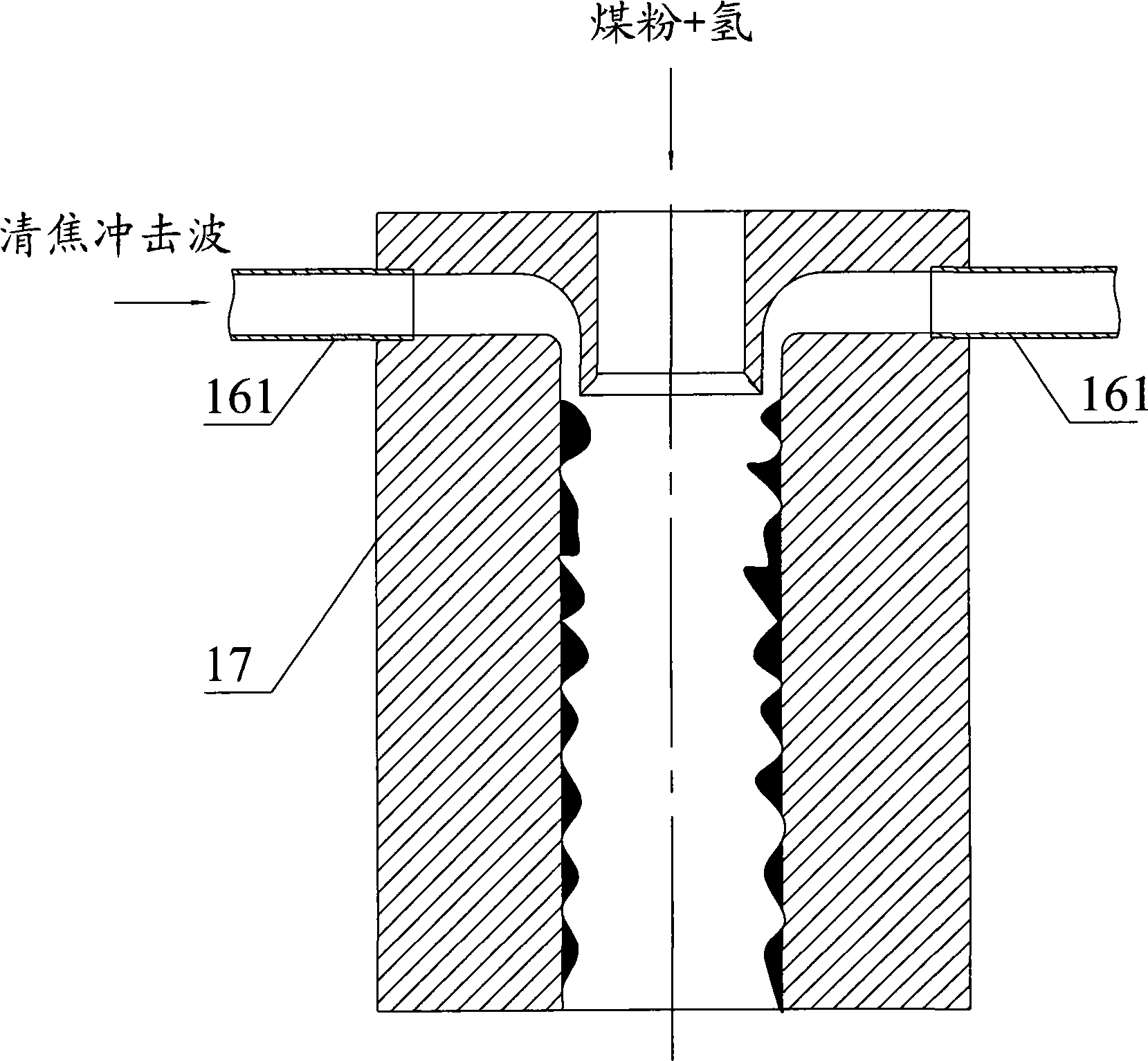

Coke cleaning system and method for plasma cracking reactor

InactiveCN101487596AEliminate cokingGuarantee unimpededHydrocarbonsEnergy based chemical/physical/physico-chemical processesShock waveCombustion chamber

The invention provides a plasma pyrolysis reactor decoking system and a method thereof. The system comprises a pre-combustion chamber, a rapid combustion chamber, a shock wave ejector device and a reactor; secondary combustible gas is deflagrated in the rapid combustion chamber by the deflagration and ignition of the gas in the pre-combustion chamber, and the generated shock wave is introduced into the inner wall of the reactor through the shock wave ejector device. The decoking method comprises: initial deflagration is generated by the premixed combustion of primary combustible gas and oxygen; the introduced secondary combustible gas is ignited, reducing atmosphere is generated to enhance the combustion reaction; finally, powerful shock wave is generated and directly acts on the inner wall of the reactor. By adopting prefiring deflagration in the pre-combustion chamber, the secondary combustible gas in the rapid combustion chamber can be ensure to be burnt rapidly; as the generated shock wave energy is high, the coked inner wall of the reactor can be effectively cleaned, and a channel of the reactor is kept smooth; furthermore, the acting time of the shock wave is very short and only has the magnitude of 10 milliseconds, thus not affecting the normal work of plasma torch.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Multifunctional heavy oil and fuel oil additive, preparation and use thereof in preparing emulsified oil

InactiveCN1169927CIncrease surface areaMix well and evenlyLiquid carbonaceous fuelsActive agentOil additive

An oil-soluble multifunctional additive for heavy oil or fuel oil contains more surfactants, composite catalytic combustion adjuvant and detergent disperser, and is characterized by saving oil by 10-25%, increasing added water to 10-30% and eliminating black smoke. A process for preparing emulsified heavy oil or fuel oil is also disclosed.

