Patents

Literature

160results about "Electroforming nanostructures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

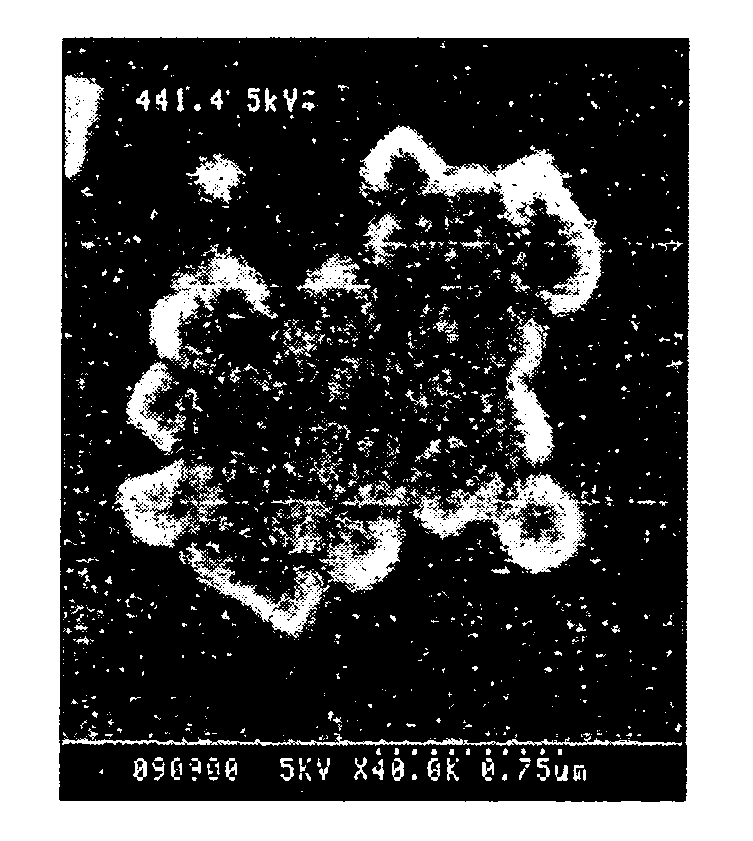

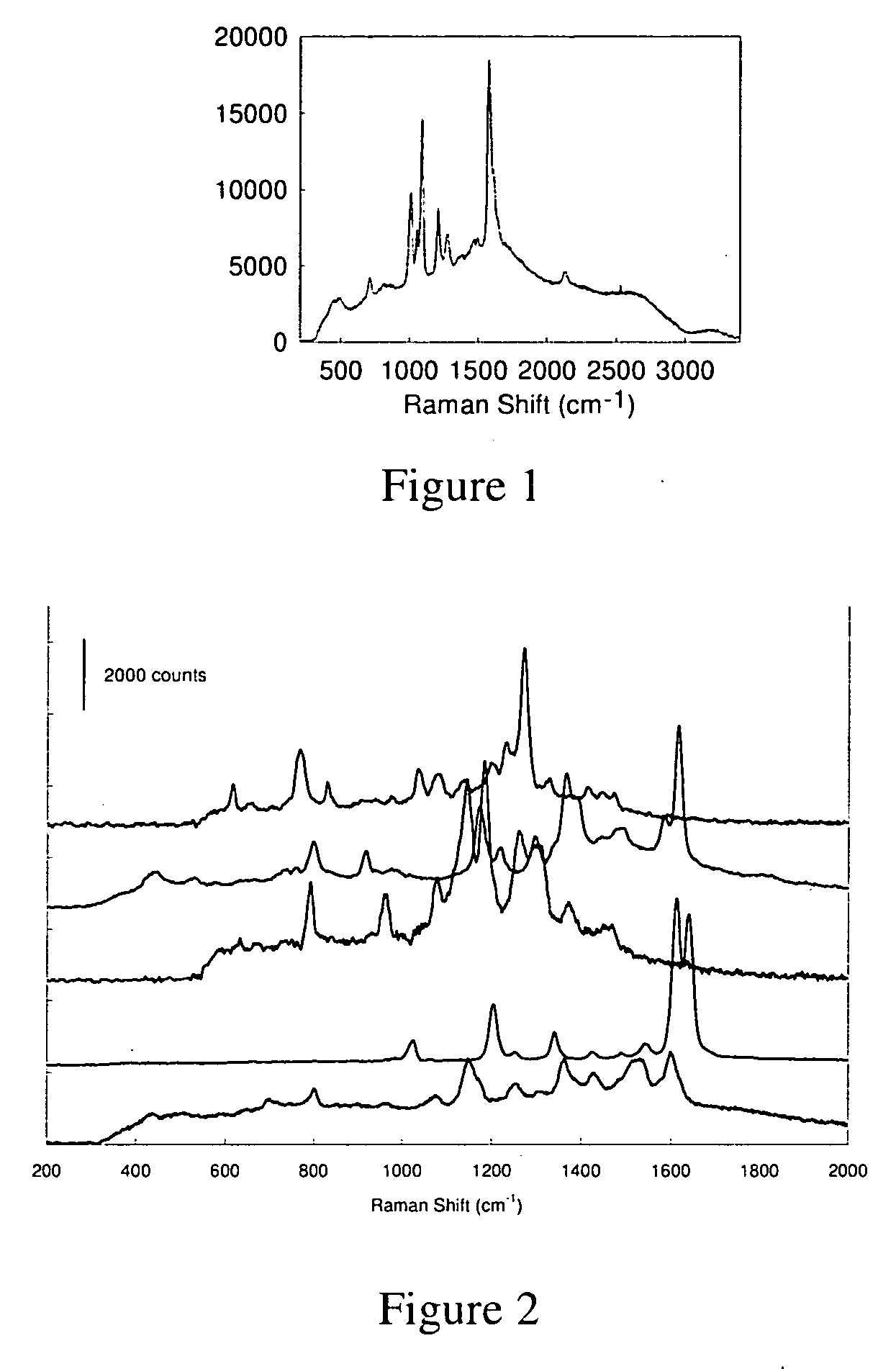

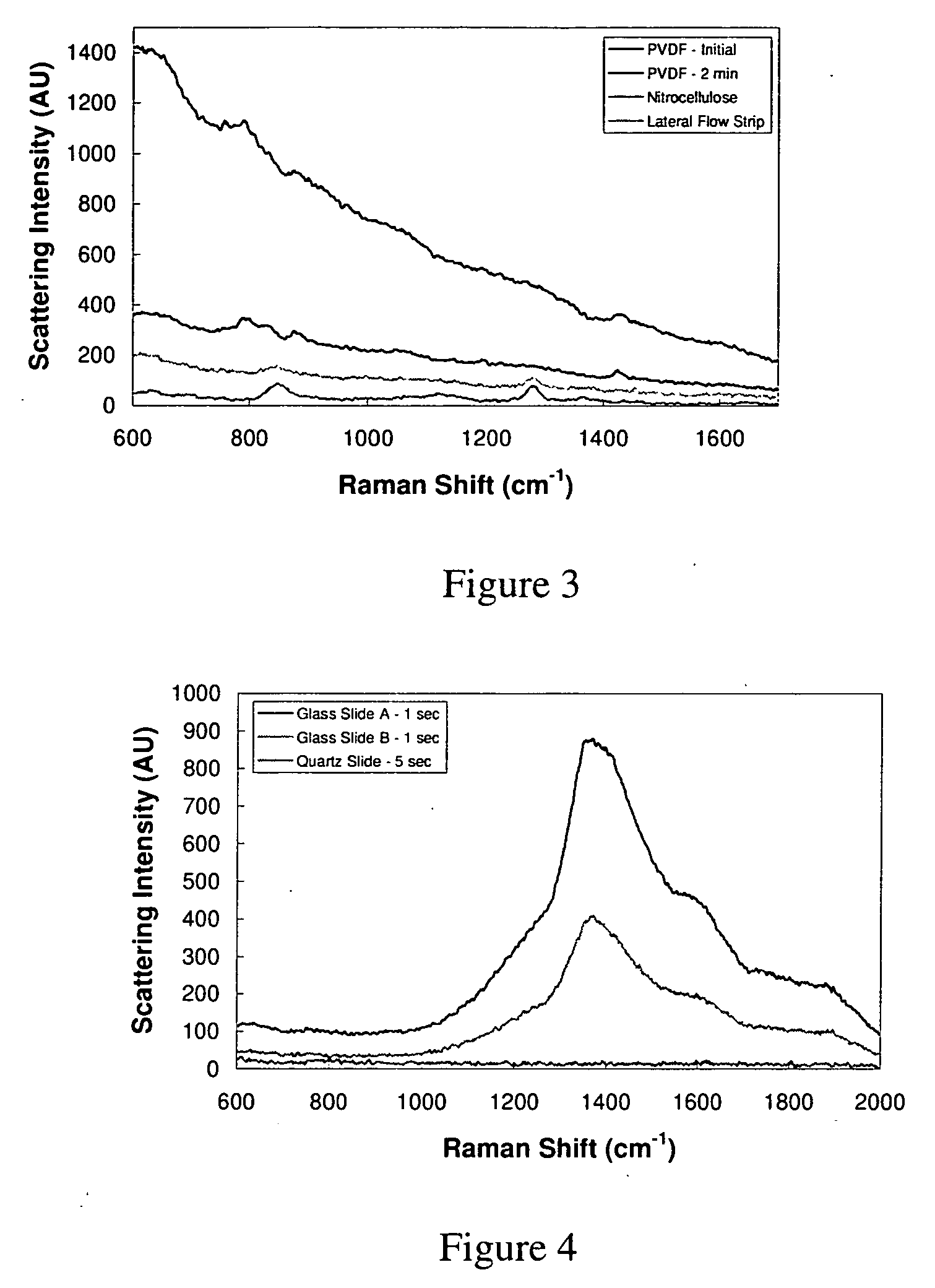

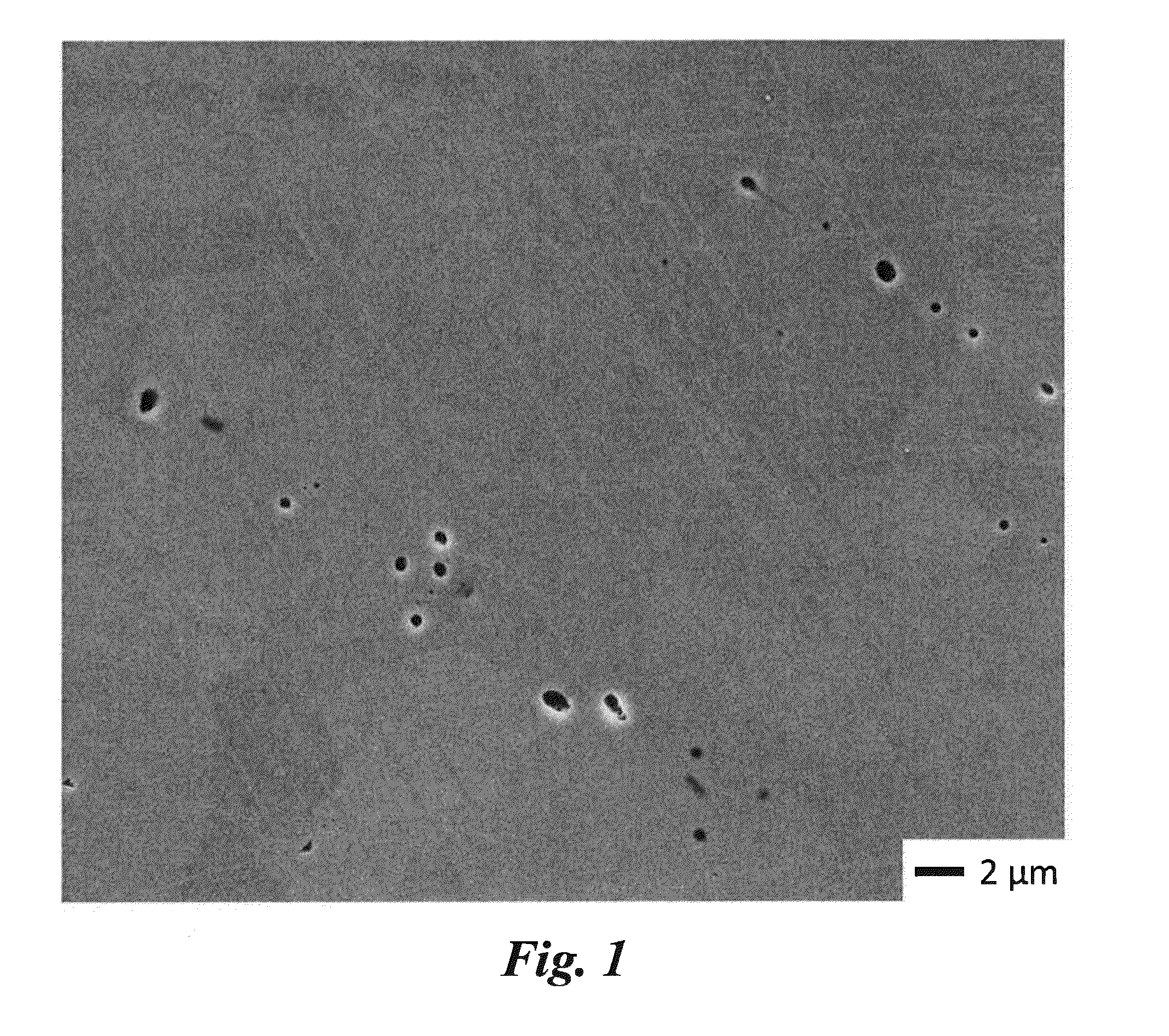

Surface enhanced spectrometry-active composite nanoparticles

InactiveUS20060054506A1Material nanotechnologyTransportation and packagingComposite nanoparticlesMaterials science

Owner:NANOPLEX TECH +1

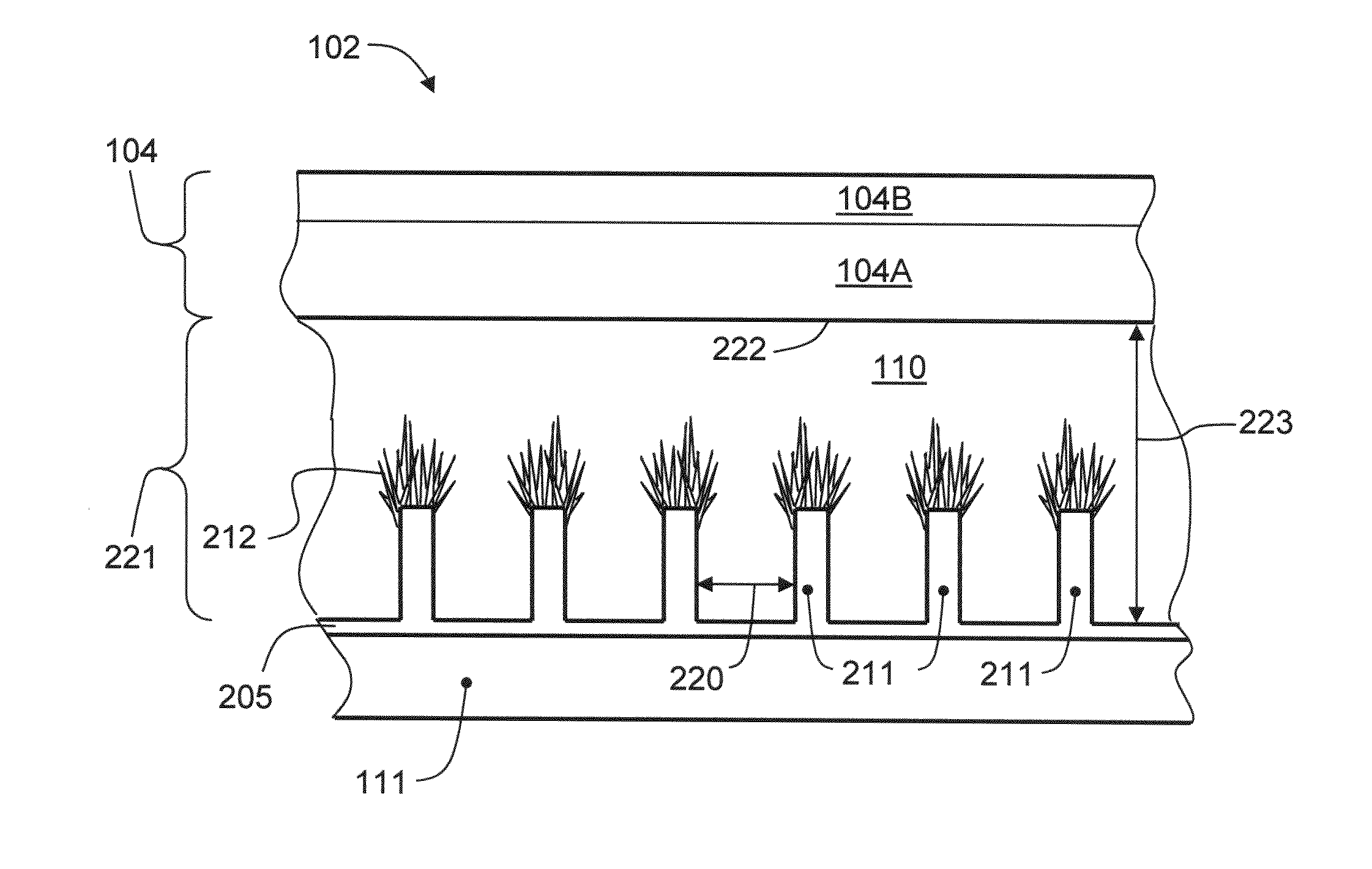

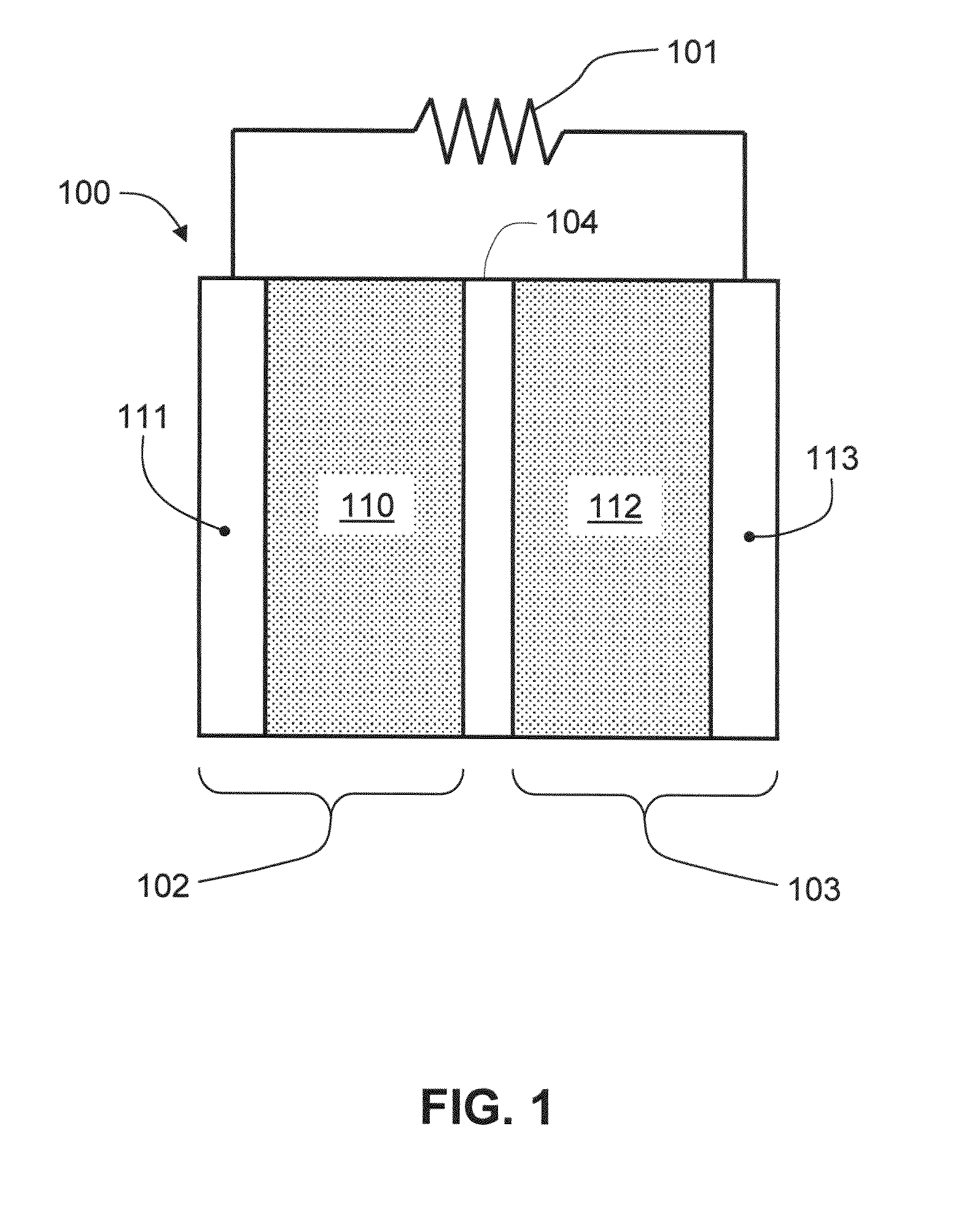

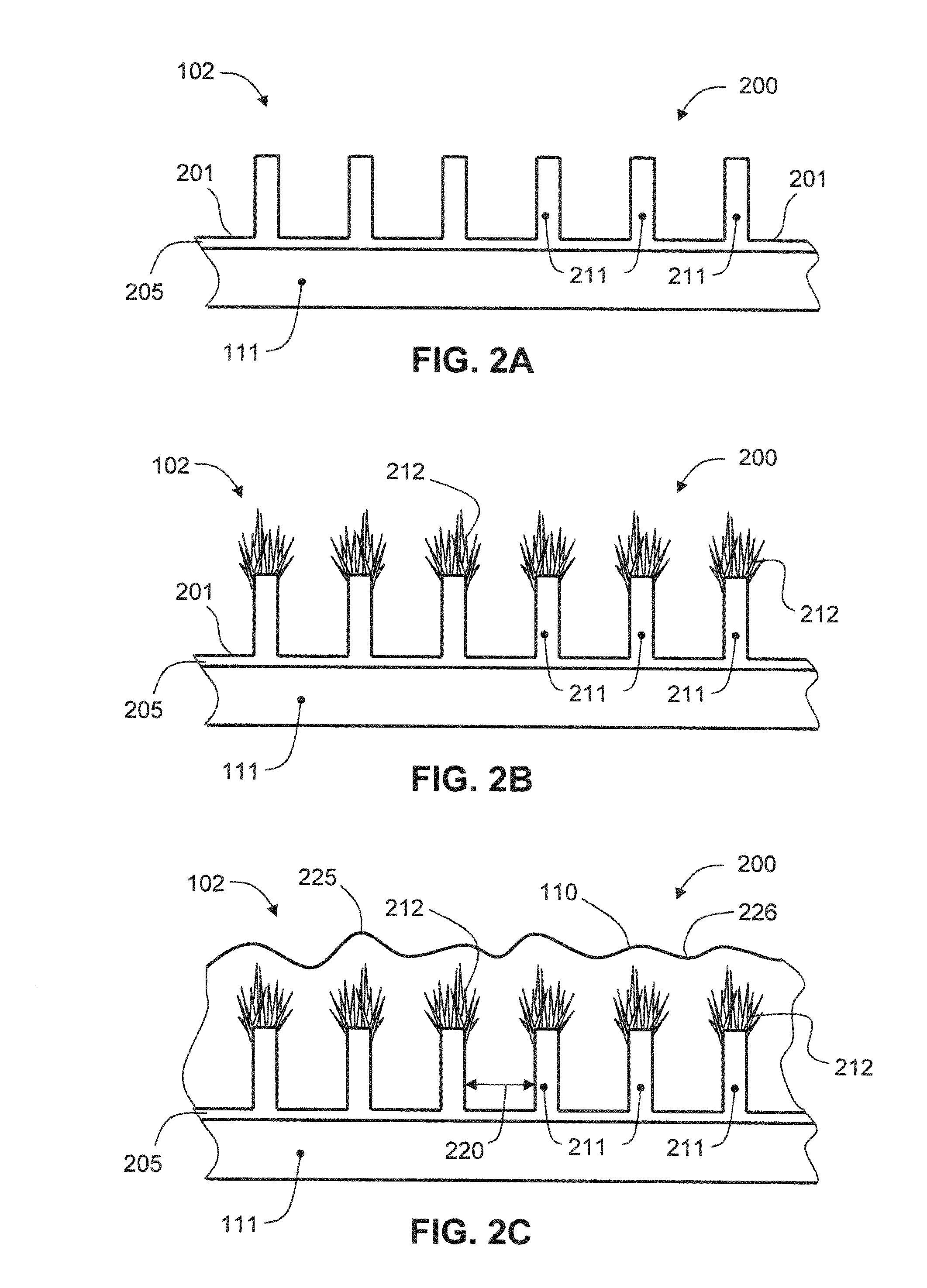

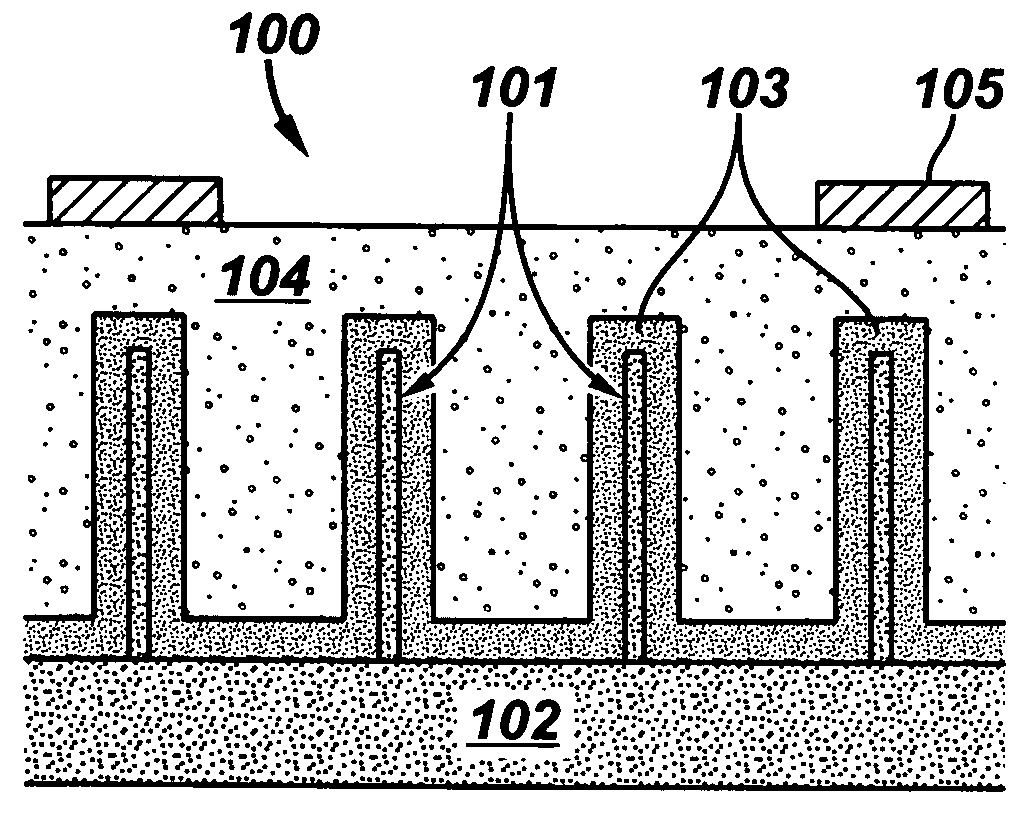

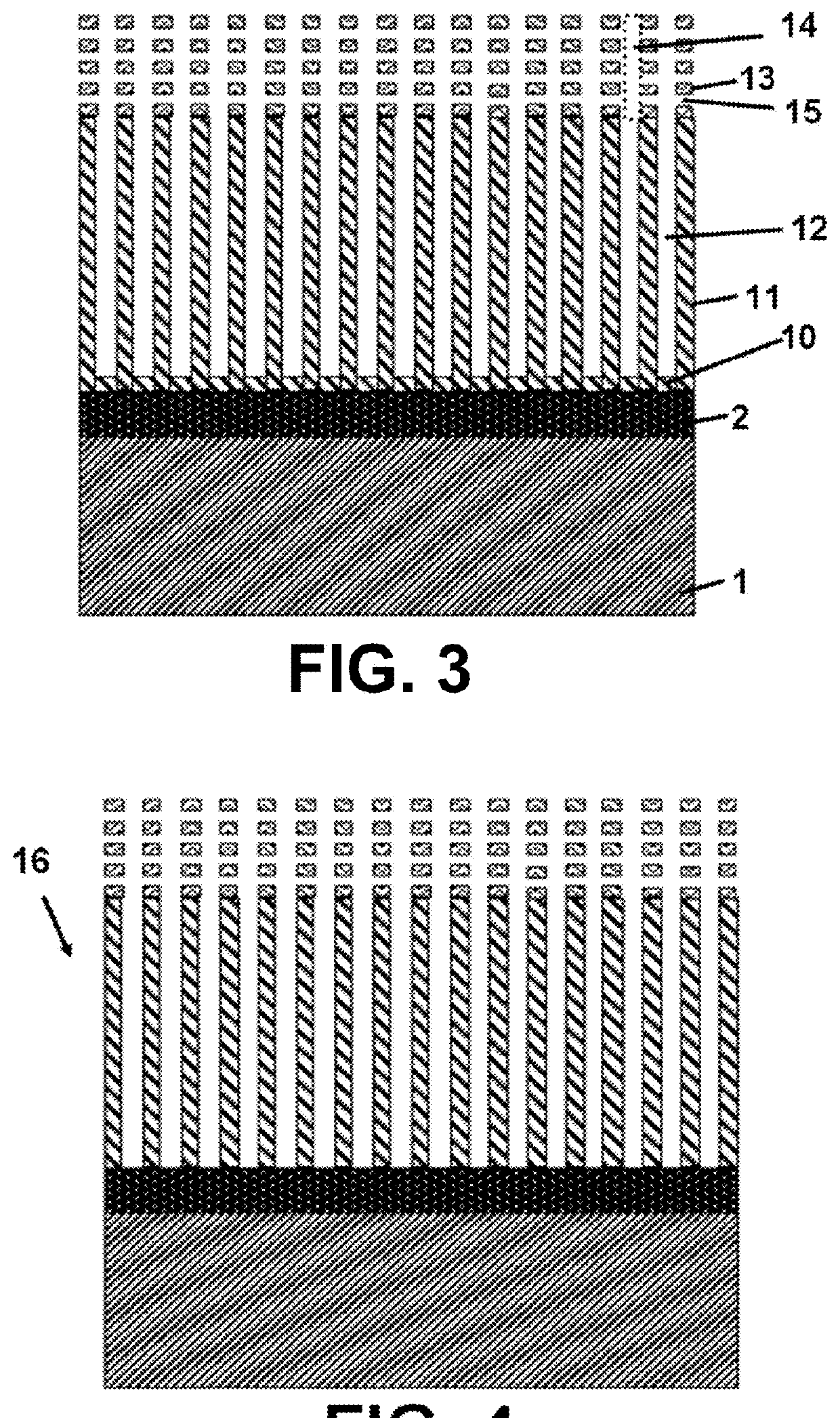

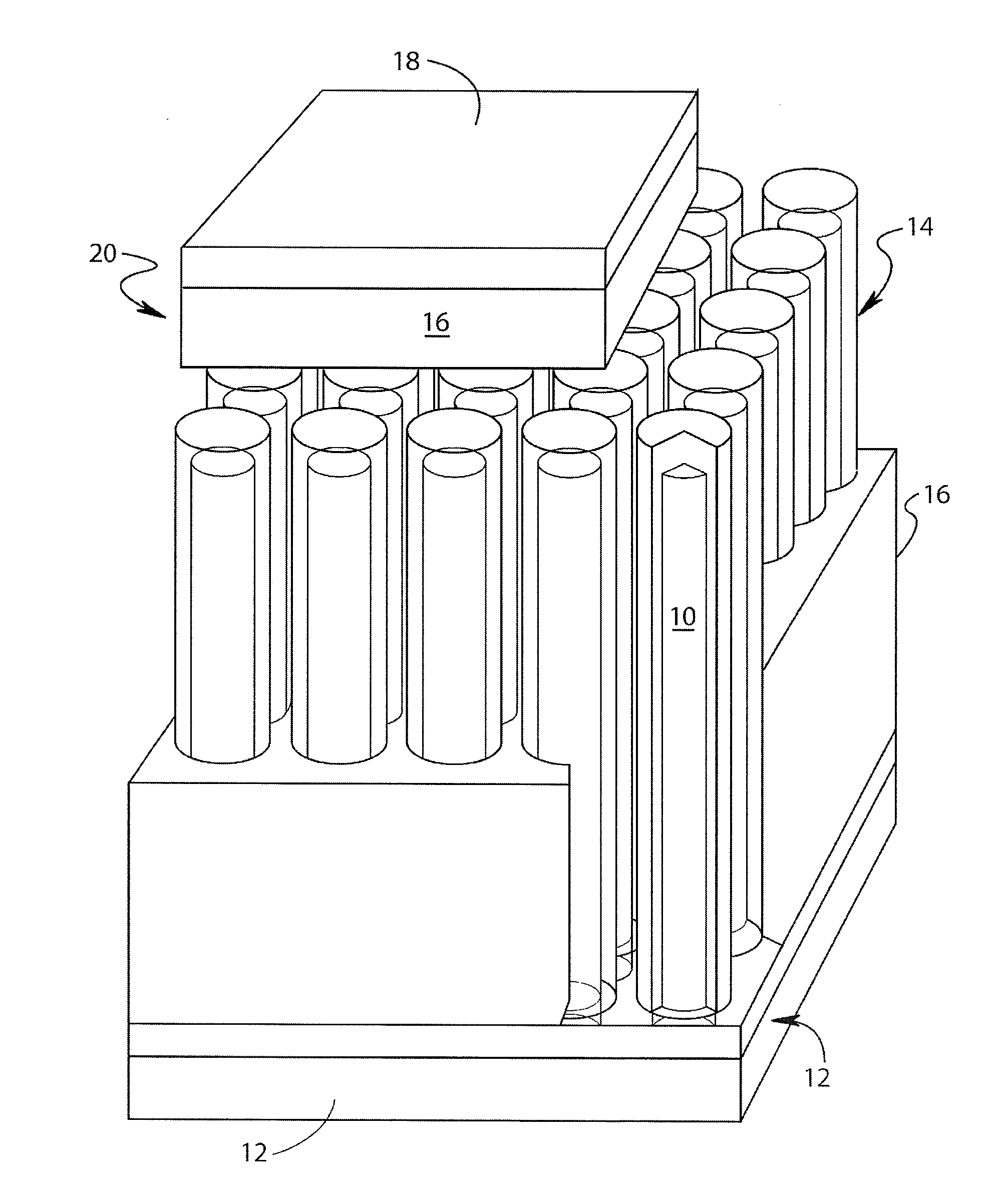

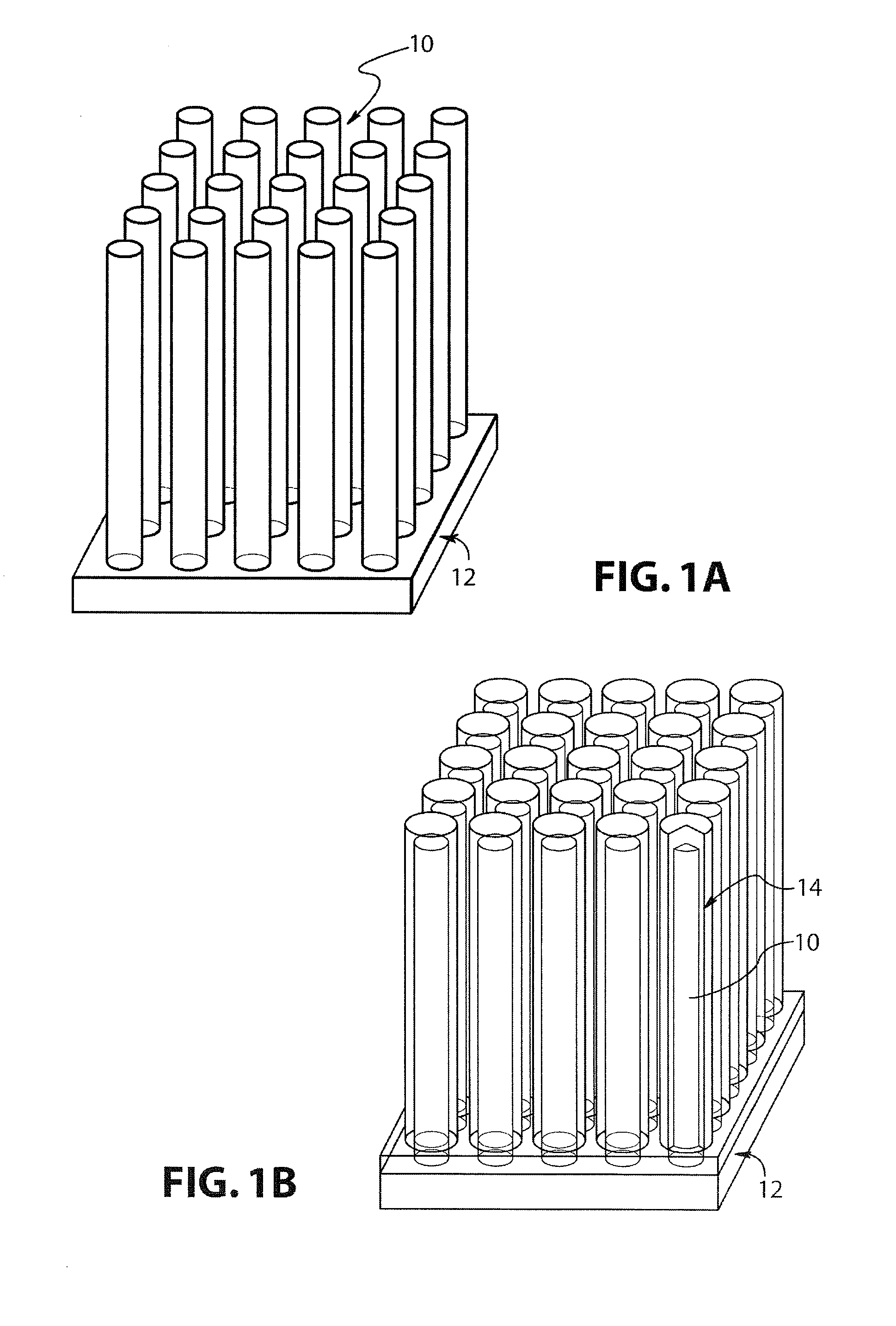

Thin film electrochemical energy storage device with three-dimensional anodic structure

InactiveUS20100216026A1Final product manufactureElectrode carriers/collectorsPorosityMicro structure

A method for forming a battery from via thin-film deposition processes is disclosed. A mesoporous carbon material is deposited onto a surface of a conductive substrate that has high surface area, conductive micro-structures formed thereon. A porous, dielectric separator layer is then deposited on the layer of mesoporous carbon material to form a half cell of an energy storage device. The mesoporous carbon material is made up of CVD-deposited carbon fullerene “onions” and carbon nano-tubes, and has a high porosity capable of retaining lithium ions in concentrations useful for storing significant quantities of electrical energy. Embodiments of the invention further provide for the formation of an electrode having a high surface area conductive region that is useful in a battery structure. In one configuration the electrode has a high surface area conductive region comprising a porous dendritic structure that can be formed by electroplating, physical vapor deposition, chemical vapor deposition, thermal spraying, and / or electroless plating techniques.

