Settler-free gas-solid separation method and equipment

A gas-solid separation, non-settling technology, applied in the field of fluidization and petrochemical industry, can solve the problems of poor feeding leg of the secondary separator, catalyst loss, unfavorable flow of fine powder, etc., to reduce excessive oil and gas. Thermal cracking reaction, reduced dry gas yield, and smooth discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

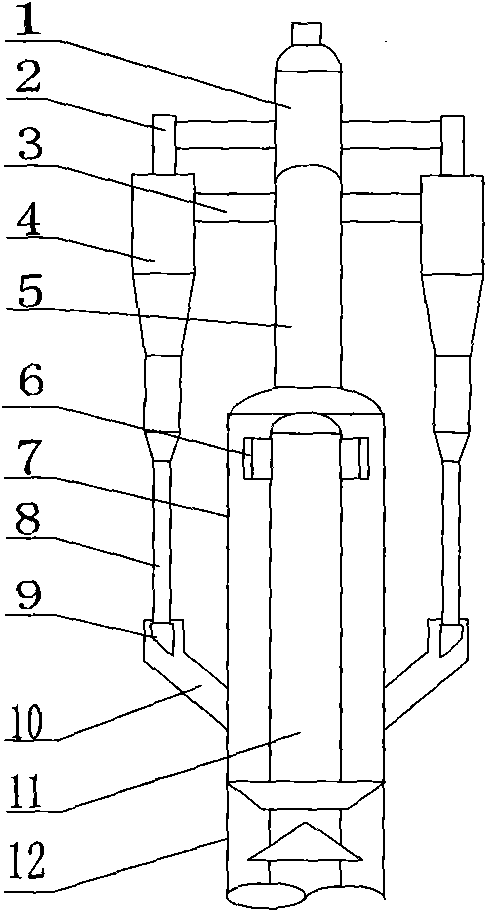

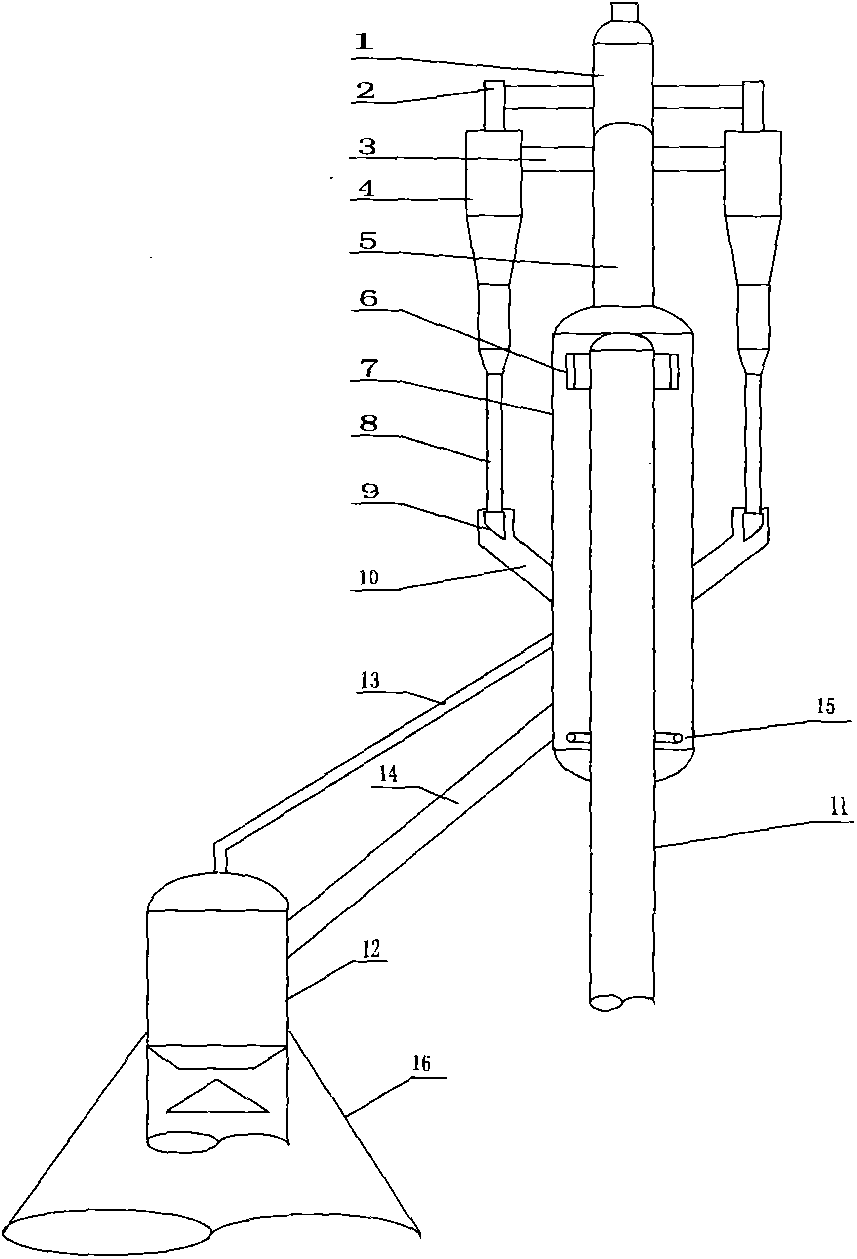

[0023] See figure 1 , the outlet of the riser 11 is connected to the cyclone 6, and the outer side of the cyclone 6 is provided with a sealing cover 7. The sealing cover 7 adopts a straight cylinder structure, the lower end of the sealing cover 7 is connected with the stripping