Owner:WUHAN UNIV OF TECH

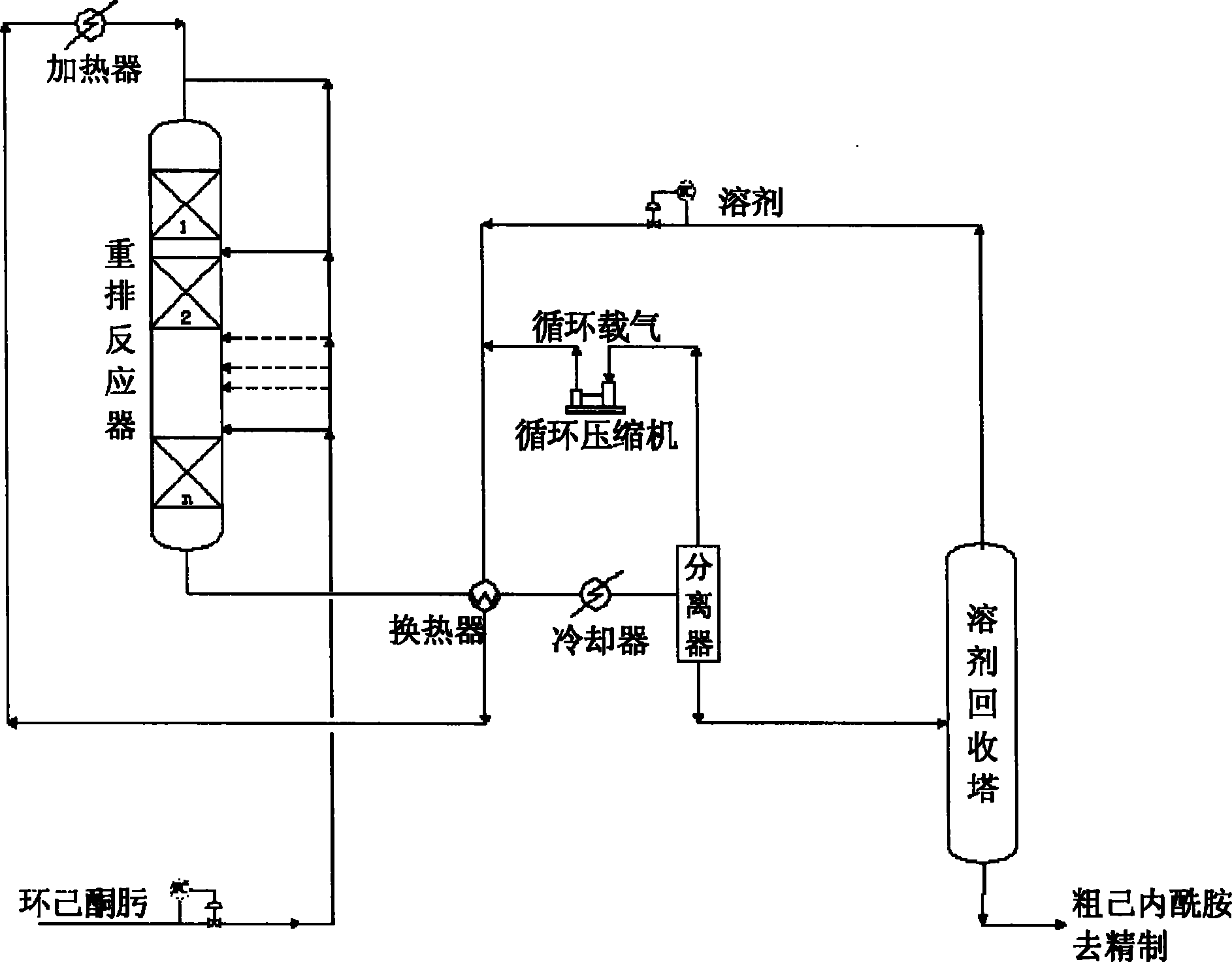

Cyclohexanone-oxime vaporizing method

The invention discloses a cyclohexanone-oxime vaporizing method which comprises the following steps of: introducing liquid-phase cyclohexanone-oxime into a vaporizing device; atomizing into small liquid drops by using an atomizing spray gun; contacting the cyclohexanone-oxime small liquid drops with high-temperature gas for fully vaporizing; and introducing the obtained cyclohexanone-oxime gas out of the vaporizing device. The vaporizing method provided by the invention is suitable for the vaporizing process of cyclohexanone-oxime, is used for preventing cyclohexanone-oxime from being coked in a vaporizing process, is particularly suitable for a cyclohexanone-oxime vapor phase rearrangement process, and can be applied to rapid vaporization of other heat-sensitive liquids.