Owner:APPLIED MATERIALS INC

Method of manufacture of colloidal rod particles as nanobarcodes

Owner:SURROMED +1

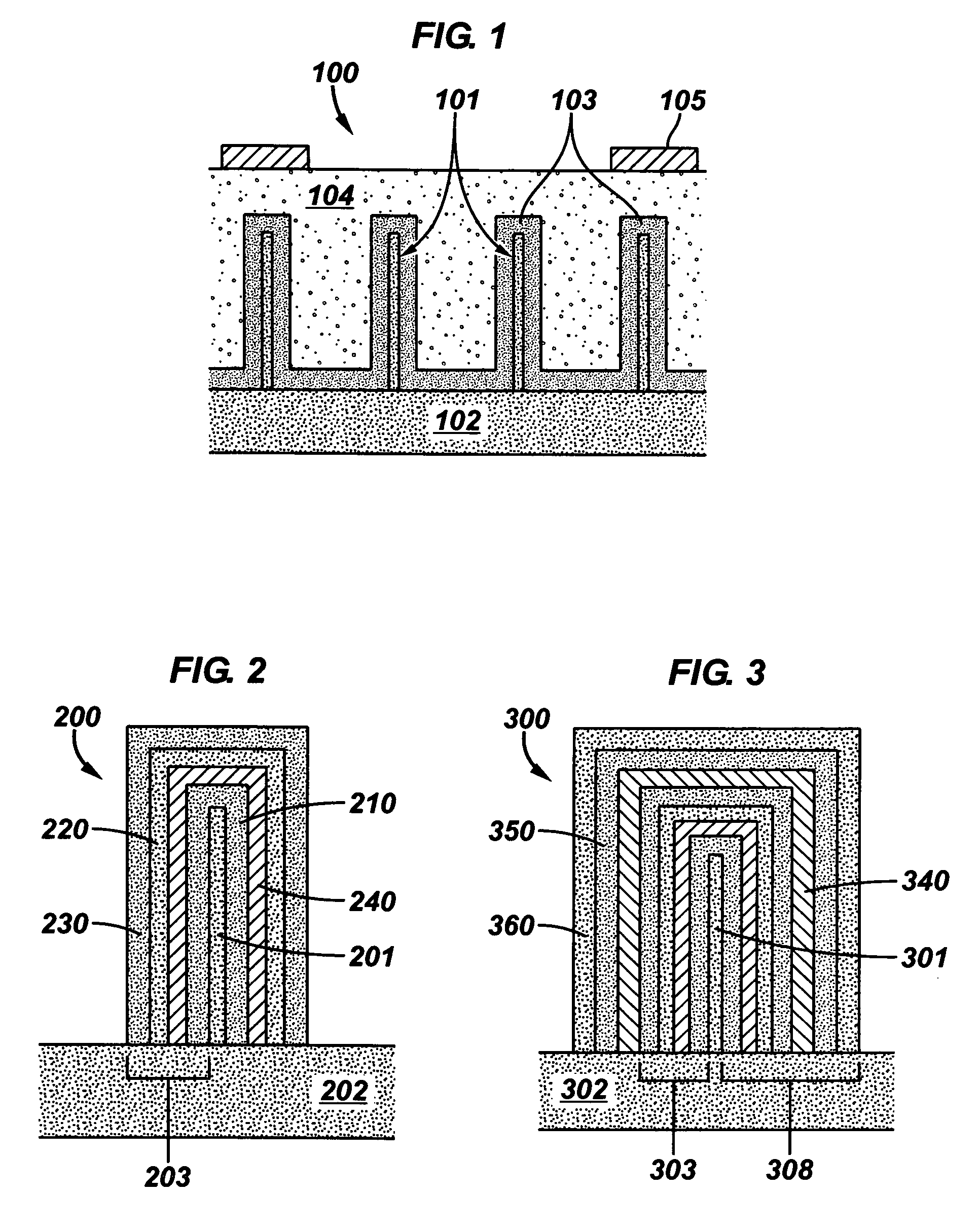

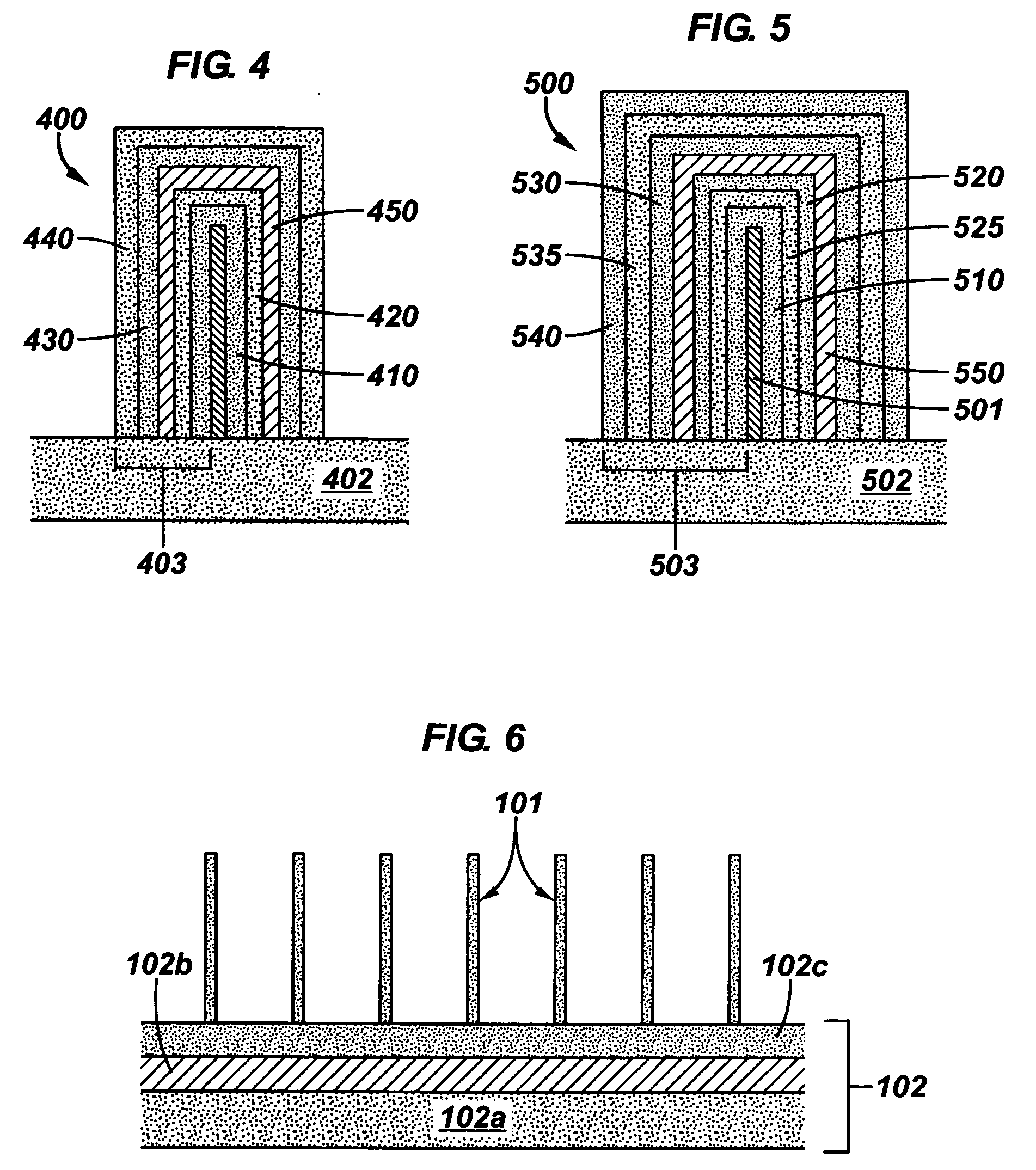

Amorphous-crystalline tandem nanostructured solar cells

InactiveUS20080110486A1Enhanced light absorptionBroad spectrumMaterial nanotechnologyPV power plantsEngineeringSolar cell

A photovoltaic device that includes a plurality of elongated nanostructures disposed on the surface of a substrate and a multilayered film deposited conformally over the elongated nanostructures forming a plurality of photoactive junctions. A method making such a photovoltaic device includes generating a plurality of elongated nanostructures on a substrate surface and conformally depositing a multilayered film forming a plurality of photoactive junctions. The plurality of photoactive junctions are designed to capture different wavelengths of light. A solar panel includes at least one photovoltaic device.

Owner:C3 PROTECTION +1

Metallic articles with hydrophobic surfaces

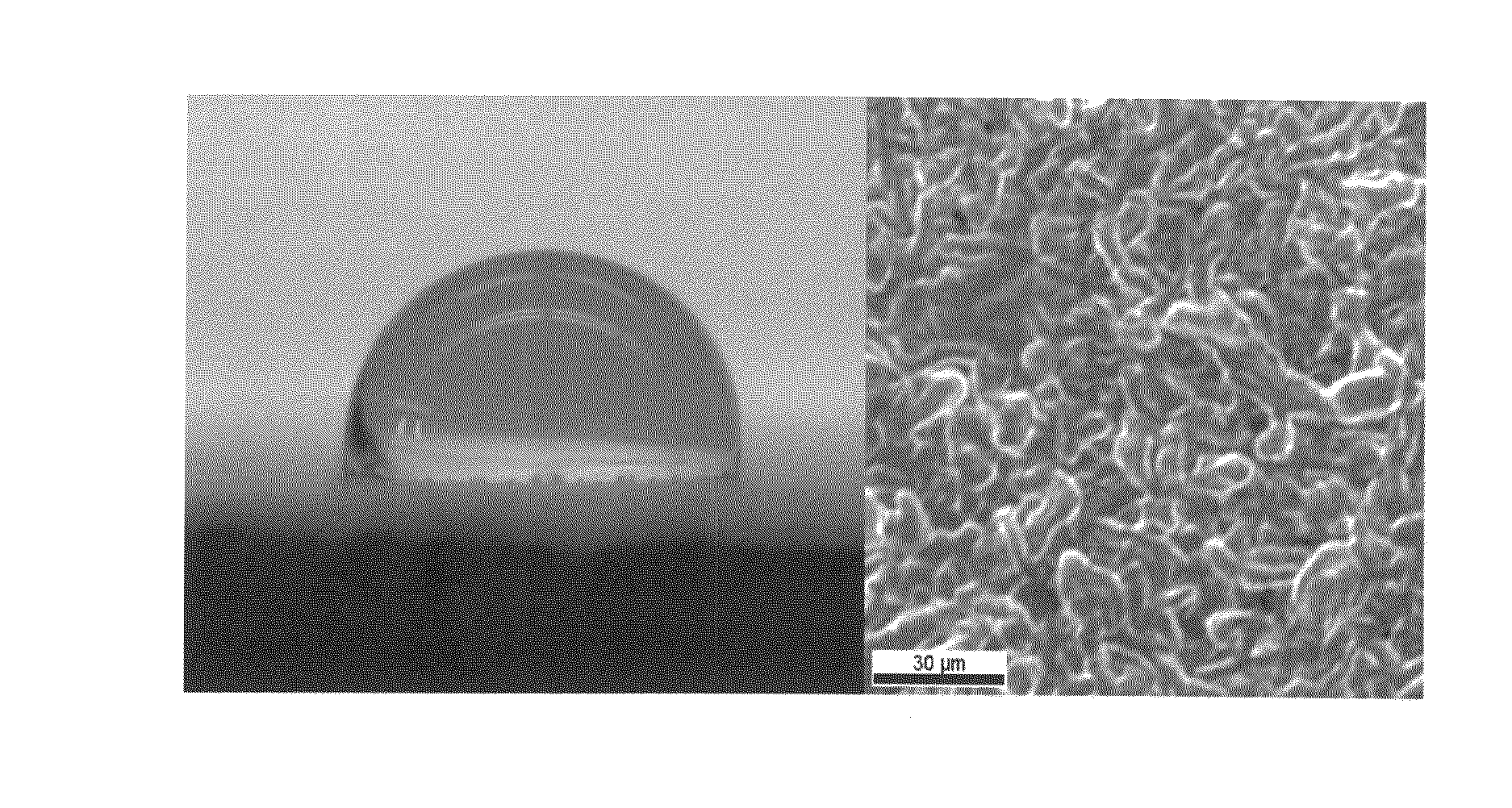

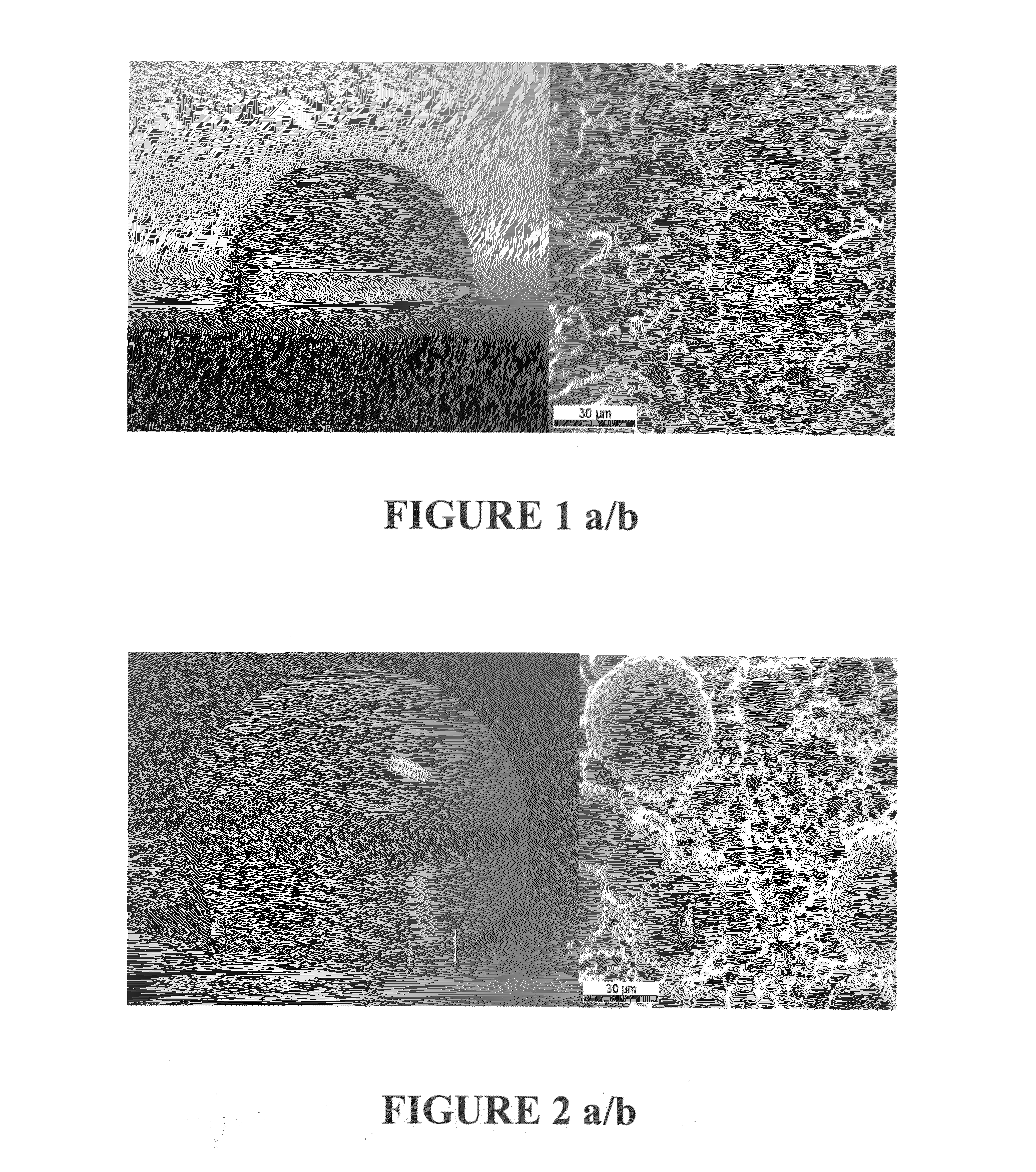

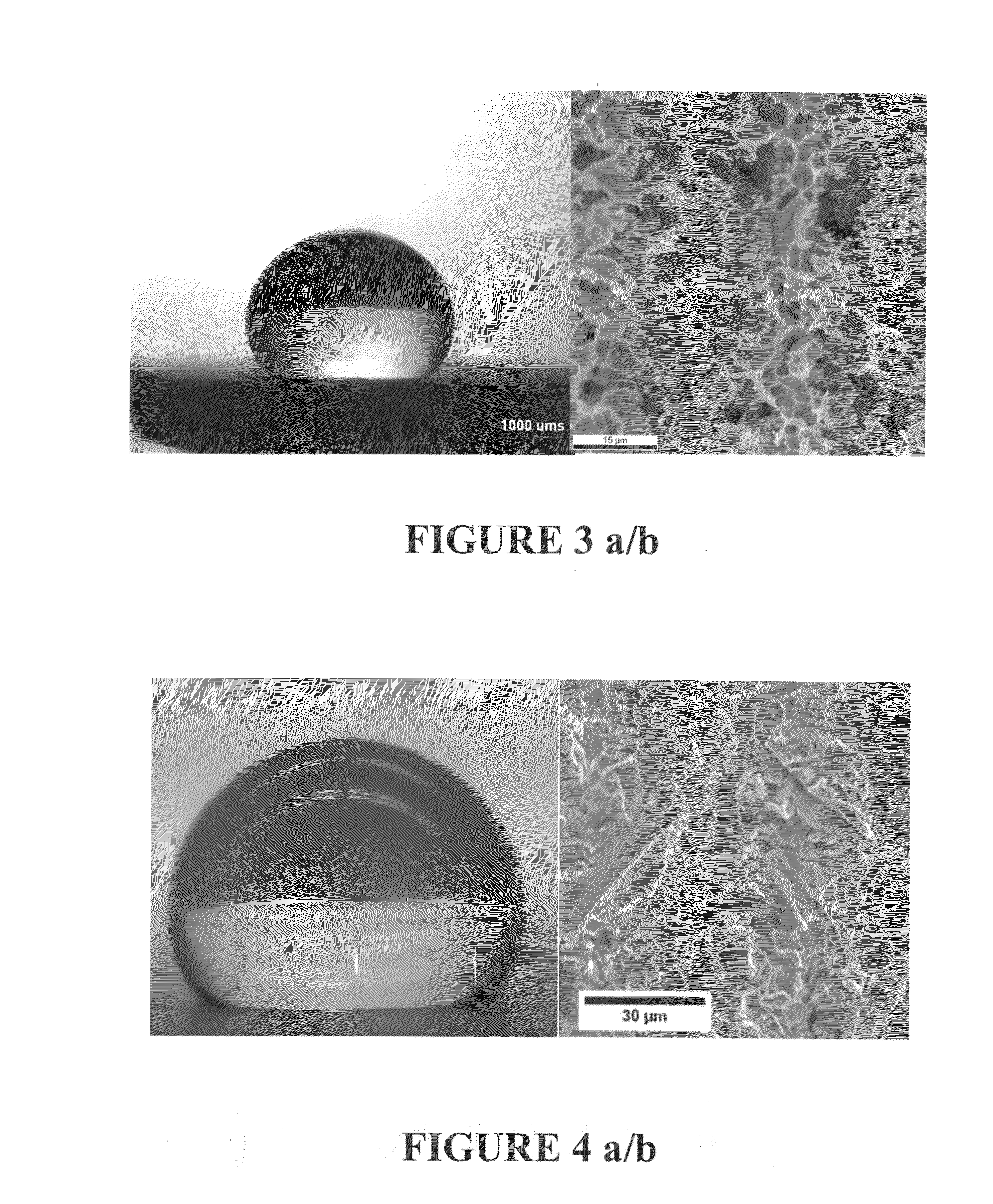

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

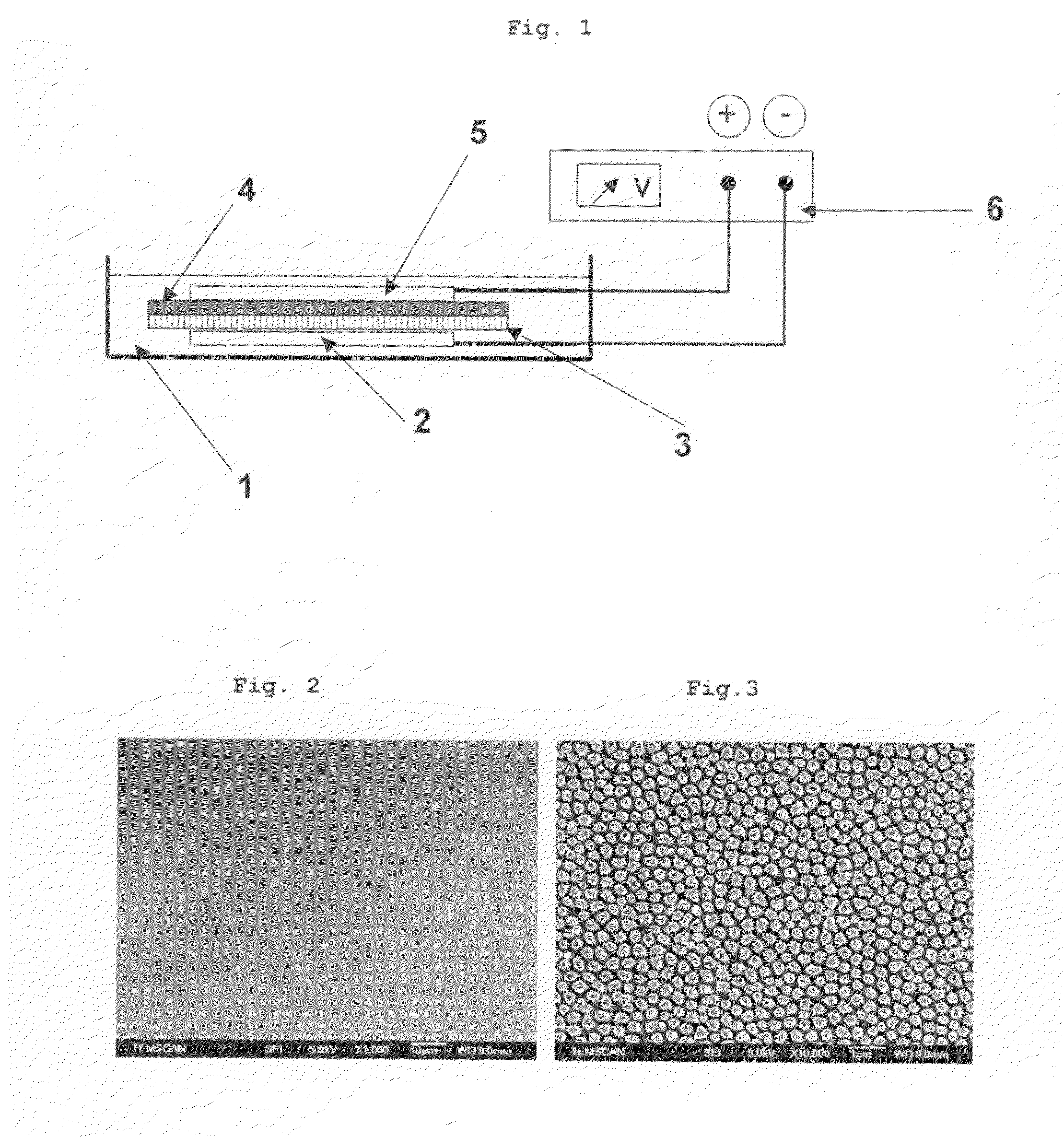

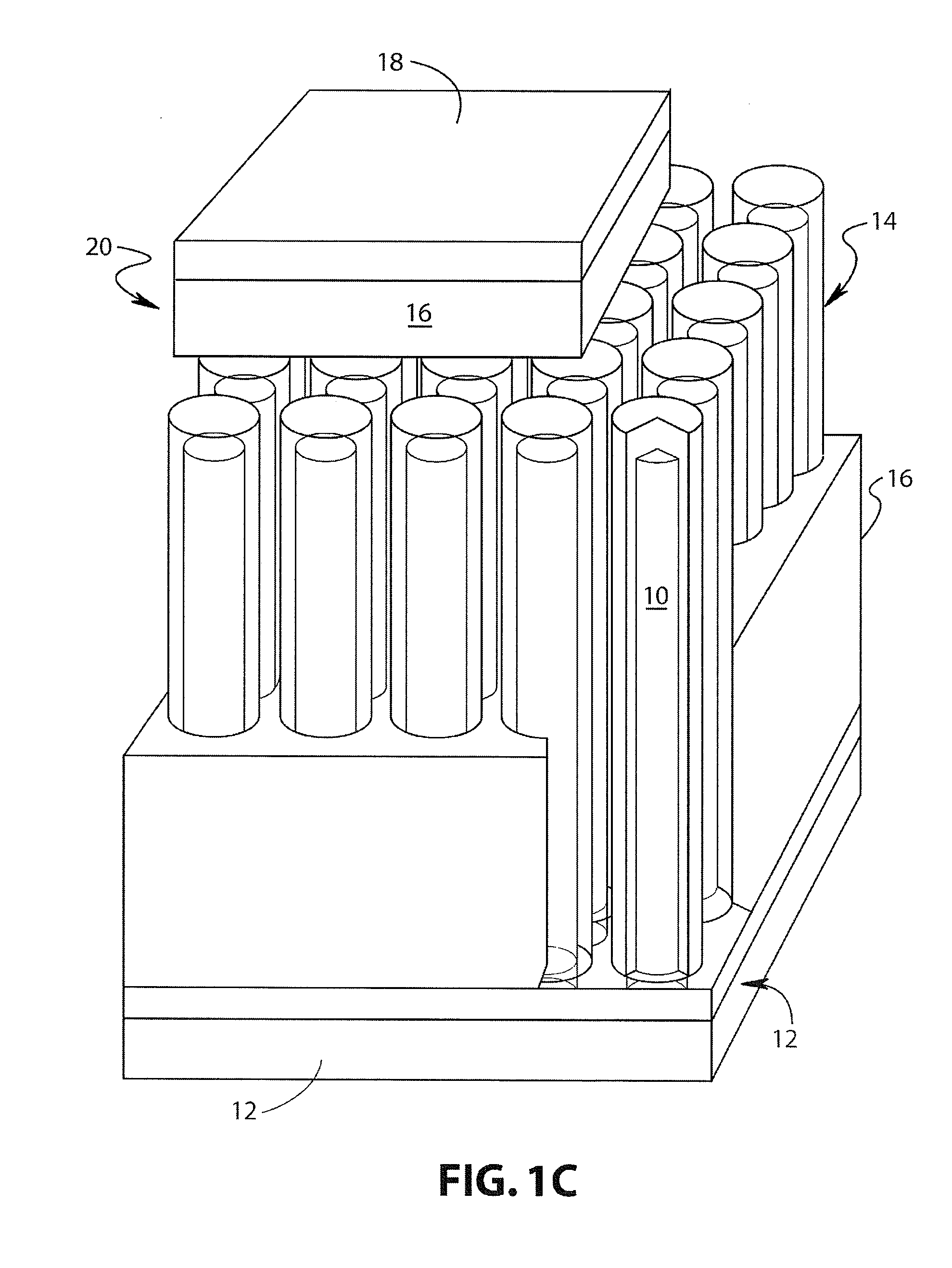

Method for the Electrolytic Production of Self-Supporting Conductive Nanocomposite Elements

InactiveUS20090316335A1Electrolytic capacitorsFinal product manufactureElectrolysisMetallic materials

The invention relates to a self-supporting composite element and to a method of producing same. The composite element comprises a substrate of electronic conductive material which is covered with metal nanowires that are essentially oriented along a plane that is perpendicular to the substrate. The element is produced in a cell comprising a cathode which is formed by the substrate to be covered, one or more anodes and an electrolyte which is formed by a solution of a precursor of the metal material and optionally containing a conductive ionic salt, a flat porous membrane which is placed between the cathode and each of the anodes and a spacer element between each membrane and the anode adjacent thereto, the different constituent parts of the cell being maintained in contact.

