Device for decomposing trimethylamine malodorous gas

A technology of malodorous gas and trimethylamine, which is applied in gas treatment, separation method, and separation of dispersed particles, etc., can solve the problems of improvement of purification efficiency, change of discharge stability, and insufficient reaction time, so as to ensure the utilization rate of ozone and improve energy efficiency , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

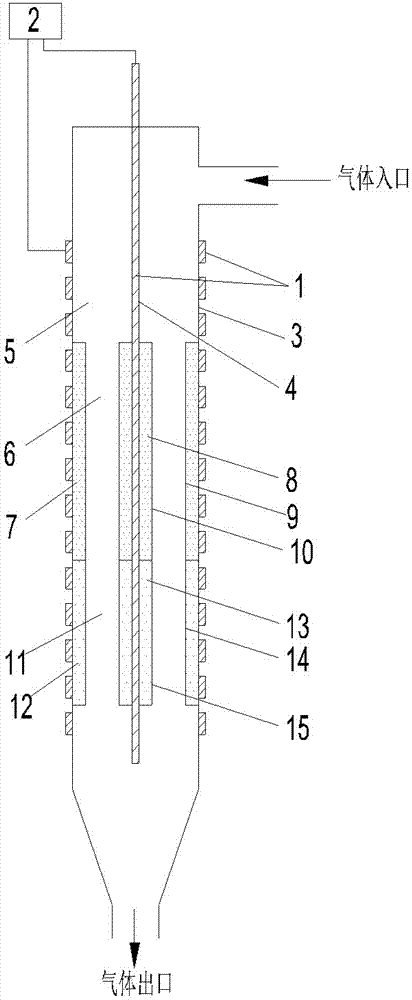

Embodiment 1

[0033] Adopt the technology of the present invention to process the odorous gas containing trimethylamine, adopt the inner medium of the quartz tube with the wall thickness of 2mm and the inner diameter of 35mm, and the outer medium of the quartz tube with the wall thickness of 2mm and the outer diameter of 60mm, and fill it in the sealed cavity of the deep ultraviolet radiation area and the outer area. 30000 Pa argon gas and 900 Pa chlorine mixed gas, the inner and outer areas of the light ultraviolet radiation area, the filled airtight cavity is filled with 35000 Pa krypton gas and 600 Pa fluorine mixed gas, the discharge voltage is 5000 V, and the inlet concentration of trimethylamine 1500mg / m 3 , the residence time of trimethylamine gas in the reactor is about 0.8 s, and the degradation rate of trimethylamine after treatment is 77.2%.

Embodiment 2

[0035] Adopt the technology of the present invention to process the odorous gas containing trimethylamine, adopt the inner medium of the quartz tube with the wall thickness of 2mm and the inner diameter of 35mm, and the outer medium of the quartz tube with the wall thickness of 2mm and the outer diameter of 60mm, and fill it in the sealed cavity of the deep ultraviolet radiation area and the outer area. 35000 Pa xenon gas, the inner and outer areas of the light ultraviolet radiation area, the filled airtight cavity is filled with 20000 Pa krypton gas and 800 Pa chlorine mixed gas, the discharge voltage is 9000 V, and the intake concentration of trimethylamine is 900mg / m 3 , the residence time of trimethylamine gas in the reactor is about 1.2 s, and the degradation rate of trimethylamine after treatment is 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com