Ethylene oligomerization tanks-in-series technology

A multi-tank series, ethylene oligomerization technology, used in the purification/separation of hydrocarbons, hydrocarbons, hydrocarbons, etc. It can improve the catalytic efficiency, reduce the content and facilitate the reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

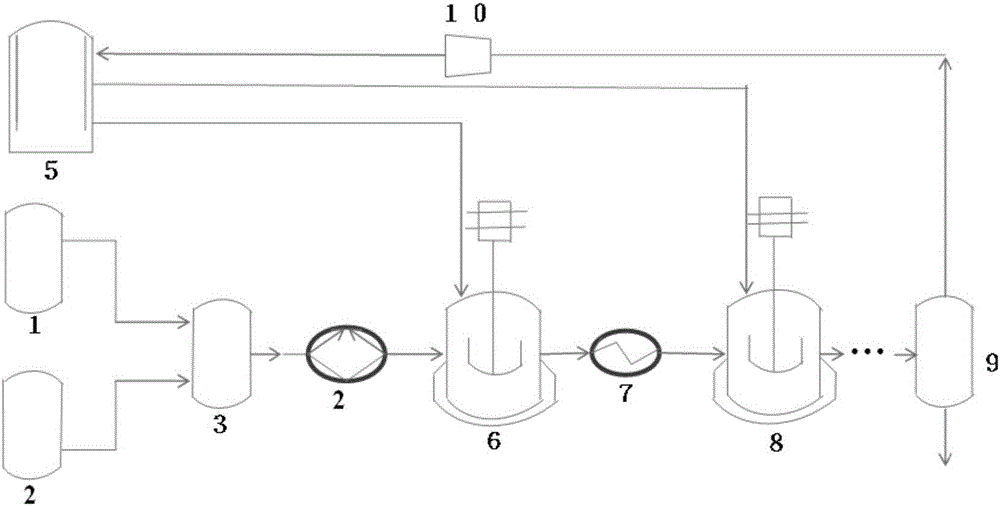

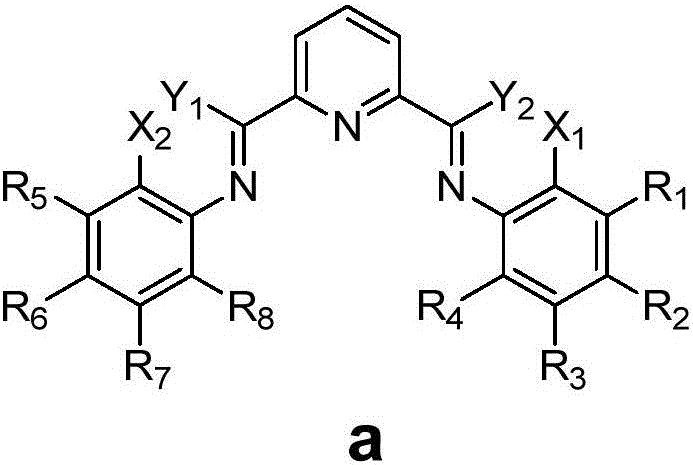

[0029] Such as figure 1 As shown, under the protection of nitrogen, the pyridine bis-imine ligand L{2,6-bis-[(2-methyl-4-methoxyanilinoethyl)pyridine]} and iron acetylacetonate molar After adding anhydrous toluene solvent after mixing at a ratio of 1:1, place it in the main catalyst tank 1 so that the concentration of iron is 1×10 -3 mol / L. The cocatalyst tank 2 is a mixture of methylaluminoxane (MAO) and p-bromophenol, wherein the ratio of aluminum phenolate is -OH / Al=0.8. The two stocks of materials in tank 1 and tank 2 are mixed according to the ratio of Al / Fe(mol)=1500, then added to the catalyst mixing tank 3 and fully mixed, then pumped into the first stirred tank reactor 6 through metering pump 4, and simultaneously passed The purified polymerization-grade ethylene raw material gas enters the first stirred tank reactor 6 from the storage tank 5 to carry out ethylene oligomerization reaction, and the reacted material is transferred to the second stirred tank reactor 8 ...

Embodiment 2

[0032] Such as figure 1 As shown, under the protection of nitrogen, the pyridine bis-imine ligand L{2,6-bis-[(2-methyl-4-methoxyanilinoethyl)pyridine]} and iron acetylacetonate molar After adding anhydrous toluene solvent after mixing at a ratio of 1:1, place it in the main catalyst tank 1 so that the concentration of iron is 1×10 -3 mol / L. The cocatalyst tank 2 is a mixture of methylaluminoxane (MAO) and p-bromophenol, wherein the ratio of aluminum phenolate is -OH / Al=0.8. The two stocks of materials in tank 1 and tank 2 are mixed according to the ratio of Al / Fe(mol)=1500, then added to the catalyst mixing tank 3 and fully mixed, then pumped into the first stirred tank reactor 6 through metering pump 4, and simultaneously passed The purified polymerization-grade ethylene raw material gas enters the first stirred tank reactor 6 from the storage tank 5 to carry out ethylene oligomerization reaction, and the reacted material is transferred to the second stirred tank reactor 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com