Owner:UNIV DE PICARDIE JULES VERNE +1

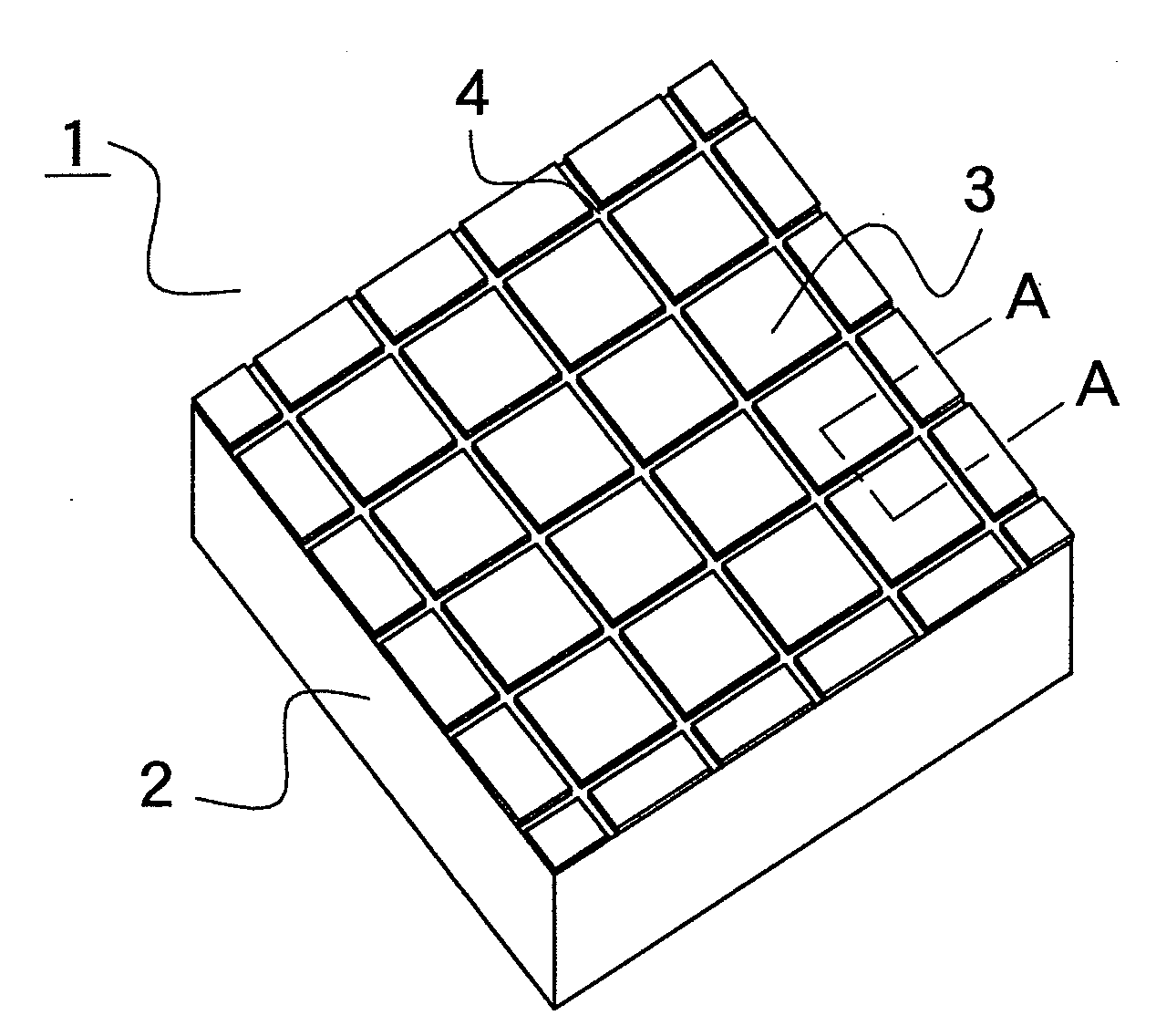

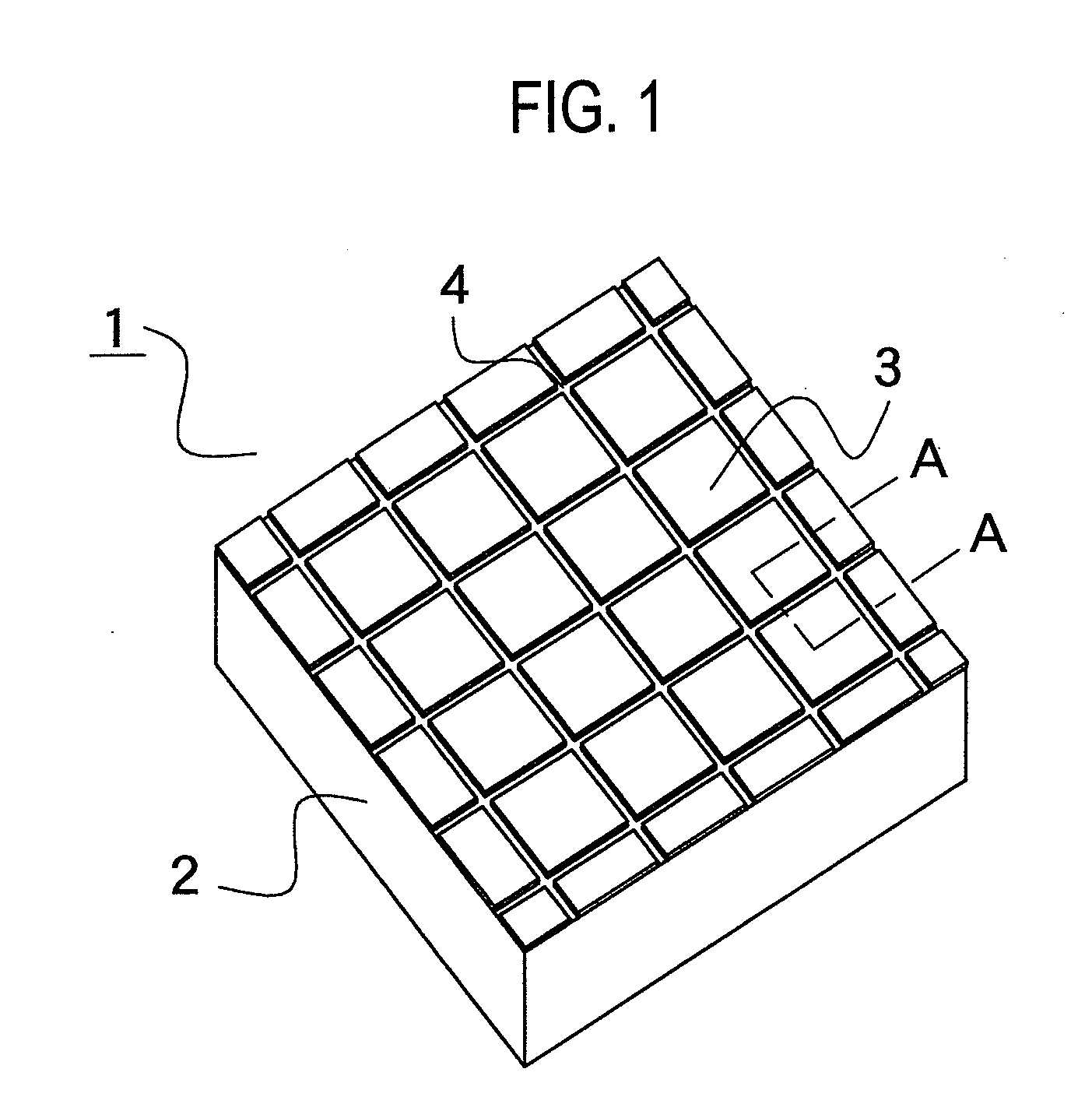

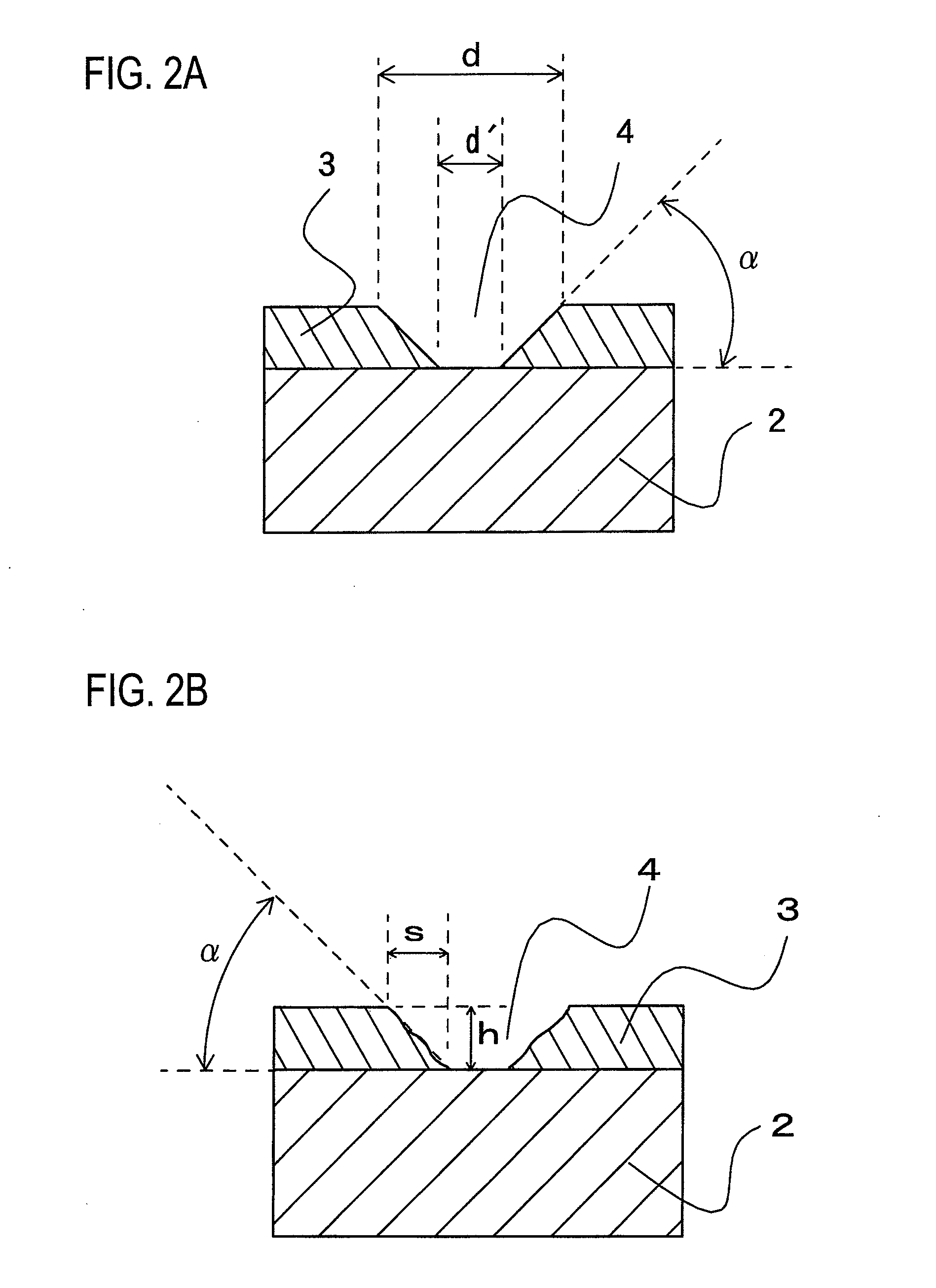

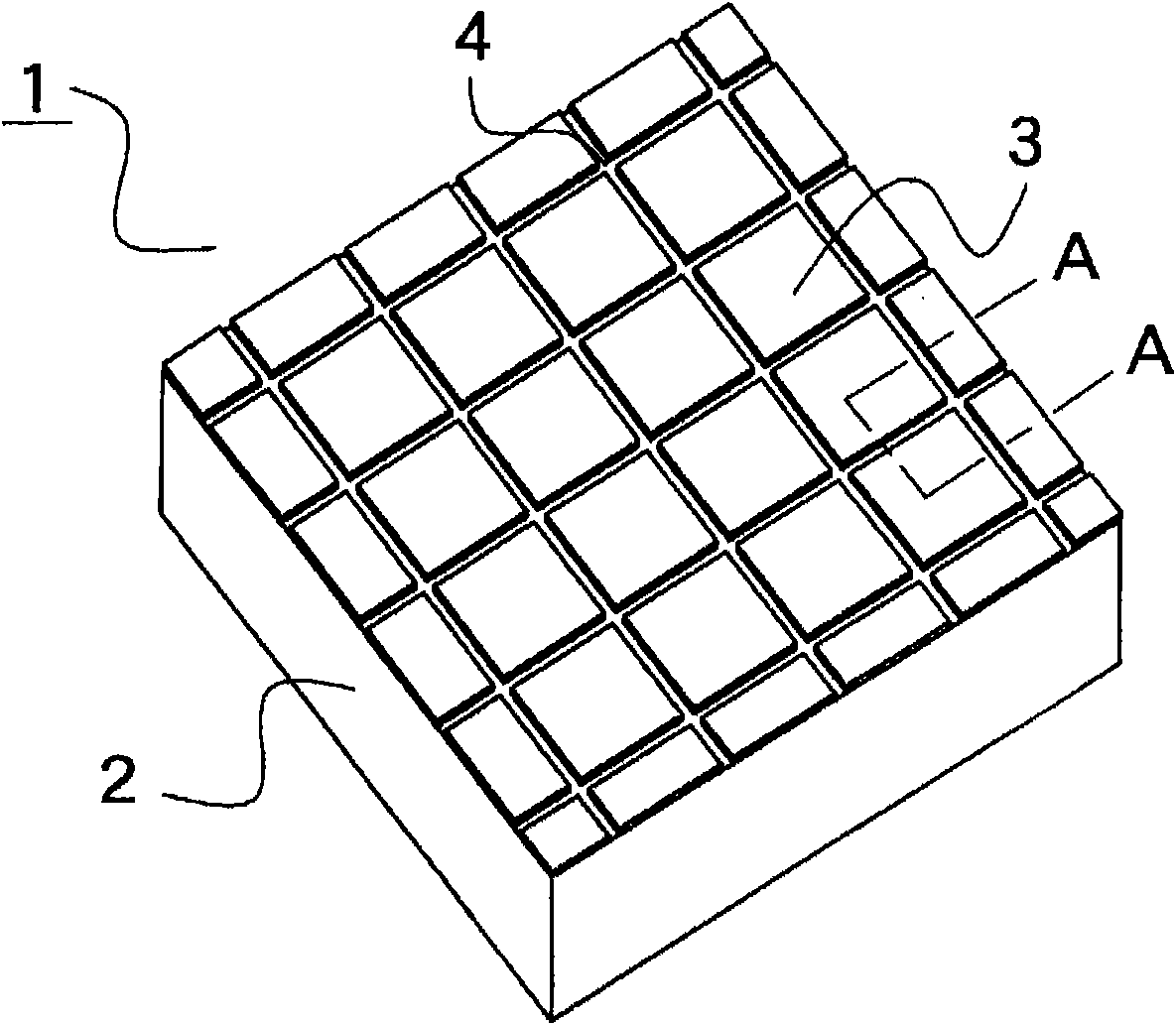

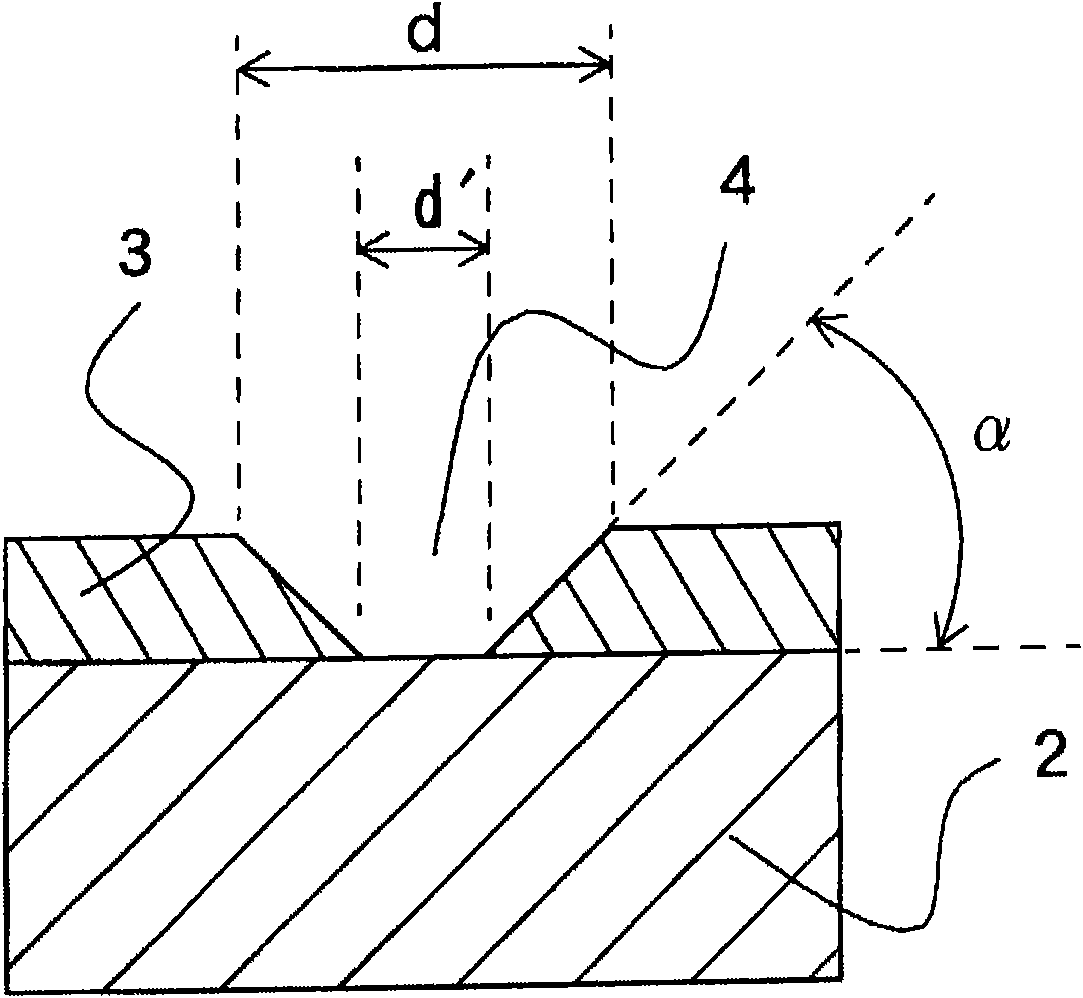

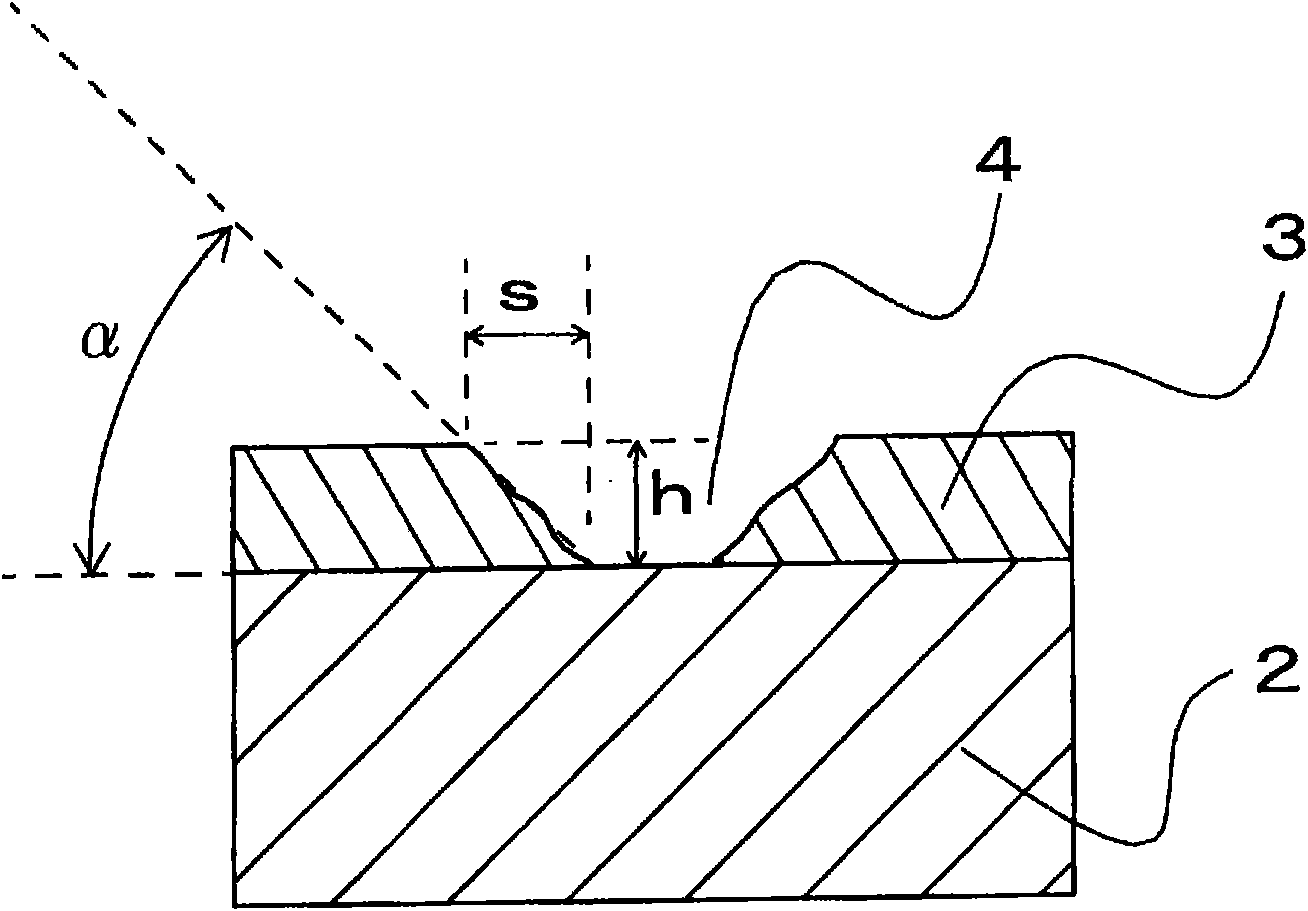

Engraved plate and substrate with conductor layer pattern using the same

InactiveUS20100021695A1High precision and miniaturization of patterningFlat surfaceMagnetic/electric field screeningLayered productsElectrical conductorEngineering

Owner:HITACHI CHEM CO LTD

Method of manufacture of colloidal rod particles as nanobar codes

InactiveUS7045049B1Speed up the processMaterial nanotechnologyNanomagnetismNanoparticleSynthesis methods

Owner:SICPA HLDG SA +1

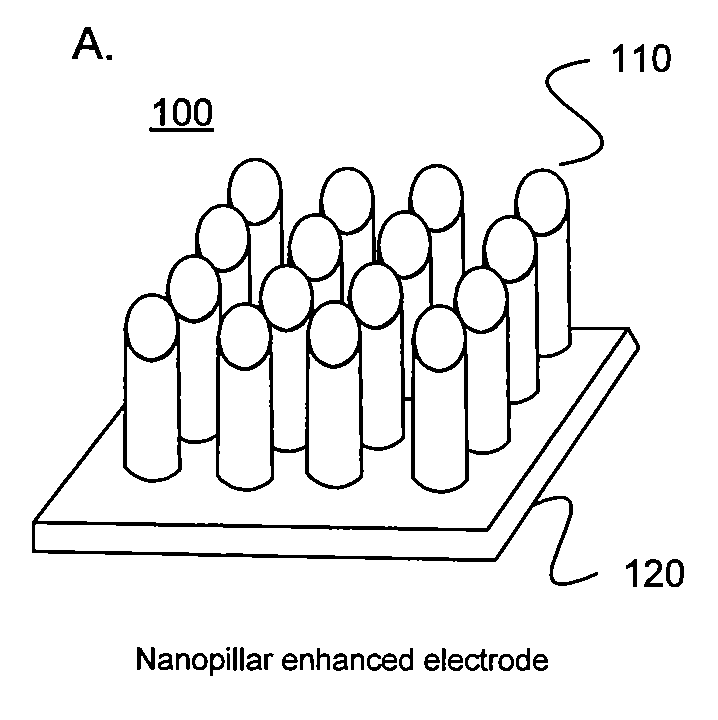

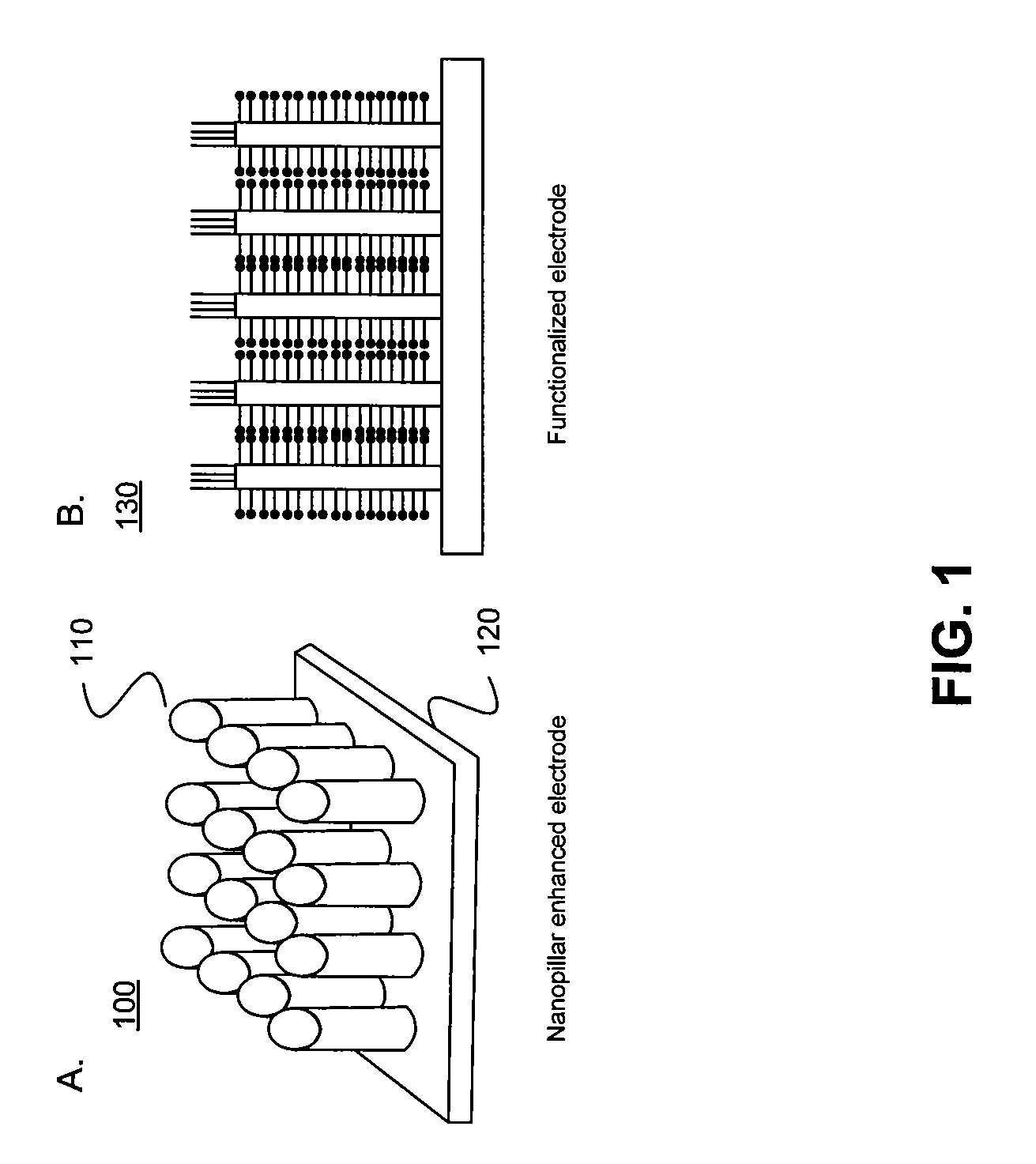

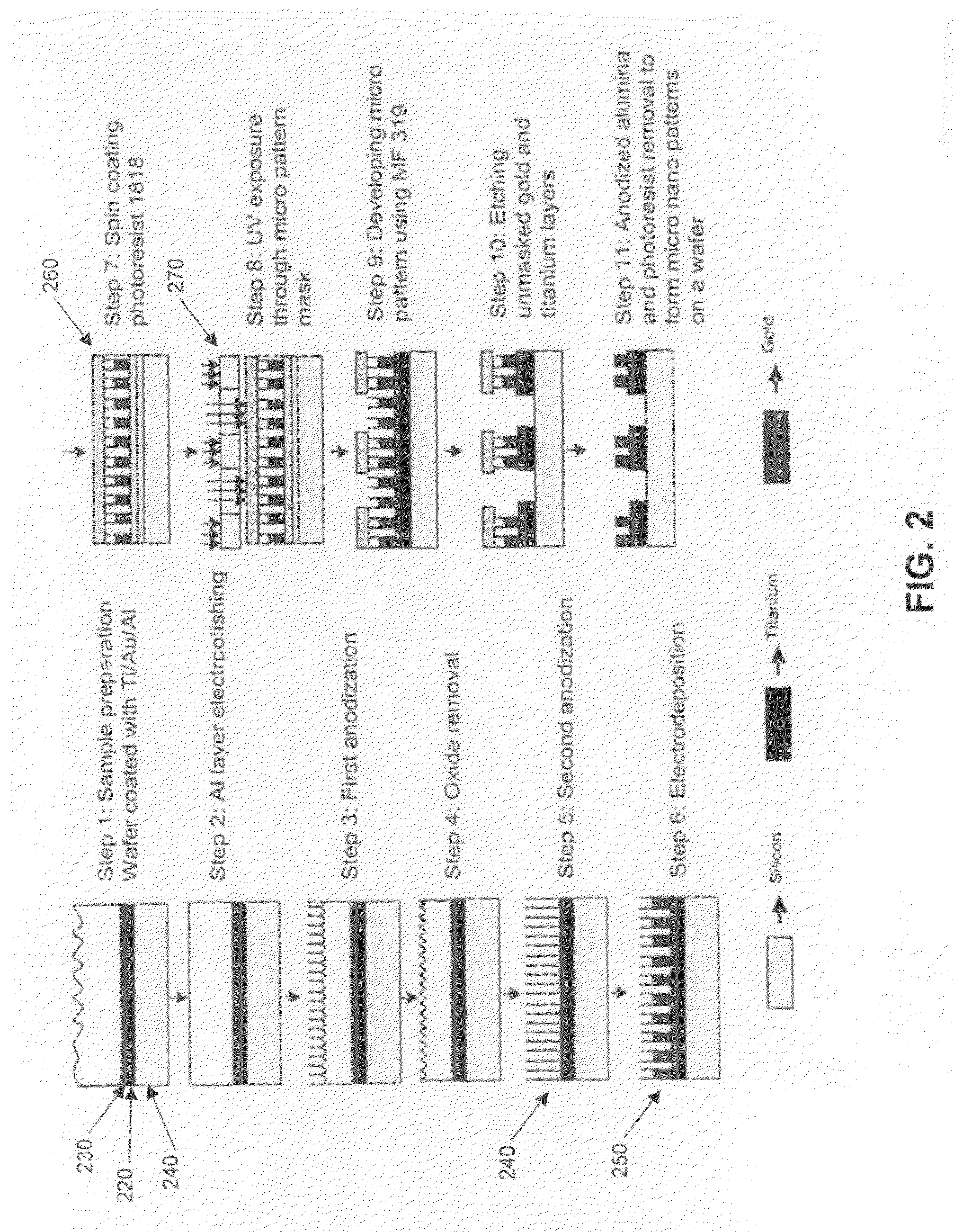

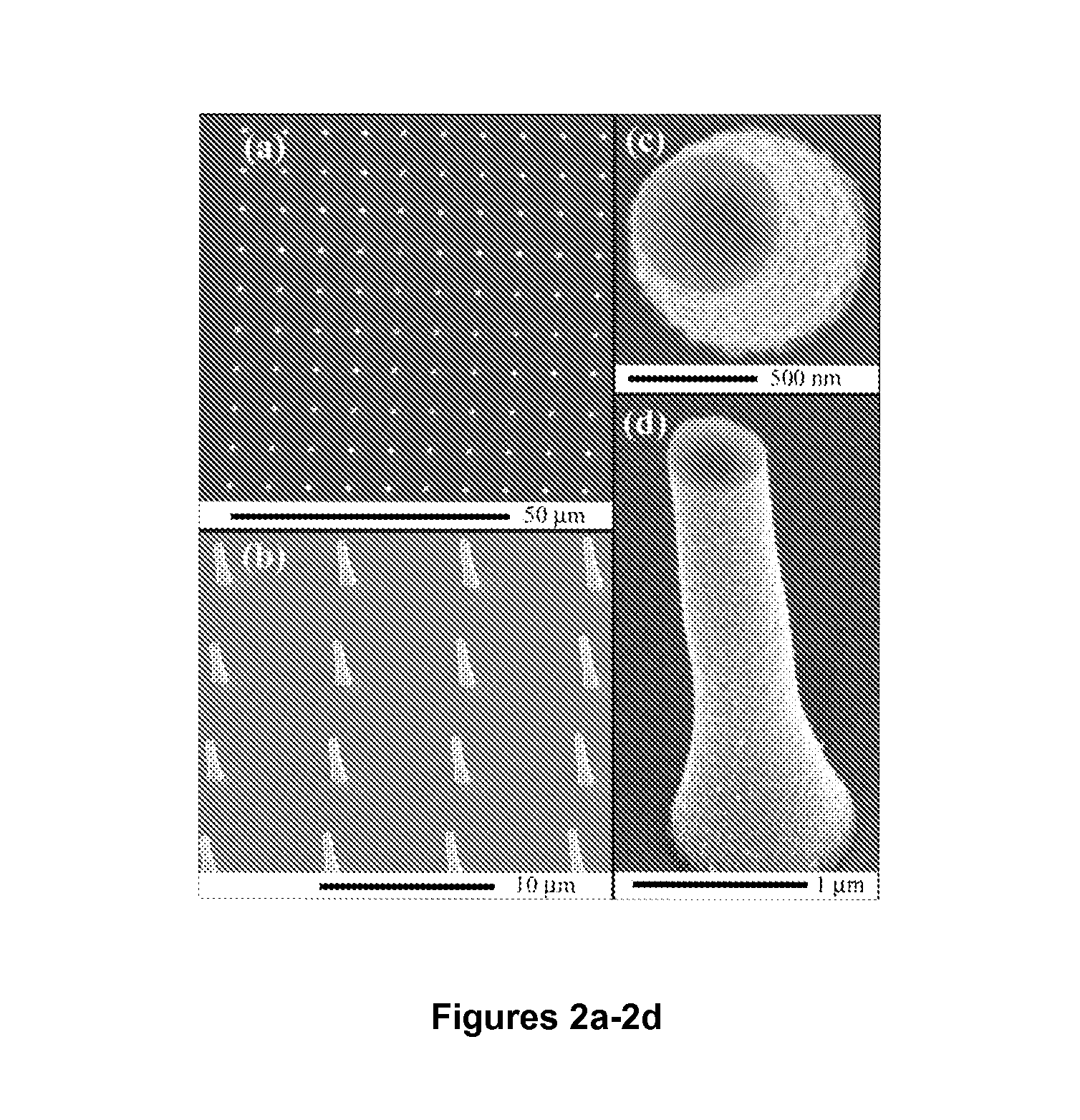

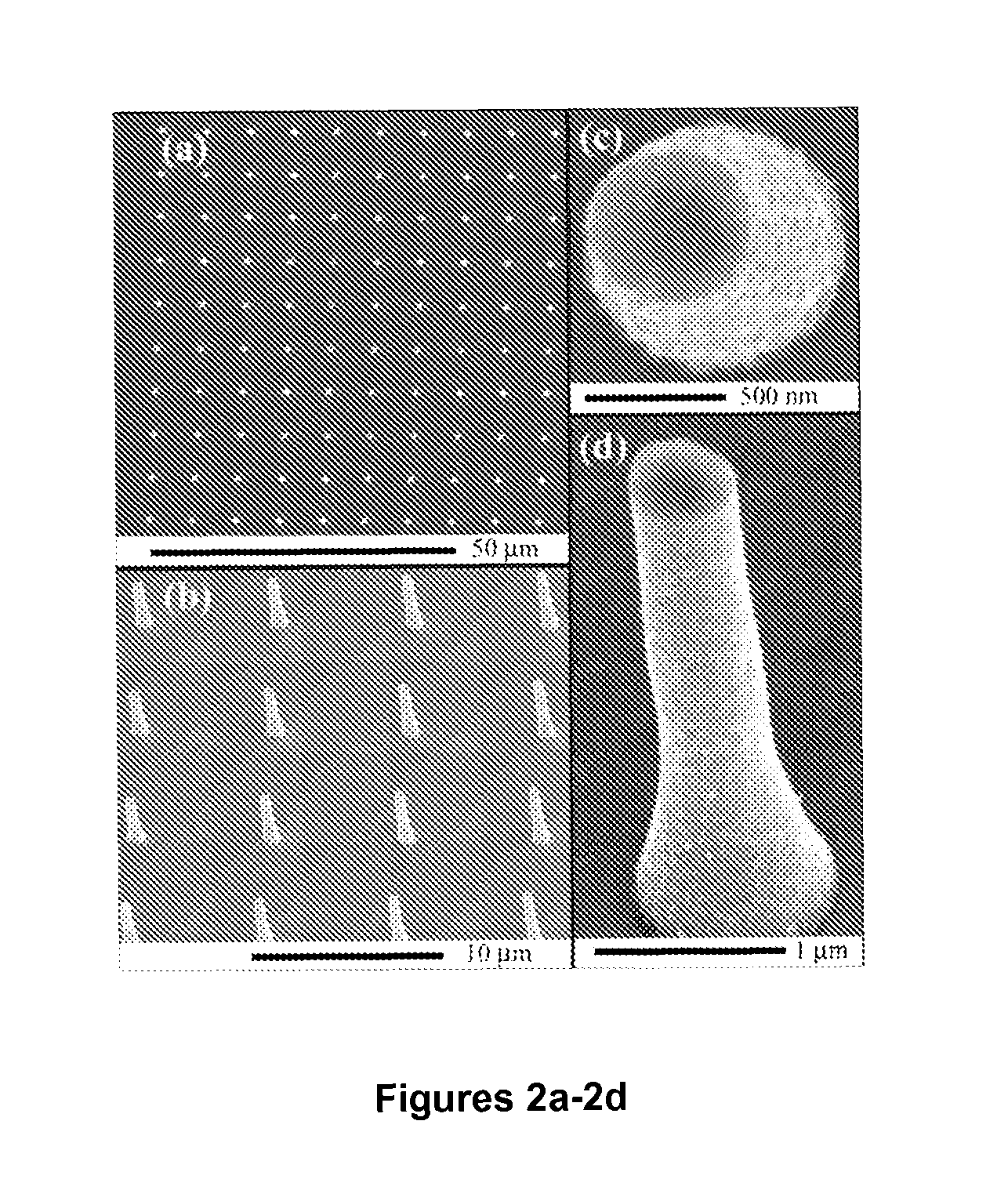

Fabrication of microstructures integrated with nanopillars along with their applications as electrodes in sensors

InactiveUS20100066346A1Improve mechanical propertiesHigh detection sensitivityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNanopillarEngineering

This invention presents microstructures enhanced with nanopillars. The invention also provides ways for manufacturing nanopillar-enhanced microstructures. In some embodiments, the invention also provides methods of use for the nanopillar-enhanced microstructures.

