Novel flow aid technology promoting mixing of raw oil and catalyst in catalytic cracking riser feeding area

A technology of flow aids and risers, applied in the field of flow aids, can solve the problems of slow oil contact, unreasonable matching, uneven matching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

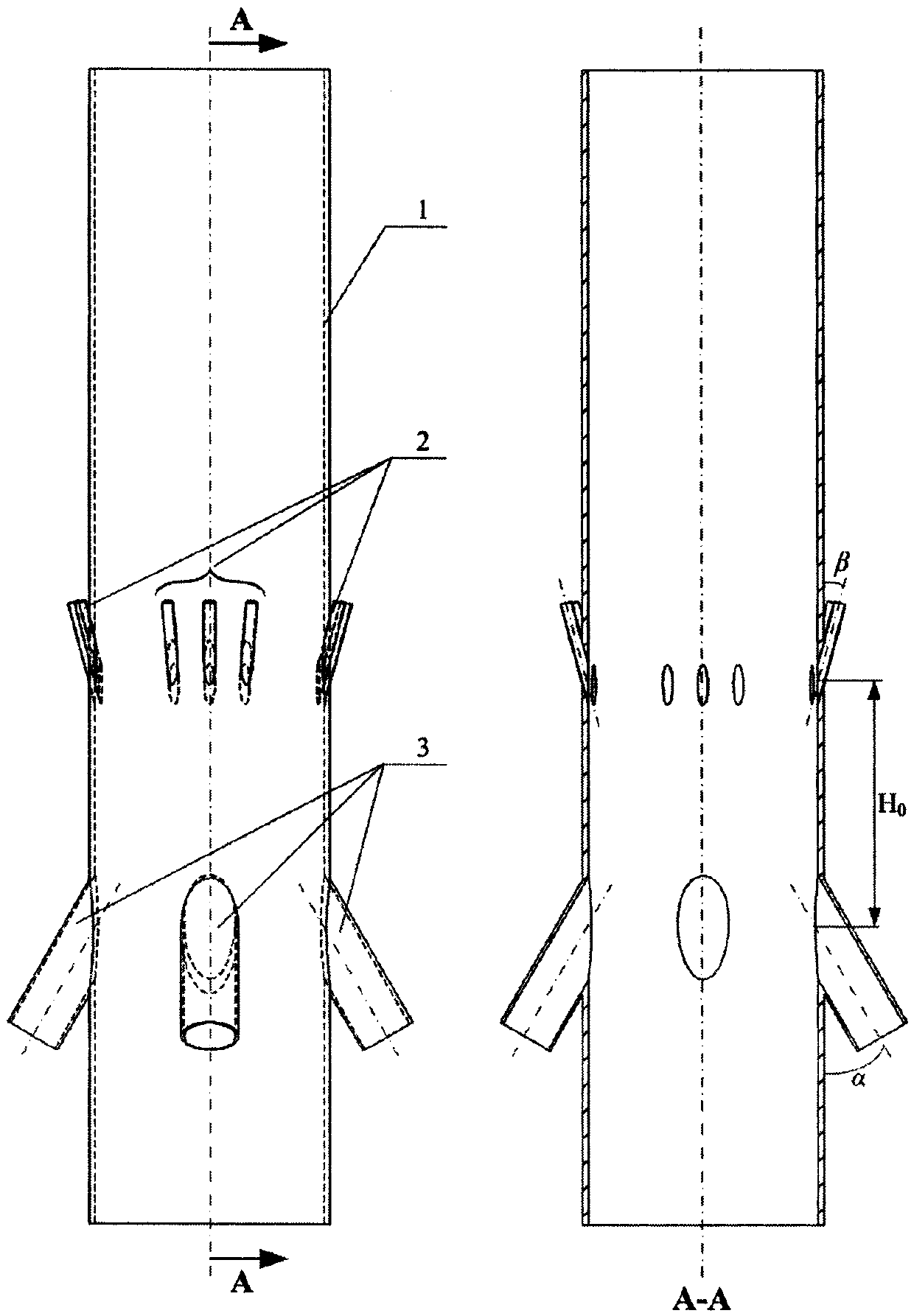

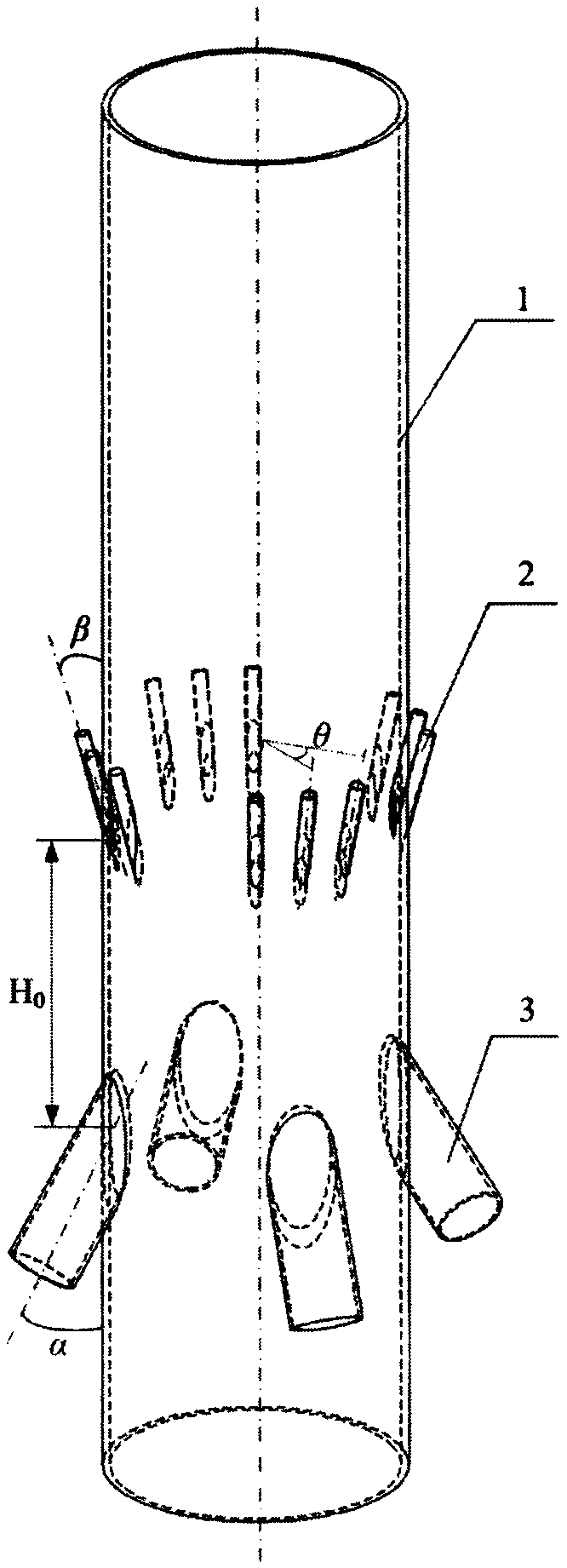

[0022] The present invention is further described with reference to the accompanying drawings and embodiments:

