Energy-saving and environment-friendly distillation recovery device

A technology of distillation recovery, energy saving and environmental protection, which is applied in the field of energy saving and environmental protection, can solve the problems of environmental pollution, water resource waste, etc., and achieve the effects of ensuring personal safety, saving electric energy, and preventing the leakage of vapors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

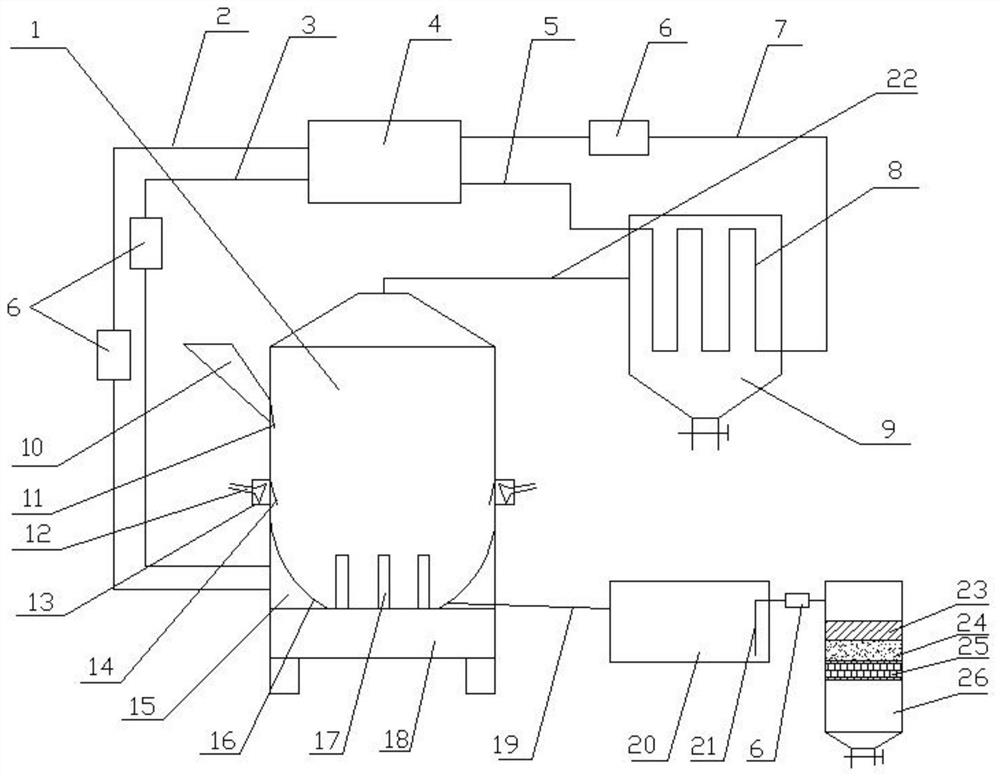

[0026] Such as Figure 1-2 As shown, a kind of energy-saving and environment-friendly distillation recovery device comprises a distillation tank 1, an intermediate tank 4, a receiving tank 9, a recovery tank 20 and a filter tank 26, and one side of the distillation tank 1 is provided with a feed hopper 10, and the distillation The top of the tank 1 is a distillation outlet, and the steam inlet pipe 22 is connected between the distillation outlet and the receiving tank 9;

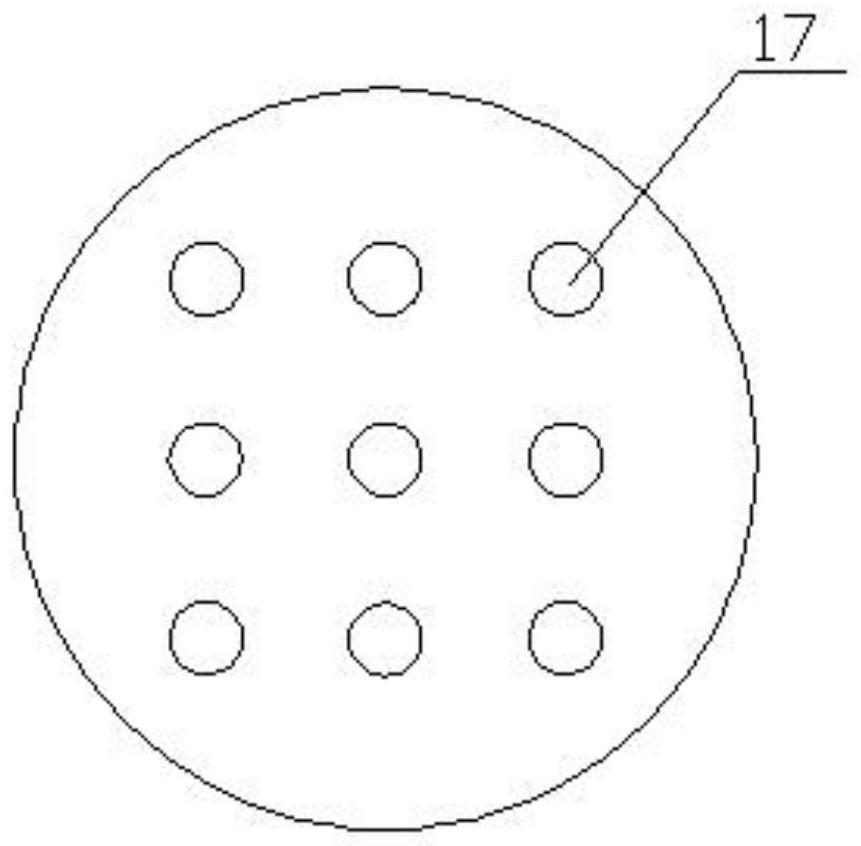

[0027] The bottom of the retort 1 is provided with a heating device 18, the upper end of the heating device 18 is fixed with a material holding chamber 16, the side wall of the material holding chamber 16 is a spherical surface, and a cooling chamber 15 is left between the material holding chamber 16 and the side wall of the retort 1 , the first cooling water inlet pipe 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com