Method for modifying mesoporous-rich USY (Ultra-Stable Y) molecular sieve in combined manner

A molecular sieve, rich mesopore technology, applied in the direction of crystalline aluminosilicate zeolite, favhedral crystalline aluminosilicate zeolite, etc., can solve the problems of unfavorable industrialization, harsh modification conditions, and high EDTA price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

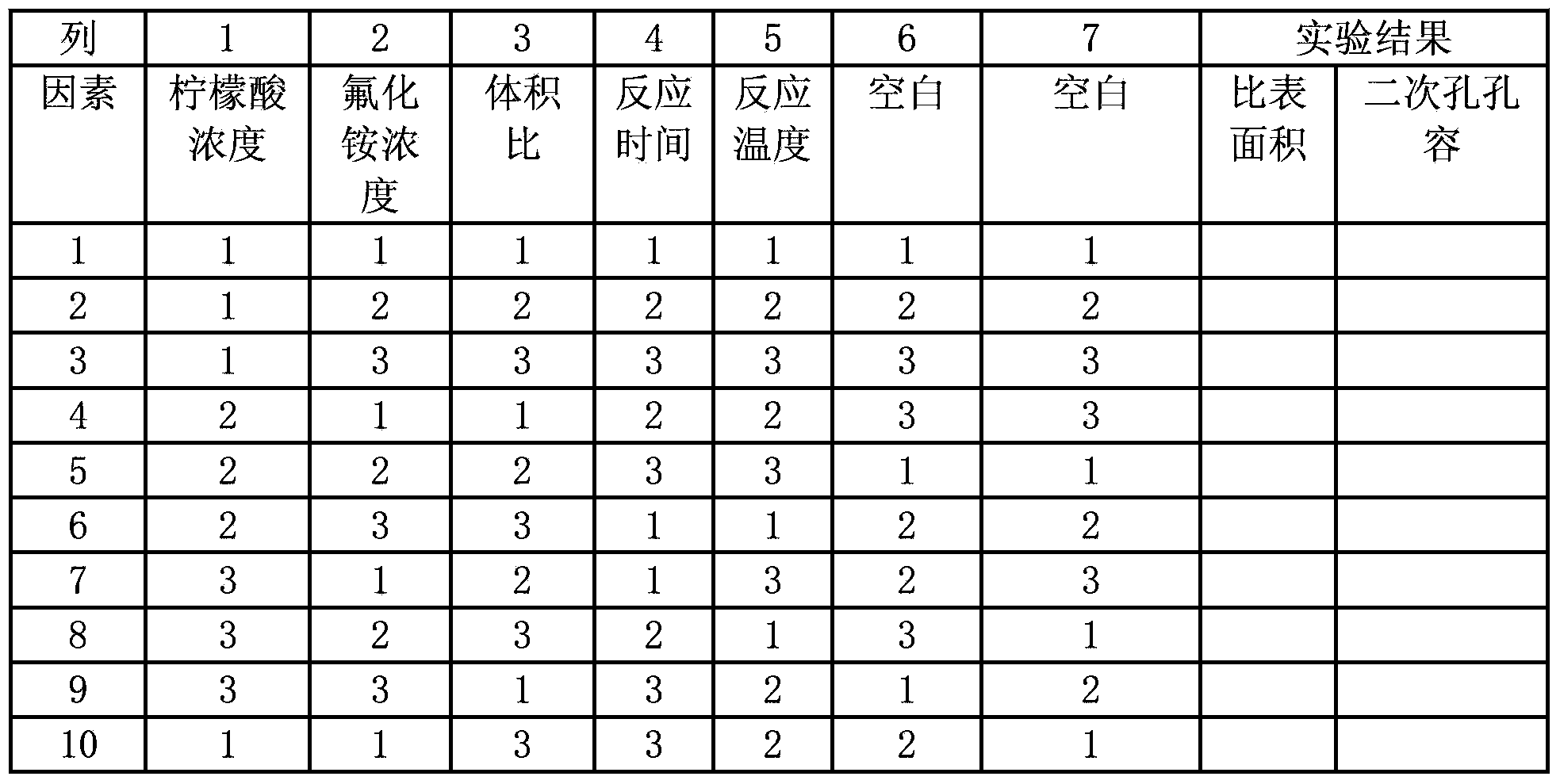

[0025] Weigh 12g of a fixed amount of industrial USY and pour it into a 250ml three-necked flask (plastic); according to the design ratio of the orthogonal test (orthogonal test, see Table 1), measure a certain concentration and a certain amount of citric acid and ammonium fluoride Salt solution; at room temperature, use a 250ml three-necked flask as a reactor, install and stir, and set a certain water bath temperature to start the reaction; after the water temperature reaches the set temperature, record the time. After reacting at constant temperature for a certain period of time, wash and filter until the surface of the sample is neutral; put it in an oven at 110°C, dry at constant temperature for 16 hours, and grind to obtain a modified sample. Through the visual analysis of the orthogonal test, the optimal modification conditions for the industrial USY adopted are citric acid concentration 0.4mol / L, MAP concentration 0.2mol / L, volume ratio 0.5, reaction time 8h, reaction te...

example 2

[0027] Prepare the required 0.4mol / L citric acid solution and 0.2mol / L ammonium fluoride salt solution; enlarge the modification scale by 4 times, weigh 48g of industrial USY and pour it into a 1L autoclave; according to the optimal condition ratio , Measure 160ml of citric acid solution and 320ml of ammonium fluoride solution respectively, install and stir, install the kettle, and set the temperature of the inner kettle to 90°C; when the temperature of the inner kettle reaches the set temperature, record the time. After 8 hours of constant temperature reaction, wash and filter until the surface of the sample is neutral; put it in an oven at 110°C, dry it at a constant temperature for 16 hours, and grind to obtain a modified sample in a large kettle.