Owner:CHINA PETROLEUM & CHEM CORP +1

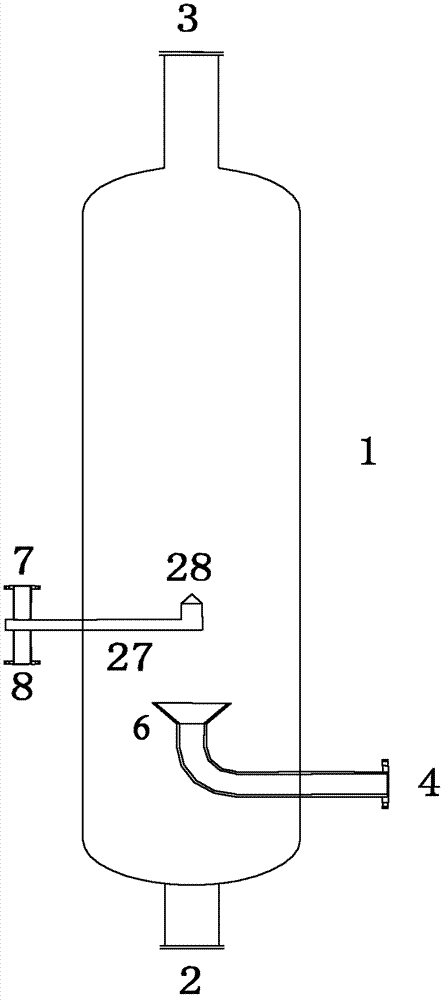

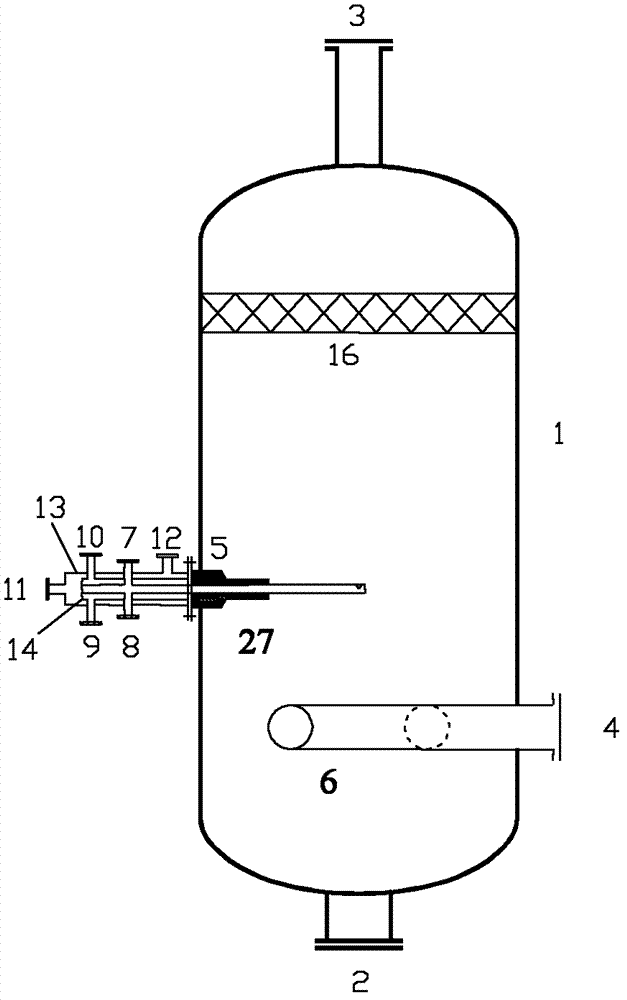

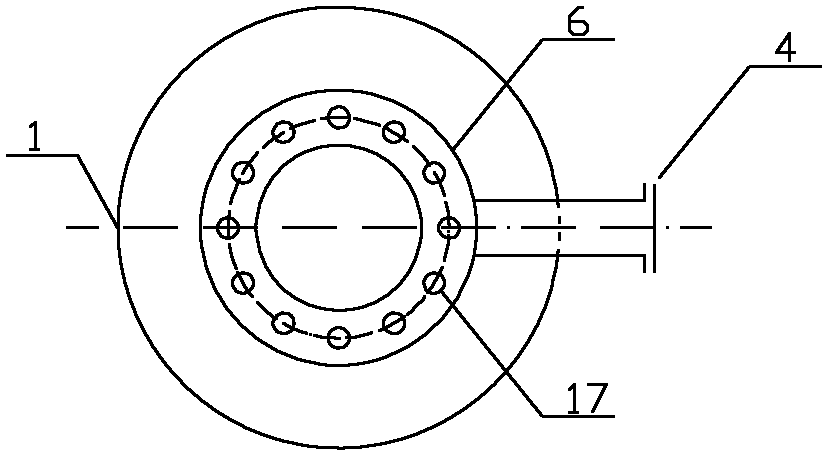

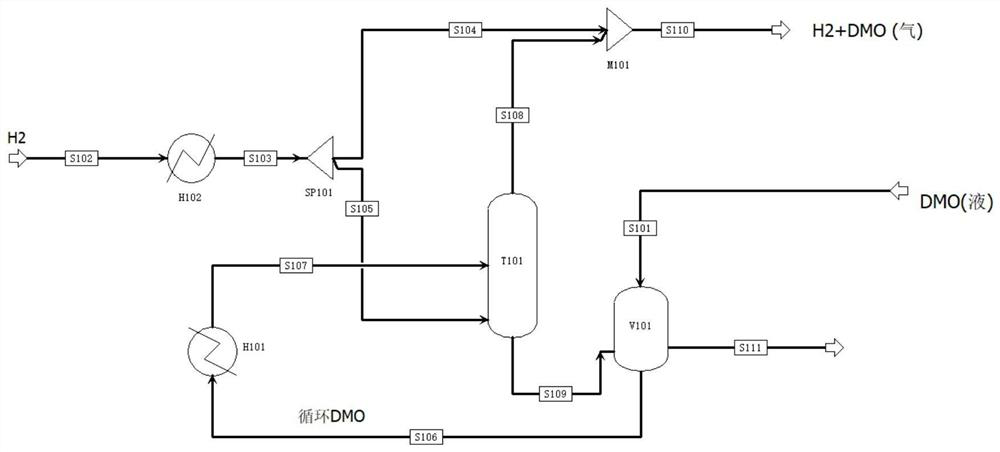

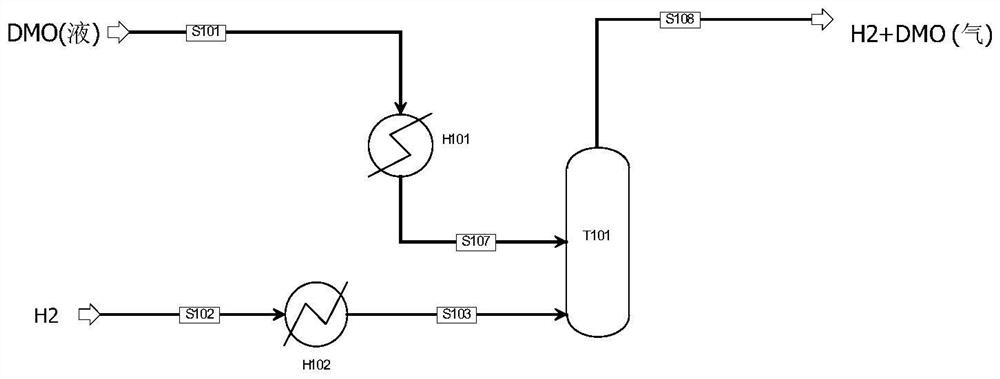

Vaporization method and vaporization device of dimethyl oxalate

ActiveCN109482107BLow impurity contentEliminate cokingBoiling apparatusFeed devicesOxalatePtru catalyst

The invention discloses a method for vaporizing dimethyl oxalate, which comprises the following steps: (1), DMO fresh feed and DMO circulating material are mixed to form DMO feed, and the DMO feed is preheated and enters a vaporization tower for vaporization ; 2), the total hydrogen feed is divided into two stocks of materials, the first hydrogen feed does not enter the vaporization tower, the second hydrogen feed enters from the bottom of the vaporization tower, and the vaporized DMO from the vaporization tower The upper part of the vaporization tower is taken out, and then mixed with the first hydrogen feed; the vaporization method of dimethyl oxalate of the present invention significantly reduces the impurity content in the mixed gas discharge from the vaporization tower, so that the packing layer and The operation period of the catalyst is significantly extended, which greatly improves the production efficiency and reduces the production cost. The invention also discloses a vaporization device of dimethyl oxalate based on the vaporization method of dimethyl oxalate.

