A kind of catalytic cracking catalyst and its preparation and application

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as the inability to obtain the silicon-aluminum ratio, the inability to effectively increase the content of gasoline isomerized hydrocarbons, and the high Y-type zeolite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] In the catalytic cracking catalyst preparation method provided by the present invention, the preparation method of the modified Y-type molecular sieve, an embodiment comprises the following steps:

[0046] (1) carry out ion exchange reaction with NaY molecular sieve (also claiming NaY zeolite) and soluble magnesium salt solution, filter, wash, obtain the Y type molecular sieve of the conventional unit cell size containing magnesium that sodium oxide content reduces; Said ion exchange is usually in Stir and exchange for 30-120 minutes at a temperature of 15-95°C, preferably 65-95°C;

[0047] (2) The Y-type molecular sieve with the rare earth-containing conventional unit cell size whose sodium oxide content is reduced is roasted for 4.5 to 7 hours at a temperature of 350 to 480° C. in an atmosphere containing 30 to 90% by volume of water vapor, and dried to obtain water A Y-type molecular sieve with a reduced unit cell constant content of less than 1% by weight; the unit ...

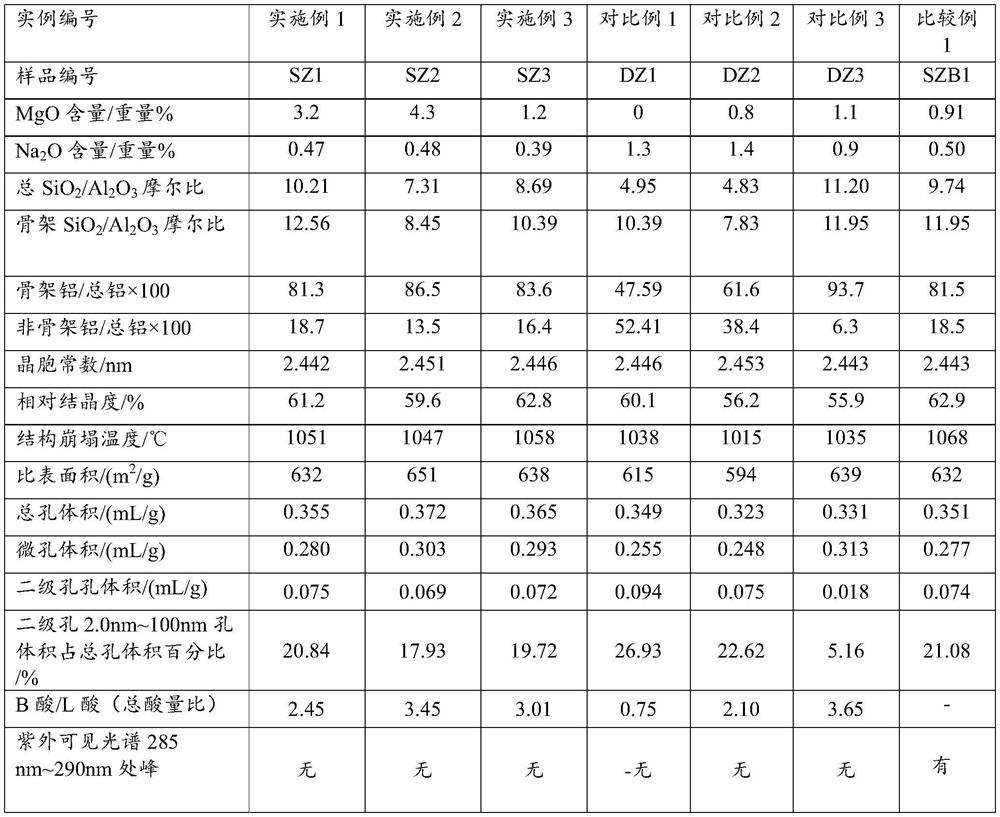

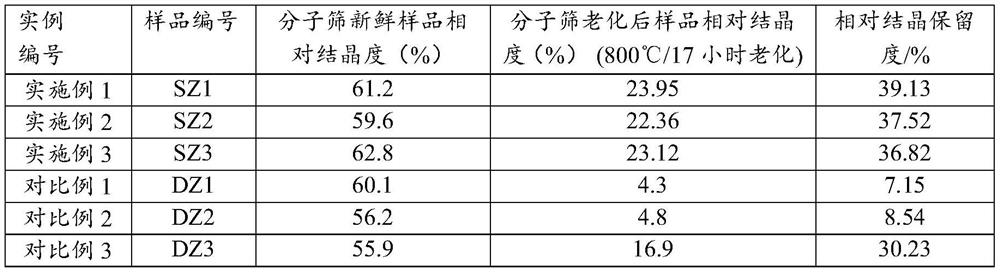

Embodiment 1

[0059] Get 2000 grams of NaY molecular sieves (on a dry basis) and add to 20 liters of decationized aqueous solution and stir to make it evenly mixed, add 492ml of Mg(NO 3 ) 2 solution (concentration in terms of MgO is 248g / L), stirred, heated to 90-95°C for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a unit cell constant of 2.471nm and a sodium oxide content of 6.6 % by weight, a Y-type molecular sieve with a magnesium content of 5.7% by weight based on MgO, and then calcined for 6 hours at a temperature of 390 ° C in an atmosphere containing 50% by volume of water vapor and 50% by volume of air to obtain a Y-type molecular sieve with a unit cell constant of 2.455nm Molecular sieves, followed by drying to a water content of less than 1% by weight, followed by SiCl 4 : Y-type molecular sieve (dry basis) = 0.5: 1 weight ratio, feed SiCl vaporized by heating 4 Gas, at a temperature of 400°C, reacted for 2 hours, after that, washed with 20 li...

Embodiment 2

[0063] Get 2000 grams of NaY molecular sieves (on a dry basis) and add to 25 liters of decationized aqueous solution and stir to make it evenly mixed, add 524ml of MgCl 2 solution (concentration in terms of MgO: 248g / L), stirred, heated to 90-95°C for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a unit cell constant of 2.471nm and a sodium oxide content of A Y-type molecular sieve with 5.2% by weight and a magnesium content of 6.2% by weight based on MgO is then calcined at a temperature of 450°C and 80% water vapor for 5.5 hours to obtain a Y-type molecular sieve with a unit cell constant of 2.461nm, and then dried treated so that its water content is less than 1% by weight, and then according to SiCl 4 : Y-type zeolite = 0.6:1 weight ratio, feed SiCl vaporized by heating 4 The gas was reacted for 1.5 hours at a temperature of 480° C., and then washed with 20 liters of deionized water, and then filtered to obtain a modified Y-type molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com