A continuous rectification system and process of bio-aviation kerosene based on shallow liquid layer evaporator

A technology for aviation kerosene and rectification system, which is applied in the field of bio-aviation kerosene continuous rectification system and process, can solve the problems of high operating cost, increased fouling thermal resistance, long residence time, etc., so as to improve the rectification yield and oil The effect of improving the quality of the product, increasing the amount of heating vaporization, and reducing the thickness of the liquid layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the drawings:

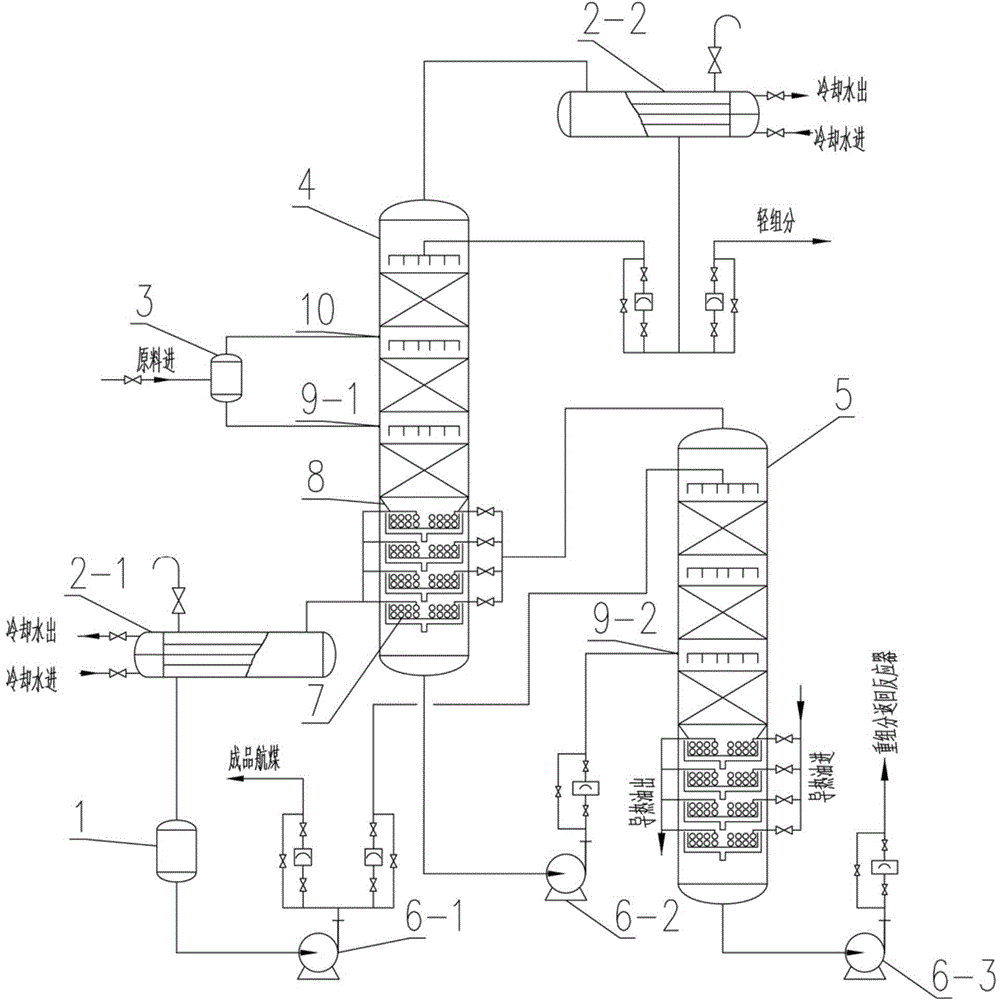

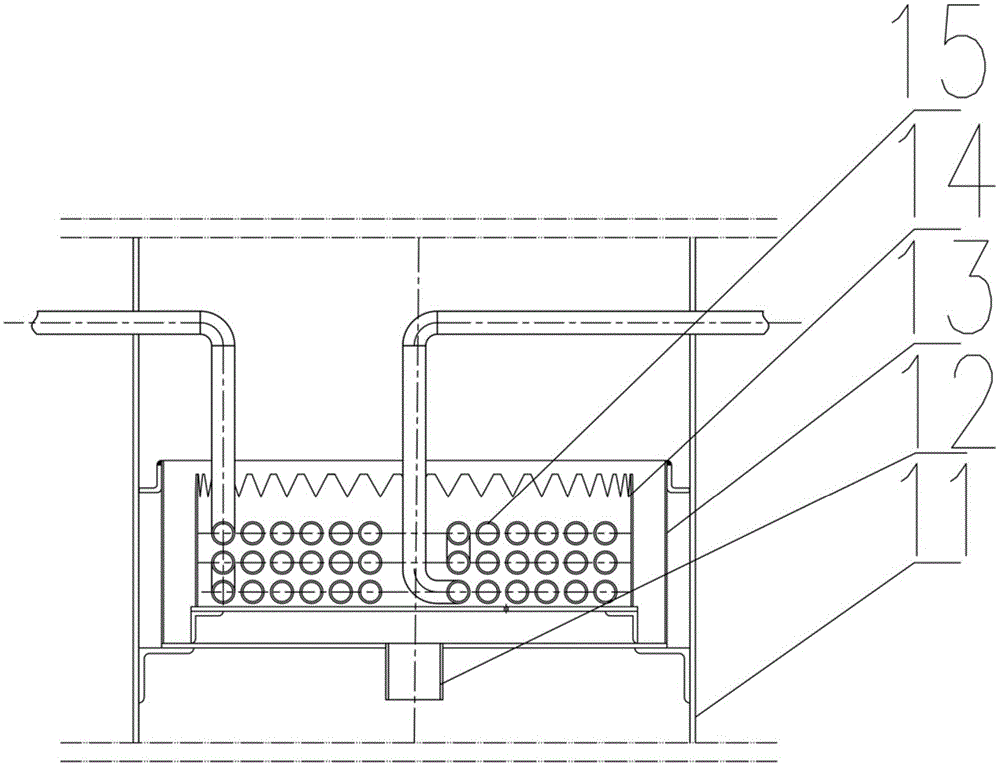

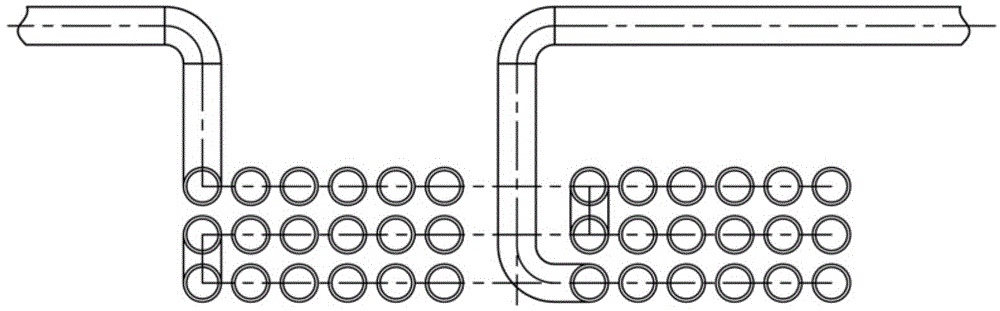

[0022] As shown in the figure, this kind of biological aviation kerosene continuous rectification system based on shallow liquid layer evaporator mainly includes light removal tower 4 and finished product tower 5. The bottoms of light removal tower 4 and product tower 5 are equipped with shallow liquid evaporation The vapor phase inlet 10 of the light-removing tower and the liquid phase inlet 9-1 of the light-removing tower are connected to the flash tank 3. The top of the light-removing tower 4 is connected with condenser II 2-2, and the bottom of the light-removing tower 4 is passed through the discharge pump Ⅱ6-2 is connected to the liquid phase inlet 9-2 of the finished product tower, the top of the finished product tower 5 is connected to one side of the shallow liquid layer evaporator of the light removal tower 4, and the other side of the shallow liquid layer evaporator of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com