Owner:EAST CHINA UNIV OF SCI & TECH

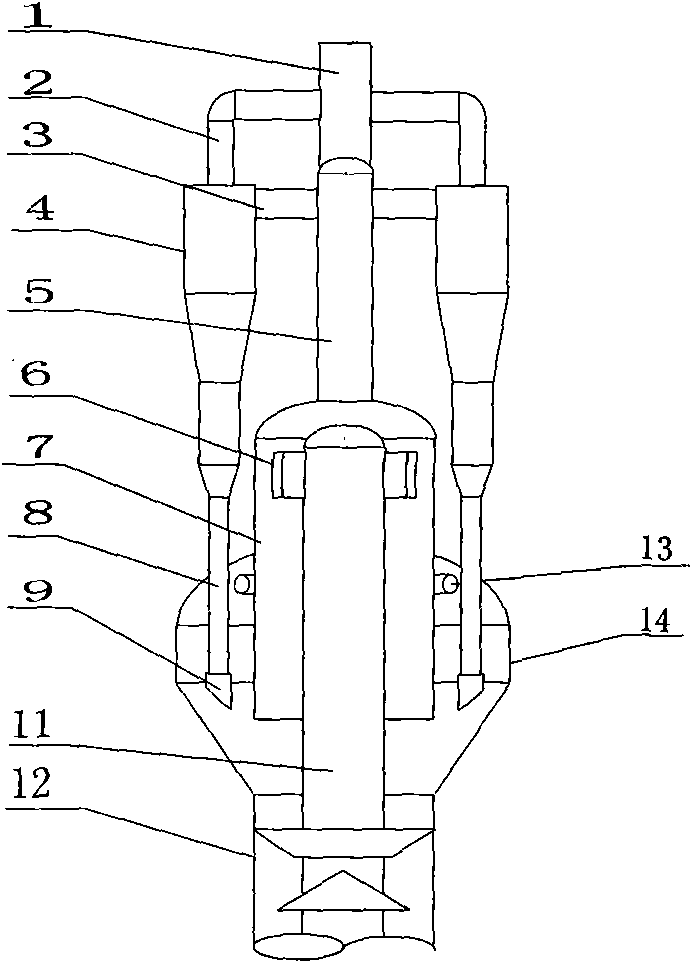

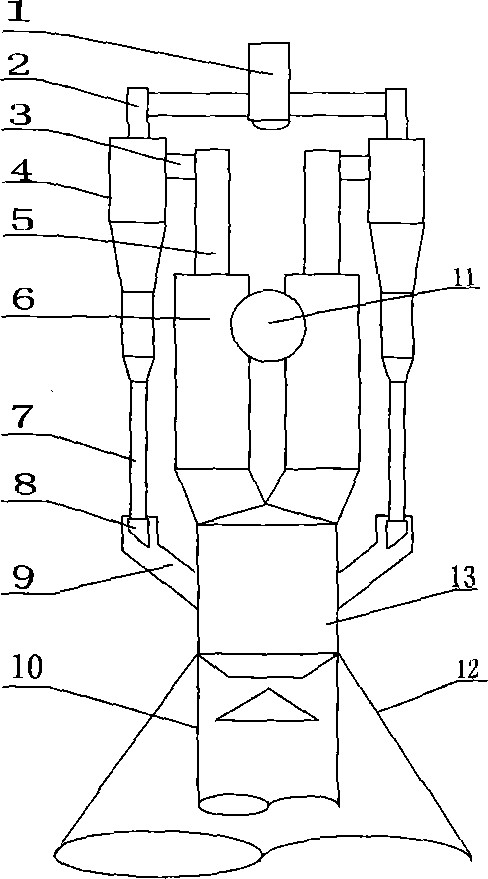

Coaxial settler-free gas-solid separation method and equipment

InactiveCN104275038AEliminate cokingSmooth nestingCatalytic crackingDispersed particle separationCatalytic pyrolysisRetention time

The invention relates to a coaxial settler-free gas-solid separation method and belongs to the technical field of petrochemical engineering and fluidization. The method is used for solving the problems of coaxial type devices that settlers undergo coking and excessive oil vapor thermal cracking. The method comprises the processes of rapid separation, second-stage separation, dipleg flutter valve discharge and oil vapor lead-out and is characterized in that due to a coaxial and settler-free design, external closed rapid cyclone separation is adopted to be mated with external second-stage separation, and catalyst diversion facilities are arranged; the catalyst diversion facilities are connected with the external rapid cyclone separation and the external second-stage separation, so as to form a closed separation system, and a catalyst, oil vapor and anti-coking steam, which are discharged from second-stage flutter valves, are closely guided to the closed separation system. The method has the advantages that the problem of coking of the settlers is eliminated; due to closed rapid cyclone separation, the gas-solid separation efficiency reaches over 98%, and the retention time of the oil vapor is shorter than 5 seconds, so that the reaction of excessive thermal cracking of the oil vapor is obviously reduced, the yield of dry gas is lowered, and the yield of products is increased; the discharging of diplegs is smooth, so that blow-by is avoided; the equipment investment is greatly reduced. The invention further provides an external closed rapid cyclone separator, an external second-stage separator and external catalyst diversion equipment, which are used for implementing the method disclosed by the invention. The method and equipment are applied to devices for catalytic cracking, catalytic pyrolysis and the like.

