Magnetic scraper loop reactor for coal direct liquefaction and coal direct liquefaction method thereof

A loop reactor and direct coal liquefaction technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve problems such as long-term stable operation, harsh operating conditions, and wear of circulating pumps, and achieve novel and unique structures and high working atmosphere. The effect of improving and improving the hydrogen supply performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

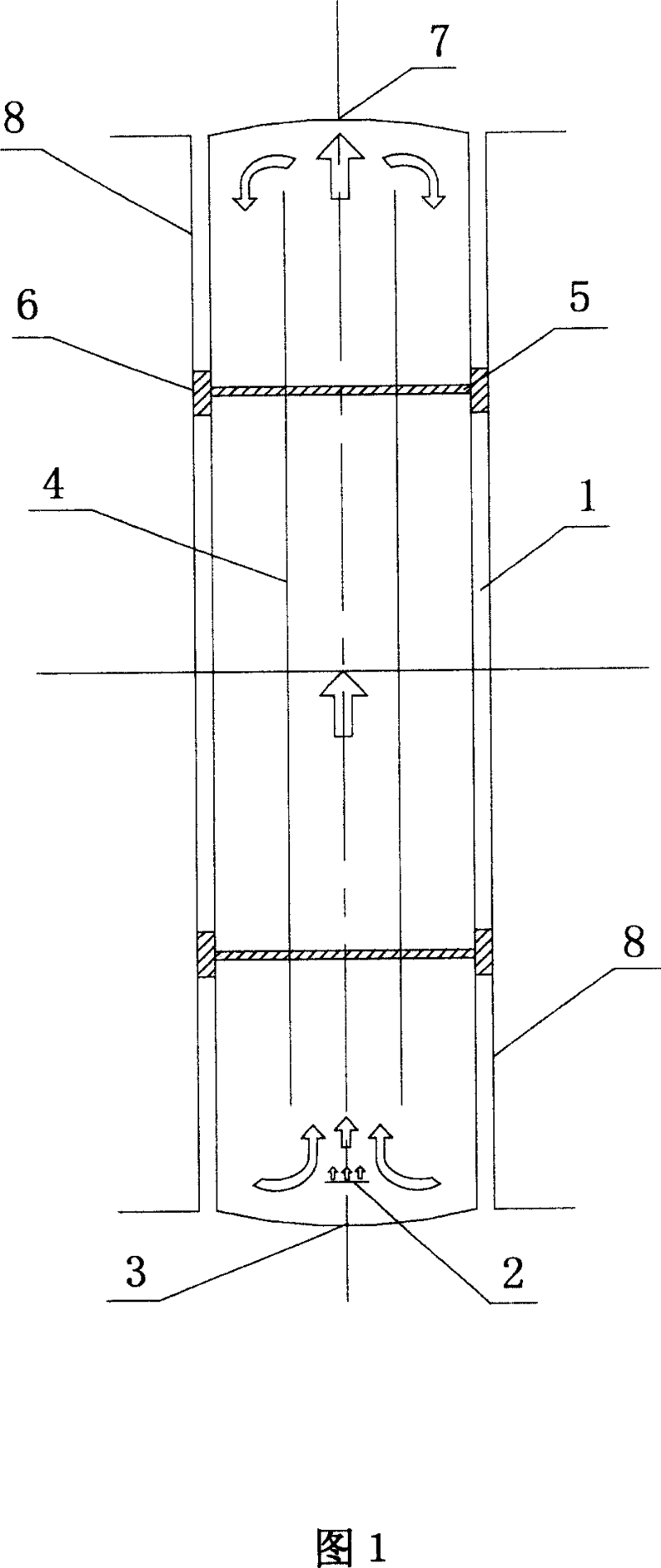

Embodiment 1

[0023] For the gas-liquid system, atmospheric pressure air is used as the gas medium, and the liquid phase medium is distilled water-Span system. Its density and viscosity are basically consistent with the properties of oil-coal slurry under actual reaction conditions. The experimental reactors are bubbling bed liquefaction reaction. reactor and magnetic scraper loop reactor. Among them, the inner diameter of the outer cylinder of the bubbling bed liquefaction reactor is 0.07m, the total height of the reactor is 2.0m, the reactor has a flat bottom, no central tube, the distributor is an empty tube with an inner diameter of 6mm, and the outlet plane of the distributor is flush with the bottom surface. The outer diameter of the magnetic scraper loop reactor is 0.07m, the inner diameter of the central tube is 0.045m, the wall thickness is 5mm, the total height of the reactor is 2.0m, the reactor has a flat bottom, the height of the central tube is 1.8m, and the height from the bot...

