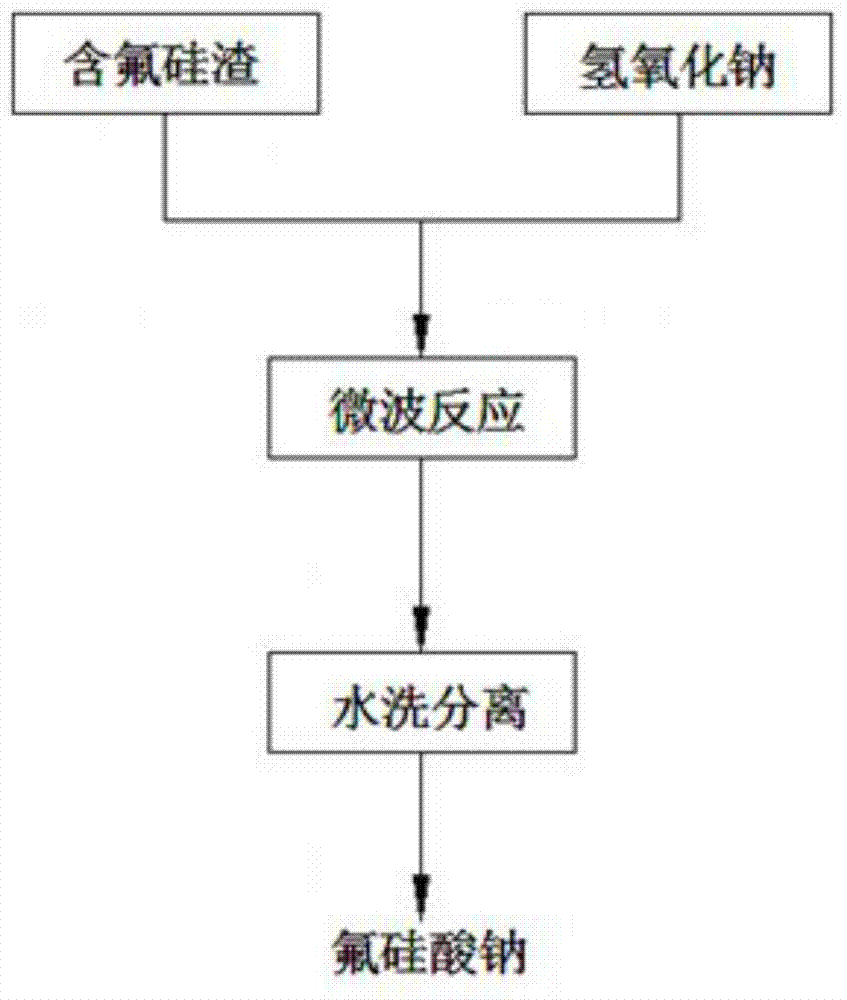

A method for preparing sodium fluorosilicate from fluorine-containing silicon slag

A technology of fluorine-containing silicon slag and sodium fluorosilicate, which is applied in the direction of silicon halide compounds, can solve problems such as complicated process steps, harsh preparation conditions, and poor product quality, and achieves reduced free acid content, shortened reaction time, and good The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing sodium fluorosilicate from fluorine-containing silicon slag, comprising the following steps:

[0025] (1) Mix and stir the fluorine-containing silicon slag and sodium hydroxide with a concentration of 28%, place it in a microwave reactor, adjust the microwave power to 16kw to a material temperature of 71°C, and perform a microwave reaction for 6 minutes;

[0026] (2) After cooling the microwave reaction product to a temperature of 48°C, the solid and liquid were obtained by solid-liquid separation, and the solid was washed 7 times and dried for 3 hours at a temperature of 70°C to obtain sodium fluorosilicate.

[0027] The fluorine-containing silicon slag is the fluorine-containing gas produced during the processing of potassium-containing rocks, which is subjected to absorption treatment to obtain acidic solids.

[0028] The mass volume ratio of the fluorine-containing silicon slag to sodium hydroxide is 1:6, and the mixing and stirring time is 7 ...

Embodiment 2

[0035] A method for preparing sodium fluorosilicate from fluorine-containing silicon slag, comprising the following steps:

[0036] (1) Mix and stir the fluorine-containing silicon slag and 17% sodium hydroxide, place it in a microwave reactor, adjust the microwave power to 3kw to a material temperature of 118°C, and perform a microwave reaction for 10 minutes;

[0037] (2) After cooling the microwave reaction product to a temperature of 32°C, the solid and liquid were obtained by solid-liquid separation, and the solid was washed three times and dried for 1 hour at a temperature of 100°C to obtain sodium fluorosilicate.

[0038] The fluorine-containing silicon slag is the fluorine-containing gas produced in the production process of hydrogen fluoride, which is subjected to absorption treatment to obtain an acidic solid.

[0039] The mass volume ratio of the fluorine-containing silicon slag to sodium hydroxide is 1:6, and the mixing time is 55 minutes.

[0040] The solid-liqui...

Embodiment 3

[0046] A method for preparing sodium fluorosilicate from fluorine-containing silicon slag, comprising the following steps:

[0047] (1) Mix and stir the fluorine-containing silicon slag and 6% sodium hydroxide, place it in a microwave reactor, adjust the microwave power to 21kw to a material temperature of 83°C, and carry out microwave reaction for 18 minutes;

[0048] (2) After cooling the microwave reaction product to a temperature of 39°C, the solid and liquid were obtained by solid-liquid separation, and the solid was washed 5 times and dried for 2.5 hours at a temperature of 58°C to obtain sodium fluorosilicate.

[0049] The fluorine-containing silicon slag is the fluorine-containing gas generated during the decomposition of phosphate rock and the concentration of phosphoric acid, which is absorbed and treated to obtain acidic solids.

[0050] The mass volume ratio of the fluorine-containing silicon slag to sodium hydroxide is 1:1, and the mixing and stirring time is 7 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com