Low-sodium aluminum oxide and preparation method thereof

A sodium alumina and alumina technology, applied in the field of low sodium alumina and its preparation, can solve problems such as environmental pollution and achieve the effect of low sodium oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

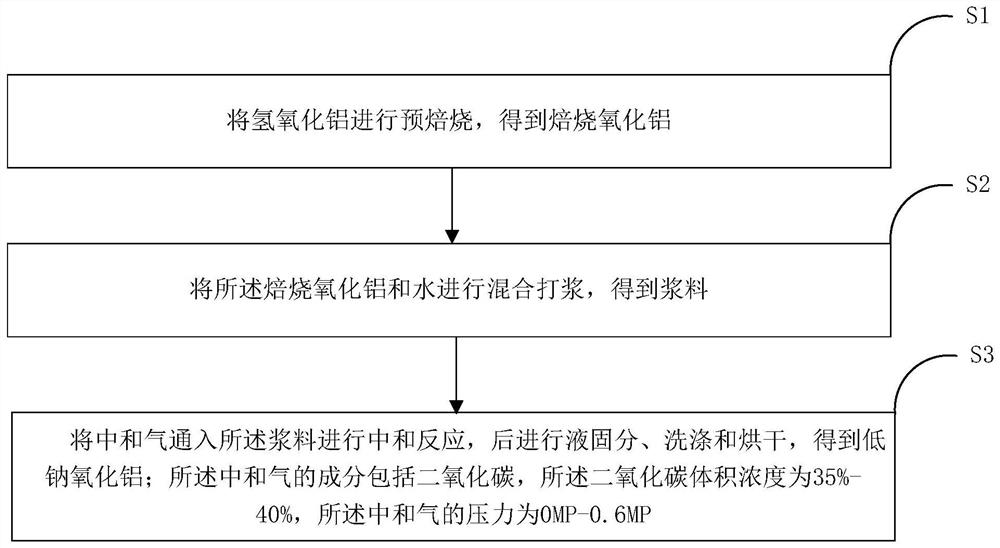

[0029] According to a typical embodiment of the present invention, there is provided a preparation method of low sodium alumina, the method comprising:

[0030] S1. aluminum hydroxide is pre-calcined to obtain calcined alumina;

[0031] S2. the calcined alumina and water are mixed and beaten to obtain slurry;

[0032] S3. pass the neutralized gas into the slurry to carry out neutralization reaction, then carry out liquid-solid fractionation, washing and drying to obtain low-sodium alumina; the composition of the neutralized gas includes carbon dioxide, and the carbon dioxide volume concentration is 35% -40%, the pressure of the neutralized gas is 0MP-0.6MP.

[0033] The reason for controlling the volume concentration of carbon dioxide to be 35%-40% is based on the comprehensive consideration of the carbon dioxide gas absorption rate and the neutralization reaction efficiency. The adverse effect of this concentration is that the carbon dioxide gas absorption rate is low and a ...

Embodiment 1

[0049] A preparation method of low-sodium alumina, the method comprising:

[0050] 1) The preparation method of the low-sodium alumina of the present invention uses ordinary industrial aluminum hydroxide as the raw material, the roasting temperature is 700° C., the roasting time is 30 minutes, the particle size D50 is 78 μm, and the sodium oxide content is 0.28%.

[0051] 2) Mix and beat with distilled water at room temperature 50 ℃ and the alumina after roasting, control the solid content of the slurry to be 300g / l, after stirring evenly, feed carbon dioxide gas with a concentration of 35%, and the gas feed rate of 1m3 slurry is 90m3 / hour, keep the ventilation pressure at 0.1MP for 20 minutes, then carry out liquid-solid separation, wash with hot distilled water, and obtain low-sodium alumina.

[0052] 3) calcined at 1350°C for 3 hours to obtain low sodium and high temperature alumina.

Embodiment 2

[0054] A preparation method of low-sodium alumina, the method comprising:

[0055] 1) The preparation method of the low-sodium alumina of the present invention uses ordinary industrial aluminum hydroxide as the raw material, the roasting temperature is 650° C., the roasting time is 60 minutes, the particle size D50 is 72 μm, and the sodium oxide content is 0.25%.

[0056] 2) Mixing and beating with 60 ℃ of distilled water and roasted alumina, control the solid content of the slurry at 350g / l, after stirring, feed carbon dioxide gas with a concentration of 35%, 1m The gas feed rate of the slurry is 90m3 / hour , the ventilation pressure is 0.2MP and the ventilation time is 20 minutes, and then liquid-solid separation is carried out, washed with hot distilled water, and low-sodium alumina is obtained.

[0057] 3) calcined at 1350°C for 3 hours to obtain low sodium and high temperature alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com