Owner:UNIV OF GEORGIA RES FOUND INC

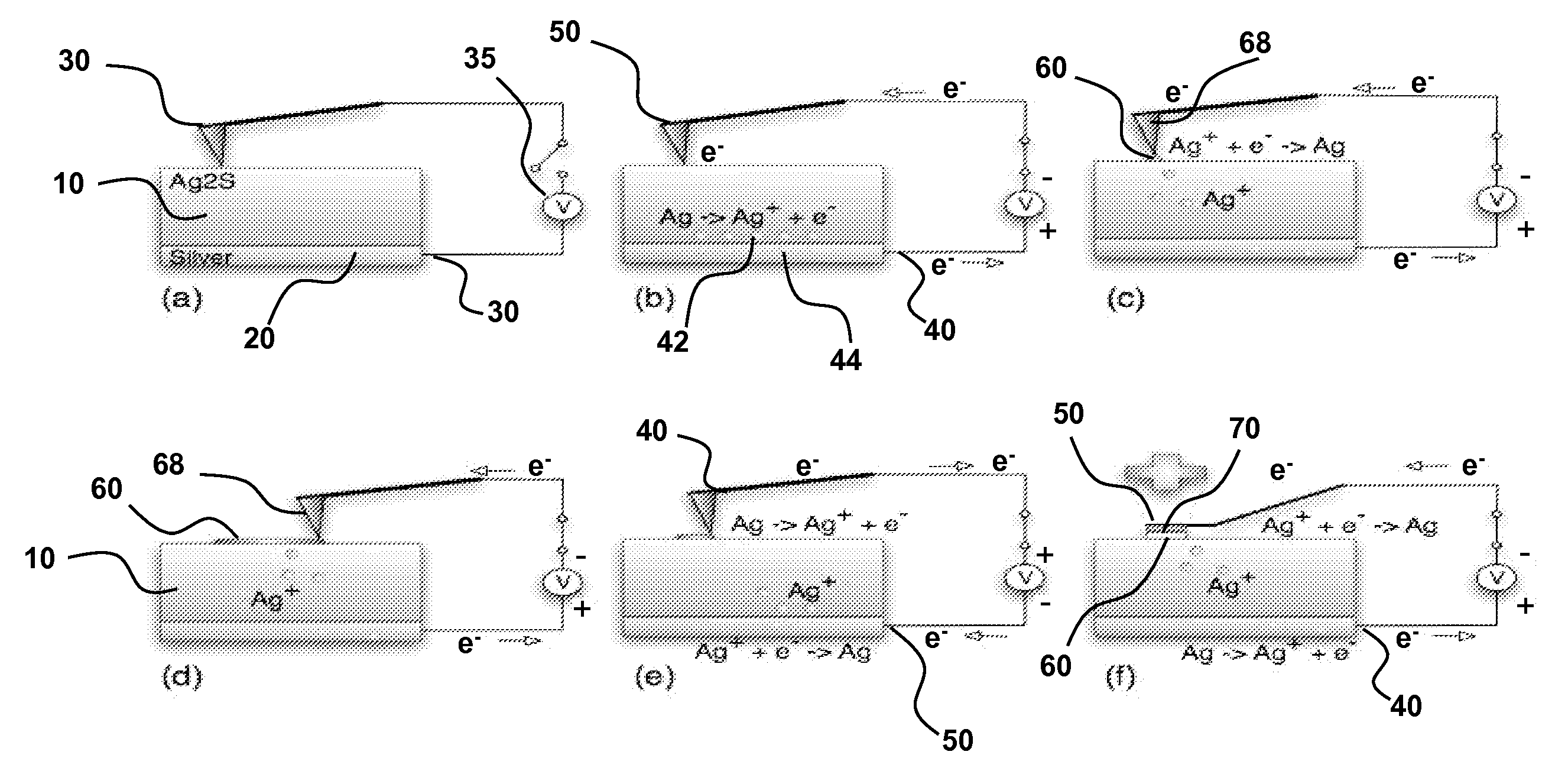

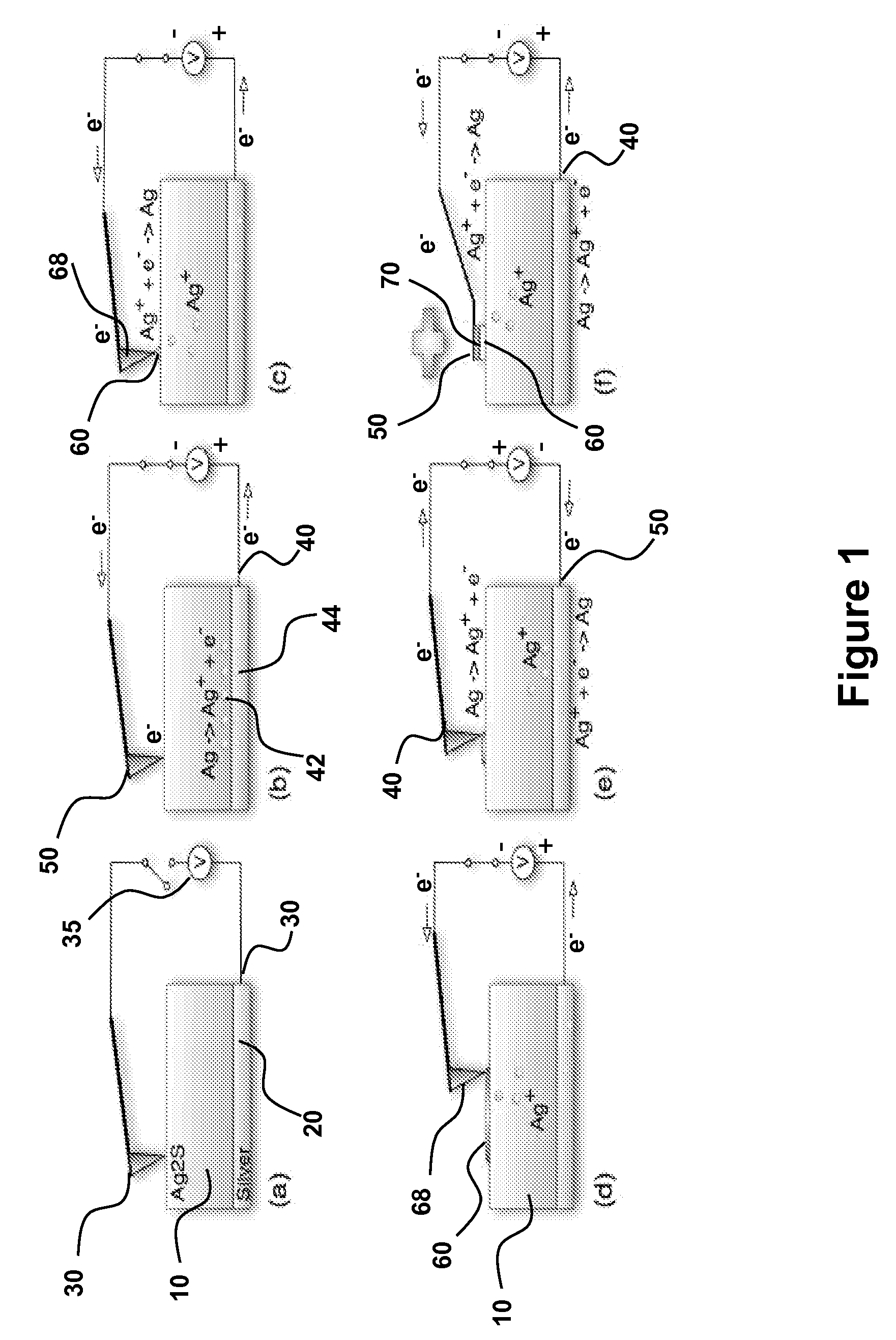

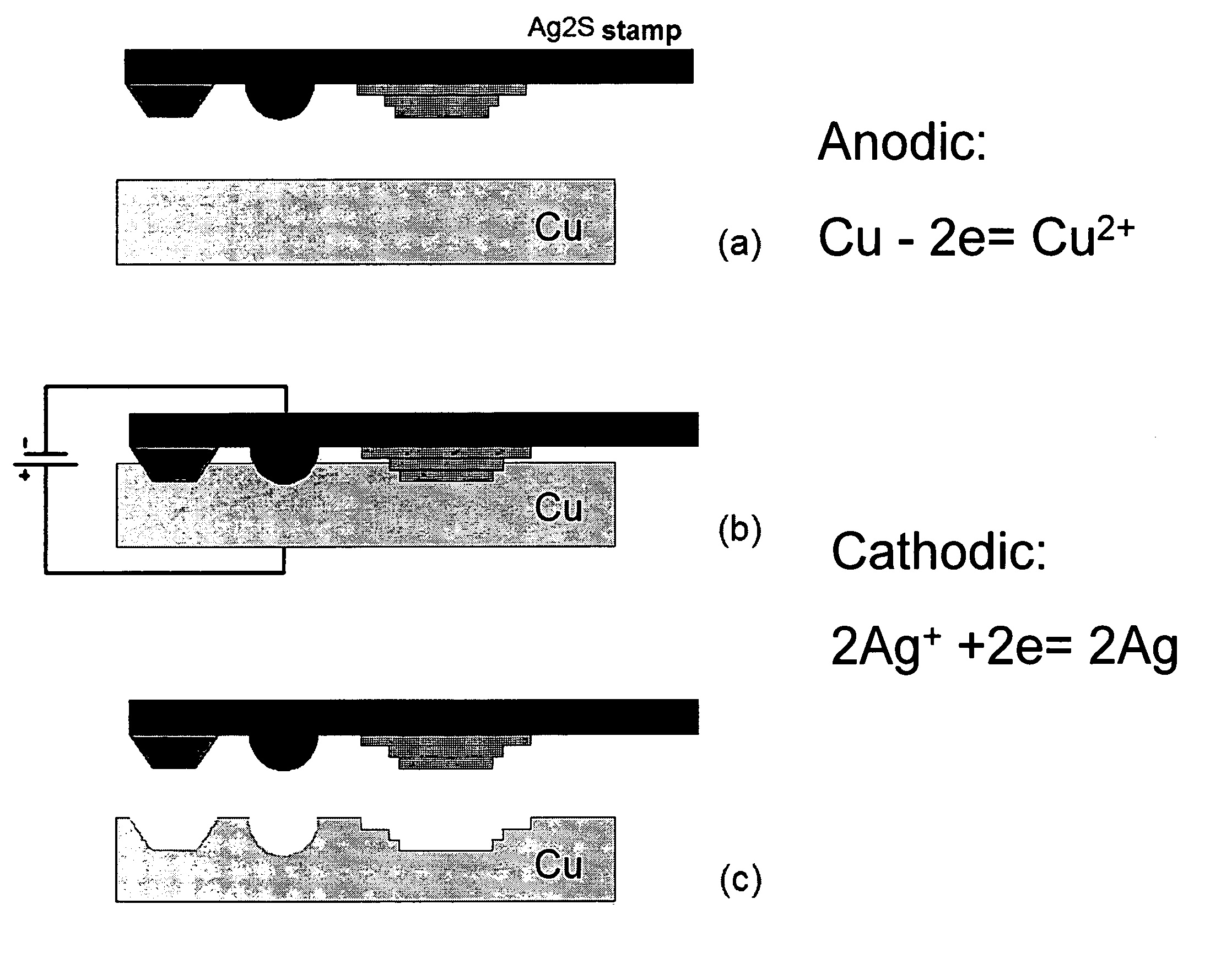

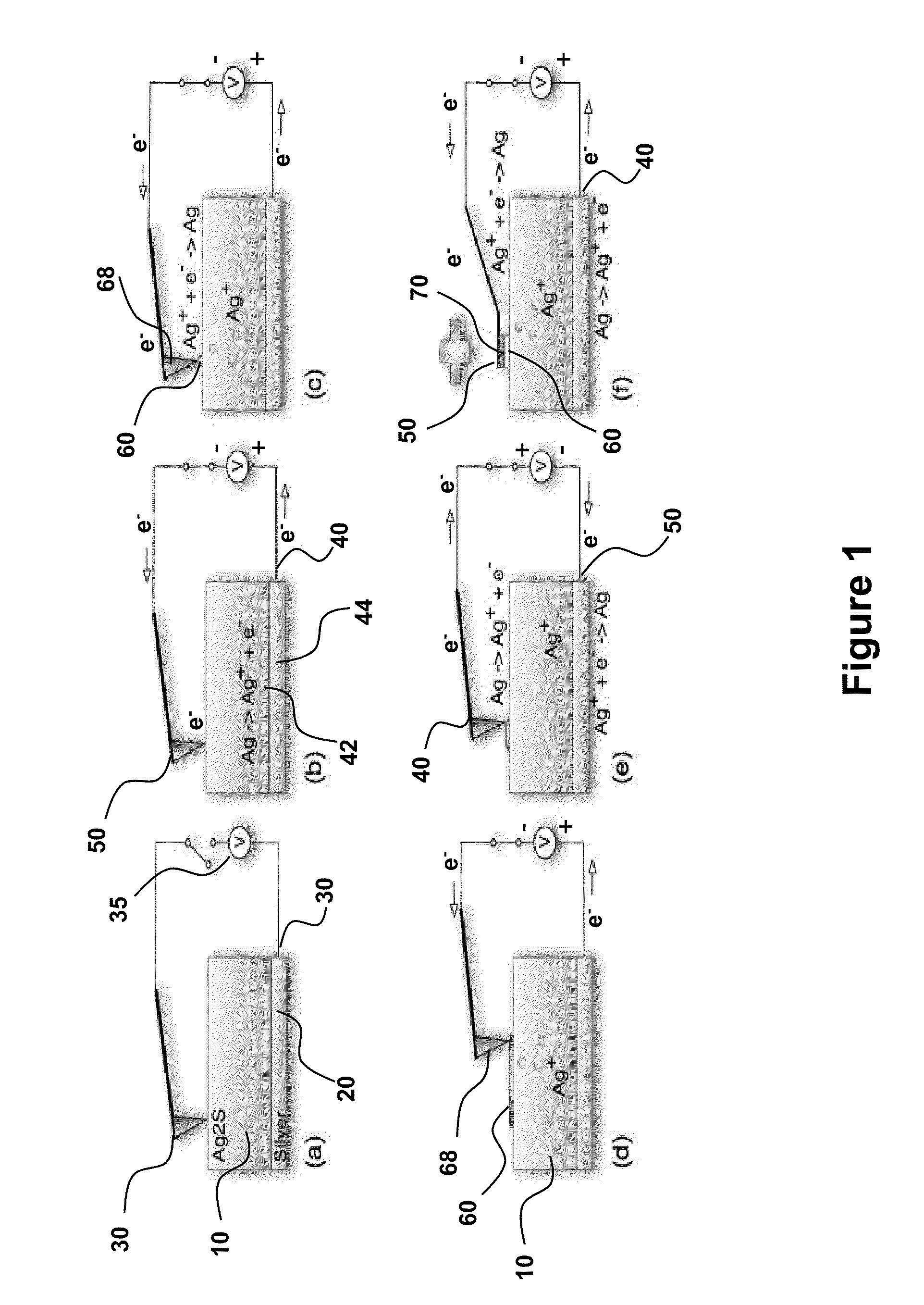

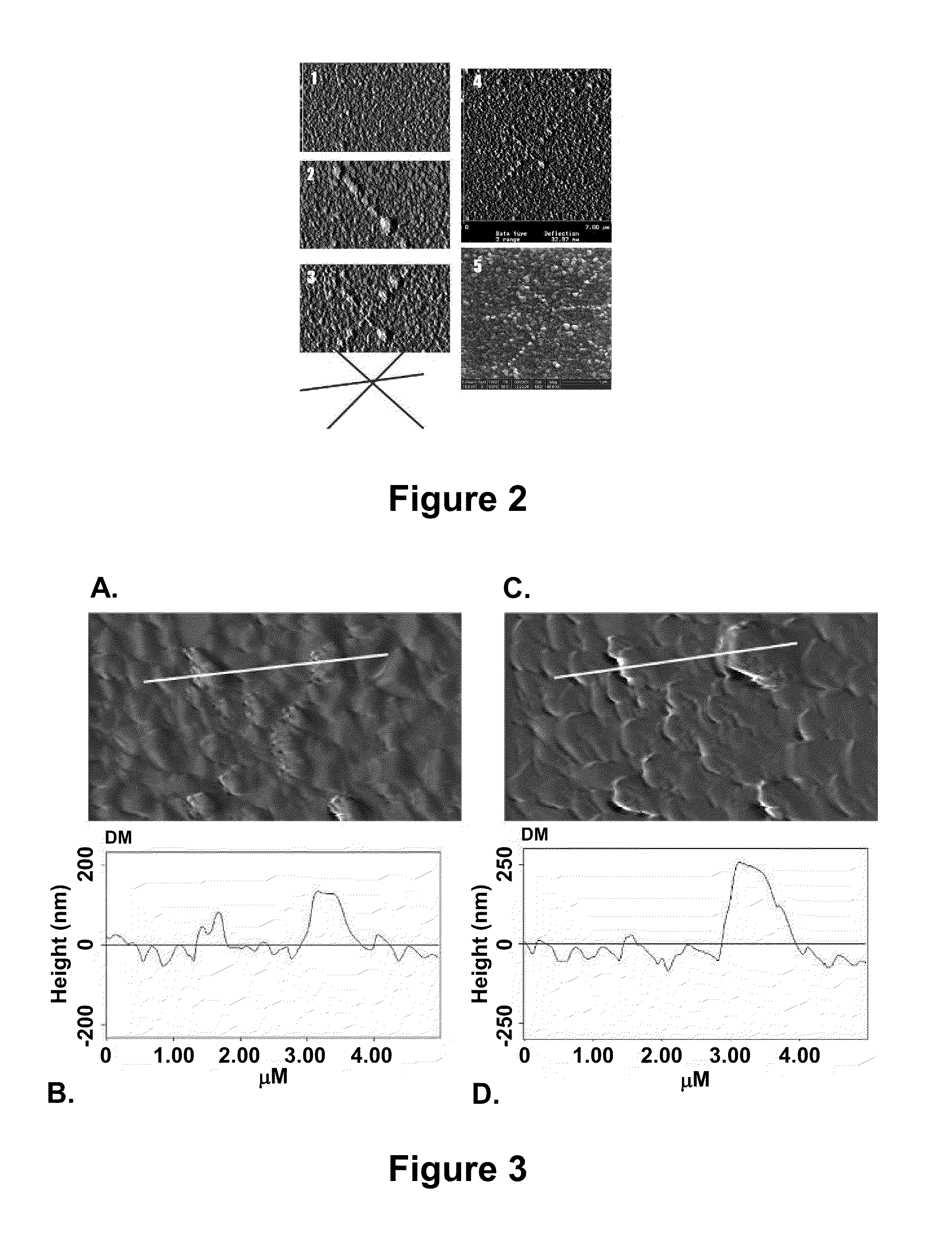

Direct Nanoscale Patterning of Metals Using Polymer Electrolytes

InactiveUS20090050487A1Improve throughputRobust and commercially attractive manufacturing pathwayMachining electrodesMaterial nanotechnologySpatial OrientationsElectrical conductor

Disclosed herein are electrochemical fabrication platforms for making structures, arrays of structures and functional devices having selected nanosized and / or microsized physical dimensions, shapes and spatial orientations. Methods, systems and system components use an electrochemical stamping tool such as solid state polymeric electrolytes for generating patterns of relief and / or recessed features exhibiting excellent reproducibility, pattern fidelity and resolution on surfaces of solid state ionic conductors and in metal. Electrochemical stamping tools are capable high throughput patterning of large substrate areas, are compatible with commercially attractive manufacturing pathways to access a range of functional systems and devices including nano- and micro-electromechanical systems, sensors, energy storage devices, metal masks for printing, interconnects, and integrated electronic circuits.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