Owner:刘英聚

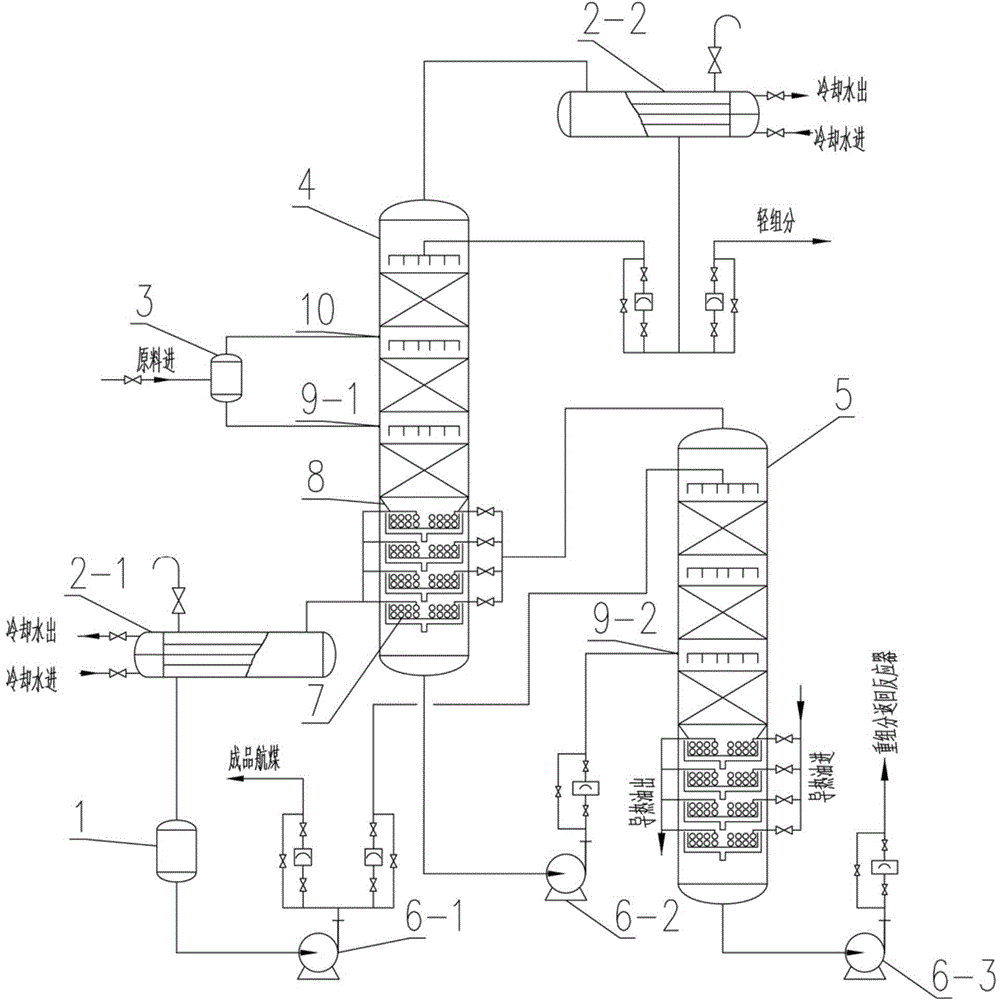

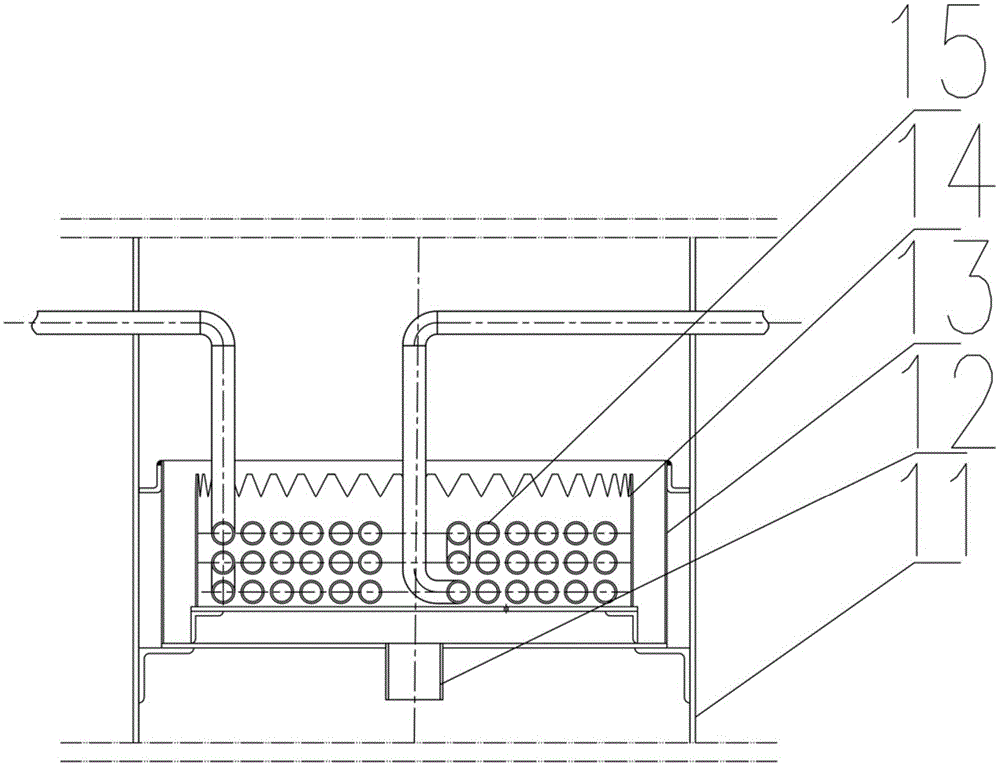

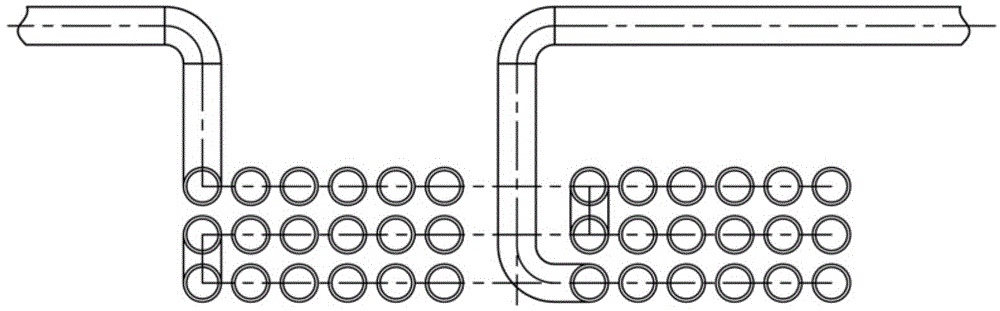

A continuous rectification system and process of bio-aviation kerosene based on shallow liquid layer evaporator

InactiveCN104017599BImprove distillation yieldReduce thicknessHydrocarbon distillationLiquid layerKerosene

The invention relates to a system and a technology for continuously rectifying biological aviation kerosene based on a shallow-liquid-layer evaporator. The system comprises a lightness-removing column and a finished-product column, the bottoms of the lightness-removing column and the finished-product tower are both provided with a shallow-liquid-layer evaporator, a gas-phase inlet of the lightness-removing column and a liquid-phase inlet of the lightness-removing column are communicated with a flash-evaporation tank, the top of the lightness-removing column is connected with a condenser II, and the bottom of the lightness-removing column is communicated with a liquid-phase inlet of the finished-product tower via a discharging pump II. The beneficial effects comprise that by employing two-tower rectification for relatively separating light compositions and heavy compositions, the high-quality target product biological aviation kerosene is obtained, the liquid-layer thickness of a heating pallet is reduced, the temperature of a heating medium is reduced, the heating vaporization amount is improved, high-temperature decomposition, polymerization and coking caused by over-long staying time are furthest eliminated, the rectification yield and the oil quality of the biological aviation kerosene are improved, and energy consumption is reduced.