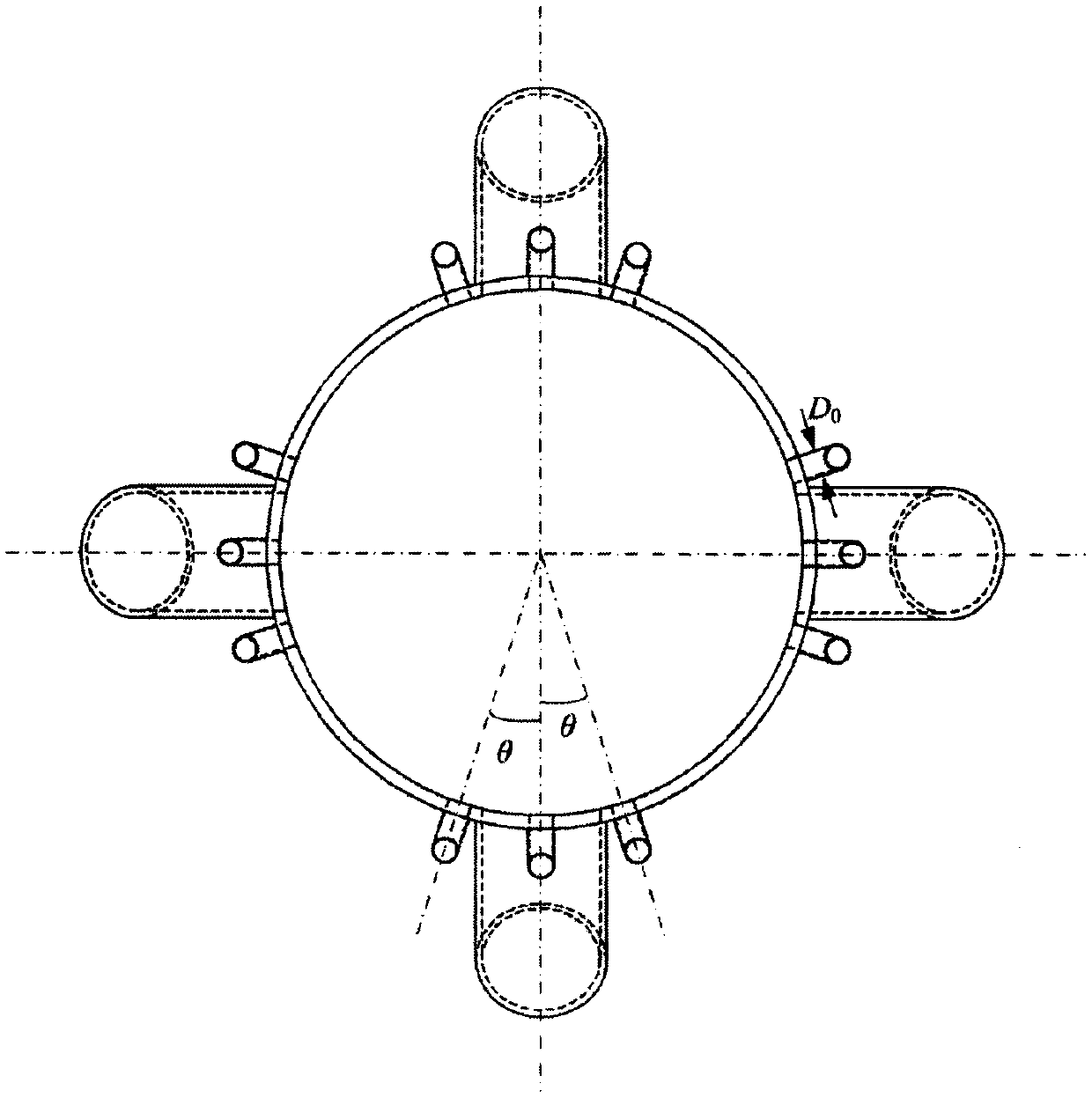

[0023] figure 1 Shown is a front view block diagram of the glidant technology of the present invention. In the feed mixing section (1) of the riser, the flow of catalyst particles flows from bottom to top; while the flow aid is injected obliquely downward through the flow aid nozzle (2), and is installed with the casing ( 3) The feedstock oil injected obliquely upwards collides; thereby forming an impinging flow, suppressing the secondary flow formed by the injection jet flow of feedstock oil, eliminating strong back-mixing and coking on the side wall, and promoting the rapid mixing and matching of feedstock oil and catalyst, and then Improve reaction efficiency and product yield.

[0024] The flow aid nozzle of the present invention is installed above the feedstock oil nozzle H 0 = 0.1 ~ 2m position, in this embodiment H 0 is 0.15m. The installation angle β is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com