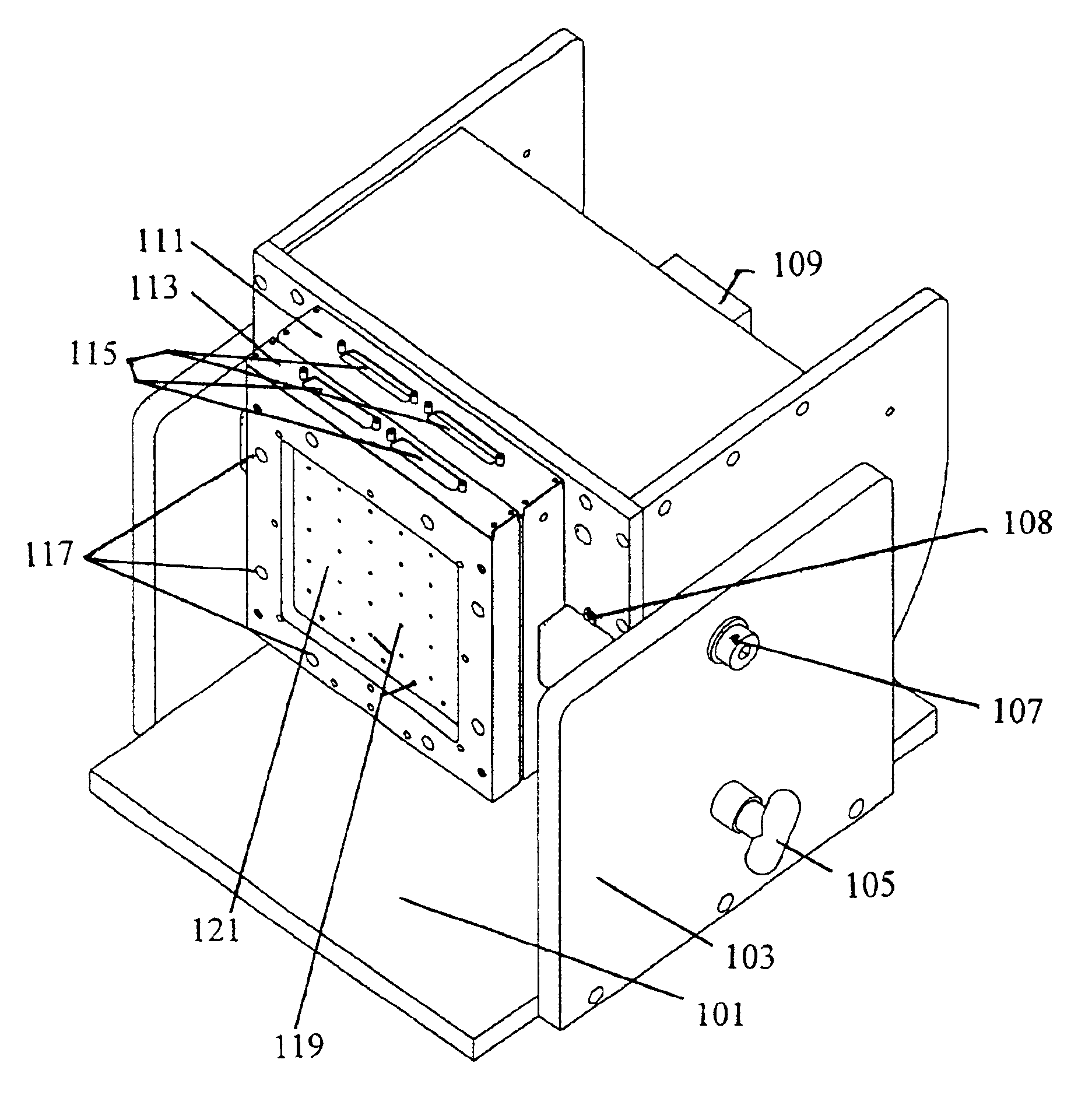

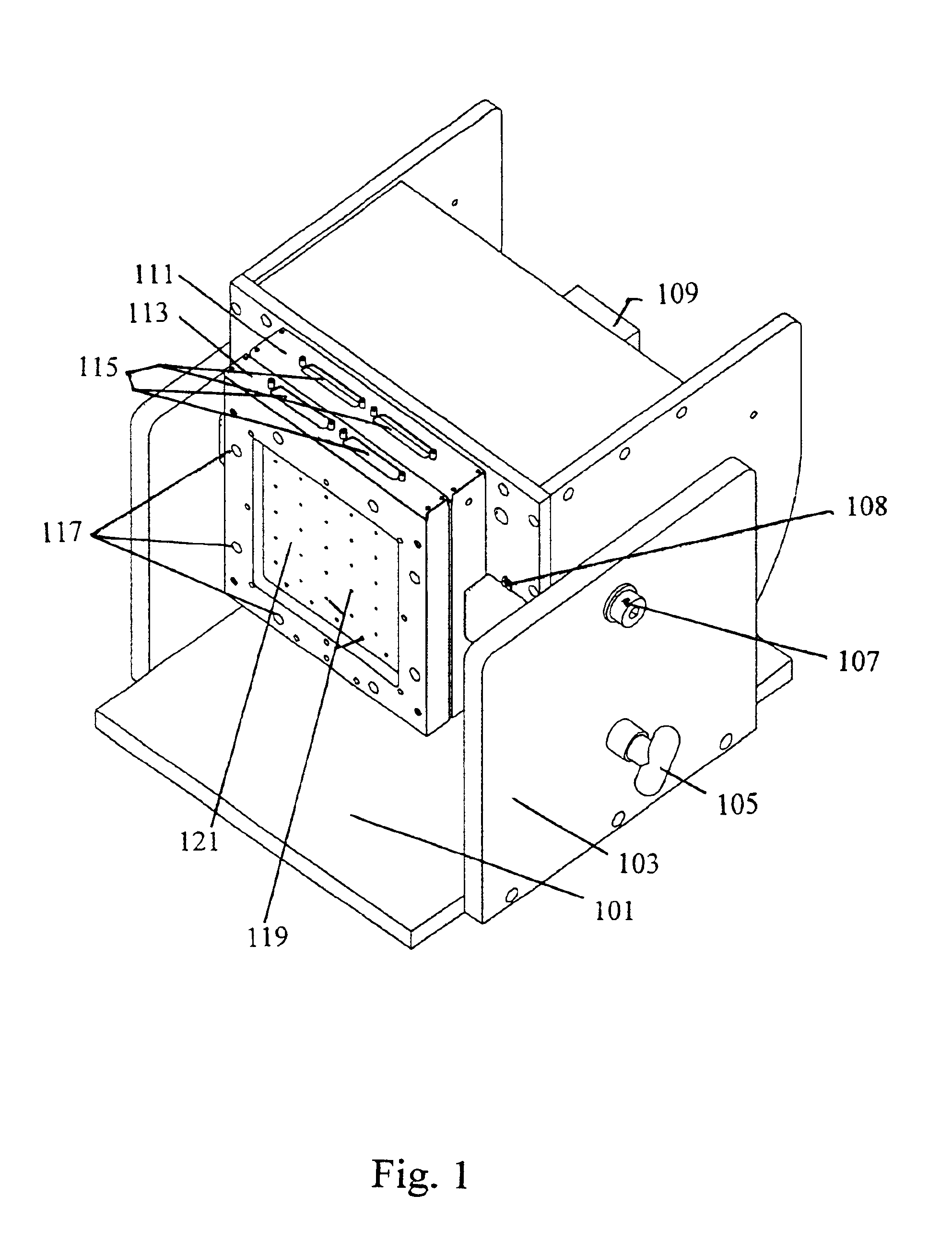

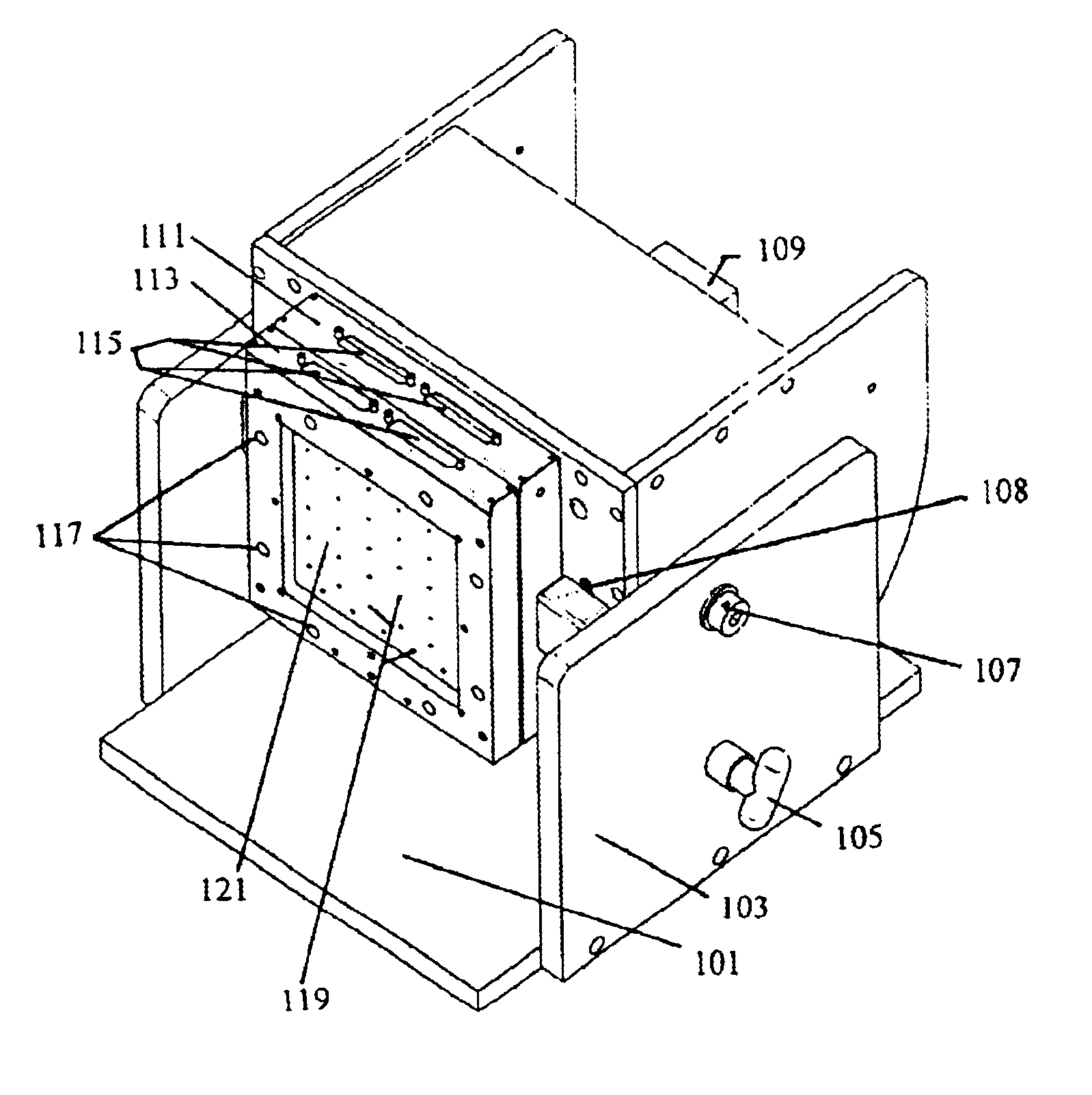

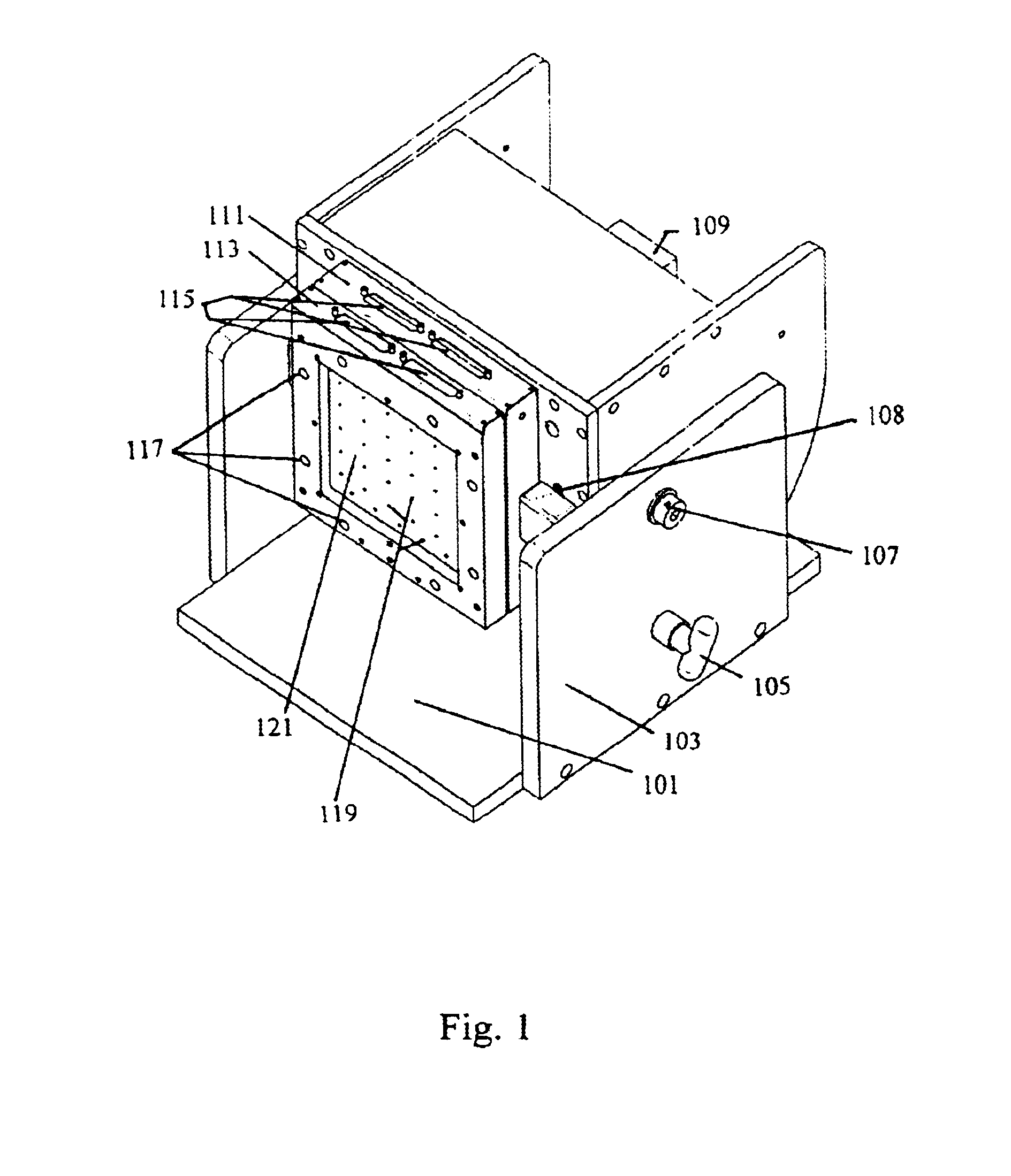

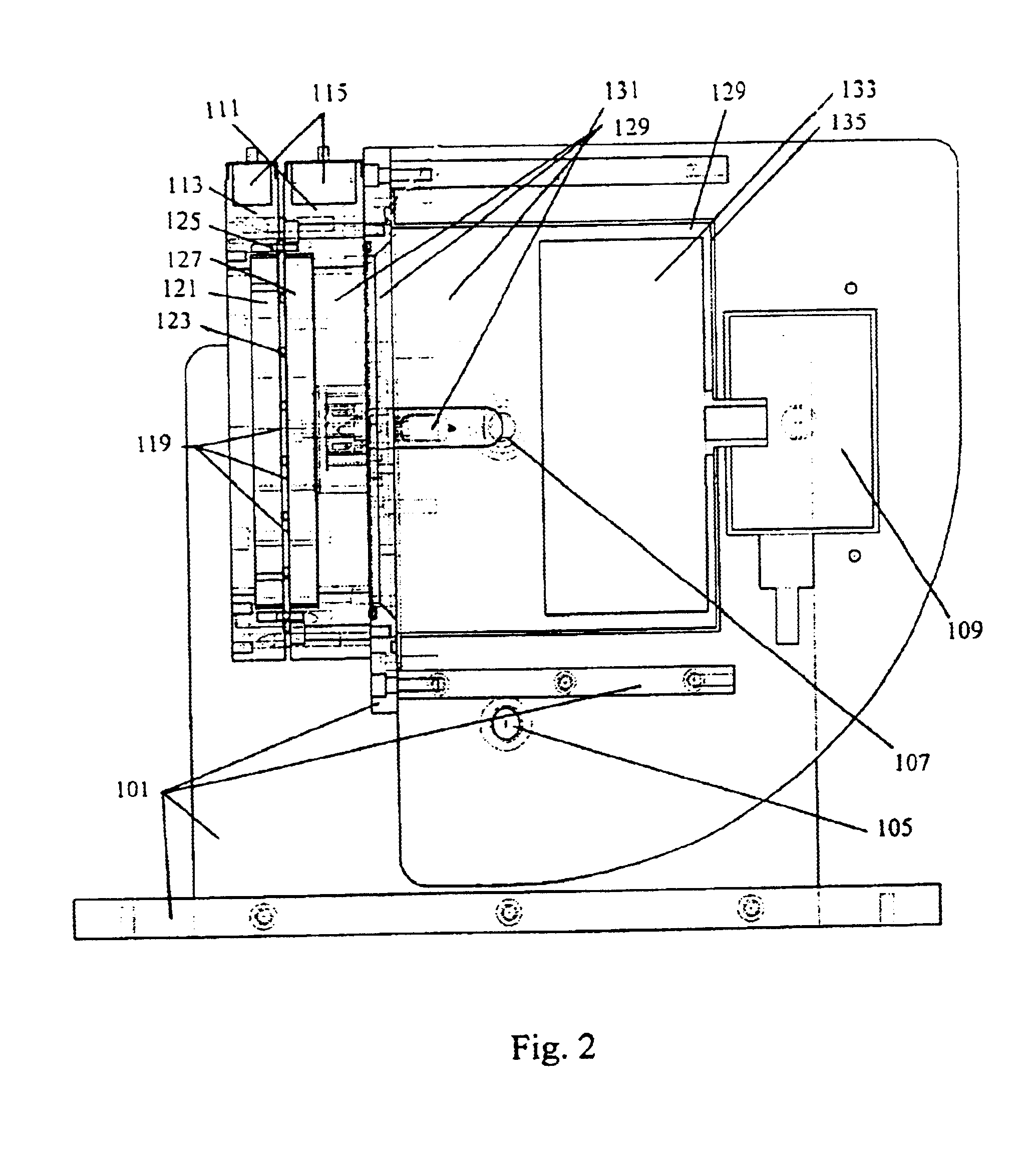

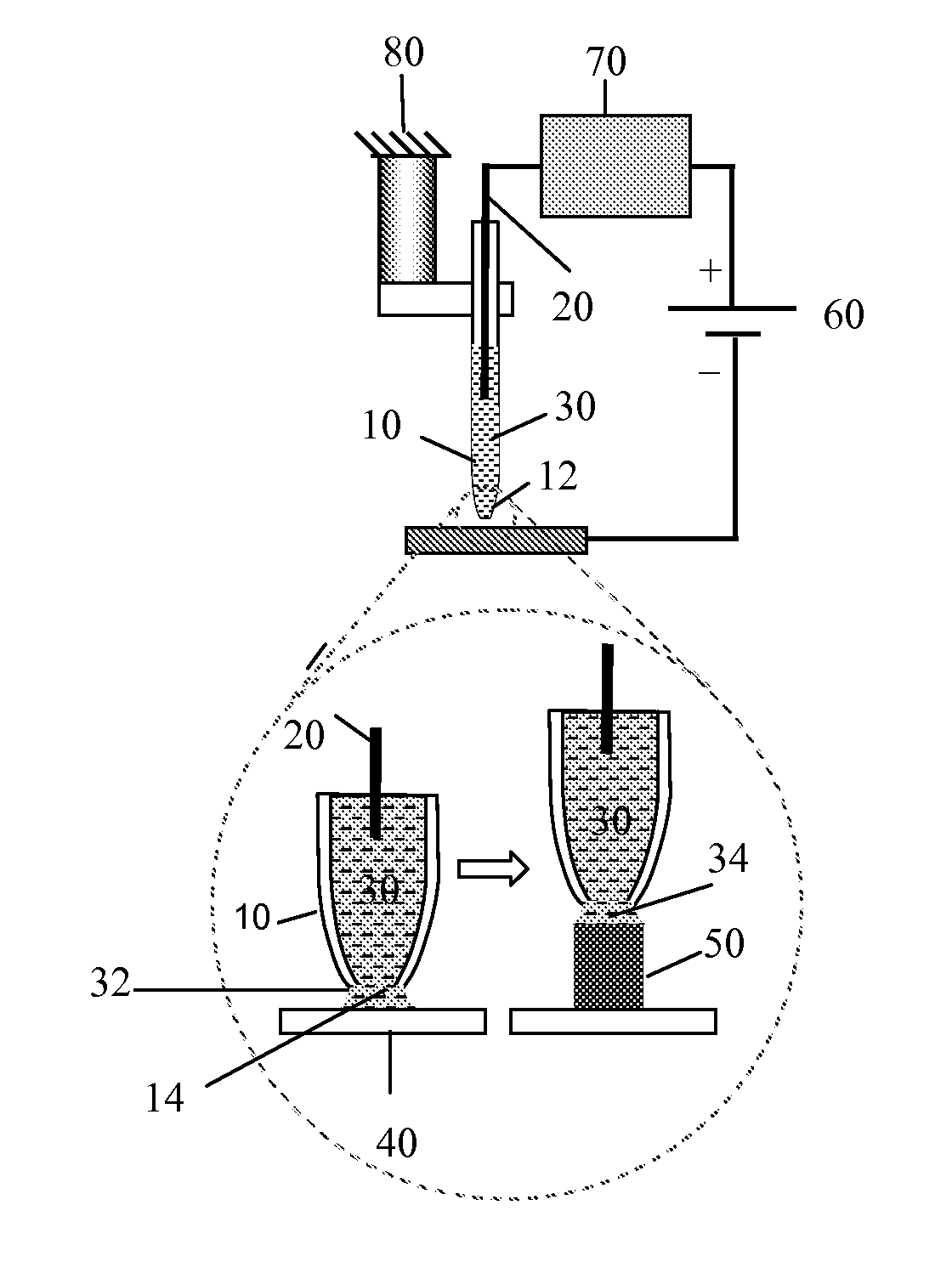

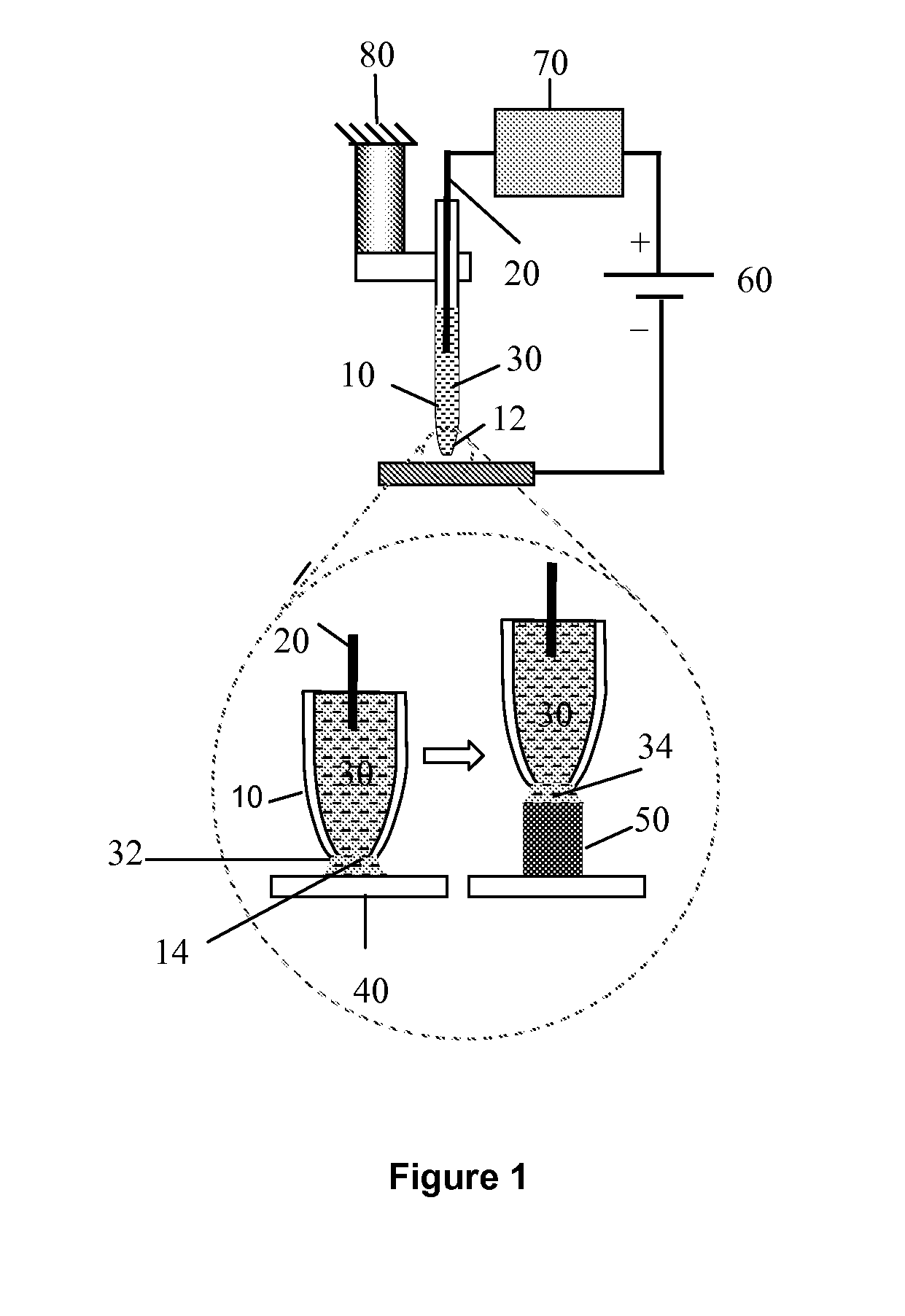

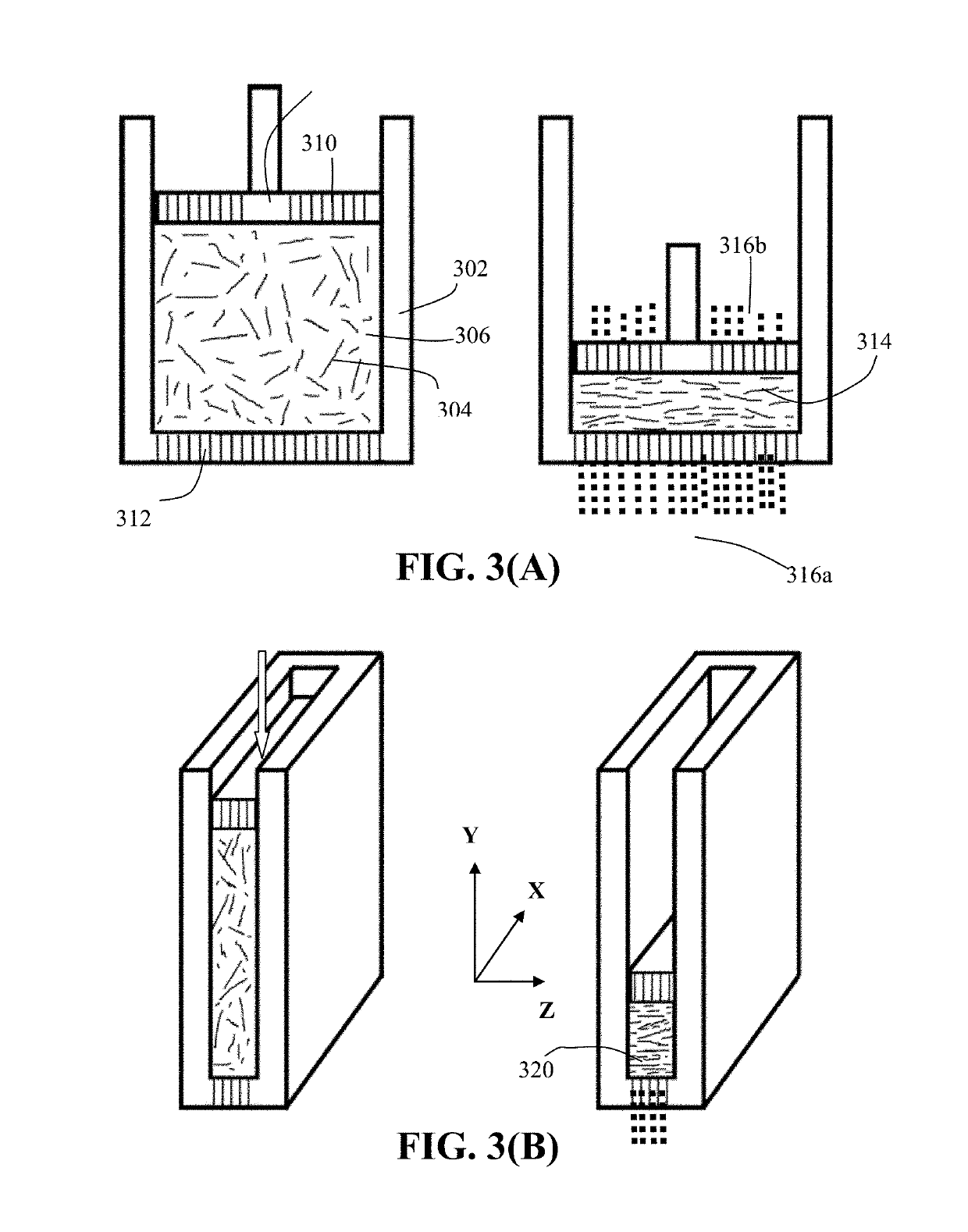

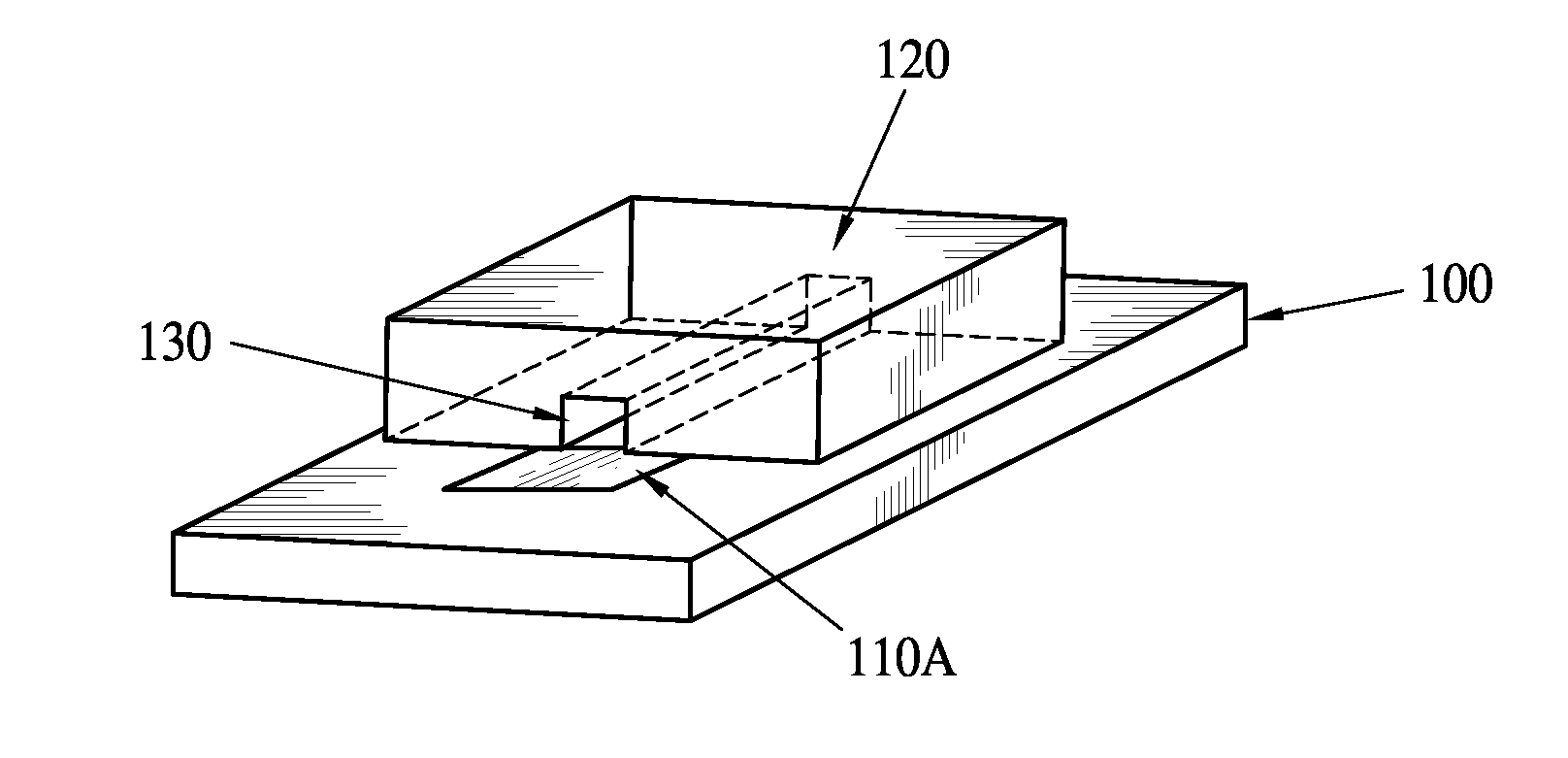

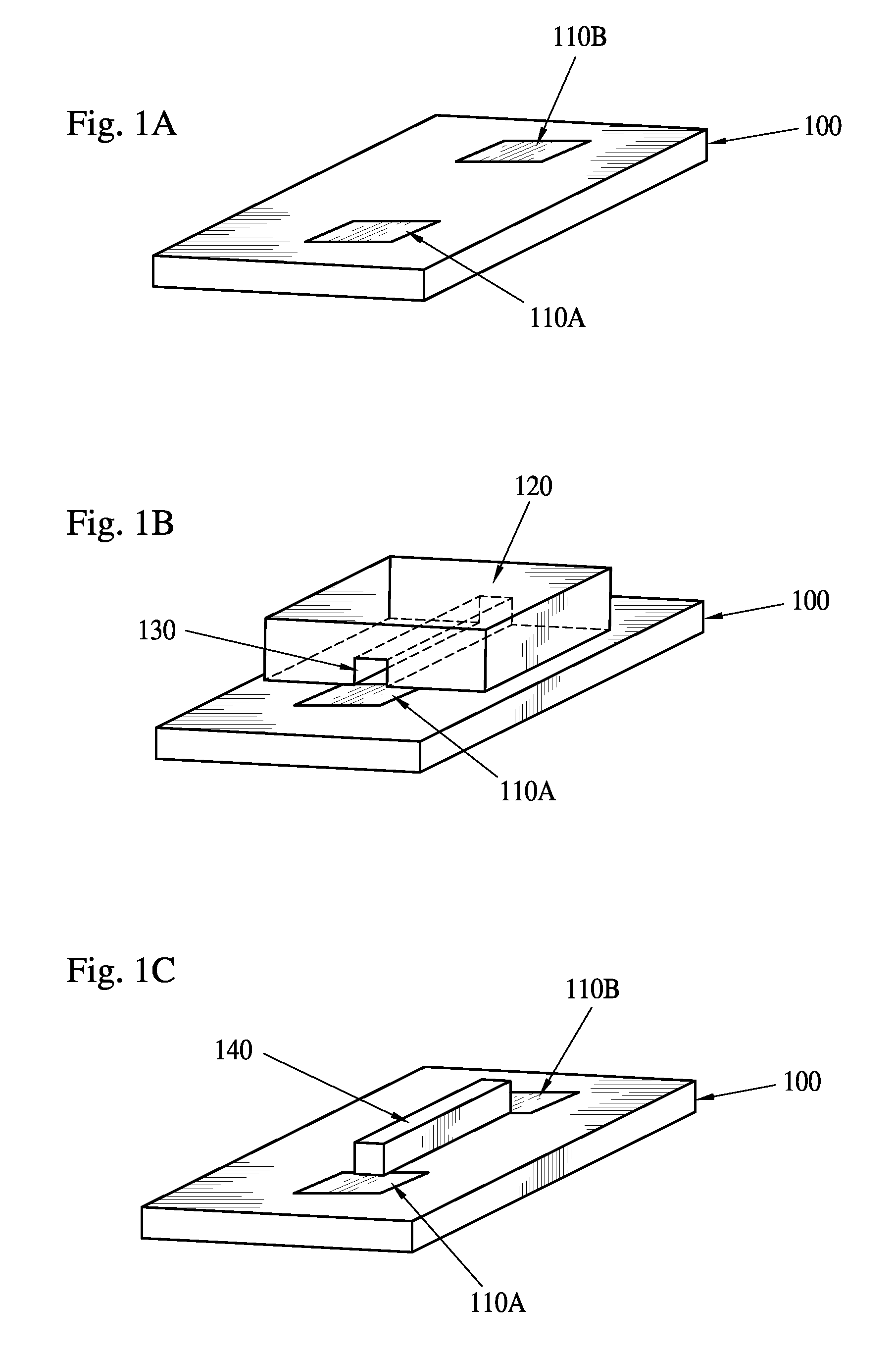

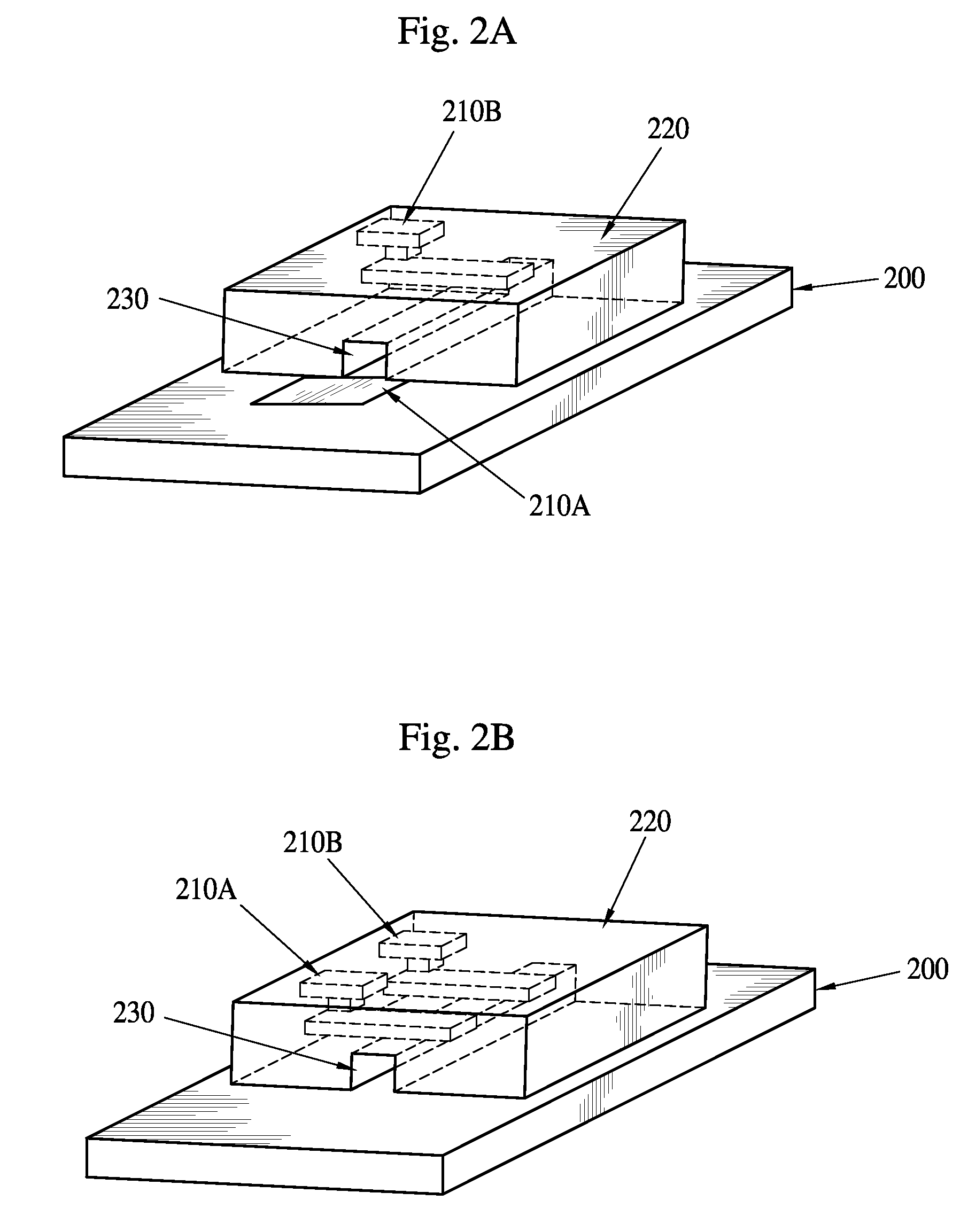

Electrochemical deposition platform for nanostructure fabrication

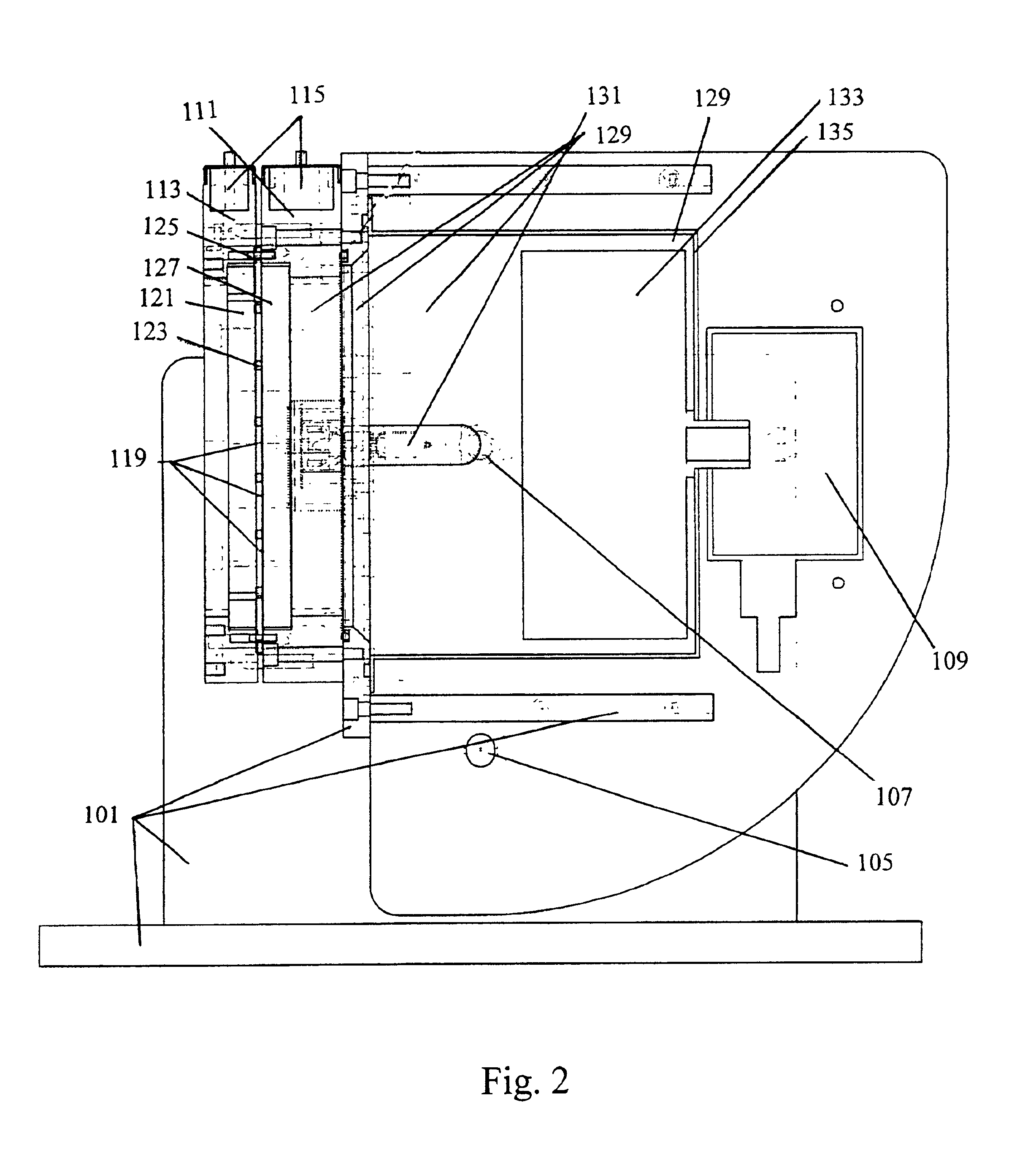

InactiveUS20090000364A1Easy to separateCellsMachining electric circuitsNanostructure fabricationEngineering

Probe-based methods are provided for formation of one or more nano-sized or micro-sized elongated structures such as wires or tubes. The structures extend at least partially upwards from the surface of a substrate, and may extend fully upward from the substrate surface. The structures are formed via a localized electrodeposition technique. The electrodeposition technique of the invention can also be used to make modified scanning probe microscopy probes having an elongated nanostructure at the tip or conductive nanoprobes. Apparatus suitable for use with the electrodeposition technique are also provided.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Carbon nanotube high frequency transistor technology

A technique of the invention reduces significantly the distance between the gate and single-walled carbon nanotubes to improve performance and efficiency of a carbon nanotube transistor device. Without using a porous template structure, single-walled carbon nanotubes are grown perpendicularly to a substrate between a base metal layer and a middle mesh layer. The nanotubes are insulated with a thin insulator and then gate regions are formed.