section 12, and the upper end is connected with the secondary separator 4 through the sealing cover exhaust pipe 5 and the secondary inlet pipe 3. The upper end of the secondary separator 4 is connected to the outlet main pipe 1 through the secondary exhaust pipe 2, and the lower end is connected to the material leg 8 and the wing valve 9. The lower end of the catalyst guide pipe 10 is connected to the lower part of the sealing cover 7 , and the upper end wraps the wing valve 9 .

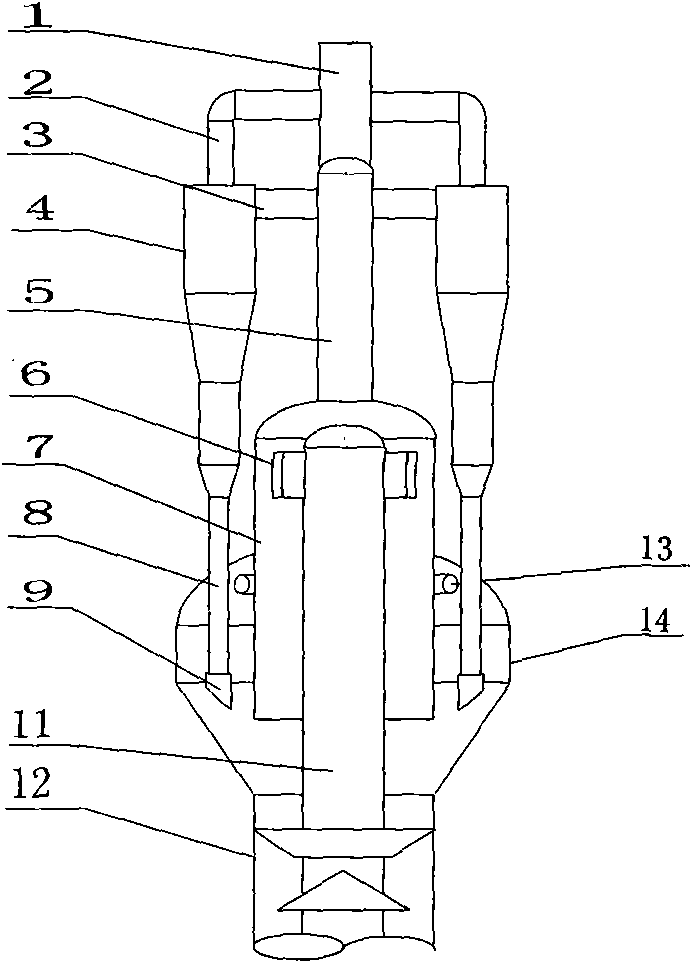

[0024] See figure 2 , There is a remodeling plan for the parallel device of the settler, the outlet of the riser 11 is connected with the cyclone 6, and the outer side of the cyclone 6 is provided with a sealing cover 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com