Embodiment 3

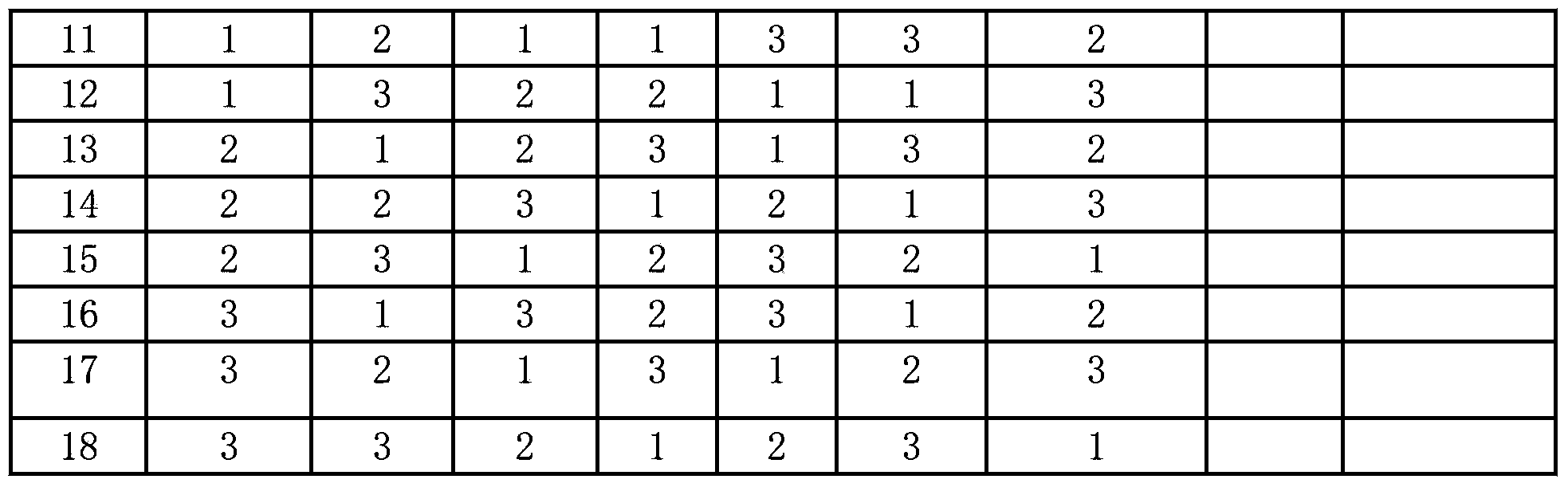

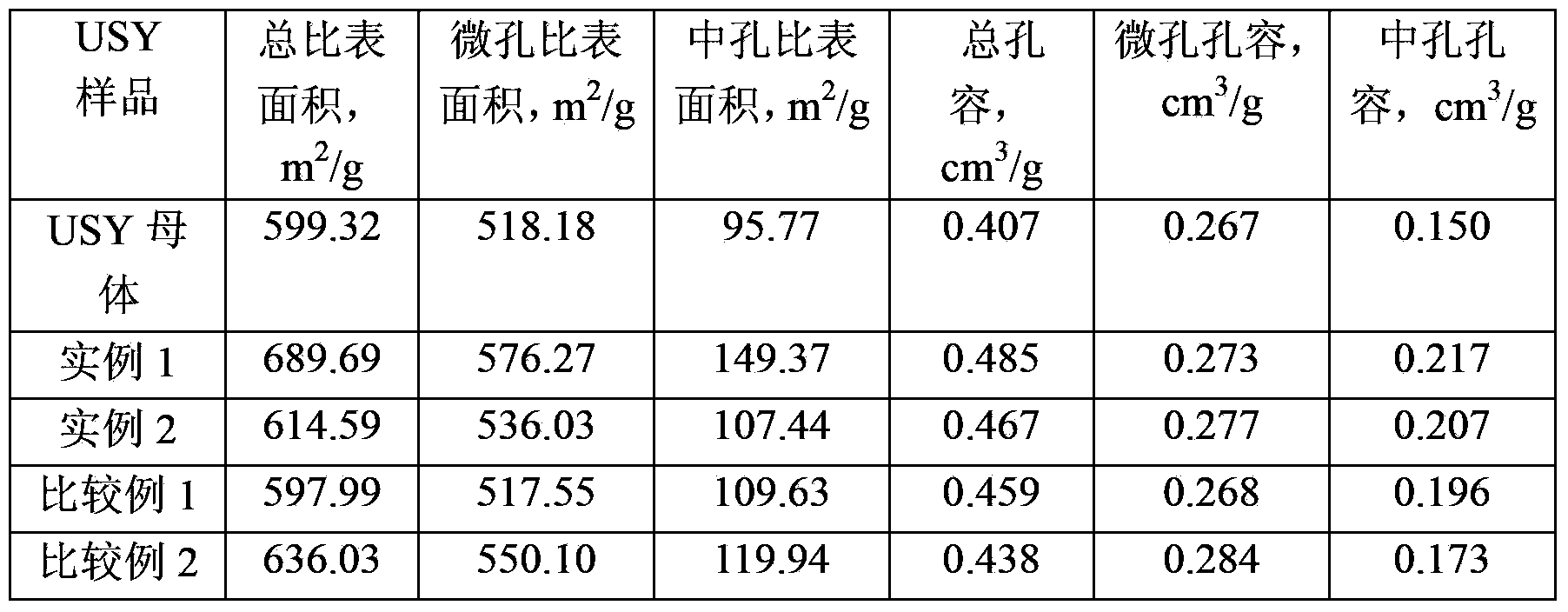

[0033] This example is the determination of the specific surface area, pore volume and skeleton information of the above-mentioned modified USY, see Table 2 and Table 3.

[0034] Table 1 USY modified orthogonal test table

[0035]

[0036]

[0037] Table 2 Specific surface area and pore distribution of modified USY molecular sieves

[0038]

[0039] Table 3 Crystal structure parameters of modified USY molecular sieves

[0040]

[0041] Combining modified USY can achieve better results than individual organic acid and inorganic salt modification. The modified USY molecular sieve sample has a high micropore retention rate, a large increase in specific surface area, and an increase in the proportion of secondary pores (>0.20cm 3 / g), and at the same time maintain a high degree of crystallinity (>75%), the ratio of silicon to aluminum increases, and the unit cell constant decreases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com