Embodiment 2

[0027] For the gas-liquid system, atmospheric pressure air is used as the gas medium, and the liquid phase medium is distilled water-Span system. Its density and viscosity are basically consistent with the properties of oil-coal slurry under actual reaction conditions. The experimental reactors are bubbling bed liquefaction reaction. reactor and magnetic scraper loop reactor. Among them, the inner diameter of the outer cylinder of the bubbling bed liquefaction reactor is 0.07m, and the total height of the reactor is 2.0m. flush. Add a small amount of viscous oil that is easy to adhere to the inner wall of the outer cylinder into the liquid phase system.

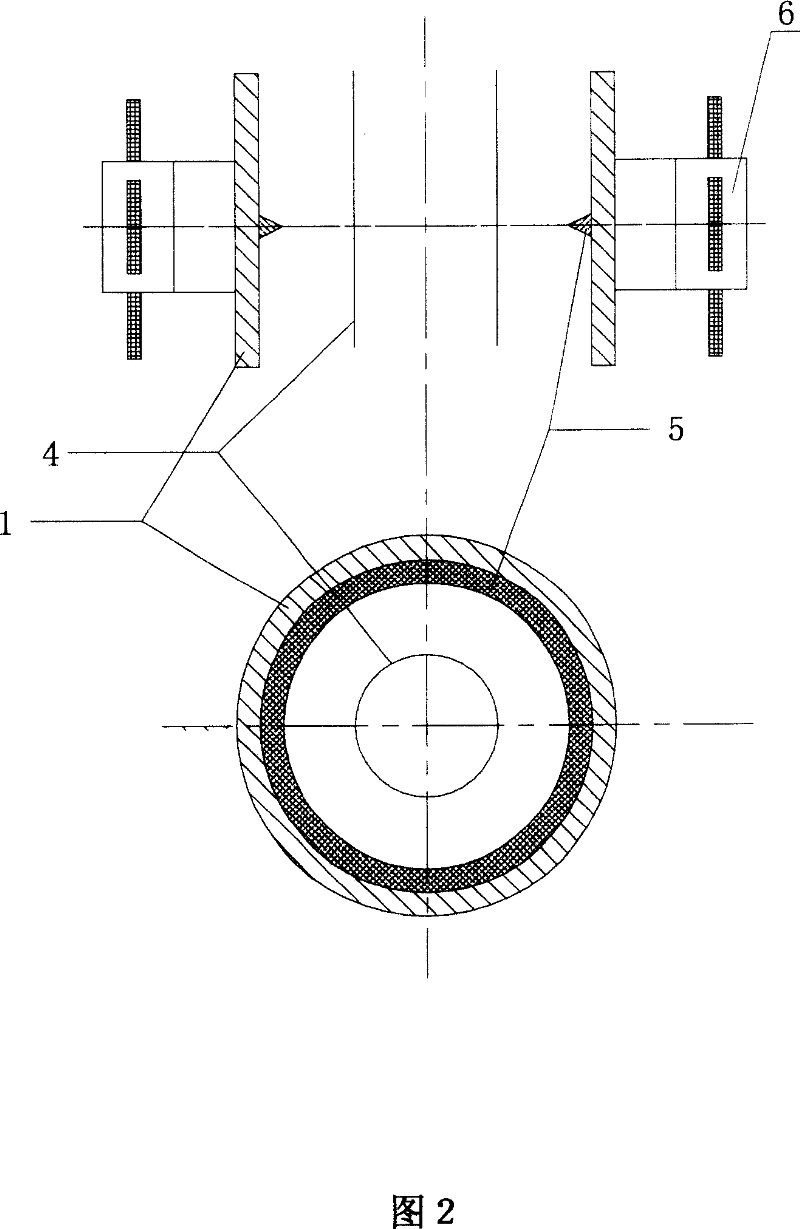

[0028] The diameter of the outer cylinder 1 of the circulation reactor with a magnetic scraper (as shown in Figure 1) is 0.07m, the inner diameter of the center pipe 4 is 0.045m, the wall thickness is 5mm, the total height of the reactor is 2.0m, the reactor is flat bottom, and the height of the center pipe is 1.8m , the heig...

Embodiment 3

[0031] In the experiment, the liquefaction results of a young bituminous coal in the same first-stage countercurrent reactor and second-stage magnetic scraper loop reactor and online hydrogenation reactor connected in series as in Example 1 were compared with a young bituminous coal in two The liquefaction results of the traditional coal liquefaction process with four bubbling bed reactors in series are listed in Table 1.

[0032] countercurrent reactor

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com