Owner:ETAMOTA CORP

Electrochemical deposition platform for nanostructure fabrication

InactiveUS7955486B2Easy to separateElectrolysis componentsElectroforming nanostructuresNanostructure fabricationEngineering

Probe-based methods are provided for formation of one or more nano-sized or micro-sized elongated structures such as wires or tubes. The structures extend at least partially upwards from the surface of a substrate, and may extend fully upward from the substrate surface. The structures are formed via a localized electrodeposition technique. The electrodeposition technique of the invention can also be used to make modified scanning probe microscopy probes having an elongated nanostructure at the tip or conductive nanoprobes. Apparatus suitable for use with the electrodeposition technique are also provided.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Engraved plate and base material having conductor layer pattern using the engraved plate

InactiveCN101557927AExcellent adhesionExtend your lifeMagnetic/electric field screeningLayered productsElectrical conductorMechanical engineering

Owner:RESONAC CORPORATION

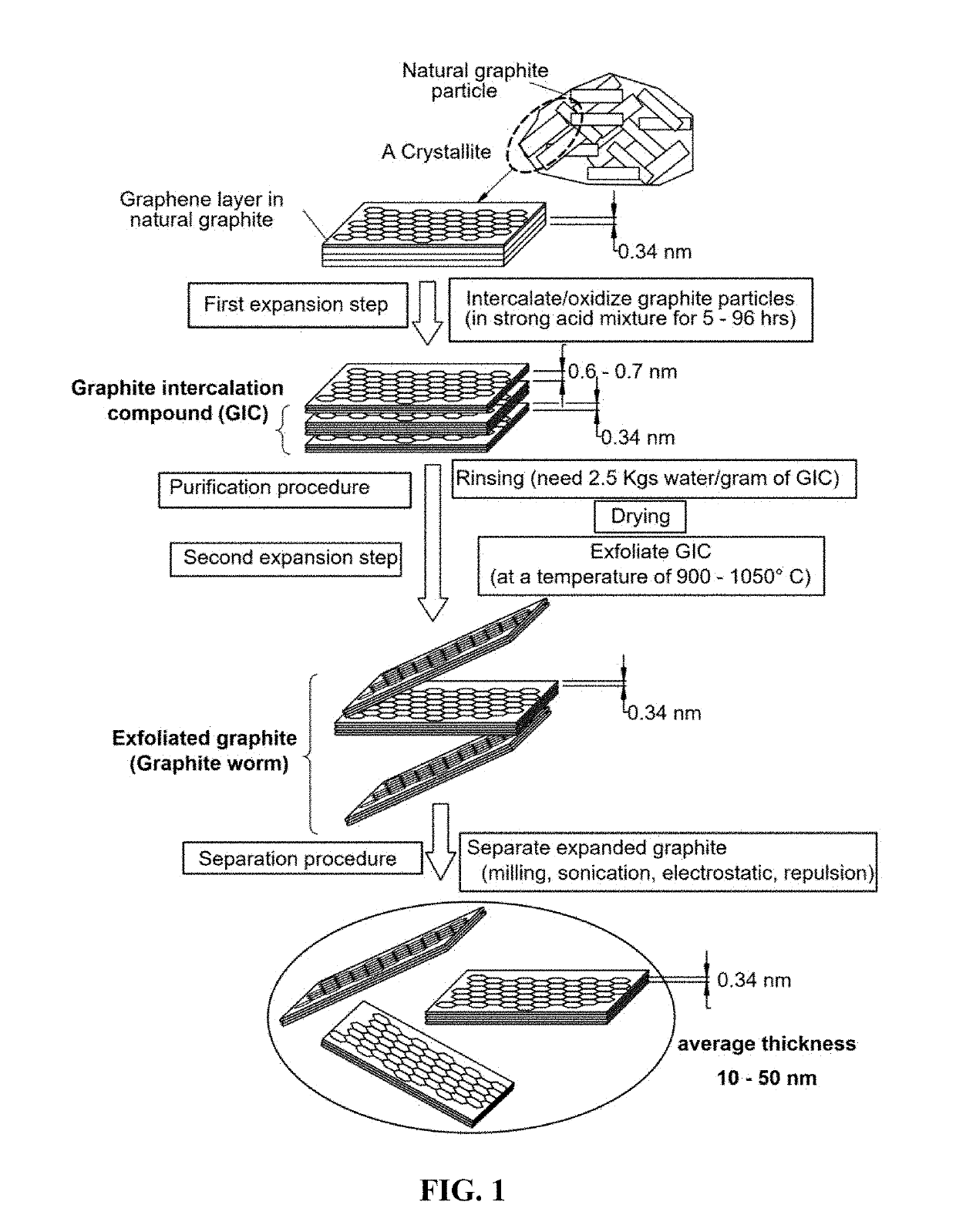

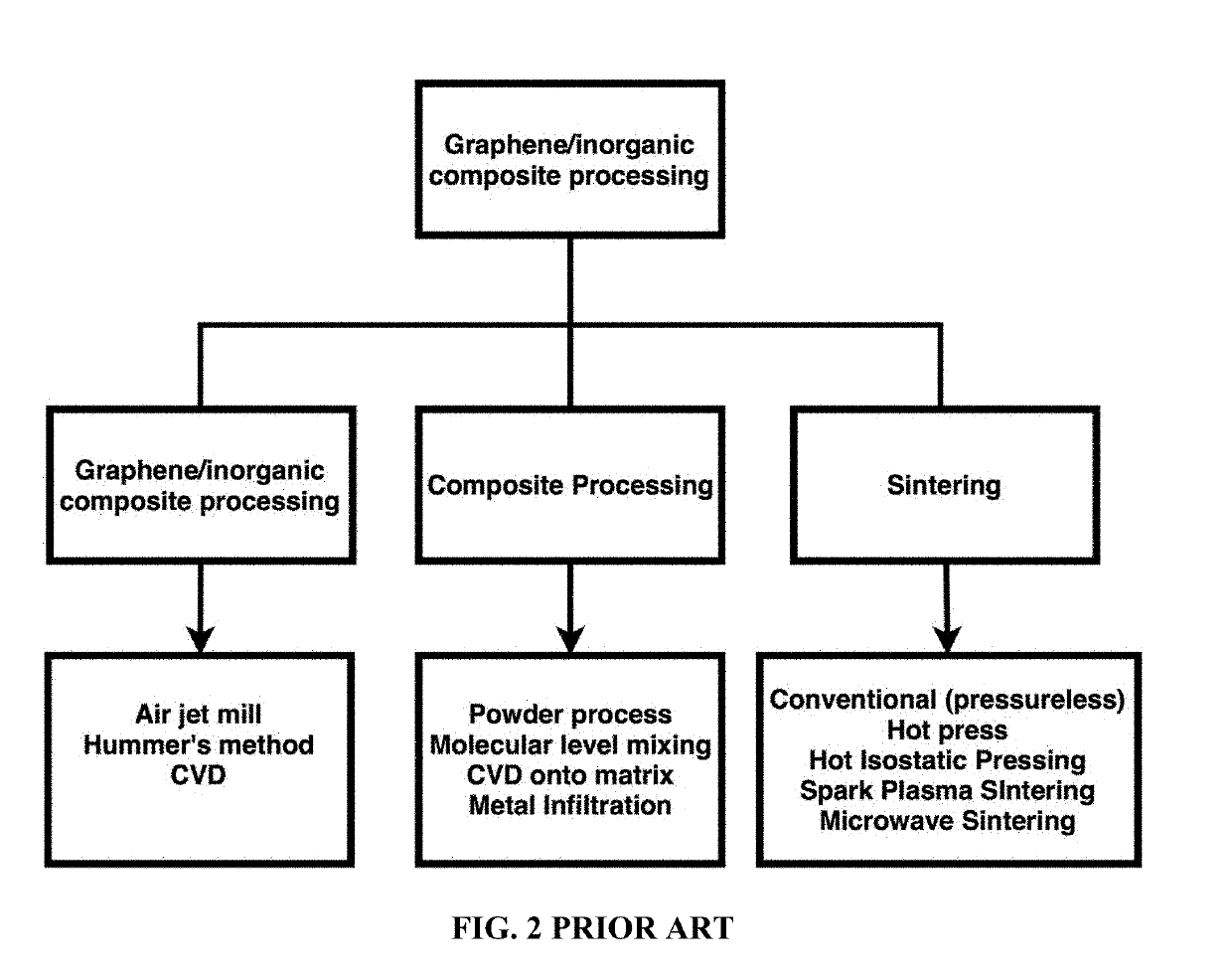

Metal matrix nanocomposite containing oriented graphene sheets and production process

PendingUS20190292671A1Reduce thicknessImprove directionMagnetic/electric field screeningTransportation and packagingDoped grapheneMetal alloy

Provided is a metal matrix nanocomposite comprising: (a) a metal or metal alloy as a matrix material; and (b) multiple graphene sheets that are dispersed in said matrix material, wherein said multiple graphene sheets are substantially aligned to be parallel to one another and are in an amount from 0.1% to 95% by volume based on the total nanocomposite volume; wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from pristine graphene, graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof and wherein the chemically functionalized graphene is not graphene oxide. The metal matrix exhibits a combination of exceptional tensile strength, modulus, thermal conductivity, and / or electrical conductivity.

Owner:GLOBAL GRAPHENE GRP INC

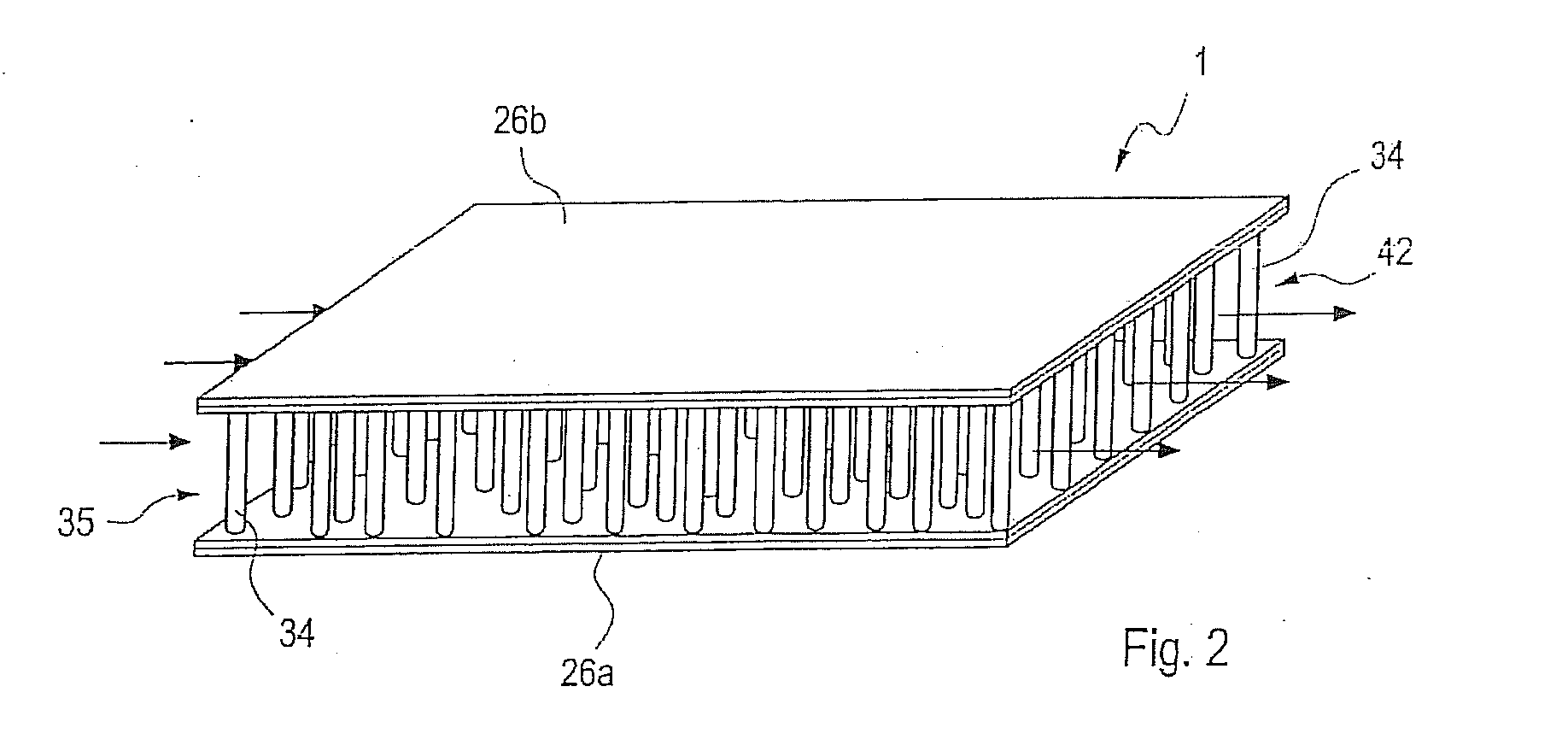

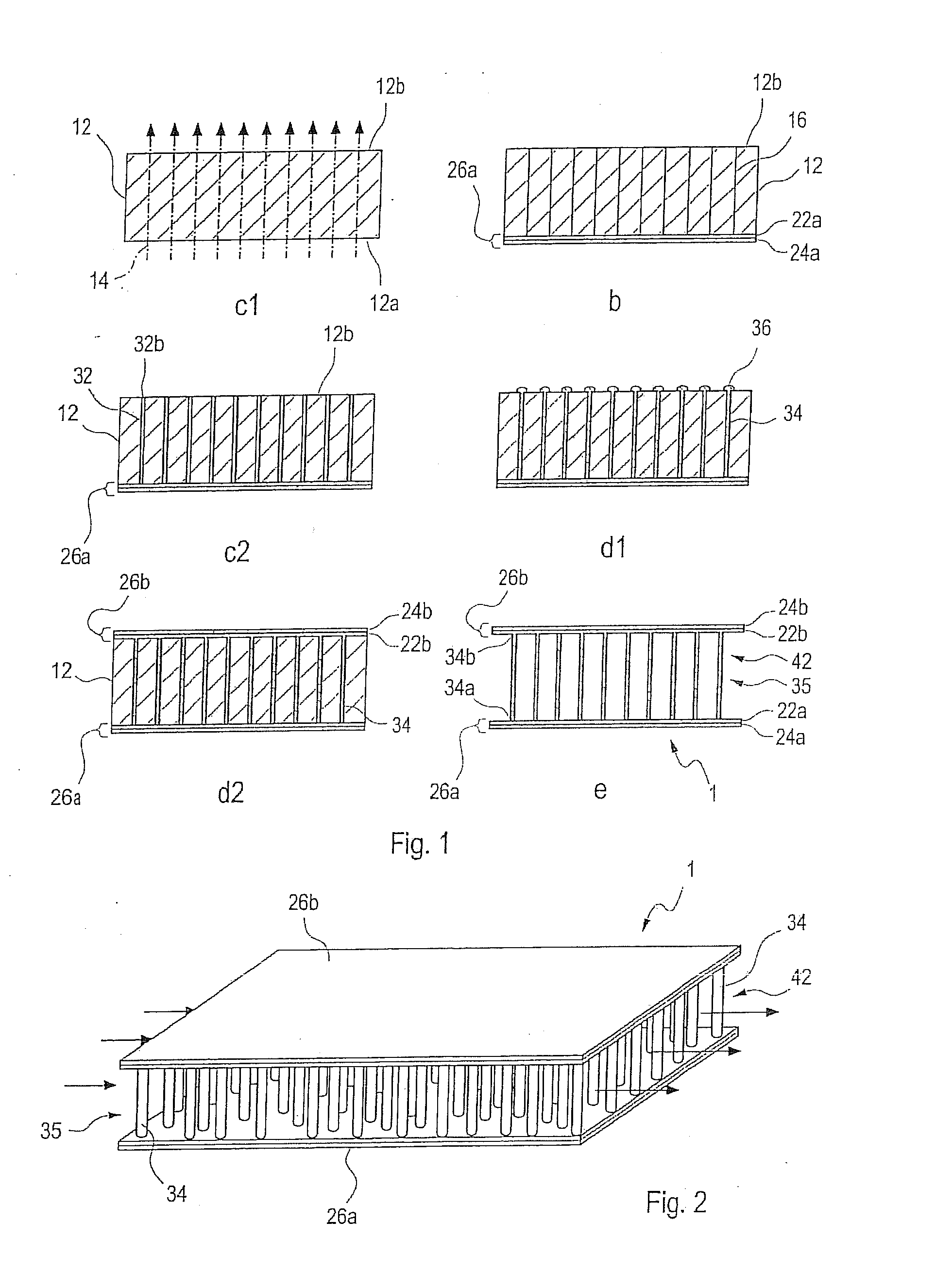

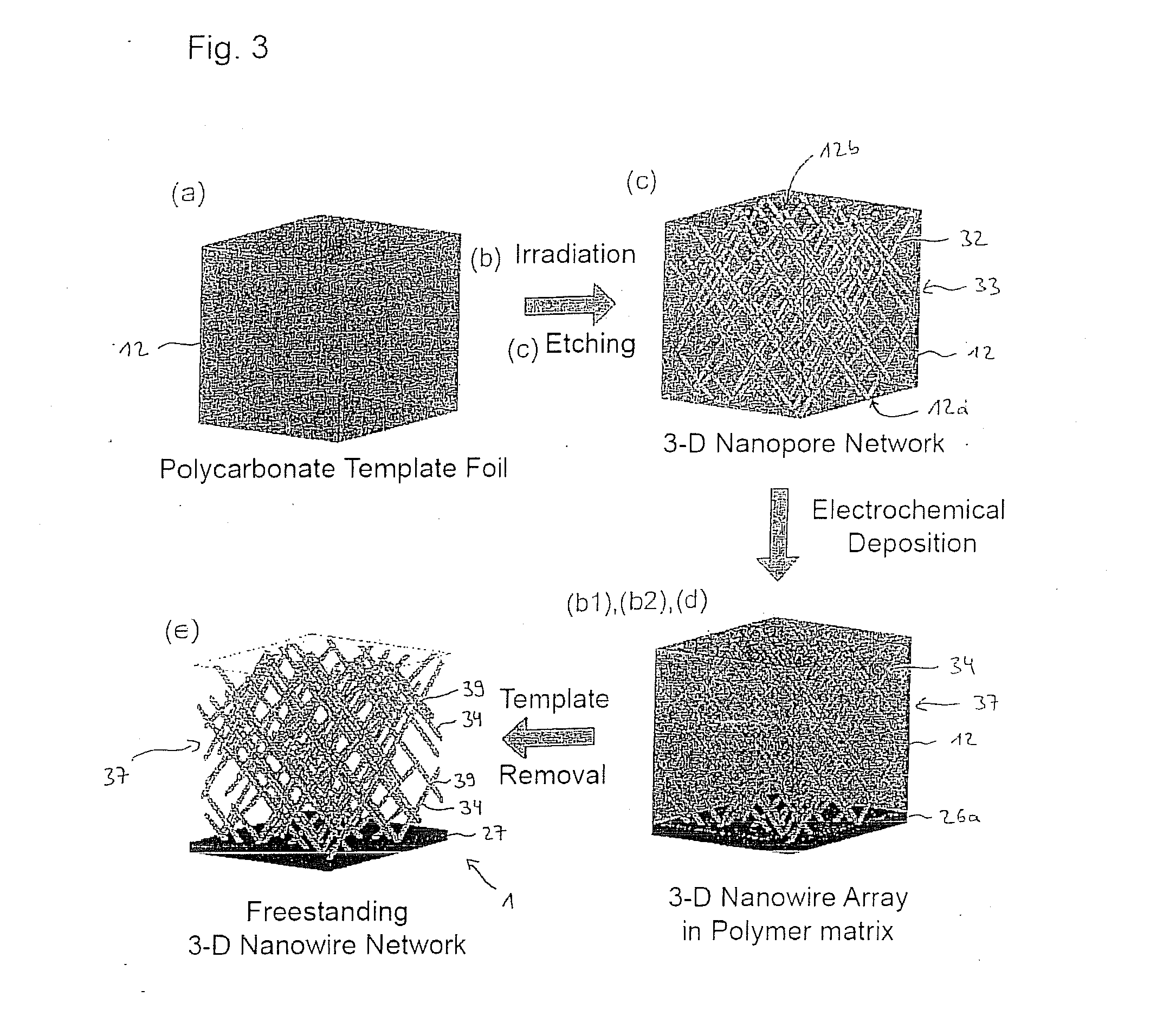

Nanowires and Method for the Production there of

InactiveUS20110174069A1Process stabilityProcess economyMaterial nanotechnologyCell electrodesNanowireTemplate based

The invention concerns the production of segmented nanowires and components having said segmented nanowires.For the production of the nanowire structural element, a template based process is used preferably, wherein the electrochemical deposition of the nanowires in nanopores is carried out. In this manner, numerous nanowires are created in the template foil.For the electrochemical deposition of the nanowires, a reversed pulse procedure with an alternating sequence consisting of cathodic deposition pulses and anodic counter-pulses is carried out. By this means, segmented nanowires can be produced.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

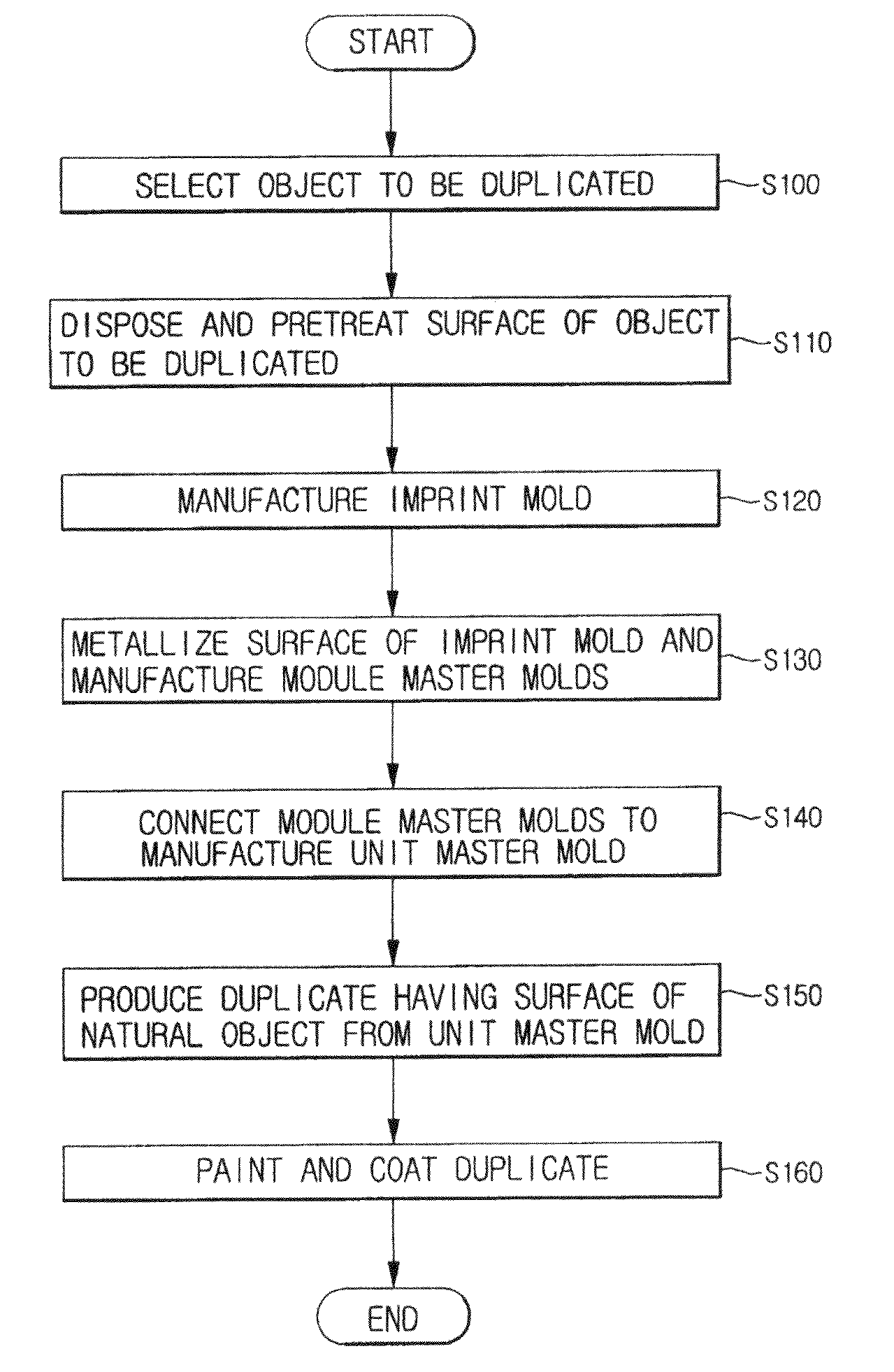

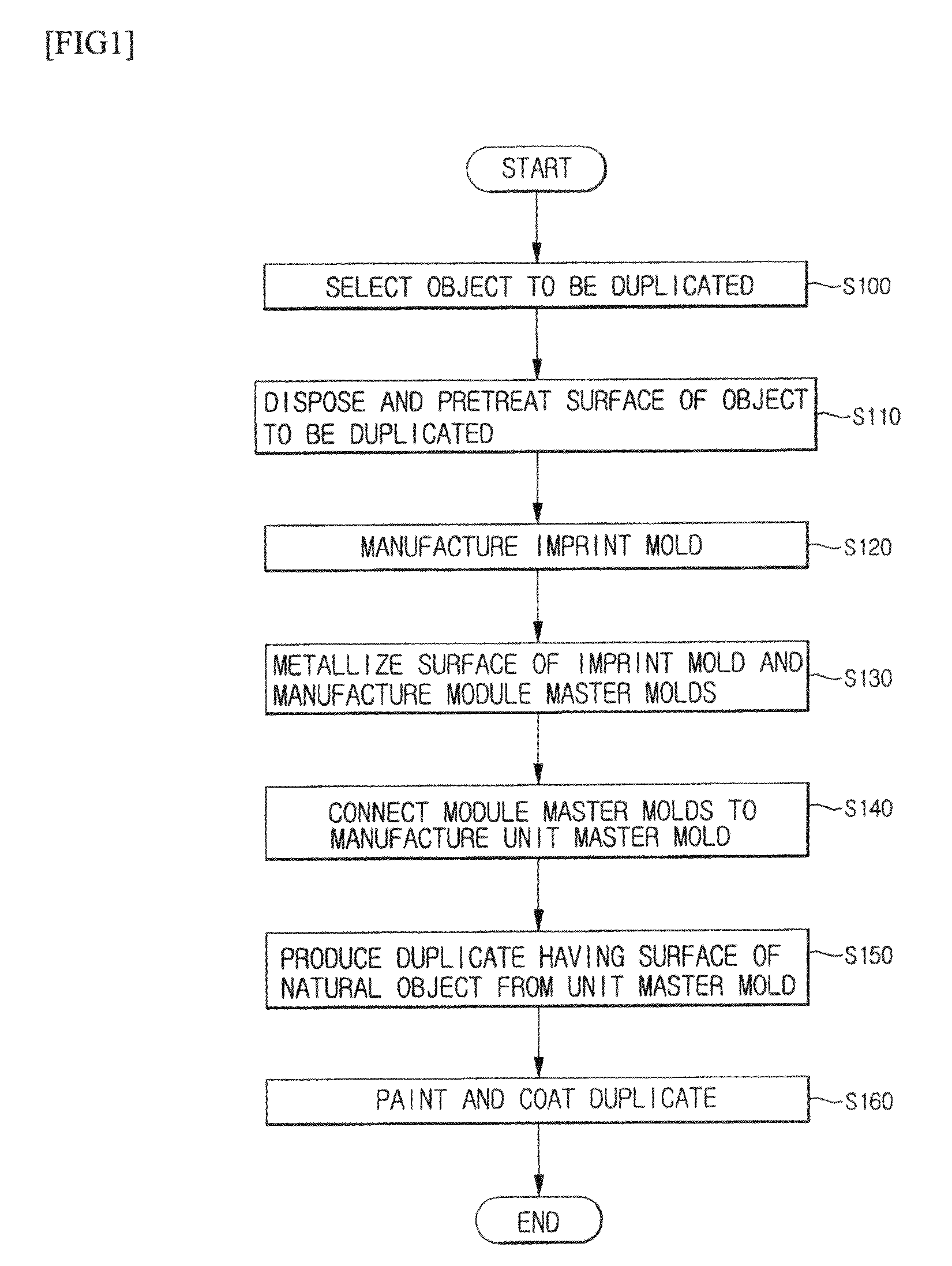

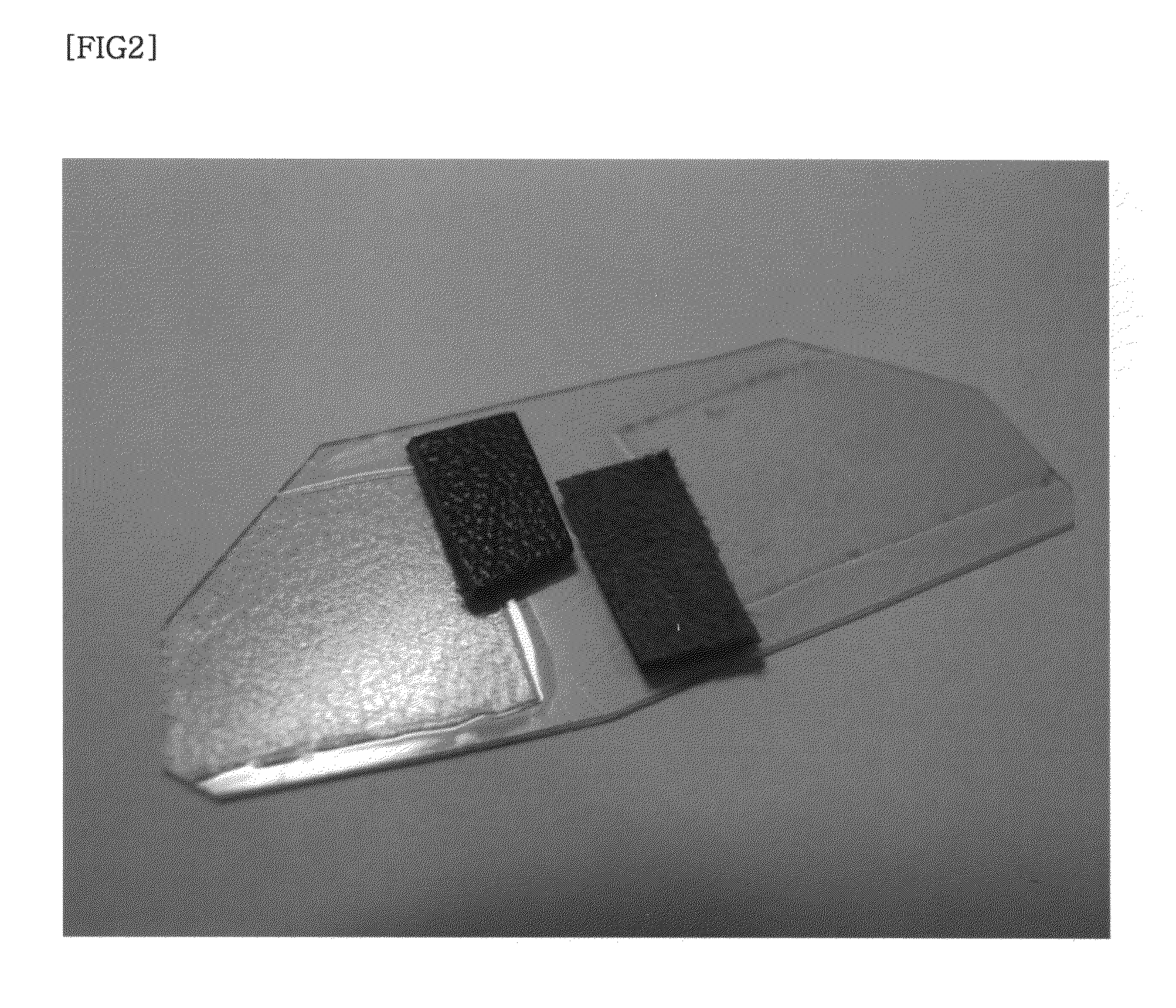

Method of duplicating nano pattern texture on object's surface by nano imprinting and electroforming

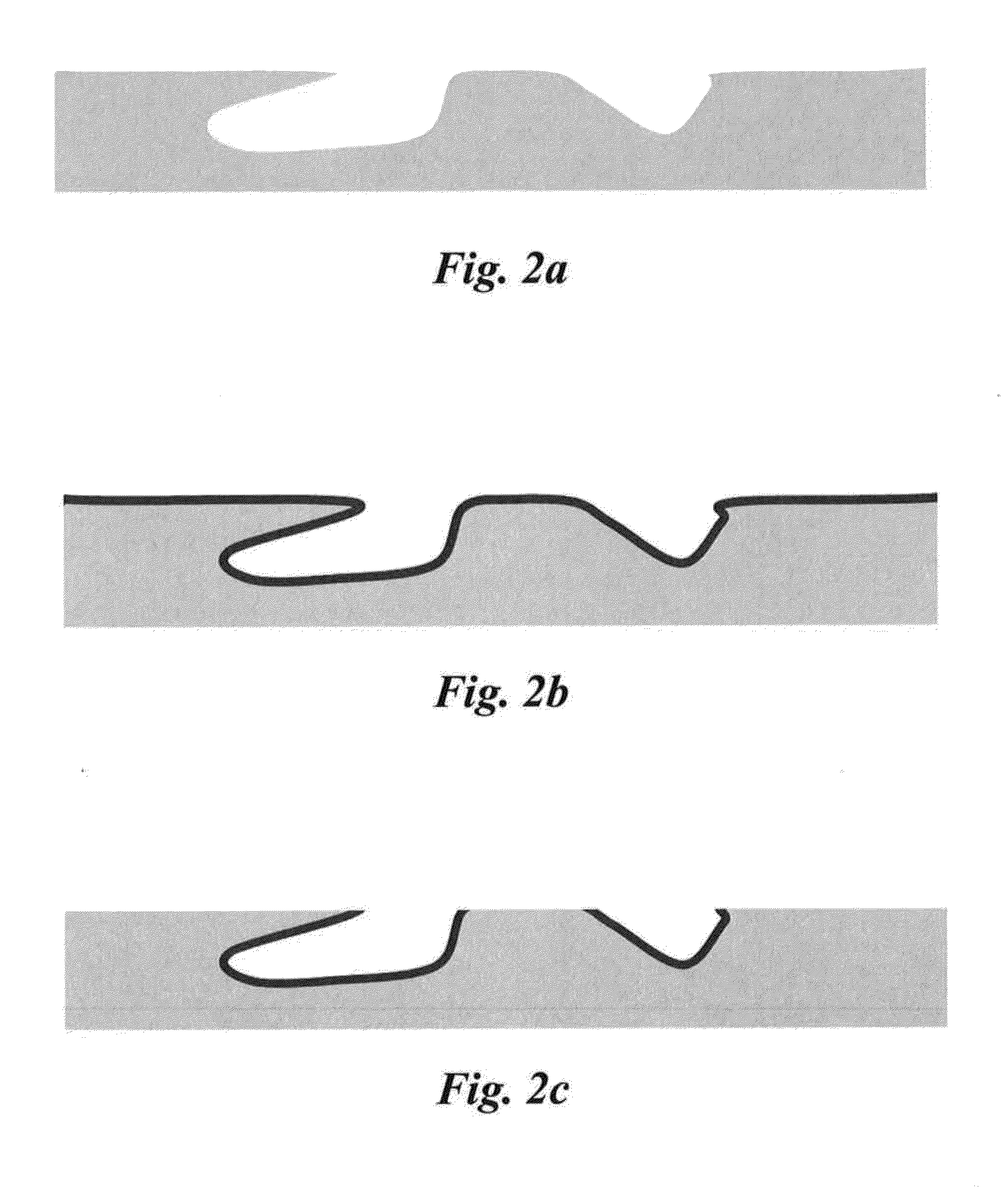

InactiveUS20100101961A1Uniform thicknessBeautiful and soft textureNatural patternsSpecial ornamental structuresGas phaseNanometre

Disclosed is a method of duplicating a nano-pattern texture of the surface of an object through electroforming using an imprint mold, including selecting the object having the surface texture to be duplicated; disposing the selected object and pre-treating the surface thereof; nano-imprinting the surface of the pretreated object, thus duplicating it on a plastic mold; metallizing the surface of the plastic mold through vapor deposition, and performing electroforming, thus manufacturing metal module master molds; trimming the edges of the metal module master molds, performing micro-processing, connecting the metal module master molds, and then performing electroforming, thus manufacturing a large-area metal unit master mold; and electroforming the metal unit master mold, thus producing a duplicate having the surface texture, thus exhibiting an effect in which the skin of a selected natural object can be duplicated on metal having a uniform thickness.

