Y molecular sieve modification method

A molecular sieve and modification technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, catalyst carriers, etc., can solve the problems of less secondary pores and lower crystallinity of Y molecular sieves, so as to improve the silicon-aluminum ratio, reduce the unit cell constant, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

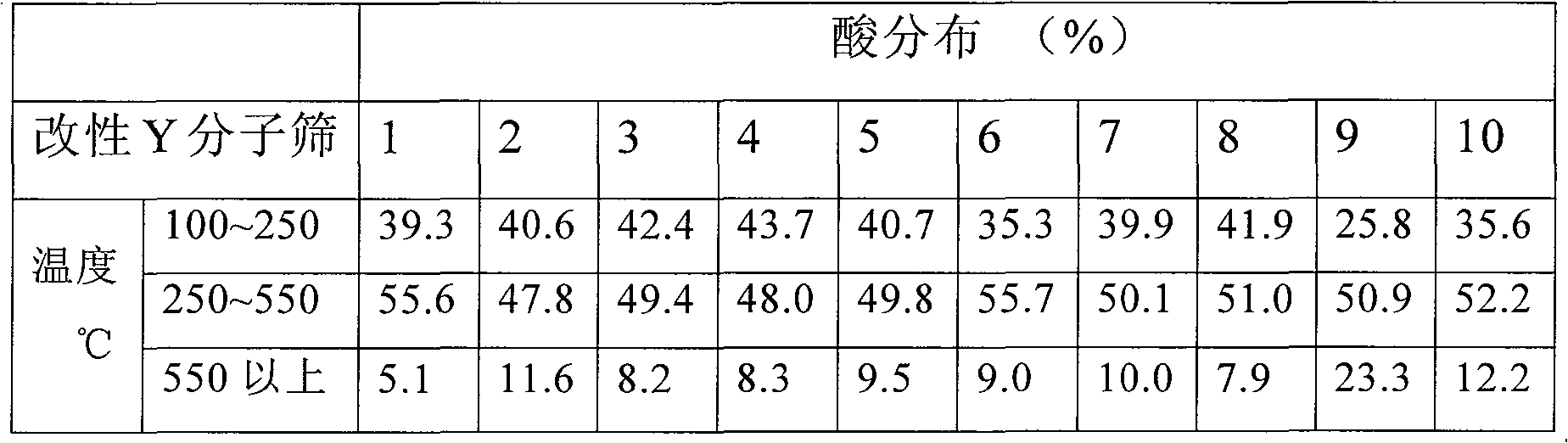

Examples

Embodiment 1

[0031] Prepare it with the ratio of 5g of NaY molecular sieve: 6.5g of ammonium sulfate: 50mL of water, and put it into a three-necked flask. The ion exchange temperature is 95°C for 1h, then, filter, wash, and then use a solution of 6.5g ammonium sulfate: 50mL of water for secondary ion exchange, finally filter, wash the wet filter cake, and roast at 600°C for 2h.

[0032] Grind the Y molecular sieve after exchange and hydrothermal treatment into powder, take 5.0g in a three-necked flask; weigh 6.5g of ammonium sulfate and add 50mL of water to prepare a solution, and then add 1.0g of surfactant hexadecyl Trimethylammonium bromide (CTAB), stir evenly; add it into the flask, heat it in a water bath to 100°C, then add 35L of 10% oxalic acid and ammonium oxalate solution, stir for 4 hours, put it in an autoclave, and set it at a certain temperature Under 120 ℃ hydrothermal crystallization for 12h. Filter, dry, and bake at 500°C for 6h. The modified Y molecular sieve 1 was obtai...

Embodiment 2

[0034] Prepare it with the ratio of 5g of NaY molecular sieve: 6.5g of ammonium sulfate: 50mL of water, and put it into a three-necked flask. The ion exchange temperature is 95°C for 1h, then, filter, wash, and then use a solution of 6.5g ammonium sulfate: 50mL of water for secondary ion exchange, finally filter, wash the wet filter cake, and roast at 600°C for 2h.

[0035] Grind the Y molecular sieve after exchange and hydrothermal treatment into powder, take 5.0g in a three-necked flask; weigh 6.5g of ammonium sulfate and add 50mL of water to prepare a solution, then add 1.0g of surfactant CTAB and stir evenly Add it into a flask, heat it in a water bath to 100°C, then add 45mL of 10% oxalic acid and ammonium oxalate solution, stir for 4 hours, put it in an autoclave, and conduct hydrothermal crystallization at a certain temperature of 120°C for 12h. Filter, dry, and bake at 500°C for 6h. The modified Y molecular sieve 2 was obtained.

Embodiment 3

[0037] Prepare it with the ratio of 5g of NaY molecular sieve: 6.5g of ammonium sulfate: 50mL of water, and put it into a three-necked flask. The ion exchange temperature is 95°C for 1h, then, filter, wash, and then use a solution of 6.5g ammonium sulfate: 50mL of water for secondary ion exchange, finally filter, wash the wet filter cake, and roast at 600°C for 2h.

[0038] Grind the Y molecular sieve after exchange and hydrothermal treatment into powder, take 5.0g in a three-necked flask; weigh 6.5g of ammonium sulfate and add 50mL of water to prepare a solution, then add 1.0g of surfactant CTAB and stir evenly Add it into a flask, heat it in a water bath to 100°C, then add 55mL of 10% oxalic acid and ammonium oxalate solution, stir for 4h, put it in an autoclave, and conduct hydrothermal crystallization at a certain temperature of 120°C for 12h. Filter, dry, and bake at 500°C for 6h. The modified Y molecular sieve 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com