Hydrogenation adsorption desulphurization and catalytic hydro-dearomatization cascade reaction process

A technology of hydrodearomatization and adsorption desulfurization, which is applied in the fields of hydrotreating process, petroleum industry, and processing hydrocarbon oil, etc., to achieve the effects of avoiding energy, reducing operating costs, and reducing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

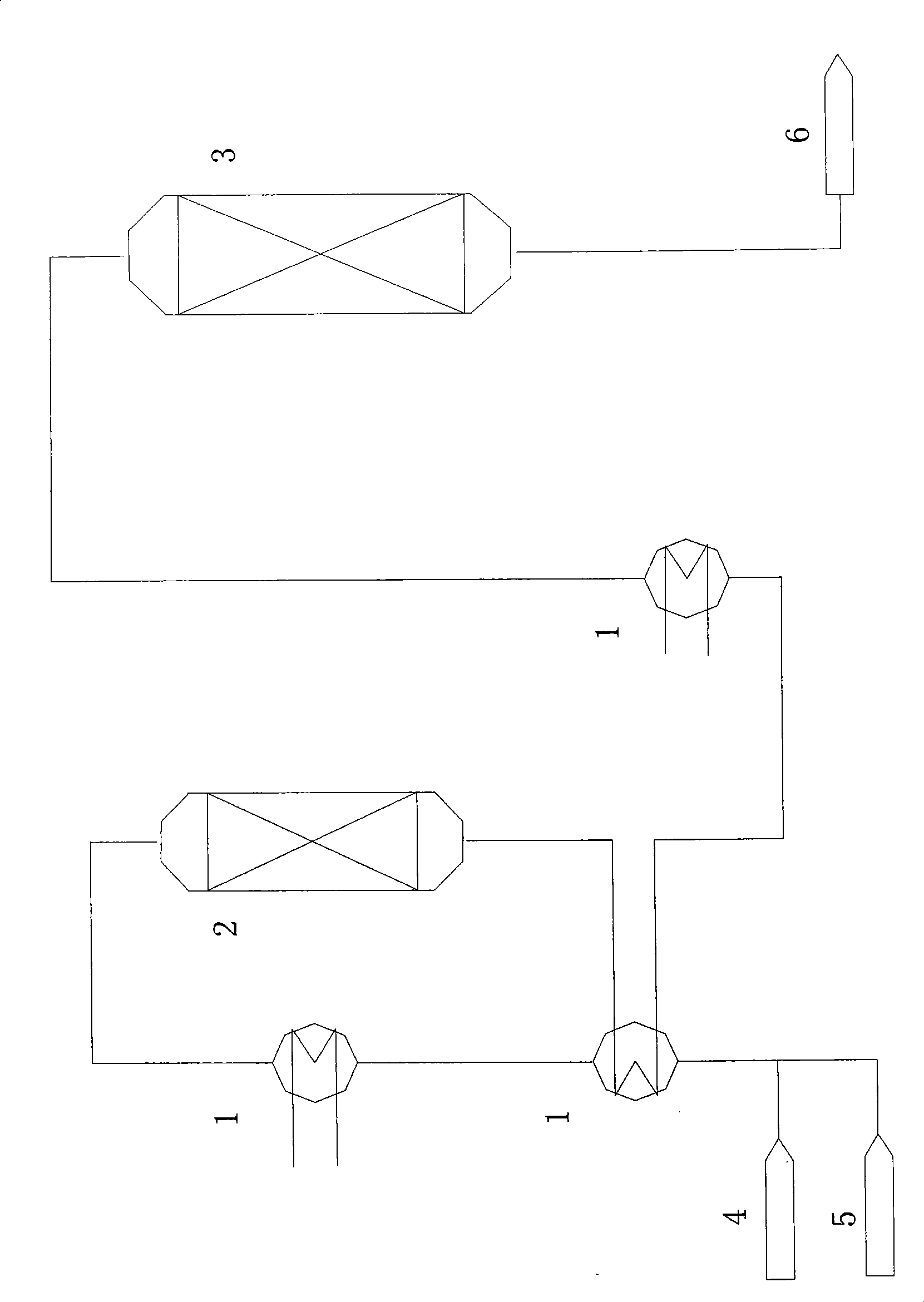

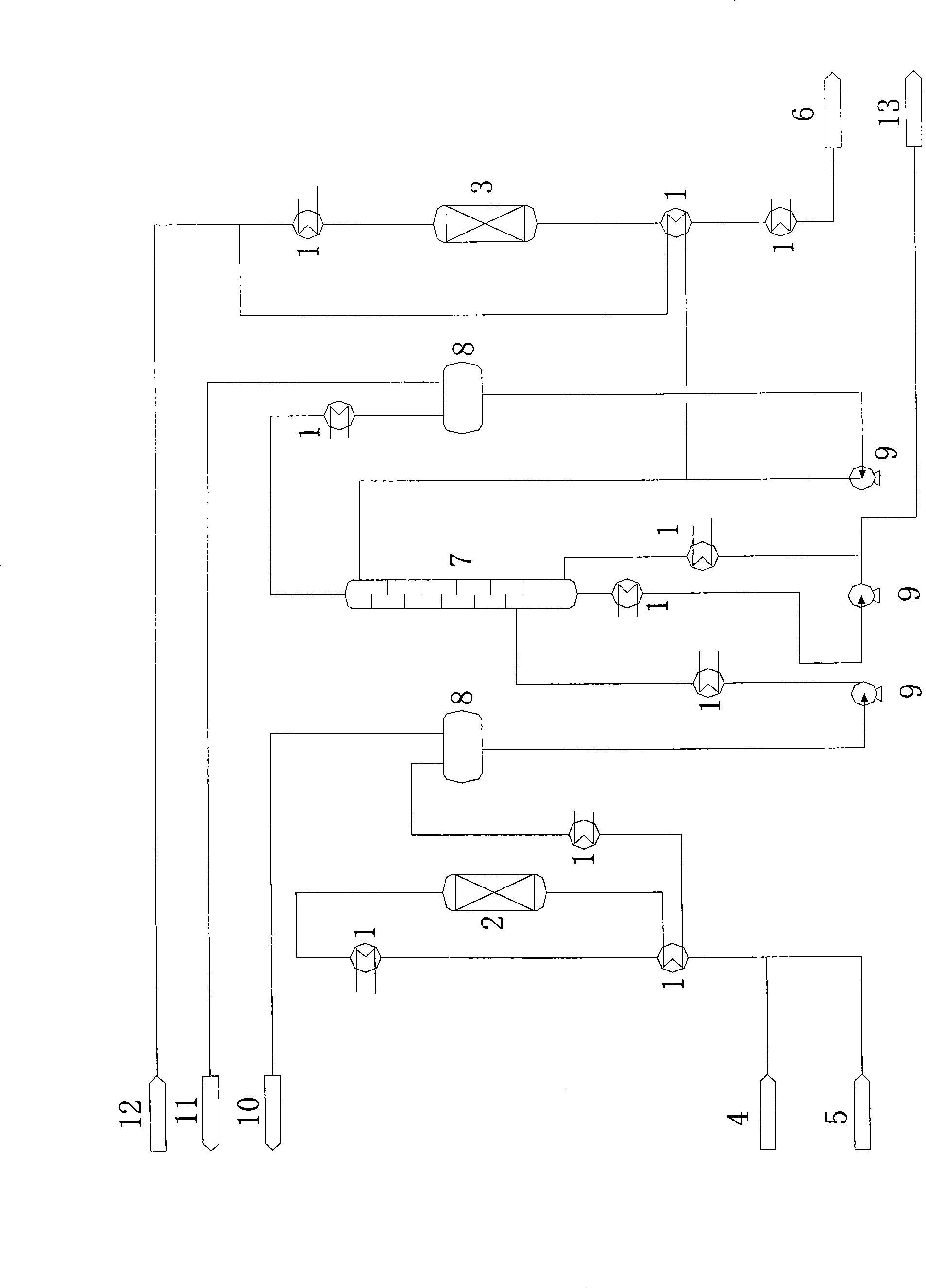

Method used

Image

Examples

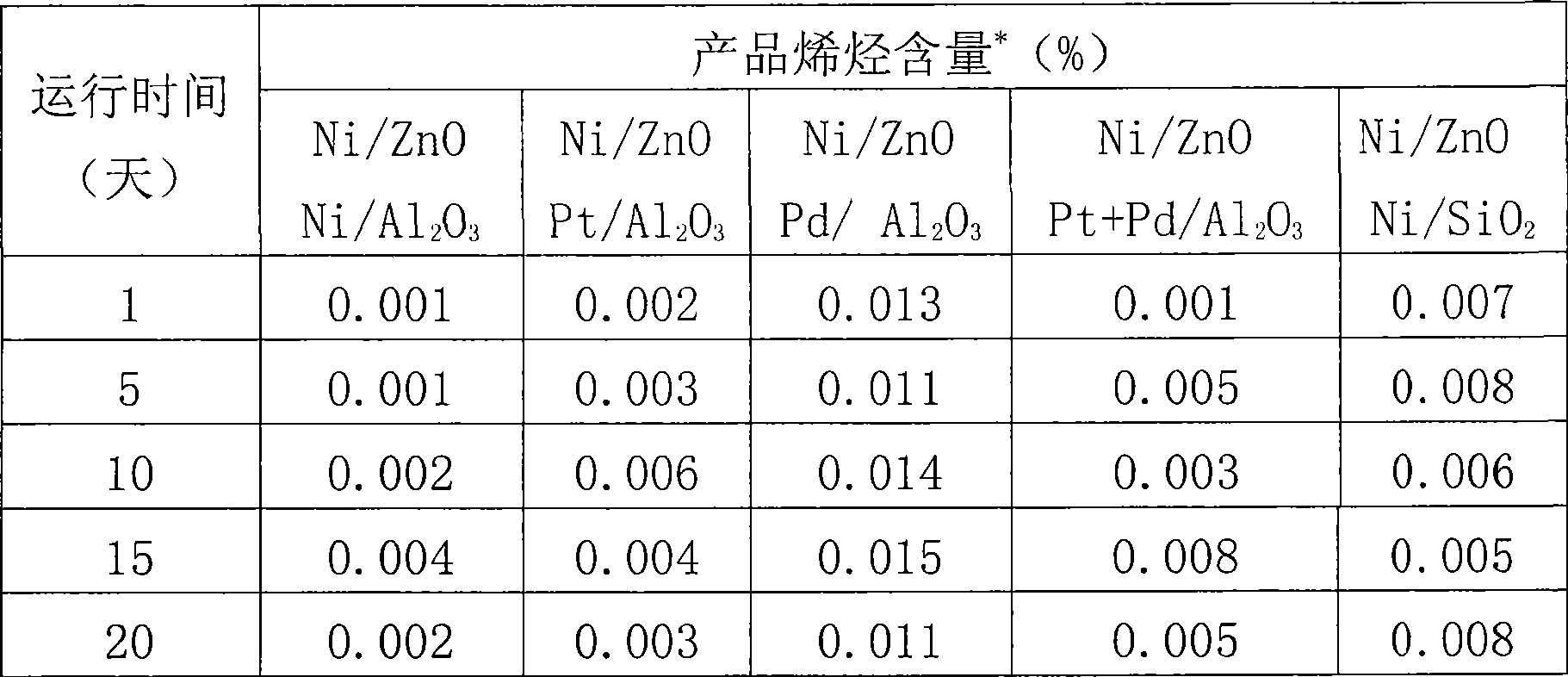

Embodiment 1

[0023] The raw material is obtained from the by-product raffinate (mainly C 6 、C 7 Hydrocarbons), olefin content 6.42%, total aromatics content 2.12% (benzene 0.20%, toluene 0.81, xylene 1.11%), organic sulfur content 5.0ppm (equivalent to 20ppm