Owner:EMOT

Direct nanoscale patterning of metals using polymer electrolytes

InactiveUS7998330B2Improve throughputRobust and commercially attractive manufacturing pathwayMaterial nanotechnologyMachining electrodesSpatial OrientationsElectrical conductor

Disclosed herein are electrochemical fabrication platforms for making structures, arrays of structures and functional devices having selected nanosized and / or microsized physical dimensions, shapes and spatial orientations. Methods, systems and system components use an electrochemical stamping tool such as solid state polymeric electrolytes for generating patterns of relief and / or recessed features exhibiting excellent reproducibility, pattern fidelity and resolution on surfaces of solid state ionic conductors and in metal. Electrochemical stamping tools are capable high throughput patterning of large substrate areas, are compatible with commercially attractive manufacturing pathways to access a range of functional systems and devices including nano- and micro-electromechanical systems, sensors, energy storage devices, metal masks for printing, interconnects, and integrated electronic circuits.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

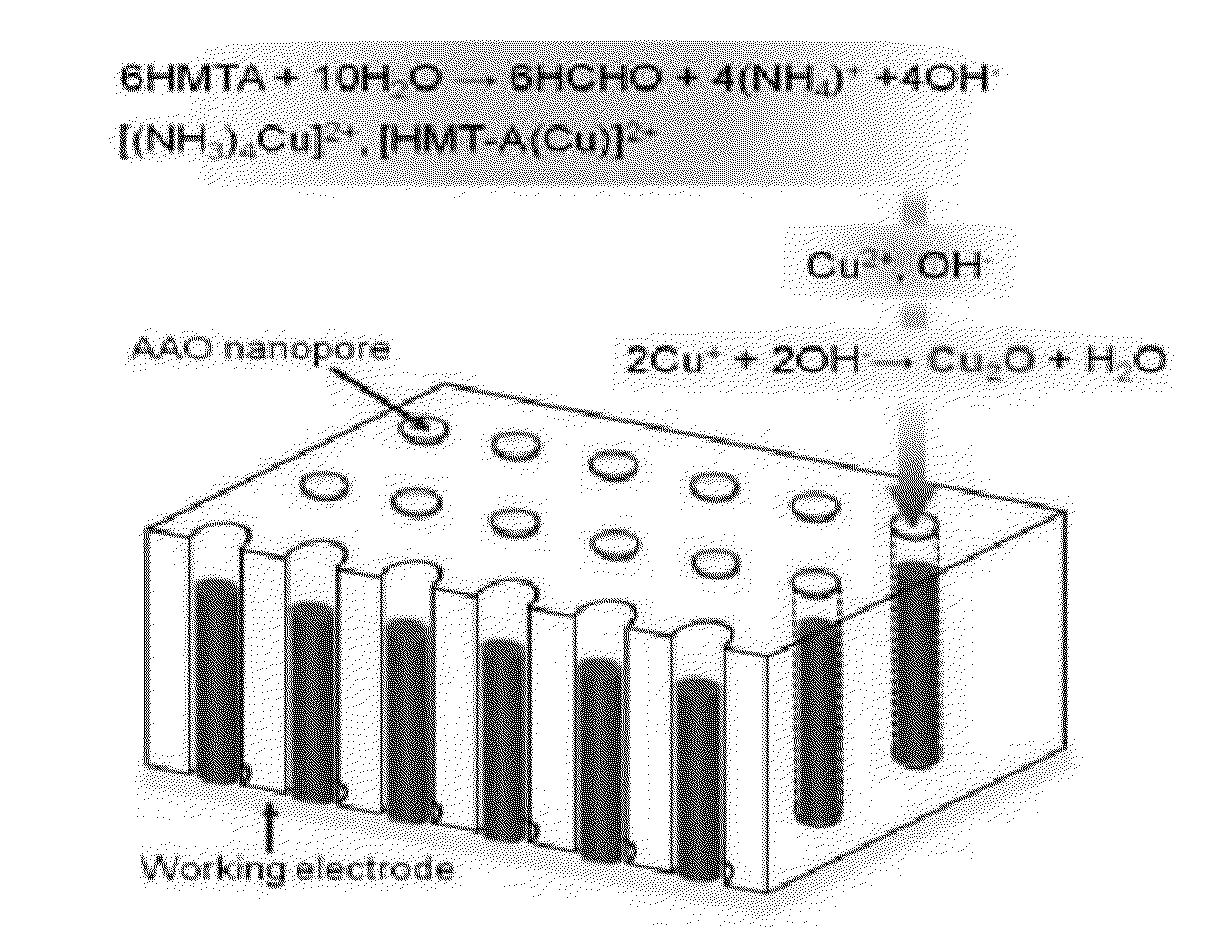

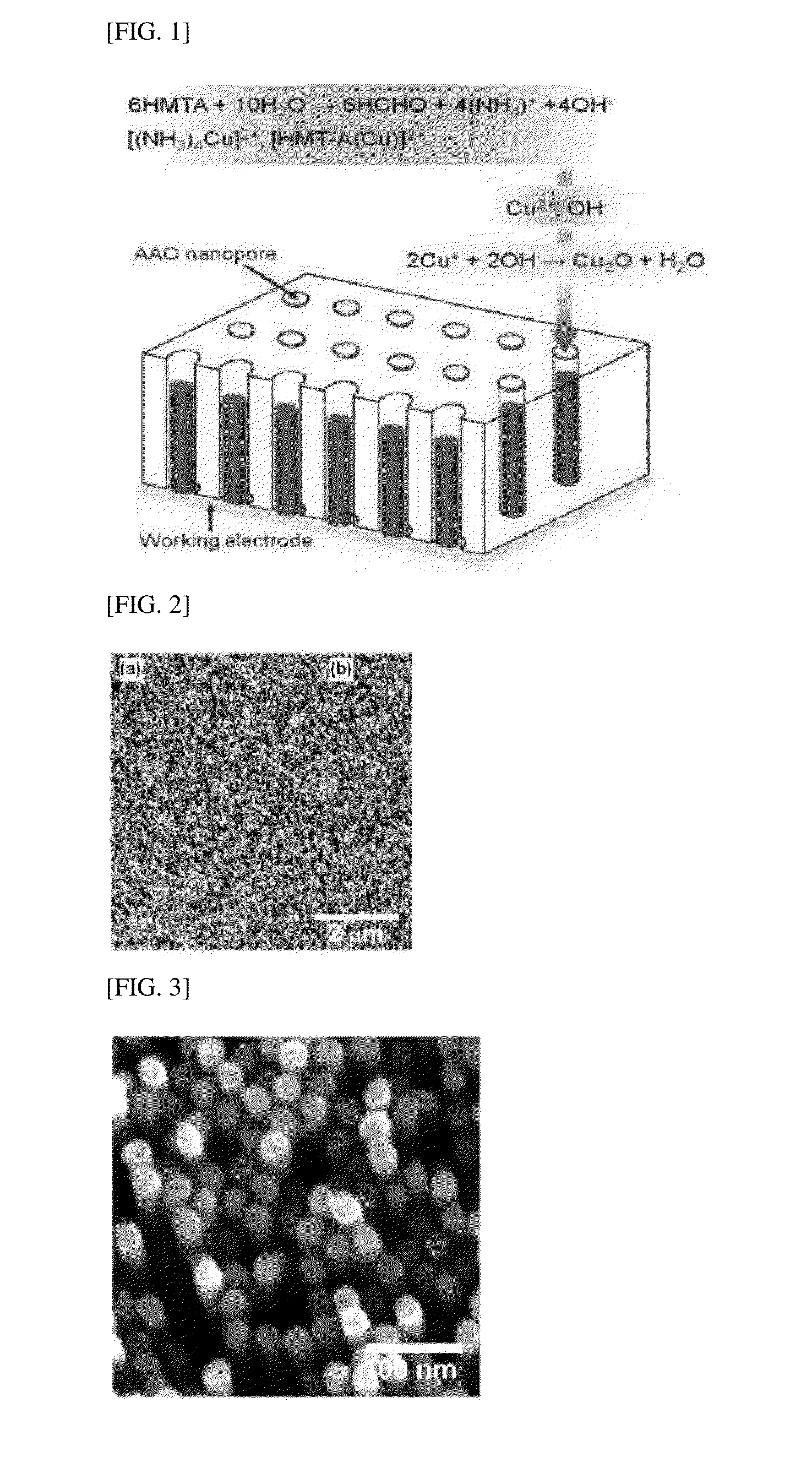

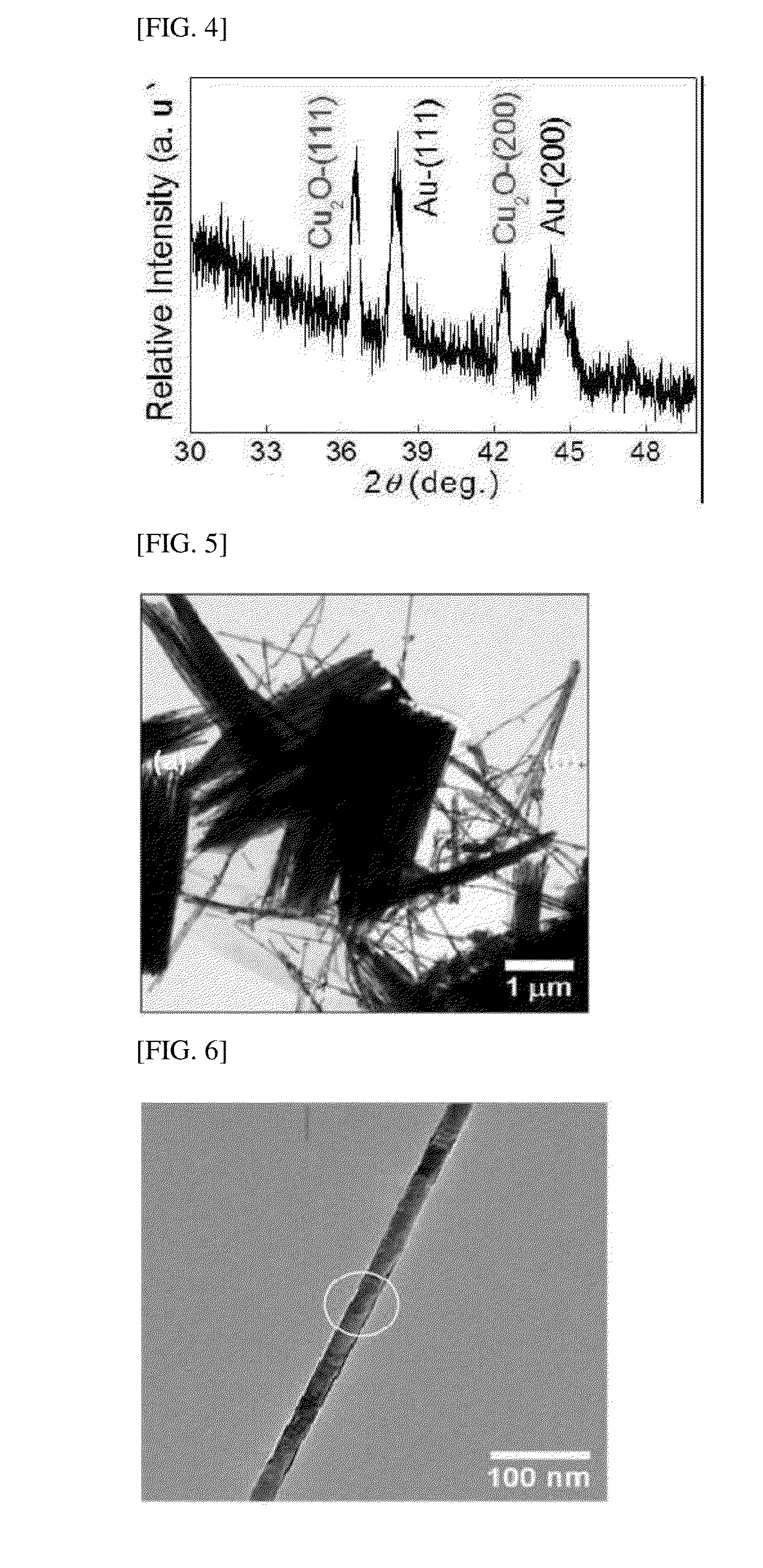

Polycrystalline cuprous oxide nanowire array production method using low-temperature electrochemical growth

There are provided a monocrystalline copper oxide (I) nanowire array manufacturing method using low-temperature electrochemical growth, and more particularly, to a manufacturing method allowing easy vapor deposition at low temperatures and also a monocrystalline copper oxide (I) nanowire array manufacturing method using low-temperature electrochemical growth which retains characteristics such as large-area growth, high-crystallinity nanowire, uniform radial distribution, easy length, radius adjustment, and the like.A monocrystalline copper oxide (I) nanowire array manufacturing method of the present invention includes a step of manufacturing a nanopore alumina layer (anodized alumina (AAO)) from a high-purity aluminum (Al) sheet by using a two-step anodic oxidation method; and a step of manufacturing a monocrystalline copper oxide (I) nanowire array by using the nanopore alumina layer as a nanopore molding flask by means of a low-temperature electrochemical growth method.

Owner:KONKUK UNIV IND COOP CORP

System and method for positioning and synthesizing of nanostructures

InactiveUS20070110639A1Material nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsSource materialEngineering

The invention relates to a method of forming at least one nano-structure with a reusable template structure having a channel. The method includes introducing at least one reagent into the channel, and reacting the at least one reagent to form a nano-structure within the channel. The nano-structure forming channel may be positioned in alignment with one or more electrode structures, which may be positioned within or upon the substrate, may be embedded in the reusable template structure, and / or may be external electrode structures positioned outside of the reusable template structure and independent of the substrate. In addition, the electrode structures may be a source material for the formation of the nano-structure in the channel.

Owner:PENN STATE RES FOUND

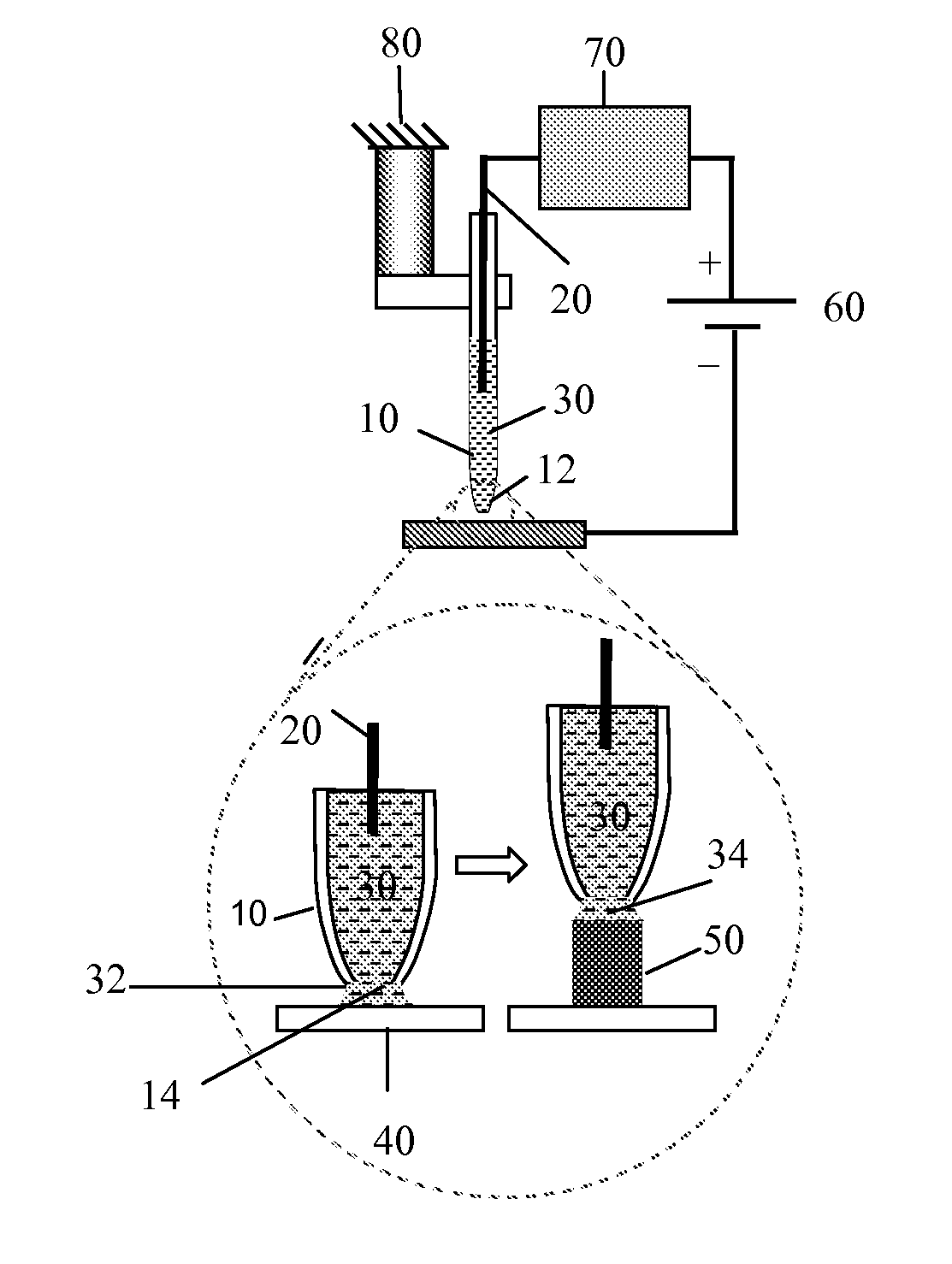

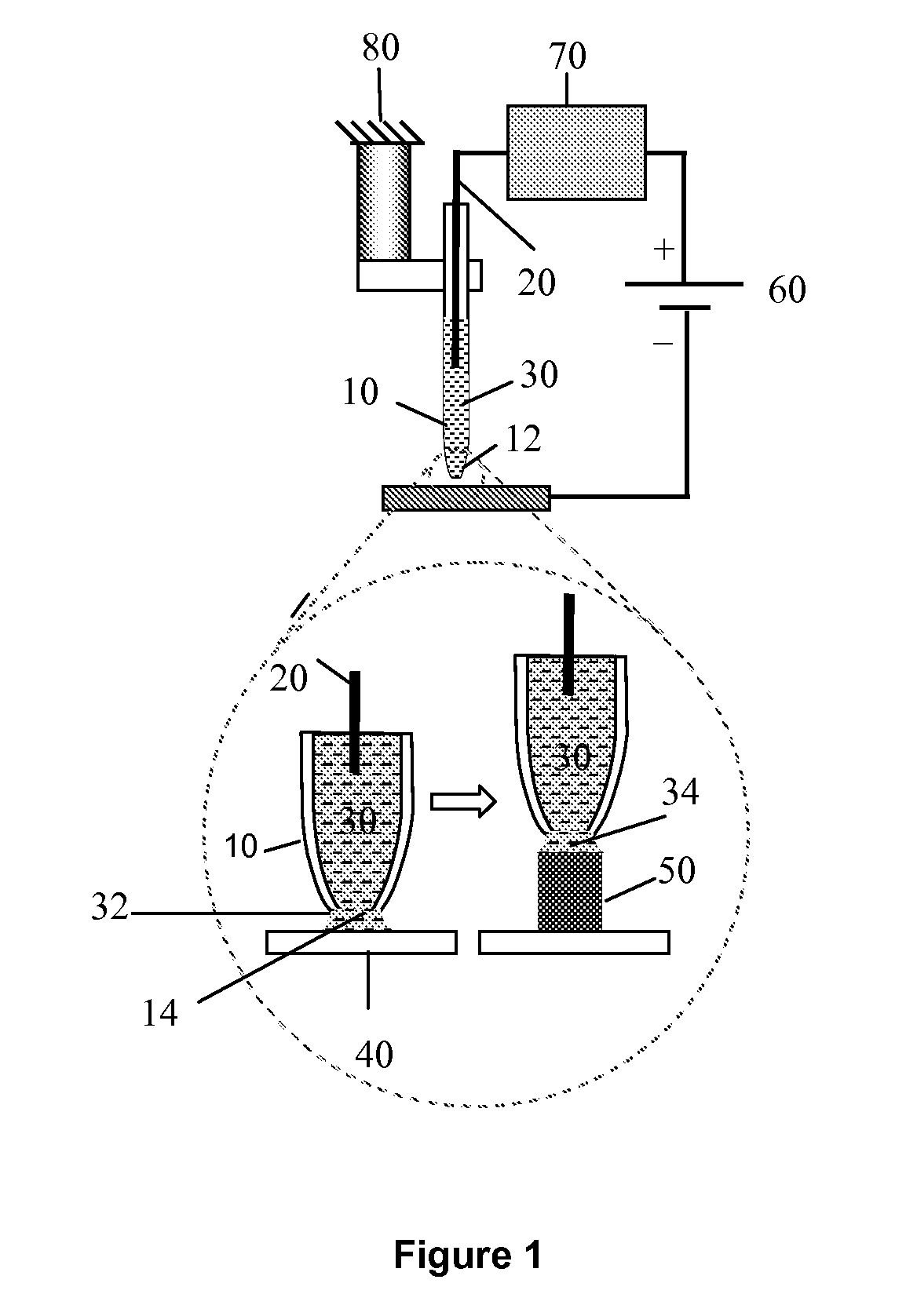

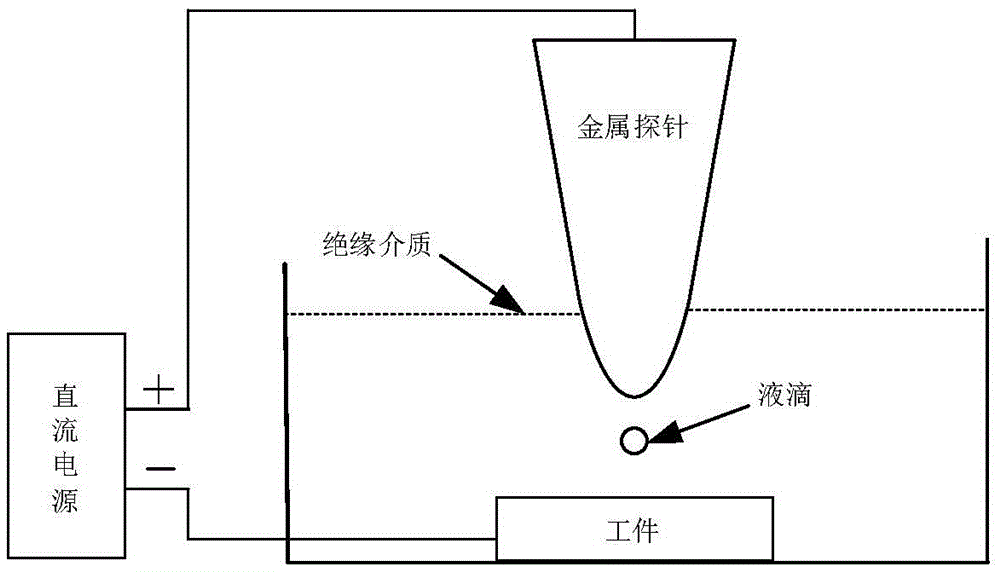

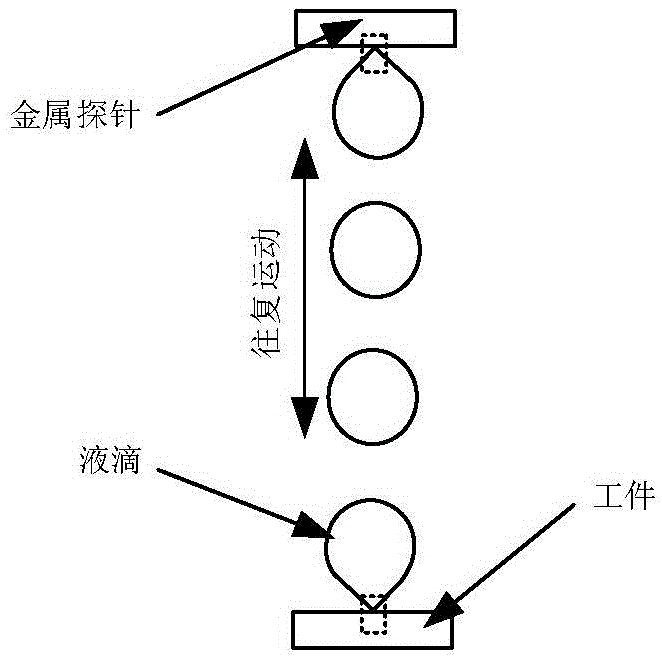

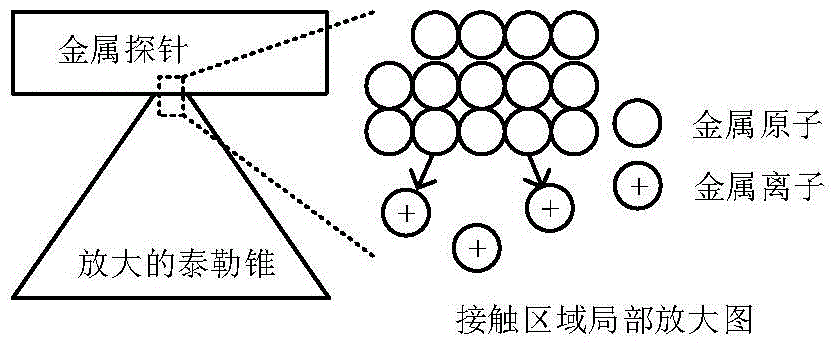

Micro-nano electrochemical deposition machining method based on liquid drop Taylor cone

ActiveCN105420763AAchieving Atomic-Level Deposition ProcessingEnables deposition processingElectroforming nanostructures3D structure electroformingMicro nanoManufacturing technology

The invention relates to a micro-nano electrochemical deposition machining method based on a liquid drop Taylor cone, and belongs to the technical field of micro-nano manufacturing. The method comprises the steps that liquid drops containing deposited metal ions are firstly put between a metal probe and a workpiece, and the materials of the probe are deposited materials; the probe and the workpiece are both immersed in an insulating medium, and the insulating medium and water are not compatible; the probe and the workpiece are connected with the positive pole and the negative pole of a direct-current power source respectively; the liquid drops do reciprocating motion between the probe and the workpiece under the action of an electric field; and when the liquid drops are close to the probe and the workpiece, the Taylor cone is formed on the surfaces of the liquid drops under the action of the electric field, by means of the electrochemical action generated during contact of the liquid drop Taylor cone, the probe and the workpiece, metal atoms of the metal probe are changed into metal cations to enter the liquid drops, then the metal cations are carried by the liquid drops to the surface of the workpiece and conveyed to the surface of the workpiece through the liquid drop Taylor cone, the metal cations obtain electrons on the surface of the workpiece to be changed into atoms to be deposited, and therefore micro-nano electrochemical deposition machining is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for Nanowire Cluster Formation

ActiveUS20160032475A1Inexpensive productionConvenient coatingTransistorAnodisationNanowireInterconnection

A cluster of non-collapsed nanowires, a template to produce the same, methods to obtain the template and to obtain the cluster by using the template, and devices comprising the cluster are described. The cluster and the template both have an interconnected region and an interconnection-free region.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

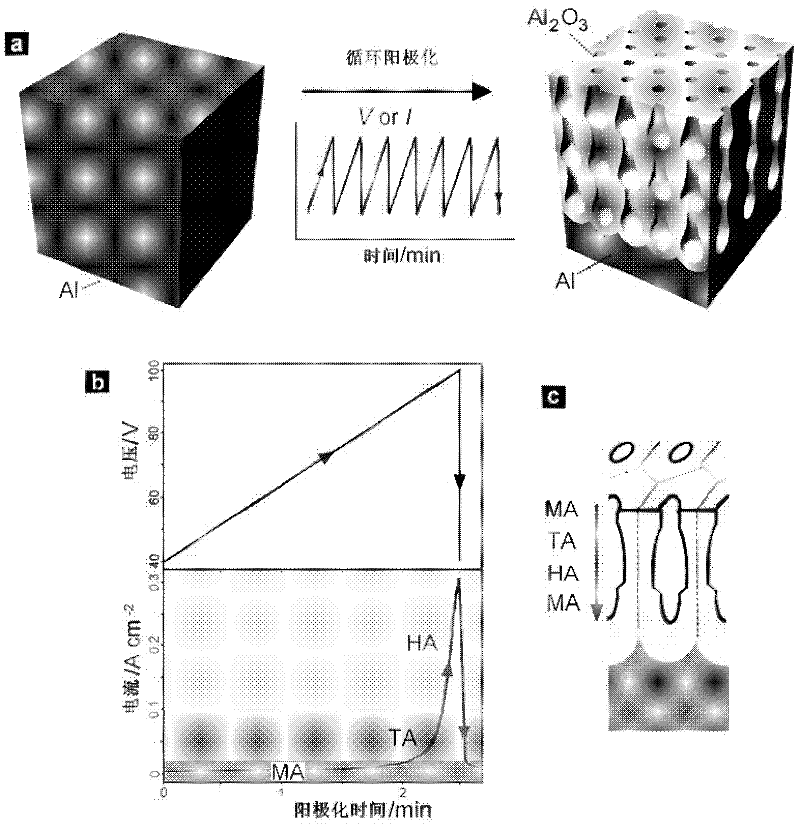

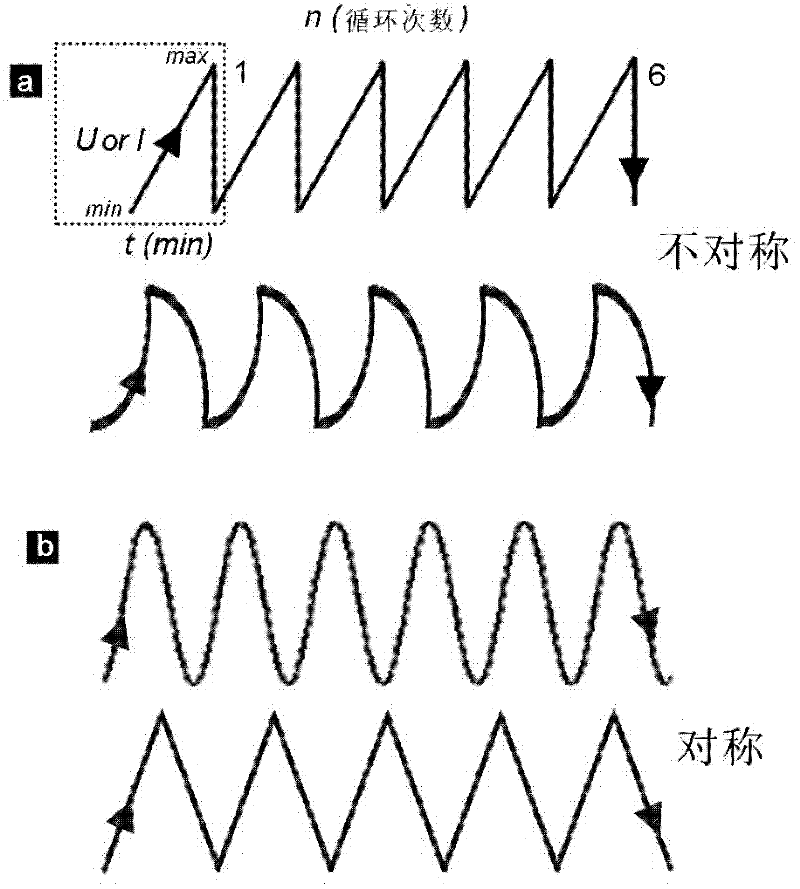

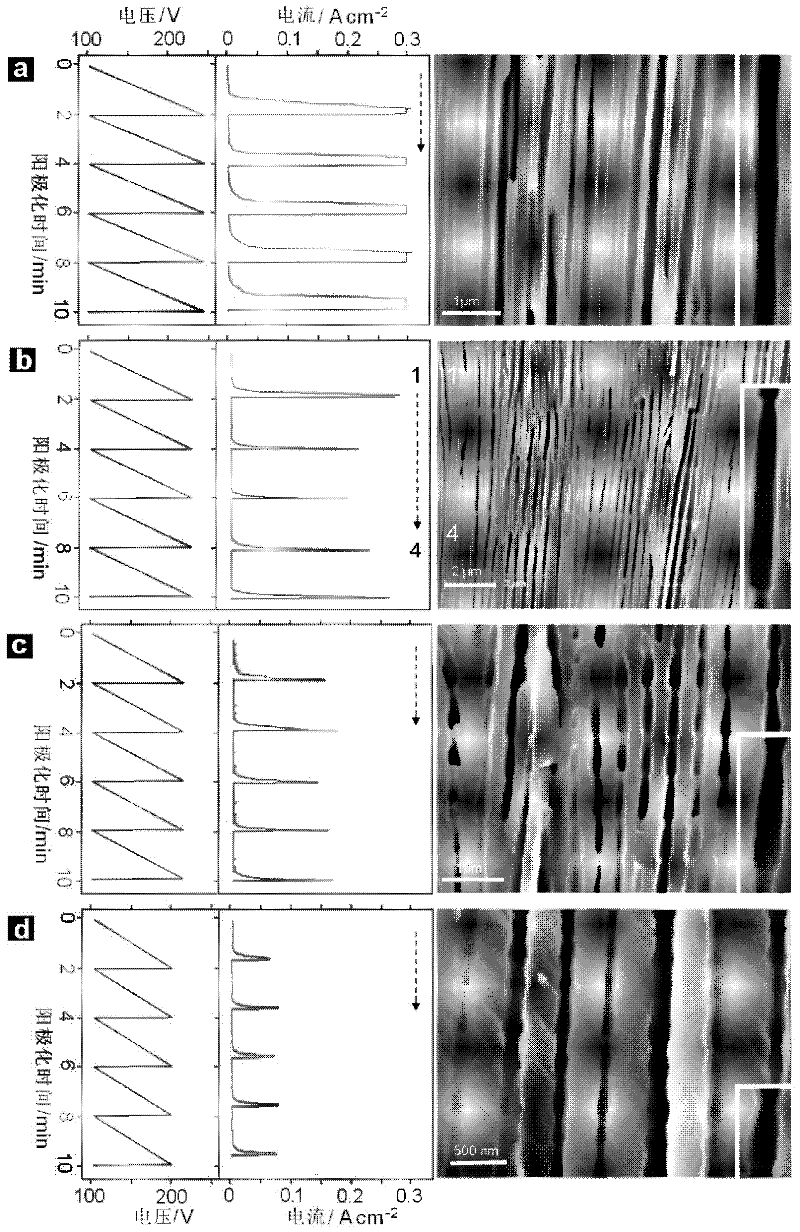

Preparation of Nanoporous Materials

A method for preparing a porous metal oxide or metalloid oxide material, the method comprising: providing an anode substrate, including a metal or metalloid substrate; providing a cathode substrate; connecting the substrates to form an electrochemical cell; applying an electrical signal to the electrochemical cell; and forming shaped pores in the metal or metalloid substrate by: (a) changing the electrical signal over time; an applied voltage of the signal to form a voltage cycle comprising a minimum voltage period in which a minimum voltage is applied, a maximum voltage period in which a maximum voltage is applied, and a transition period between said minimum voltage period and said maximum voltage period , wherein during the transition period, the voltage is rapidly increased from said minimum voltage to said maximum voltage, or (b) the current of said electrical signal is varied over time to form a current cycle comprising a period of application of a minimum current a minimum current period, a maximum current period in which a maximum current is applied, and a transition period between said minimum current period and said maximum current period, wherein during the transition period, voltage rapidly increases from said minimum current to said Maximum current.

