Eccentric rotor and axial space type coreless vibration motor having the rotor

An eccentric rotor and gap-type technology, which is applied in electric components, telephone communications, electrical components, etc., can solve the problems of durability, bearing length reduction, unevenness and other problems, and achieve the effect of increasing the effective magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

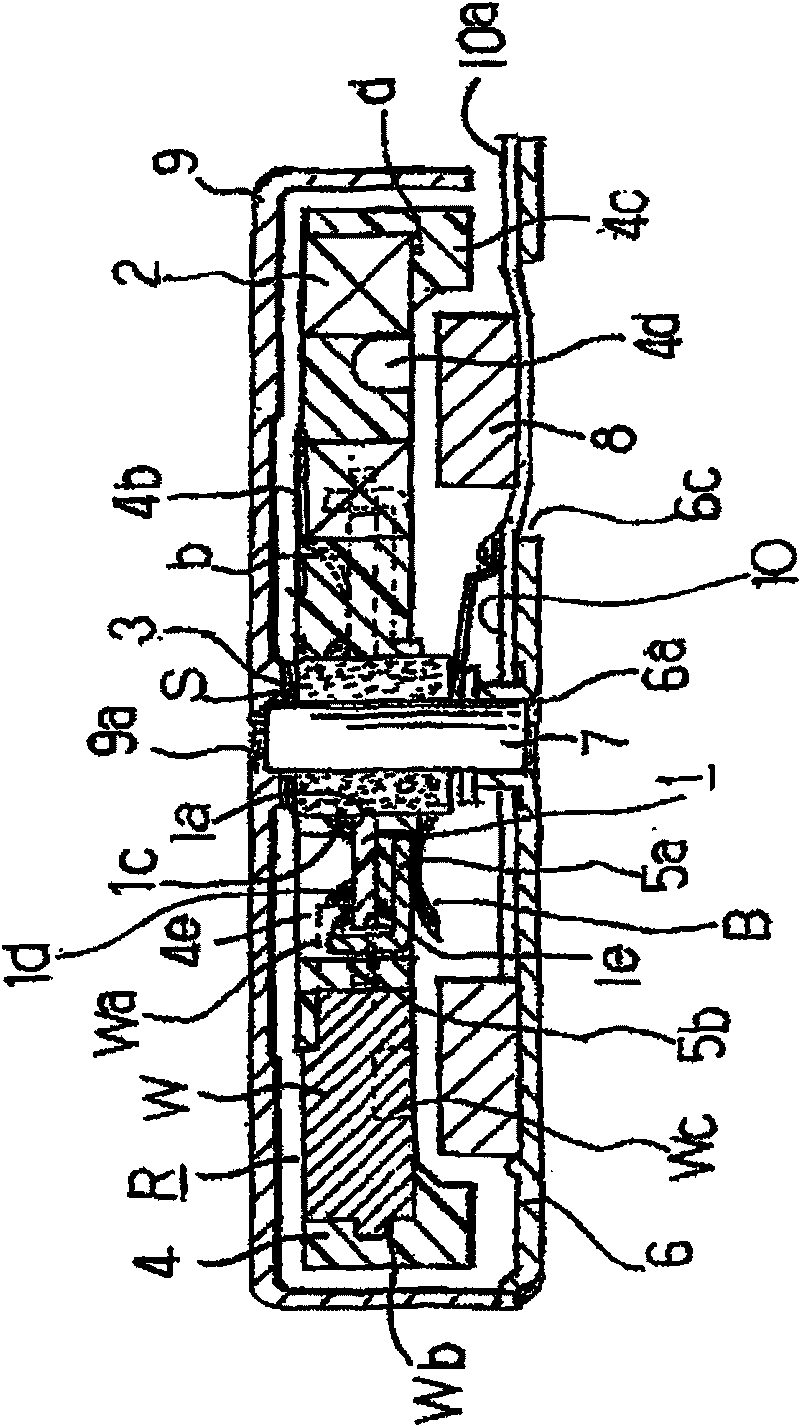

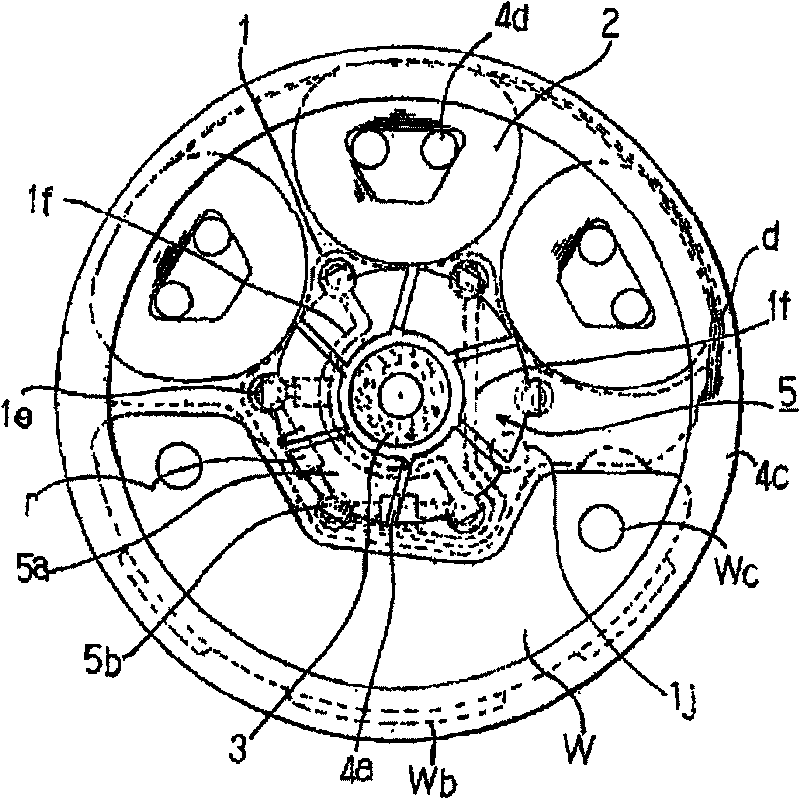

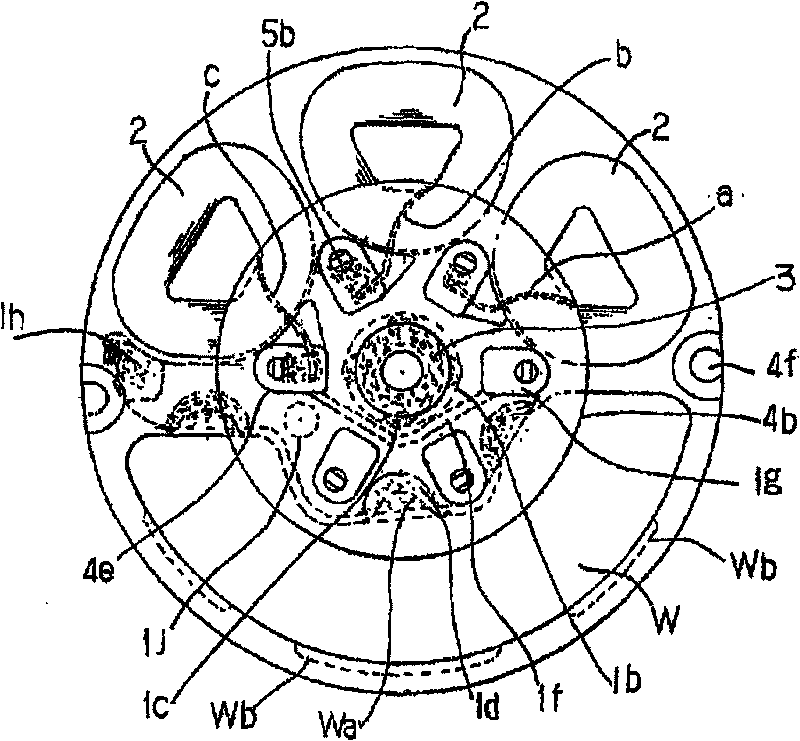

[0029] Figure 1 ~ Figure 3 In the axial gap type eccentric rotor R according to Embodiment 1 of the present invention, the following components are arranged: a printed wiring board 1 having a shaft support hole 1a formed in the center; A plurality of (here, three arranged at an arrangement pitch of 60°) hollow armature windings 2 that do not overlap the printed wiring board 1; bearings 3 that are assembled and joined to the above-mentioned shaft support hole 1a; A resin 4 with a temperature of 250° C. or higher is integrated with a partly welded eccentric weight W, and a plurality (here, 6 pieces) of commutator segments 5 are formed by covering the surface with noble metal.

[0030] The bearing 3 installed in the shaft support hole 1a of the above-mentioned printed wiring board 1 is soldered and bonded to the shaft support formed by printing with the solder part 1c after measuring its perpendicularity with a ruler, and then irradiated with laser light that does not easily tra...

Embodiment 2

[0040] Figure 4 ~ Figure 6 middle, Figure 4 express image 3 Here is an embodiment in which two wire-wound hollow armature windings 22 are arranged at an opening angle of about 120 degrees, wherein the effective conductor part of the wire-wound hollow armature winding 22 is separated to the magnetic pole of the combined magnet. The degree of opening angle (here is 90°), thus improving the efficiency. Here, in order to ensure the efficiency of the coils, the printed wiring board 11 is overlapped with these coils to form a winding start connection pattern 11k, and a winding end unified connection pattern 11h is formed between each coil. The winding start end 22a of each coil 22, 22b is soldered to the above-mentioned winding start connection pattern 11k, and the winding end terminal 22d is soldered to the above-mentioned unified connection pattern 11h. The outer periphery of the sintered oil-impregnated bearing 3 is connected to the joining pattern 11b by soldering, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com