sulfolane). The first reactor is filled with Ni / ZnO hydrogenation adsorption catalyst, at 270°C, 1.3MPa, 1.5h -1 Hydrogenation adsorption desulfurization is carried out under the reaction conditions of the volume ratio of hydrogen to oil of 200. The second reactor is filled with Ni / Al 2 o 3 , the reaction conditions are 130℃, 1.3MPa, 2h -1 , The volume ratio of hydrogen to oil is 200. The results of sulfides and olefins after hydrogenation are shown in Table 1, and the results of aromatics are shown in Table 2.

Embodiment 2

[0025] The raw material and filling method are the same as in Example 1, and the reaction conditions of the hydrogenation adsorption catalyst are at 330°C, 2.5MPa, and 3.5h -1 , The volume ratio of hydrogen to oil is 600 for hydrogenation adsorption desulfurization. The second reactor is filled with Pt / Al 2 o 3 , the reaction conditions are 220℃, 2.5MPa, 3.0h -1 , The volume ratio of hydrogen to oil is 600. The results of sulfides and olefins after hydrogenation are shown in Table 1, and the results of aromatics are shown in Table 2.

Embodiment 3

[0027] The raw material and filling method are the same as in Example 1, and the reaction conditions of the hydrogenation adsorption catalyst are at 300°C, 2.0MPa, and 2.5h -1 , The volume ratio of hydrogen to oil is 400 for hydrogenation adsorption desulfurization. Hydrodearomatics catalyst changed to Pd / Al 2 o 3 , the reaction conditions are 240℃, 2.0MPa, 2.5h -1 , The volume ratio of hydrogen to oil is 400. The results of sulfides and olefins after hydrogenation are shown in Table 1, and the results of aromatics are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com