Physical generating apparatus for fuel-oil additive

A generating device and additive technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of single effect and insufficient combustion-supporting effect of multi-fuel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

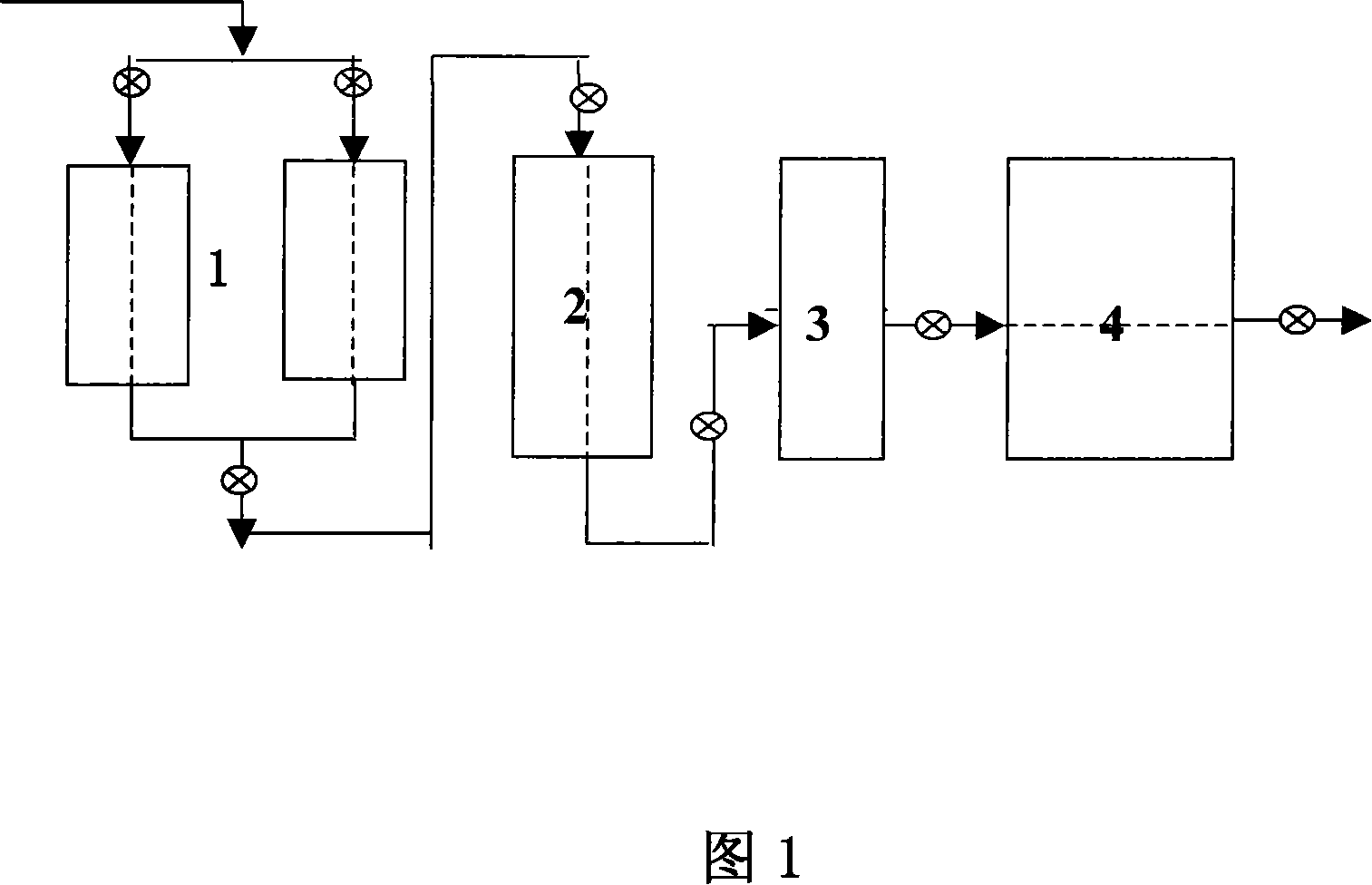

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail: as shown in Figure 1, raw material kerosene first passes through nuclear magnetic resonance generator 1 through pipeline, carries out physical electronic wave action to the raw material kerosene flowing through by the wave liquid. The vibration frequency of the induction field can be consistent with the internal natural frequency of the carbon-hydrogen building to generate resonance, thereby aggravating the vibration of the carbon-hydrogen bond, and finally breaking the carbon-hydrogen bond into smaller particles, changing the fuel composition. The state of mutual bonding. At the same time, the magnetic momentum generated by its supermagnetic force rearranges the electrons in the molecules and atoms in the fuel, ionizes the fuel molecules, and makes the molecules arrange evenly. The best combustion effect, more complete combustion to save fuel and reduce exhaust emissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com