A kind of phosphate fertilizer containing amino acid and preparation method thereof

A technology of amino acid and phosphate fertilizer, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of large amino acid damage, low humic acid activity, and high cost, and achieve the effect of activating intolerant salts, simple preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

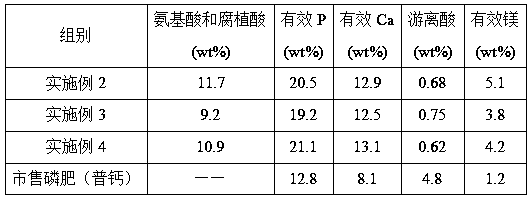

Examples

Embodiment 1

[0037] 1) Weigh each raw material according to the following parts by mass: 5~15 parts of basic amino acid, 3~5 parts of basic mineral powder, 65~80 parts of phosphate fertilizer, 5~15 parts of humic acid; the binder is saturated with Ca(OH) 2 5-8 parts, 10-30 parts of 25%-28% (w / w) ammonia water;

[0038] 2) Mix alkaline mineral powder (MgO content in alkaline mineral powder ≥ 38%) with saturated Ca(OH) 2 Mix evenly, make agglomerates, put them back into the brick kiln for calcination, the calcination time is 3~5h, the calcination temperature is 900~1100℃, cool after calcination, crush through a sieve of more than 80 mesh, and obtain the alkaline powder with MgO content ≥ 38% ;

[0039] 3) Mix the above alkaline powder with phosphate fertilizer and react at 70~85°C for 3.5~4.5h;

[0040] 4) Mix humic acid and ammonia water, and react for 3~4 hours under airtight conditions, and the reaction temperature is 60~80°C;

[0041] 5) Mix the reaction products obtained in step 3) a...

Embodiment 2

[0043] 1) Weigh each raw material according to the following parts by mass: 10 parts of basic amino acid, 4 parts of basic mineral powder, 73 parts of phosphate fertilizer, 10 parts of humic acid; saturated Ca(OH) 2 6 parts, 15 parts of 25% (w / w) ammonia water;

[0044] 2) Mix alkaline mineral powder (MgO content in alkaline mineral powder ≥ 38%) with saturated Ca(OH) 2 Mix evenly, make agglomerates, put them back into the brick kiln for calcination, the calcination time is 4 hours, the calcination temperature is 1000°C, cool after calcination, crush through 80 mesh sieve, and obtain the alkaline powder with MgO content ≥ 38%;

[0045] 3) Mix the above alkaline powder with phosphate fertilizer and react at 80°C for 4 hours;

[0046] 4) Mix humic acid and ammonia water, and react for 3.5 hours under airtight conditions, and the reaction temperature is 70°C;

[0047] 5) Mix the reaction products obtained in step 3) and step 4) evenly, add basic amino acid, mix well, react for ...

Embodiment 3

[0049]1) Weigh each raw material according to the following parts by mass: 5 parts of basic amino acid, 5 parts of basic mineral powder, 65 parts of phosphate fertilizer, 15 parts of humic acid; saturated Ca(OH) 2 8 parts, 10 parts of 28% (w / w) ammonia water;

[0050] 2) Mix alkaline mineral powder (MgO content in alkaline mineral powder ≥ 38%) with saturated Ca(OH) 2 Mix evenly, make agglomerates, put them back into the brick kiln for calcination, the calcination time is 3 hours, the calcination temperature is 1100°C, cool after calcination, crush through 80 mesh sieve, and obtain the alkaline powder with MgO content ≥ 38%;

[0051] 3) Mix the above alkaline powder with phosphate fertilizer and react at 70°C for 4.5 hours;

[0052] 4) Mix humic acid and ammonia water, and react for 4 hours under airtight conditions, and the reaction temperature is 60°C;

[0053] 5) Mix the reaction products obtained in step 3) and step 4) evenly, add basic amino acid, mix well, react for 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com