Owner:ZHEJIANG UNIV OF TECH +1

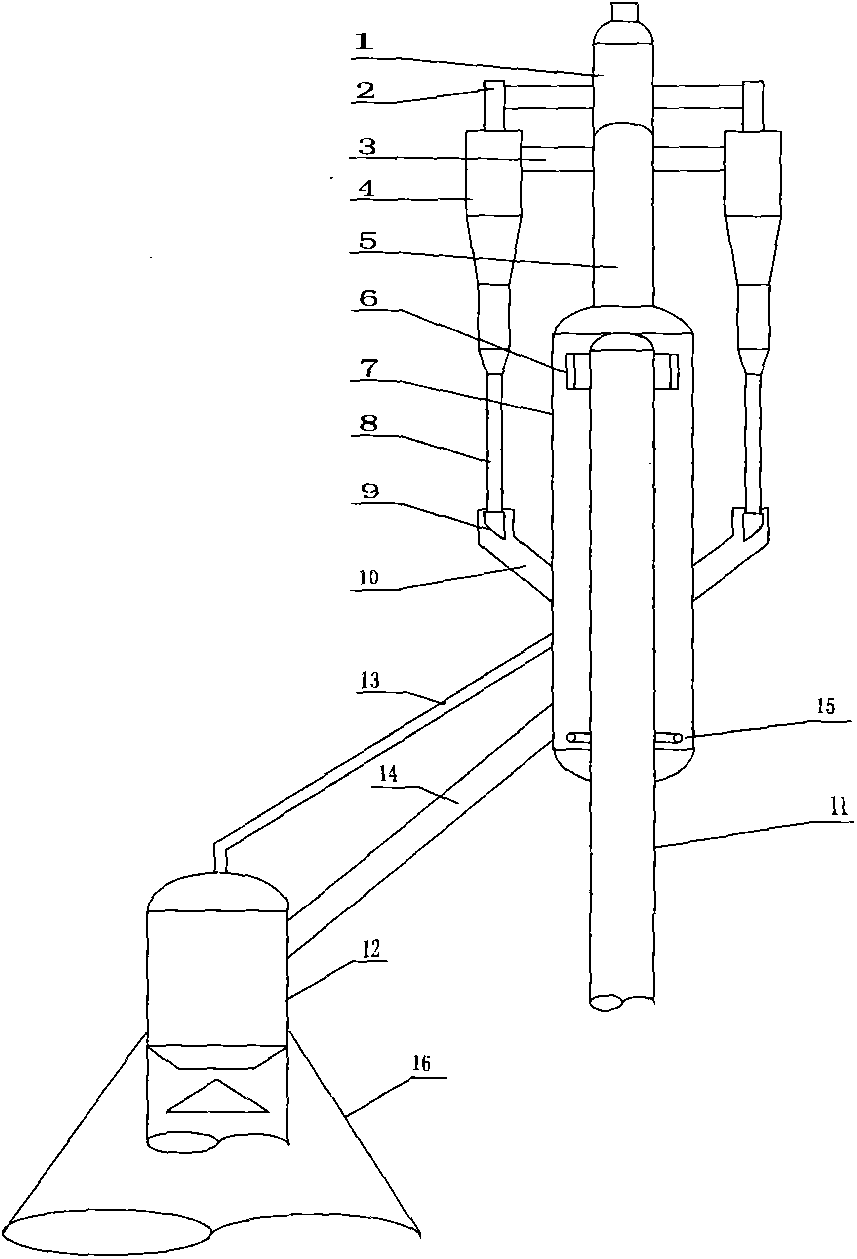

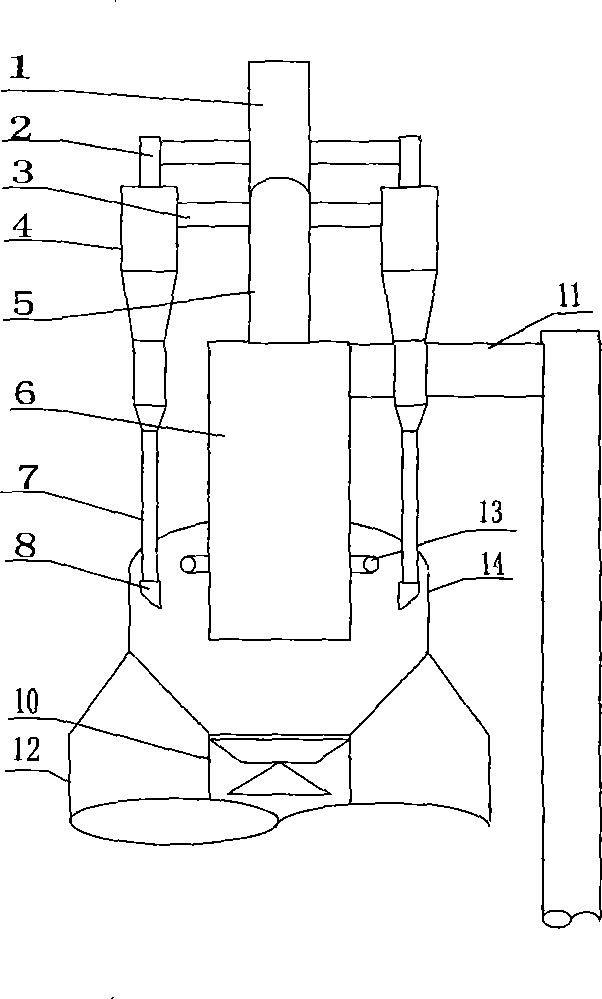

Settler-free two-stage-cyclone-series-connected gas-solid separation method and equipment

InactiveCN104275042AEliminate cokingReduce thermal cracking reactionsCatalytic crackingDispersed particle separationChemistryPetrochemical

The invention relates to a settler-free two-stage-cyclone-series-connected gas-solid separation method and belongs to the technical field of petrochemical engineering and fluidization. The method is used for solving the problems of reaction that settlers undergo coking and excessive oil vapor thermal cracking. The method comprises the processes of two-stage gas-solid separation, dipleg flutter valve discharge and oil vapor lead-out and is characterized in that due to a settler-free design, the series connection of two stages of cyclone separation is designed, and catalyst diversion facilities are designed; the catalyst diversion facilities are connected with the two stages of cyclone separation, so as to form a closed separation system, and a catalyst and oil vapor, which are discharged from flutter valves, are closely guided to the closed separation system. The method disclosed by the invention has the advantages that the problem of coking of the settlers is eliminated; due to closed rapid cyclone separation, the gas-solid separation efficiency reaches over 98%, and the retention time of the oil vapor is shorter than 5 seconds, so that the reaction of excessive thermal cracking of the oil vapor is obviously reduced, the yield of dry gas is lowered, and the yield of products is increased; the discharging of diplegs is smooth, so that blow-by is avoided; the equipment maintenance is facilitated, and the equipment investment is greatly reduced. The invention further provides two stages of external cyclone separators, catalyst diversion equipment and dipleg flutter valves, which are used for implementing the method disclosed by the invention. The method and equipment are applied to devices for catalytic cracking, catalytic pyrolysis and the like.

Owner:刘英聚

Novel connecting mode and component between rough rotator and top rotator in FCC disengager

The invention discloses a novel connecting mode and a component between a rough rotator and a top rotator in an FCC (Fluid Catlyst Cracking) disengager. After the connecting mode and the component are adopted, oil gas at an outlet of a rough rotator can enter the top rotator without entering a disengager space, so that the average residence time of the oil gas in the disengager can be reduced, and a coking phenomenon in the disengager can be inhibited; under the premise of no additional energy consumption, the concentration of a catalyst entering the top rotator is reduced by more than 50% by using rotatoral kinetic energy in an exhaust pipe of the rough rotator, thereby reducing the runoff loss of the catalyst, and performing the smooth operation of an FCC. Meanwhile, the volume of the disengager can be further reduced. The structure can be applied to all occasions with rotating incoming flows, such as the connection between the rough rotator (quick disconnect) and the top rotator in the FCC disengager.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

