Coal nanocatalysis medium and synthesis process thereof

A nano-catalysis and synthesis process technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, petroleum industry, etc., can solve the problems of adding methods, unsatisfactory product dispersion, etc. Effects of energy loss and property stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

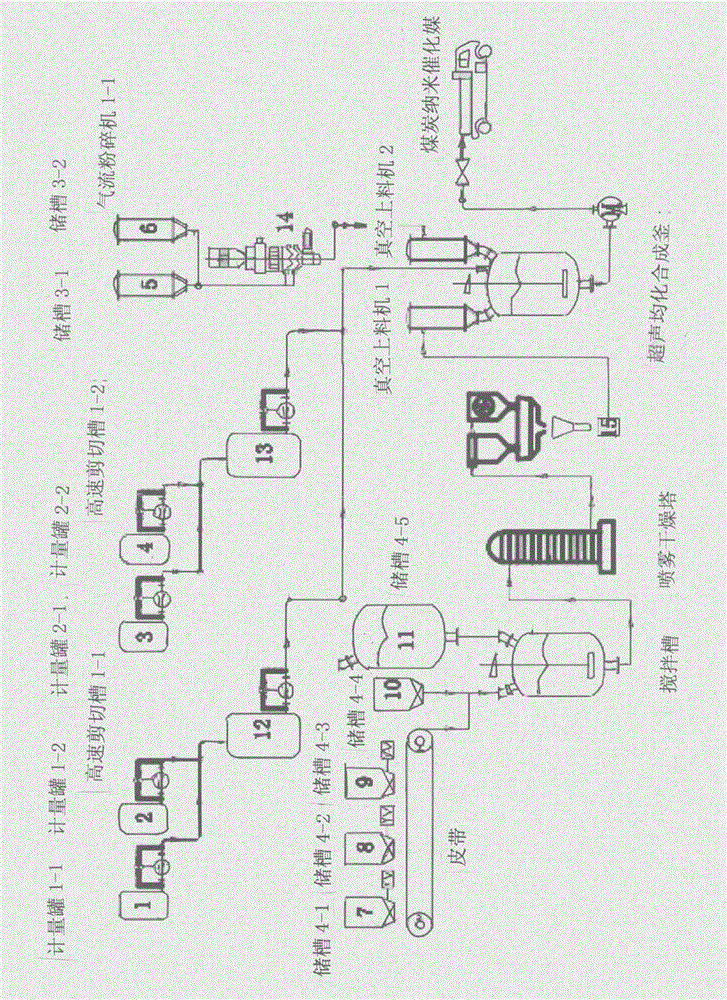

Method used

Image

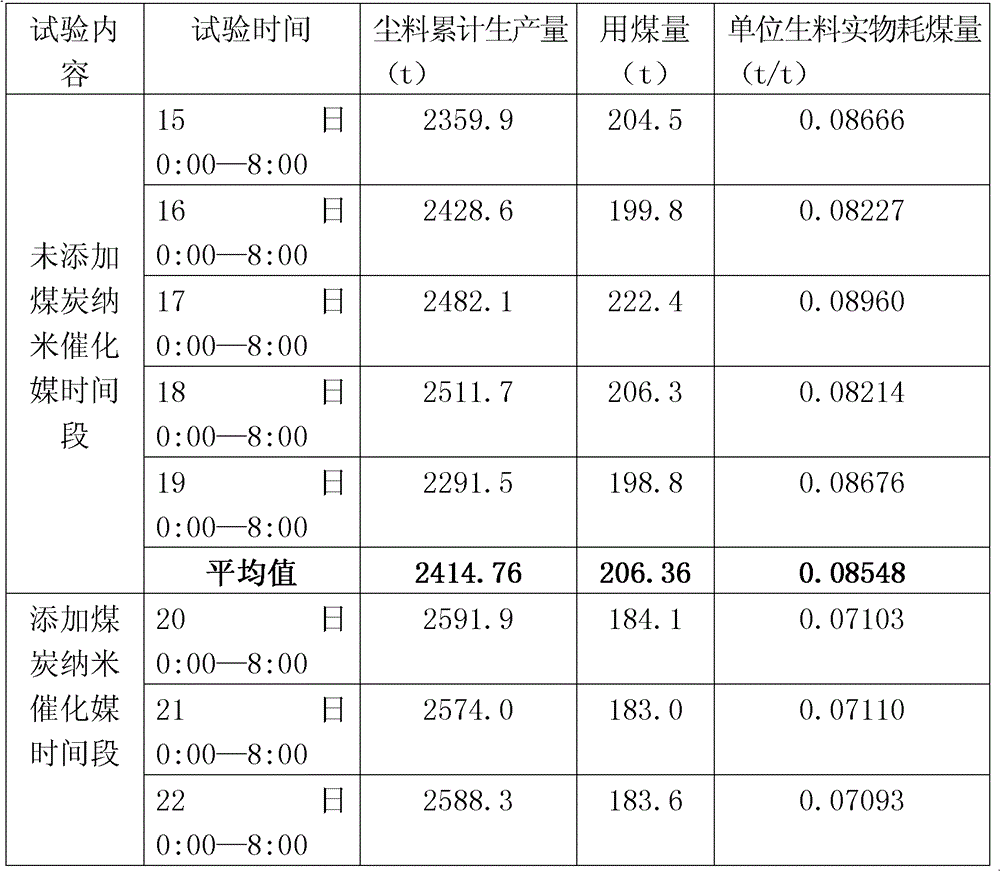

Examples

Embodiment Construction

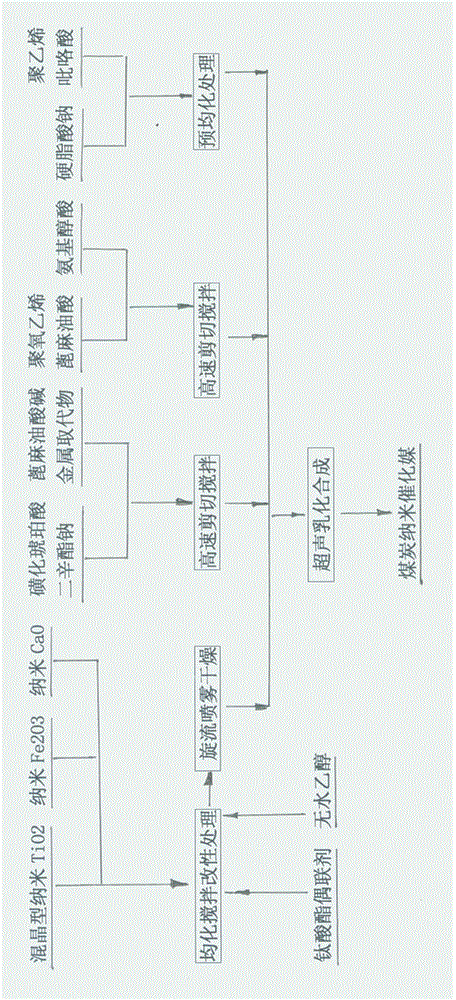

[0028] Catalyst catalyst main component of the present invention comprises:

[0029] Continuous solvent carrier phase component: composed of osmotic unit dioctyl sodium sulfosuccinate and oxidation unit ricinoleic acid alkali metal substitute, accounting for 50%-70% of the total weight;

[0030] Continuous solute carrier phase component: composed of dispersed units polyoxyethylene ricinoleic acid and amino alkyd, accounting for 5%-10% of the total weight;

[0031] Continuous solute carrier promoting phase component: composed of emulsifying unit sodium stearate and surface active unit polyvinylpyrrolidone, accounting for 20%-30% of the total weight;

[0032] Dispersed phase component of highly active nano-catalyst: mixed crystal nano-TiO 2 , Nano Fe 2 o 3 , and nano-CaO together, accounting for 5%-10% of the total weight.

[0033] Technical scheme of the present invention is, its step:

[0034] (1) 65%-85% permeation unit dioctyl sodium sulfosuccinate and 15%-35% oxidation u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com