Comprehensive utilization method for low-grade aluminum-containing raw material

A low-grade, raw material technology, used in products, alkali metal aluminate/alumina/aluminum hydroxide preparation, reagents, etc., can solve the increase of red mud sedimentation load, the influence of flotation reagents, and hinder the normal operation of the production process and other problems, to achieve the effect of lowering the content of silicon oxide and sodium oxide, turning waste into treasure, and improving the value of comprehensive utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

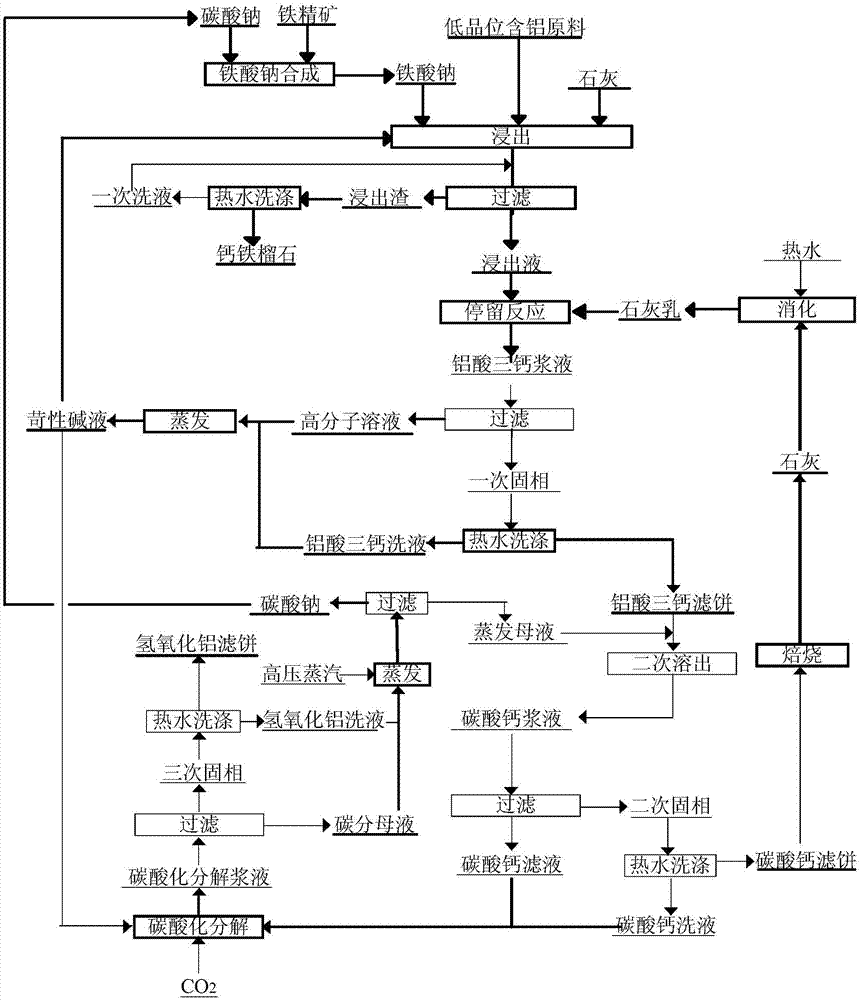

[0064] Process such as figure 1 shown, proceed as follows:

[0065] (1) The low-grade aluminum-containing raw material used is low-grade bauxite; sodium ferrite, low-grade aluminum-containing raw material and lime are mixed to make the material to be leached; the amount of sodium ferrite added is based on the amount of Fe in the material to be leached 2 o 3 with Al 2 o 3 The mass ratio of lime is 0.6, and the amount of lime added is according to the amount of CaO and Al in the material to be leached. 2 o 3 The mass ratio is 0.8; the low-grade bauxite contains Al by weight percentage 2 o 3 70%, the aluminum-silicon ratio is 5.5;

[0066] (2) Mix the caustic lye with the material to be leached, the mixing ratio is 5.0 according to the liquid-solid ratio, then leaching and reacting at 275°C for 0.5h, after the leaching reaction is completed, filter and separate to obtain leaching residue and leaching liquid; the caustic lye The concentration of sodium hydroxide in the med...

Embodiment 2

[0077] Method is with embodiment 1, and difference is:

[0078] (1) Fe in the material to be leached 2 o 3 with Al 2 o 3 The mass ratio of CaO to Al is 0.4, 2 o 3 The mass ratio is 0.6; low-grade bauxite contains Al by weight percentage 2 o 3 50%, the aluminum-silicon ratio is 3.0;

[0079] (2) The mixing ratio of caustic lye and material to be leached is 4.0 according to the liquid-solid ratio, leaching reaction at 230°C for 1.5h, and the concentration of sodium hydroxide in the caustic lye is 220g / L; the leaching residue is washed with hot water at 80°C, heated The amount of water used is 1.5 times the mass of the primary solid phase; the mass percentage of chemical alkali in the solid part of the andandrite filter cake is 0.1%; the Al in the leaching solution 2 o 3 The content is 80g / L;

[0080] (3) Add milk of lime to the leaching solution, the amount of addition is according to the amount of CaO and Al in the whole material 2 o 3 The mass ratio of CaO is 1.2,...

Embodiment 3

[0089] Method is with embodiment 1, and difference is:

[0090] (1) Fe in the material to be leached 2 o 3 with Al 2 o 3 The mass ratio of CaO to Al is 0.5. 2 o 3 The mass ratio is 07; low-grade bauxite contains Al by weight percentage 2 o 3 60%, the aluminum-silicon ratio is 4.0;

[0091] (2) The mixing ratio of caustic lye and material to be leached is 4.5 according to the liquid-solid ratio, leaching reaction at 255°C for 1 hour, and the concentration of sodium hydroxide in the caustic lye is 250g / L; the leaching residue is washed with hot water at 90°C, hot water The dosage is 1.2 times the mass of the primary solid phase; the mass percentage of the chemical alkali in the solid part of the andandrite filter cake is 0.3%; the Al in the leaching solution 2 o 3 The content is 100g / L;

[0092] (3) Add milk of lime to the leaching solution, the amount of addition is according to the amount of CaO and Al in the whole material 2 o 3 The mass ratio of CaO is 1.4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com