Vaporization method and vaporization device of dimethyl oxalate

A technology of dimethyl oxalate and vaporization tower, which is applied in chemical instruments and methods, boiling devices, feeding devices, etc., can solve the problems of short operation period of hydrogenation reaction system, increase of resistance of vaporization tower and catalyst bed, etc., and achieve Guarantee long-term stable operation, extend the operation cycle, and reduce the effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The vaporization method of embodiment 1 dimethyl oxalate

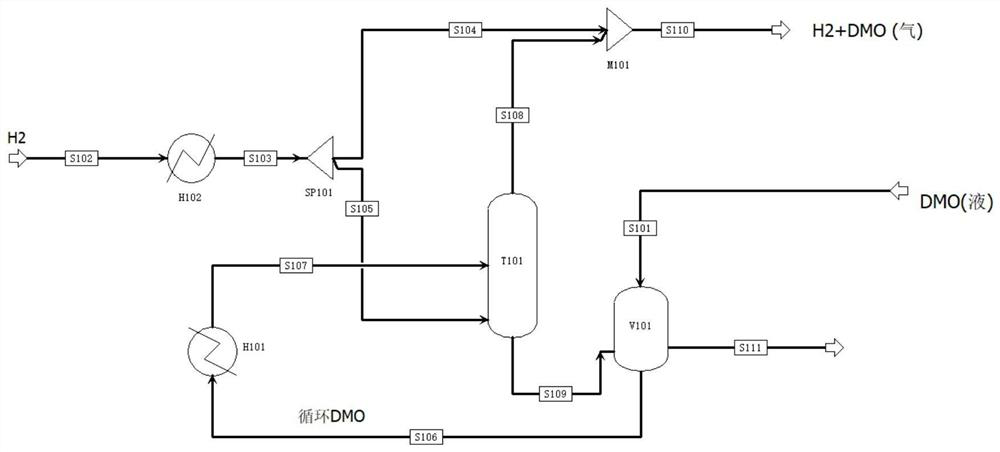

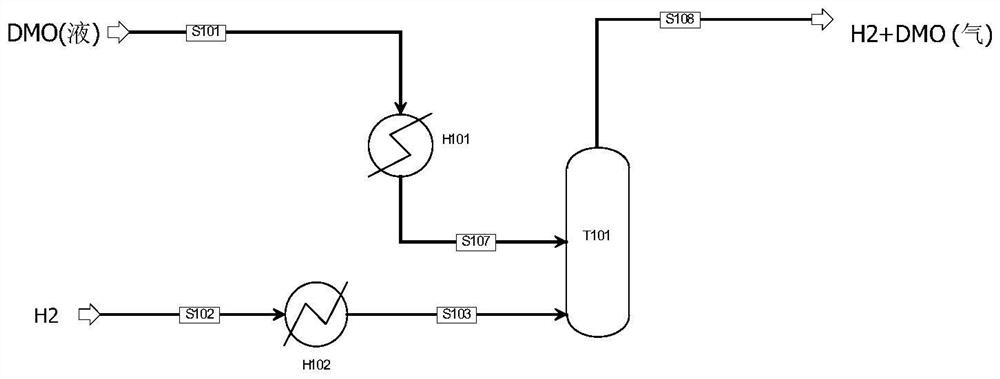

[0050] The technological process of this embodiment is as figure 1 As shown, the specific process flow is described as follows:

[0051] The DMO fresh feed S101 and the DMO circulating material S109 from the bottom of the vaporization tower T101 respectively enter the DMO circulating storage tank V101 for mixing, and the circulating ratio is 18.8. The DMO feed S106 flowing out of the DMO circulation storage tank V101 is sent to the preheater H101 to be preheated to 160°C, and the preheated DMO feed S107 then enters the middle of the two-layer packing of the vaporization tower T101 in liquid phase, and passes through Liquid distributor for spraying.

[0052] The total hydrogen feed S102 is preheated to 180°C by the preheater H102 to obtain the preheated total hydrogen feed S103, and the hydrogen ester ratio is controlled to be 50. According to the heat required to vaporize the DMO feed S107, the total hydrogen...

Embodiment 2

[0055] The vaporization method of embodiment 2 dimethyl oxalate

[0056] The flow chart is the same as in Embodiment 1, the difference is:

[0057] The cycle ratio of DMO fresh feed and DMO cycle material is controlled to be 12.9.

[0058] The DMO feed S106 is sent to the preheater H101 to be preheated to 180°C.

[0059] The total hydrogen feed S102 is preheated to 200°C through the preheater H102.

[0060] The volume flow of the second hydrogen feed S105 is controlled to be 34% of the volume flow of the total hydrogen feed S102.

[0061] Control the operating gas-liquid ratio in the vaporization tower T101 to be 14.

[0062] The theoretical plate number corresponding to the packing height required to control the vaporization tower is 1, and the operating pressure of the vaporization tower is 3Mpa.

Embodiment 3

[0063] The vaporization method of embodiment 3 dimethyl oxalate

[0064] The flow chart is the same as in Embodiment 1, the difference is:

[0065] The cycle ratio of DMO fresh feed and DMO cycle material is controlled to be 10.9.

[0066] The DMO feed S106 is sent to the preheater H101 to be preheated to 190°C.

[0067] The total hydrogen feed S102 is preheated to 210°C through the preheater H102.

[0068] The volume flow of the second hydrogen feed S105 is controlled to be 26% of the volume flow of the total hydrogen feed S102.

[0069] Control the operating gas-liquid ratio in the vaporization tower T101 to be 13.

[0070] The theoretical plate number corresponding to the packing height required for controlling the vaporization tower is 1, and the operating pressure of the vaporization tower is 5Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com