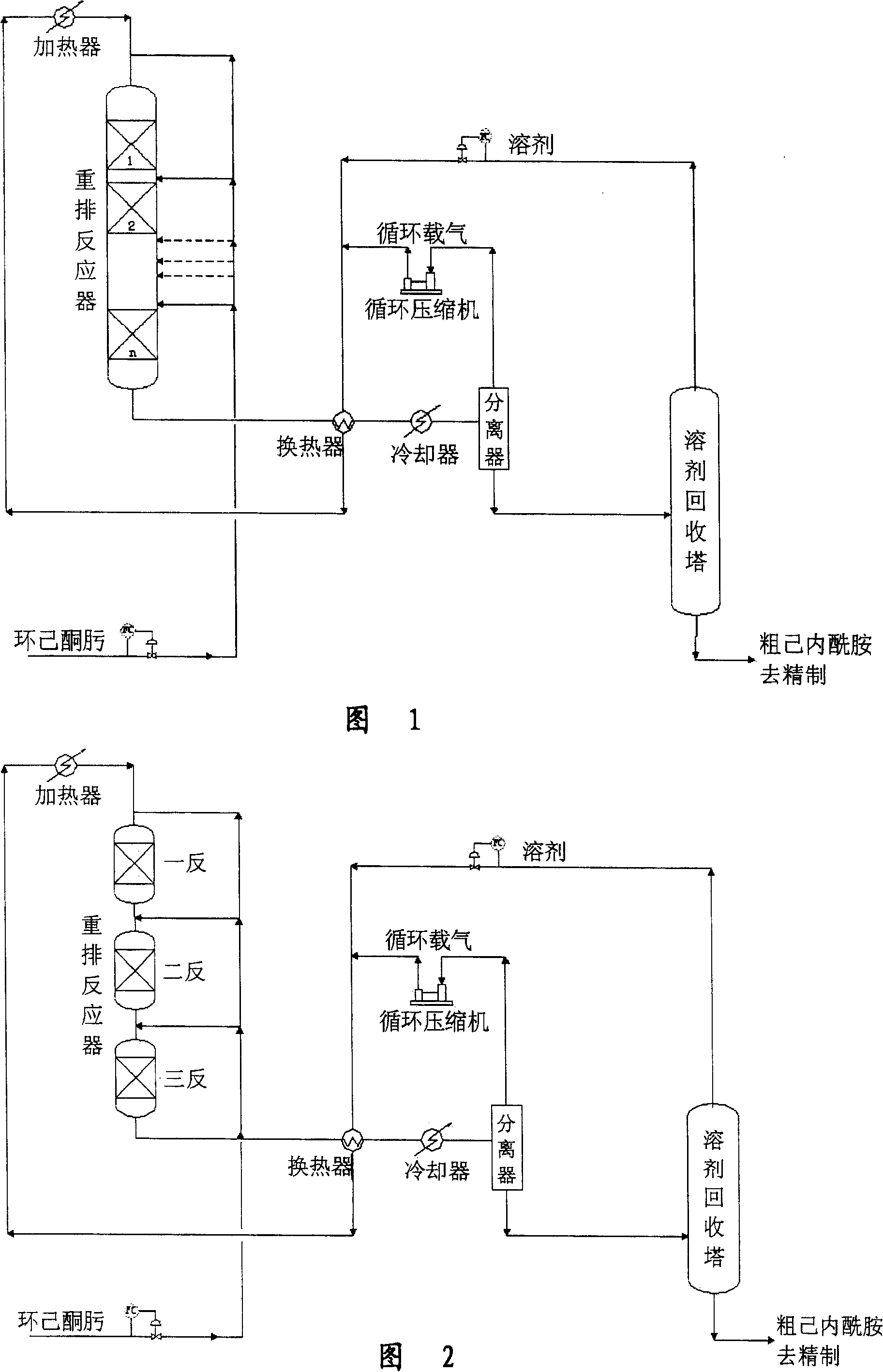

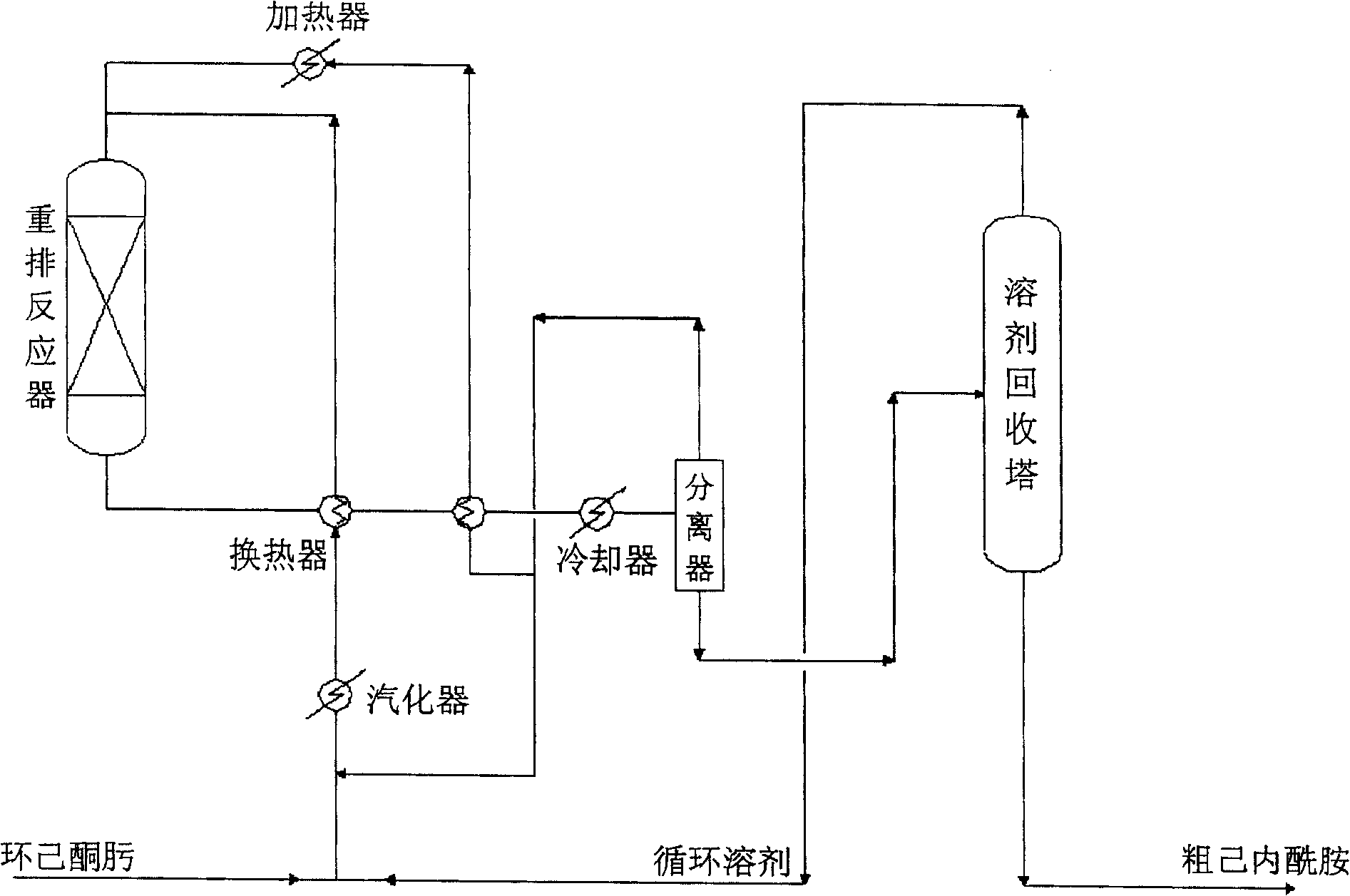

Method and equipment for preparing caprolactam from cyclohexanone oxime

ActiveCN101434569BExtend the life cycleReduce energy consumptionLactams preparationCyclohexanone oximeSolvent

The invention relates to a method for preparing caprolactam with cyclohexanone-oxime, and a device used in the method. The method includes the steps as follows: after being heated, inert supporting gas containing a solvent is continuously put into a supporting gas intake of a first-class reactor of a multi-stage series reactor provided with a catalyst. Cyclohexanone- oxime is directly divided into two parts which then enter all stages of the multi-stage series reactor, thereby ensuring that reaction effluents are cooled. The supporting gas is separated and recycled to the supporting gas intake of the first-class reactor, and then products from a liquid phase reaction are separated and purified.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal nanocatalysis medium and synthesis process thereof

