Waste lubricating oil regeneration method and system

A waste lubricating oil and regeneration system technology, applied in the direction of lubricating compositions, etc., can solve problems such as easy coking and clogging of equipment during operation, complicated equipment technology, and serious secondary pollution, etc., to achieve extended stable operation period, reduced solvent loss, cooling The effect of reducing source consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

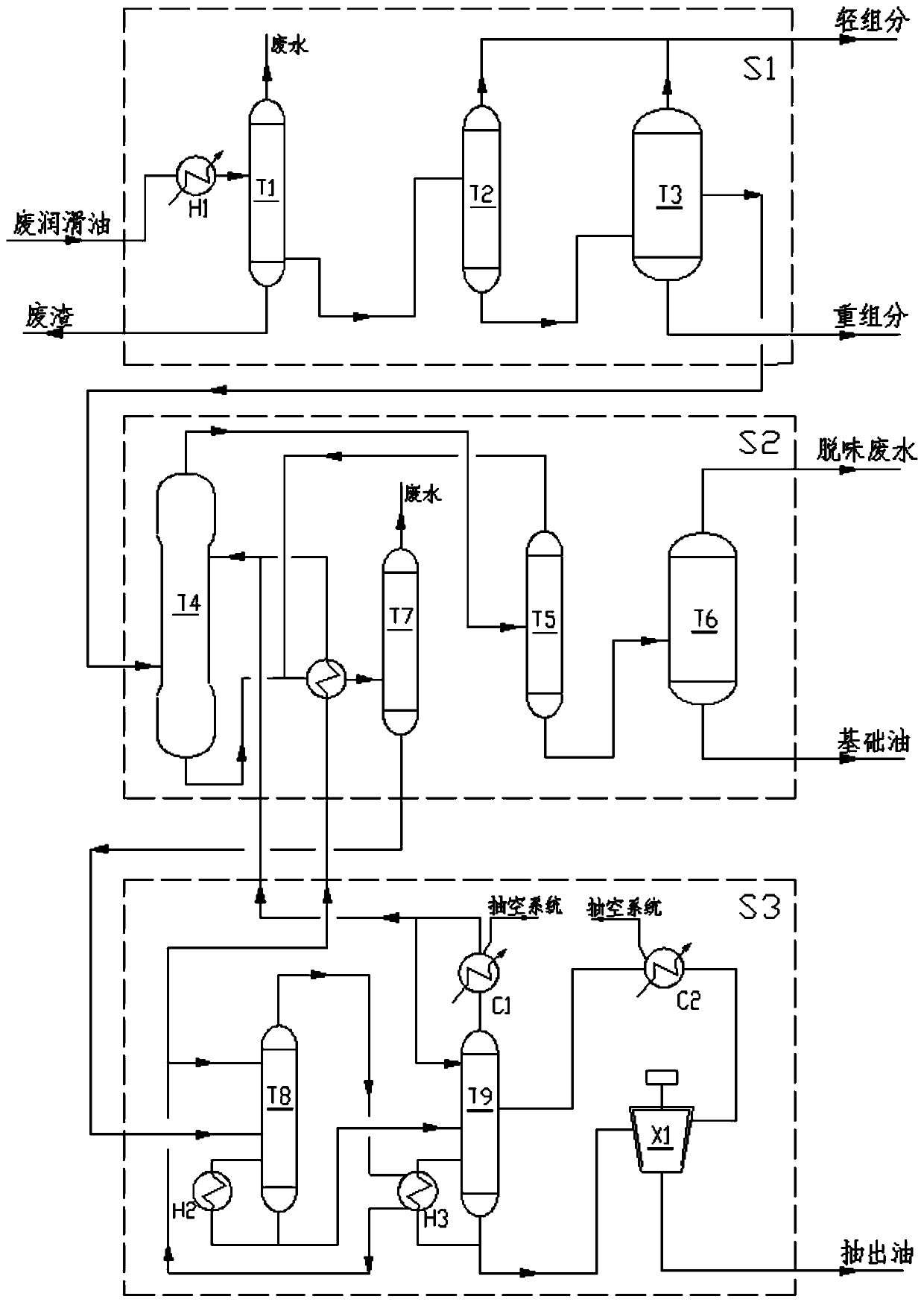

[0025] This embodiment adopts figure 1 The waste lubricating oil regeneration system shown performs regeneration of waste lubricating oil using N-methylpyrrolidone (NMP) as a solvent, and the regeneration method is as follows:

[0026] 18.18t / h of waste lubricating oil raw material is pretreated to remove water, light components and heavy components, and the base distillate oil produced is 15.05t / h into the solvent extraction tower T4, and the solvent NMP volume after regeneration is 30.0t / h (The extraction ratio is selected as 2:1) into the solvent extraction tower T4, the raffinate phase is desolventized, stripped and deodorized to obtain 12.12t / h base oil; the flow rate of the extracted phase is 32.83t / h after heat exchange drying and light removal The temperature is 180°C and enters the first-effect regeneration tower T8.

[0027] The operating pressure of the first-effect regeneration tower T8 is normal pressure, the temperature at the top of the tower is 202°C, bubble p...

Embodiment 2

[0031] Using the same waste lubricating oil regeneration process as in Example 1, the operating pressure of the first-effect regeneration tower T8 is 0.10MPa, the tower top temperature is 220°C, the bubble point is refluxed, the reflux ratio is 0.5, the output is 11.0t / h, and the tower kettle reboiler , the normal heat load is 2.36MKcal / h; the operating pressure of the second-effect regeneration tower T9 is 1.0KPa(A), the temperature at the top of the tower is 72.5°C, the gas phase temperature at the bottom of the tower is 120°C, the reflux ratio is 0.56, and the output is 19.0t / h. The operating pressure of the primary evaporator T8 is 1.0KPa(A), the evaporation temperature is 230°C, the processing feed rate is 3.0t / h, it is heated by heat conduction oil, and the heat load is 0.22MKacal / h, and the output oil flow rate is 2.83t / h, of which NMP content 0.1%.

[0032] It can be seen from the above results that after changing the operating temperature and pressure of the two regen...

Embodiment 3

[0034] This embodiment adopts figure 1 The waste lubricating oil regeneration system shown performs regeneration of waste lubricating oil using N-methylpyrrolidone (NMP) as a solvent, and the regeneration method is as follows:

[0035] After 7.0t / h of waste lubricating oil raw material is pretreated to remove water, light components and heavy components, two kinds of basic distillate oils are recovered, which are 4.6t / h and 1.2t / h respectively, and are extracted by two series respectively , single-series solvent regeneration. After regeneration, solvent NMP volumes of 8.0t / h and 2.2t / h (extraction ratio 1.7~1.9:1) respectively enter the respective series of solvent extraction towers T4, and the raffinate phase is desolventized, stripped and deodorized to obtain 4.1t / h No. 1 base oil, 1.1t / h No. 2 base oil; the two extraction phases are mixed and delightened by heat exchange drying, and the flow rate is 10.8t / h, and the temperature is ~150°C and enters the first-effect regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com