InactiveCN102492521BStable combustionEmission reductionSolid fuelsCatalyst activation/preparationSolventOxygen

The invention discloses a preparation technology of a nanocatalysis medium for increasing coal combustion efficiency. The prepared catalysis medium is an oily liquid which is insoluble in water, has stable properties in the air, does not contain any explosive component or heavy metal component, and does not cause any damage to combustion equipment. The catalysis medium is characterized by consisting of a continuous solvent carrier phase component, a continuous solute carrier phase component, a continuous solute promoting phase component and a high-activity nanocatalysis medium dispersed phase. Due to the adoption of the coal nanocatalysis medium prepared with the technology, pulverized coal combustion can be promoted, the amount of fly ash, non-combusted carbon particles and residues is reduced, the using amount of coal is lowered, catalytic coal saving rate is up to 11-18 percent, the emission of pollutants such as Sox, NOx and the like is lowered effectively, the phenomena of coking and skin formation in a furnace are eliminated, stable combustion of pulverized coal is promoted, the flowing activity of oxygen is increased, the utilization ratio of oxygen is increased, the introducing amount of primary air is reduced, and energy loss caused by the introduction of inert gases is lowered.

Owner:郯城华彩混凝土有限公司

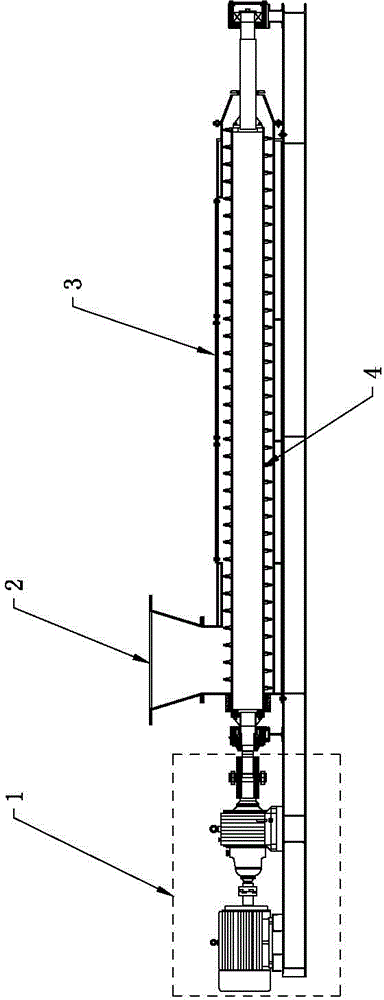

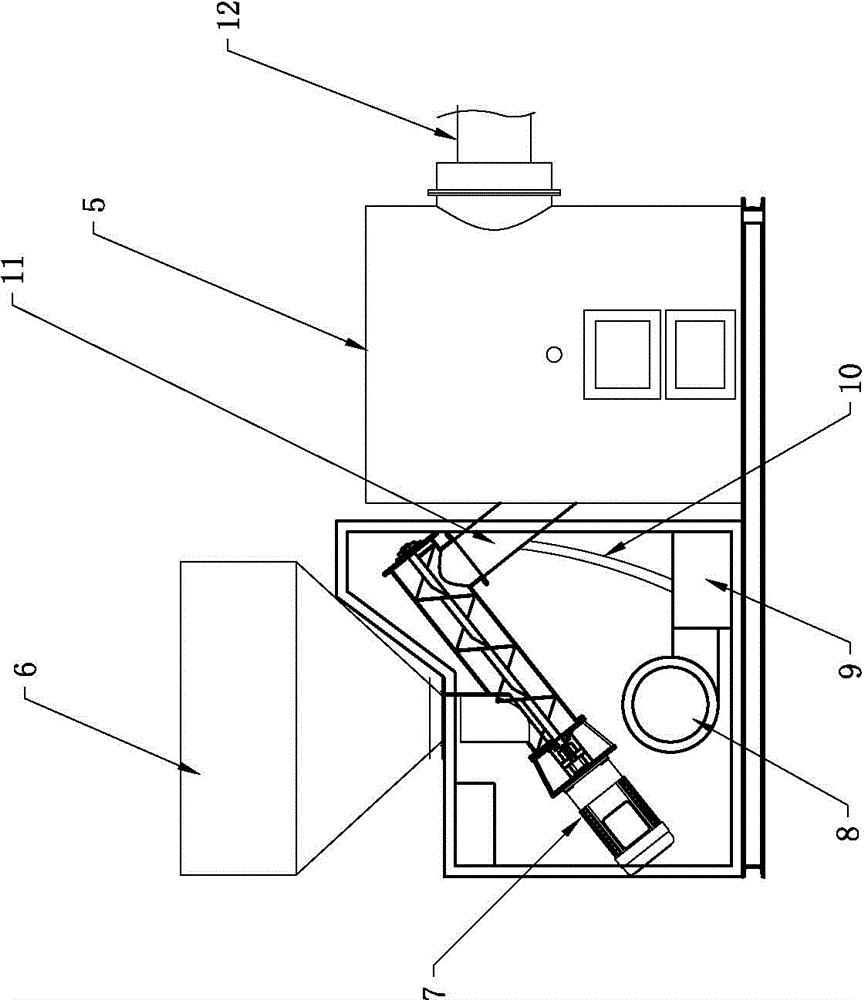

Biomass combustion device for docking boilers, heat exchangers, heating systems

InactiveCN103557516BSmall molecular weightAvoid cokingSolid fuel combustionNon-combustible gases/liquids supplyCarbonizationBiomass fuels

Biomass combustion device for docking boilers, heat exchangers, and heating systems, including the burner body, the carbonization machine used to generate the fuel required for combustion of the burner body, and the steam generator. The steam output pipe of the steam generator is connected to the combustion The furnace of the machine body is connected. After the biomass raw material is initially cracked by the carbonization machine, tar is precipitated, and the resulting biomass fuel has a low tar content, which effectively avoids coking in the furnace during the combustion process. At the same time, the use of steam to support combustion can not only help to eliminate coking, but also improve the fire temperature of the combustion flame, the biomass fuel rate and the calorific value. The present invention organically combines the carbonization machine, the steam generator and the burner itself to improve Traditional biomass burners have problems such as low combustion rate, easy coking, low work efficiency and unstable operation. In addition to being used for docking boilers, heat exchangers, and heating systems, the present invention can also be applied to other equipment or systems that use open flame heating, such as large thermal motors.

Owner:黎明 +1

Magnetic scraper loop reactor for coal direct liquefaction and coal direct liquefaction method thereof

InactiveCN100338179CNovel structureGood up and down circulationLiquid hydrocarbon mixture productionProcess equipmentProcess engineering

Owner:CHINA COAL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com