Owner:UNIV OF SOUTH AUSTRALIA

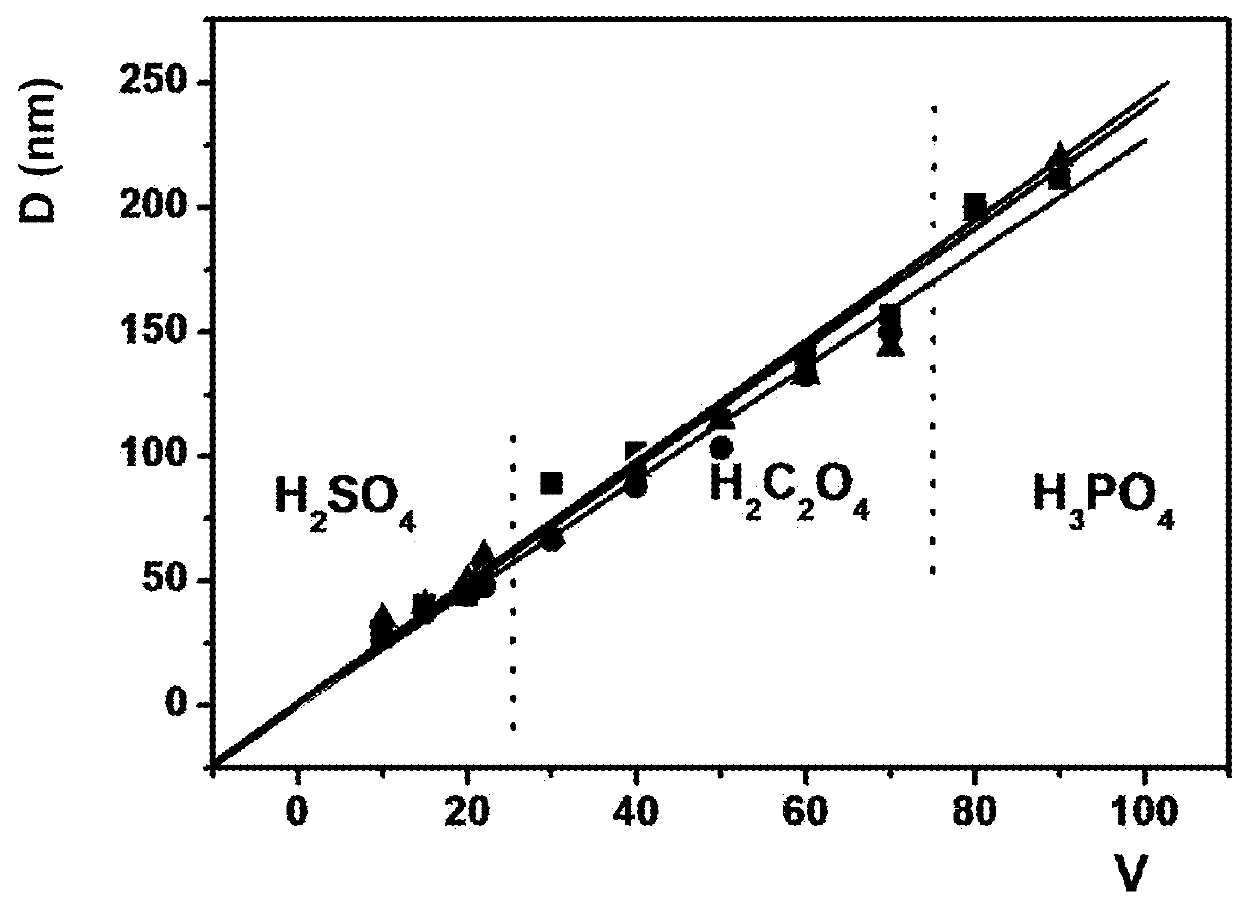

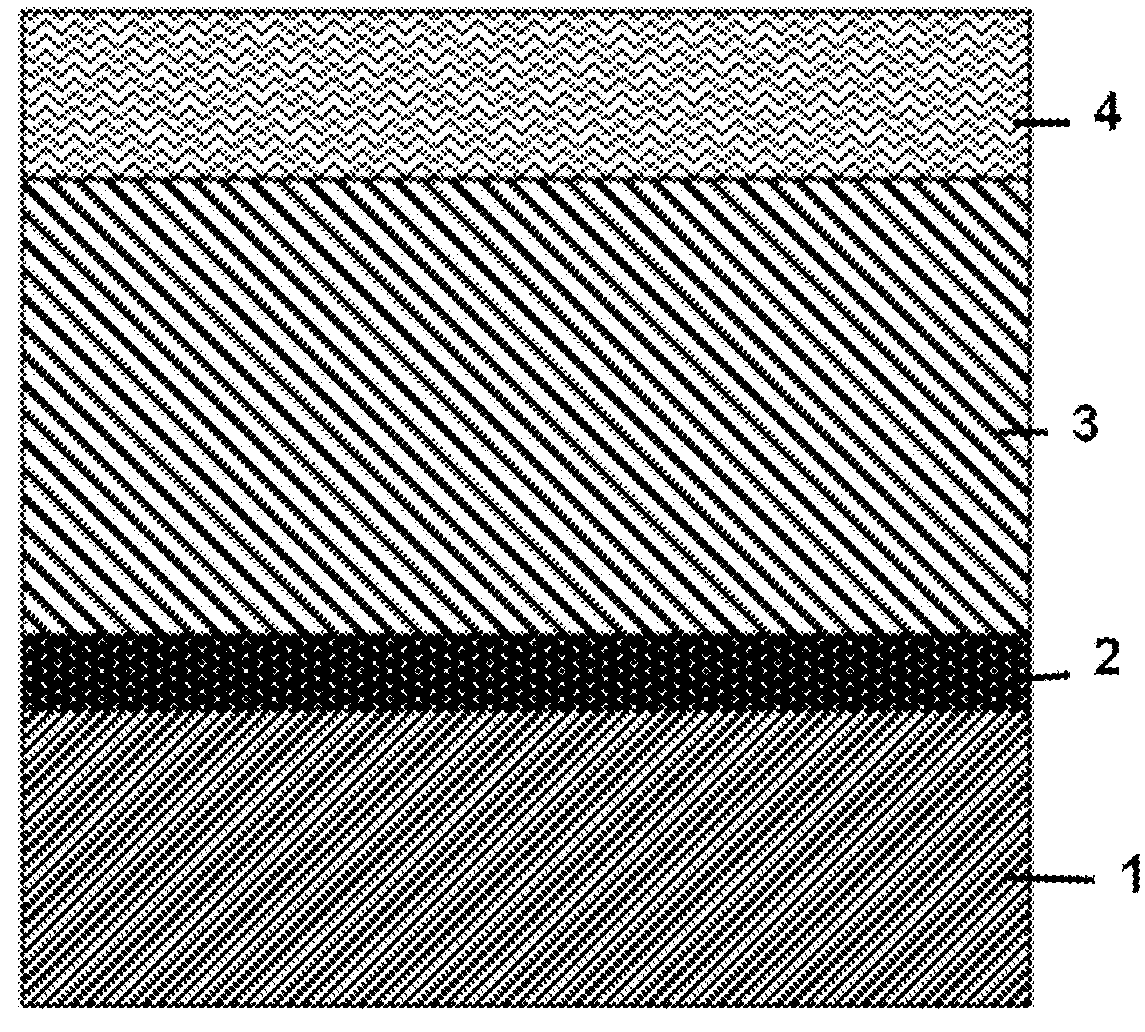

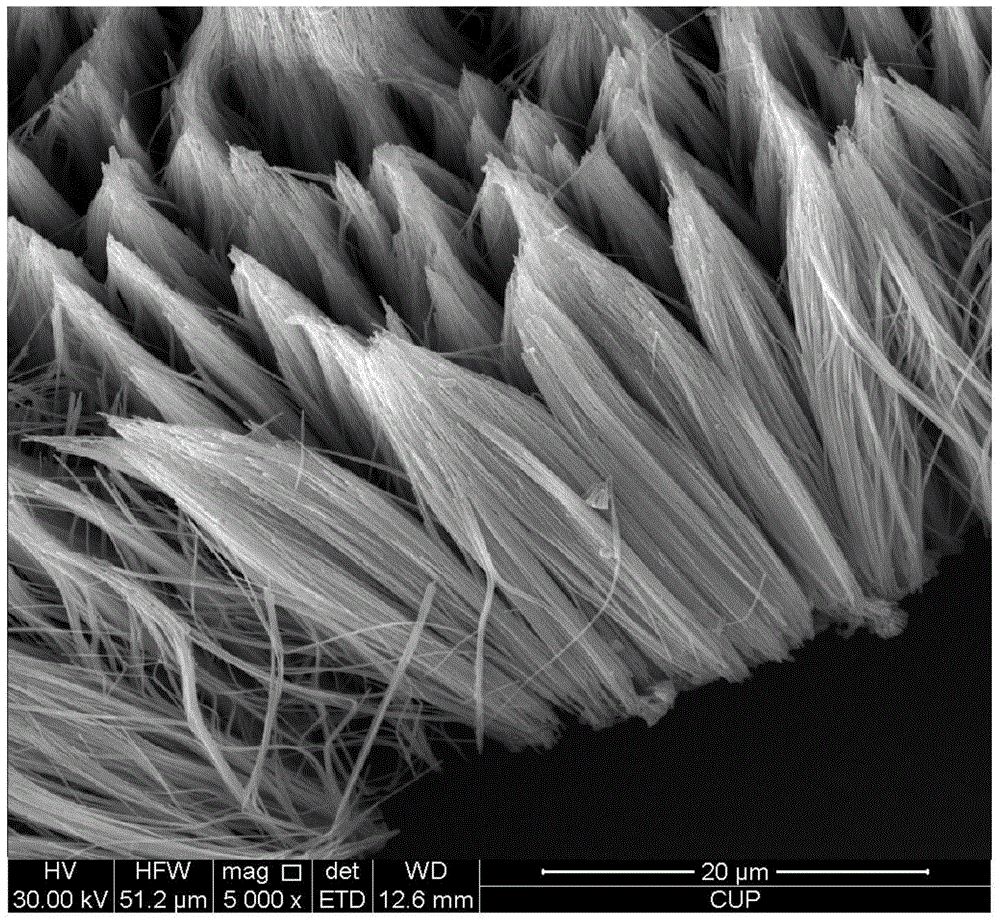

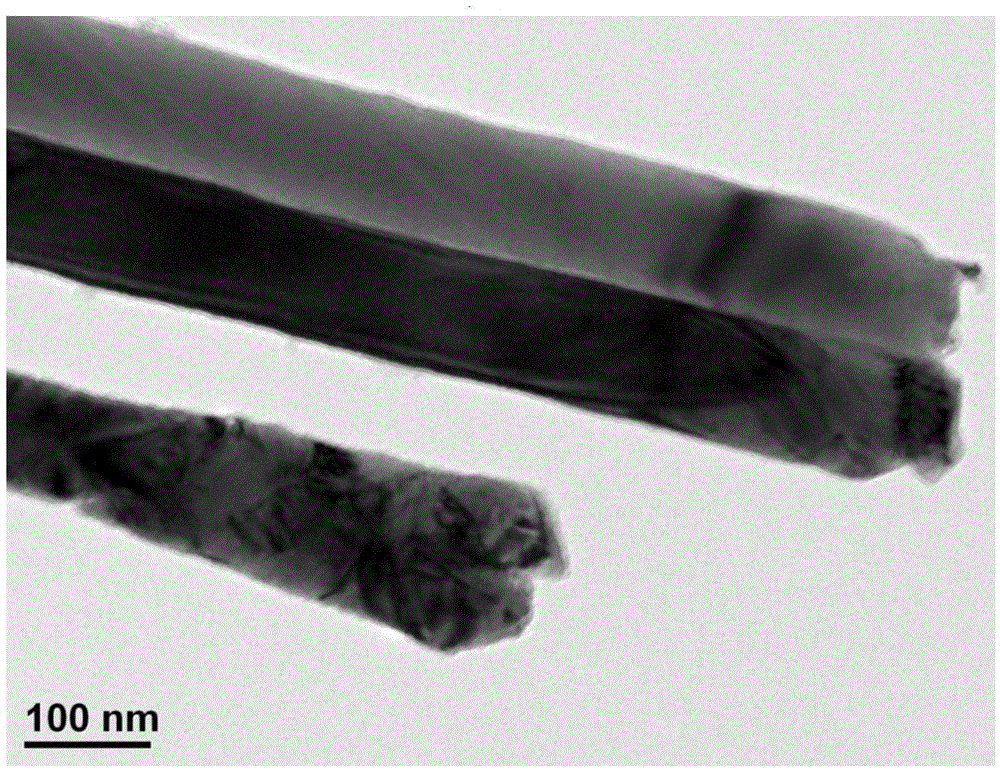

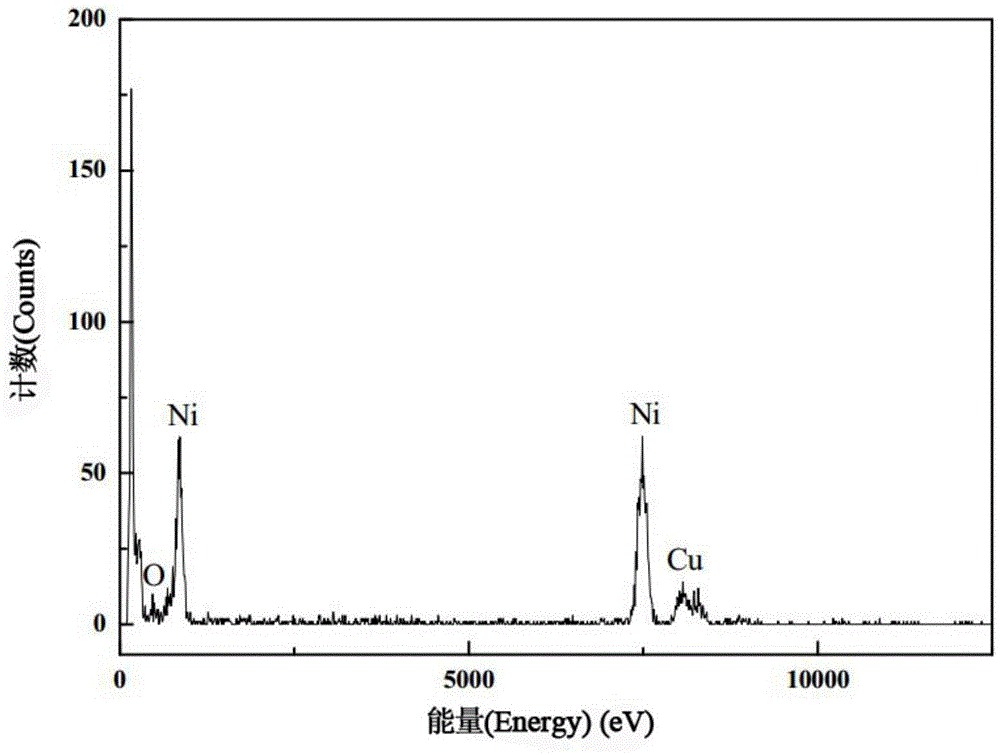

CuO/Ni core-shell nanowire and preparation method thereof

InactiveCN105603469ASimple processLow costNanotechnologyElectroforming nanostructuresPhosphoric acidElectrochemistry

The invention provides a CuO / Ni core-shell nanowire and a preparation method thereof. According to the preparation method, an AOO (anodic aluminum oxide) template is taken as a cathode, a carbon rod is taken as an anode, copper nanowire arrays are deposited in the AOO template with an electrochemical deposition method and then soaked in a phosphoric acid solution for pore expansion, thermal treatment is also performed, nickel nanowire arrays are deposited on the treated template, the AOO template containing the nickel nanowire arrays and the CuO nanowire arrays is obtained, finally, the AOO template is soaked in a sodium hydroxide solution, an aluminum oxide template is removed, and the CuO / Ni core-shell nanowire is obtained after ethanol cleaning and infrared drying. The preparation method adopts a simple process and can realize mass production, the cost is low, and the prepared CuO / Ni core-shell nanowire can be 25 mu m long.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Lithium-ion battery

ActiveUS8795885B2Improve diffusivityNanotechElectrolytic inorganic material coatingSolid state electrolytePhosphate

A lithium-ion battery having an anode including an array of nanowires electrochemically coated with a polymer electrolyte, and surrounded by a cathode matrix, forming thereby interpenetrating electrodes, wherein the diffusion length of the Li+ ions is significantly decreased, leading to faster charging / discharging, greater reversibility, and longer battery lifetime, is described. The battery design is applicable to a variety of battery materials. Methods for directly electrodepositing Cu2Sb from aqueous solutions at room temperature using citric acid as a complexing agent to form an array of nanowires for the anode, are also described. Conformal coating of poly-[Zn(4-vinyl-4′methyl-2,2′-bipyridine)3](PF6)2 by electroreductive polymerization onto films and high-aspect ratio nanowire arrays for a solid-state electrolyte is also described, as is reductive electropolymerization of a variety of vinyl monomers, such as those containing the acrylate functional group. Such materials display limited electronic conductivity but significant lithium ion conductivity. Cathode materials may include oxides, such as lithium cobalt oxide, lithium magnesium oxide, or lithium tin oxide, as examples, or phosphates, such as LiFePO4, as an example.

Owner:COLORADO STATE UNIVERSITY

Method for preparing aluminum nanostructure array, three-dimensional solar cell and photovoltaic cell

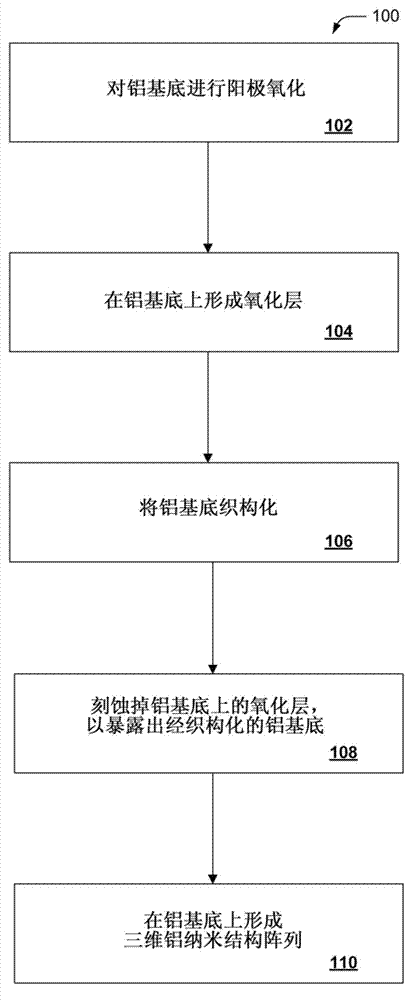

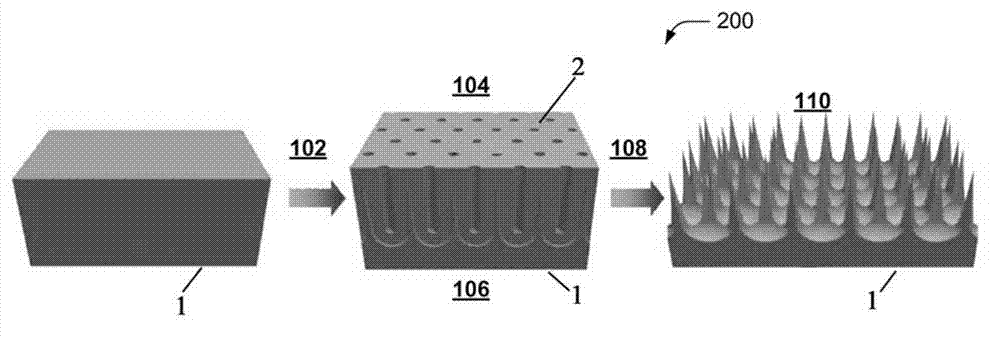

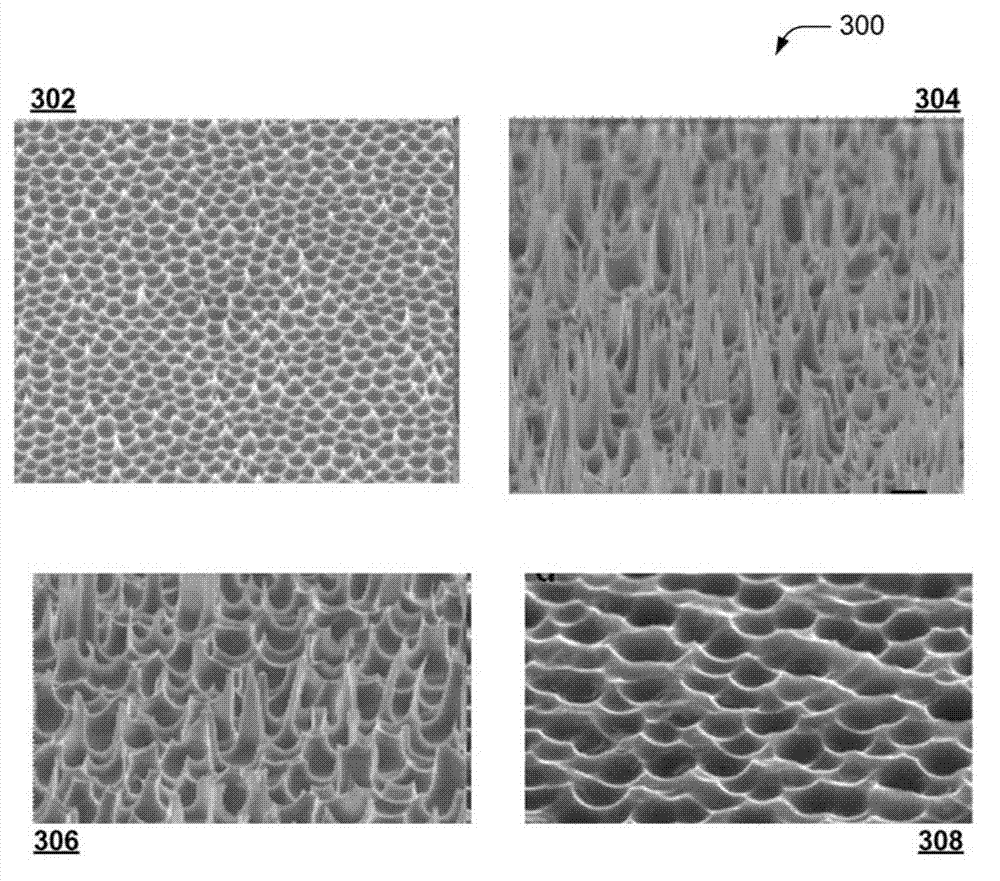

ActiveCN103000754ASurface reaction electrolytic coatingElectroforming nanostructuresAluminum substrateNanostructure

Described herein are a method for obtaining a three-dimensional nanostructure array on an aluminum substrate, a three-dimensional solar cell including such a three-dimensional nanostructure array, and a photovoltaic cell. The method includes anodizing the aluminum substrate; forming an oxide layer on the aluminum substrate; texturizing the aluminum substrate; etching the oxide layer from the aluminum substrate to expose the texturized aluminum substrate; and forming a three-dimensional aluminum nanostructure array on the aluminum substrate. The method is a low cost and scalable process to obtain three-dimensional nanostructure arrays on an aluminum surface. The three-dimensional nanostructure array, coated with a light absorber, is utilized in a thin film solar cell or photovoltaic cell. The reflectance of the solar cell and photovoltaic cell is low compared to the reflectance exhibited by the light absorber coated on a planar aluminum substrate.

Owner:THE HONG KONG UNIV OF SCI & TECH

System and method of anodized aluminum oxide nano-porous membrane preparation

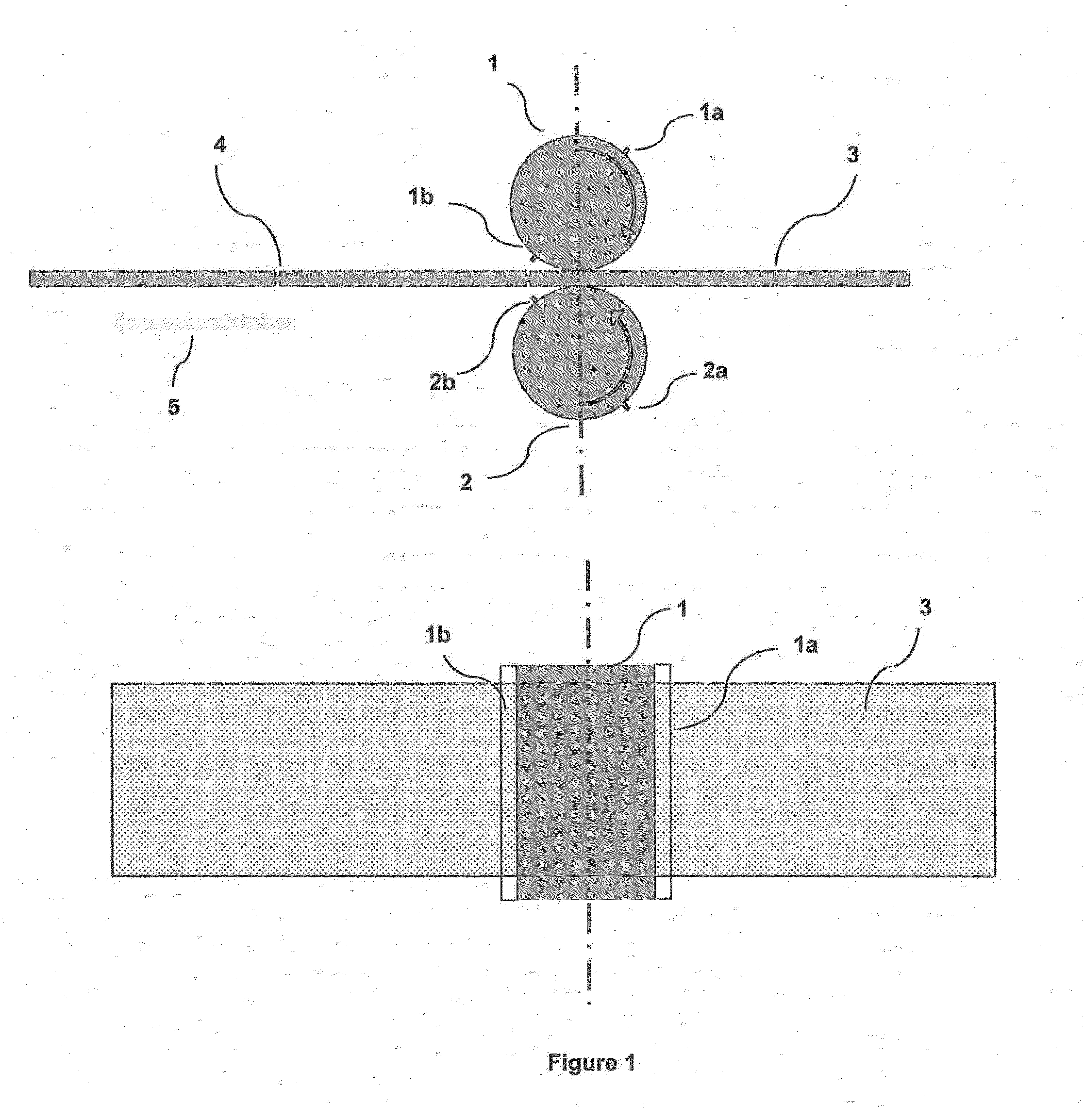

InactiveUS20140202868A1Simple methodEffective utilization of crackDuplicating/marking methodsSurface reaction electrolytic coatingEtchingVoltage pulse

A system and method for preparation of nano-porous membrane using anodized aluminium oxide and the membrane / film / thin lamina produced thereof. The system comprises a template forming device that comprises of two rolls provided with one or plurality of projections wherein the Al sheet is passed through the said rolls that are rotatable in opposite direction with respect to each other wherein in operation as the Al sheet is passed through the said rolls, the said projections of the rolls punch depressions to the predetermined depth in the said sheet wherein the depth of the depression is governed by the height of the projections. A method for preparation of anodized aluminum oxide nano-porous membrane comprising electro polishing of Al substrate; first step anodization; chemical etching of alumina; second stage anodization; etching Al for separation of alumina and barrier layer removal or voltage pulse detachment for barrier layer removal and detachment of membrane from Al substrate.

Owner:ASIAN INSTITUTE OF TECHNOLOGY

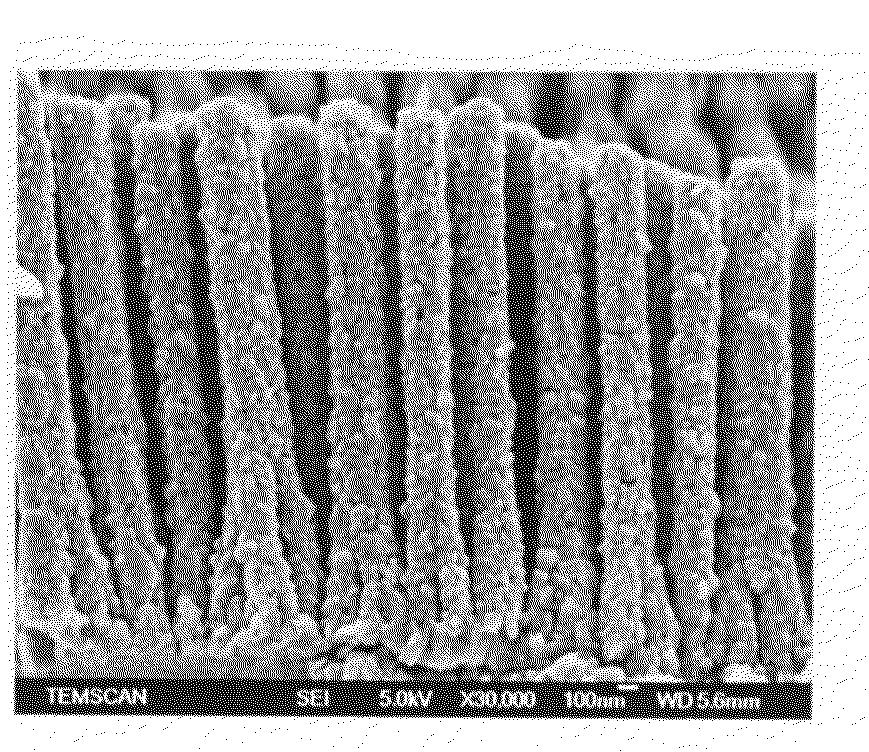

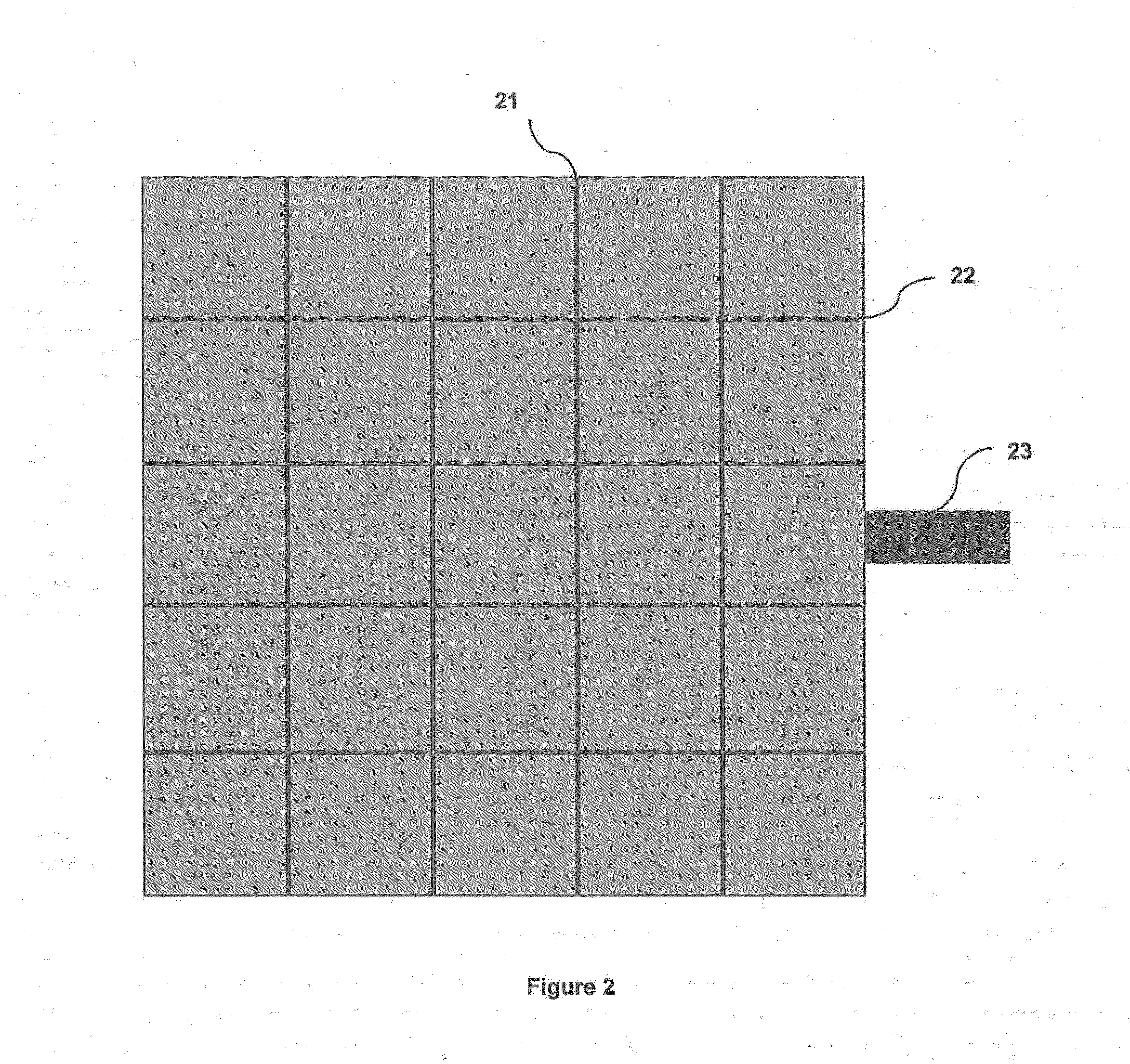

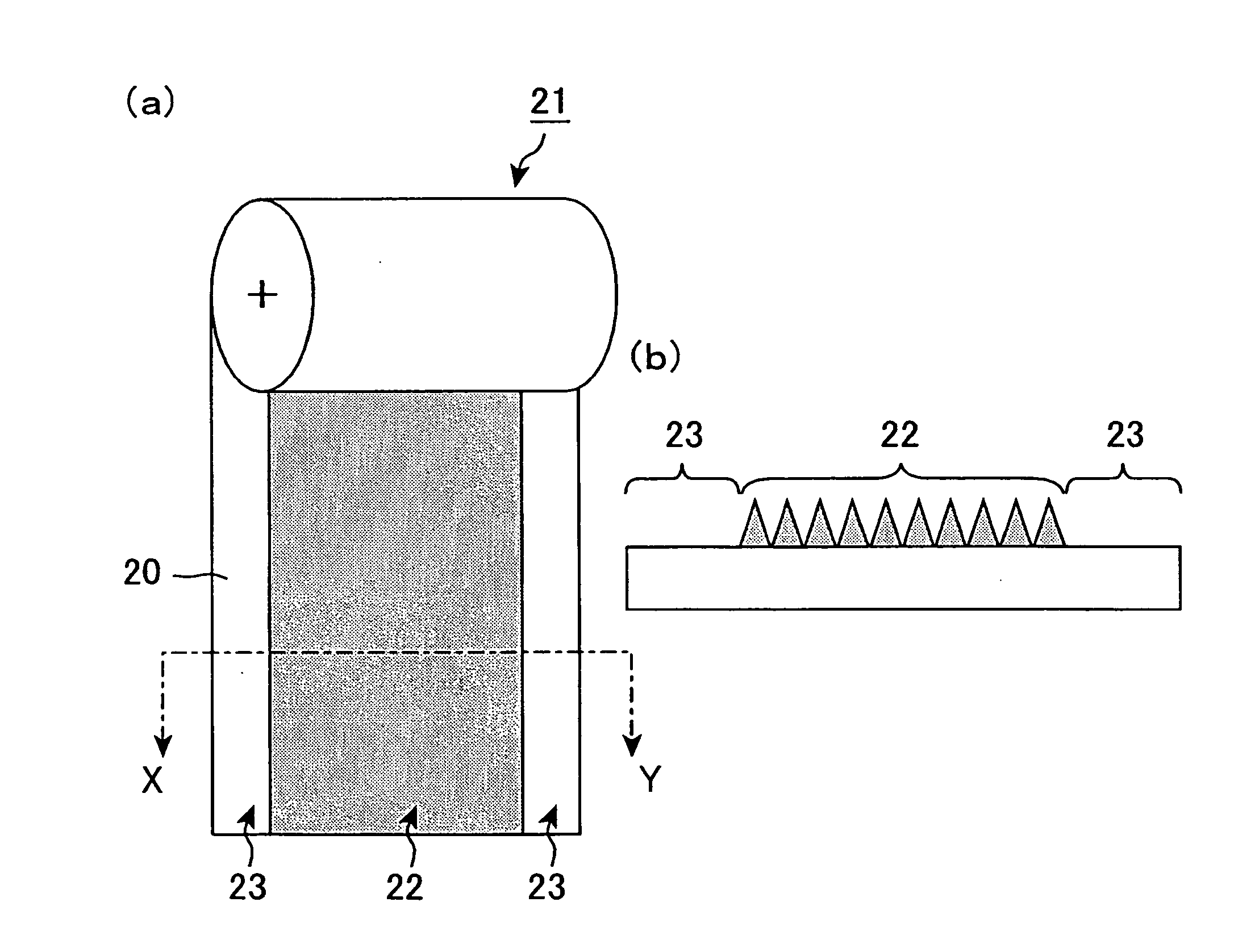

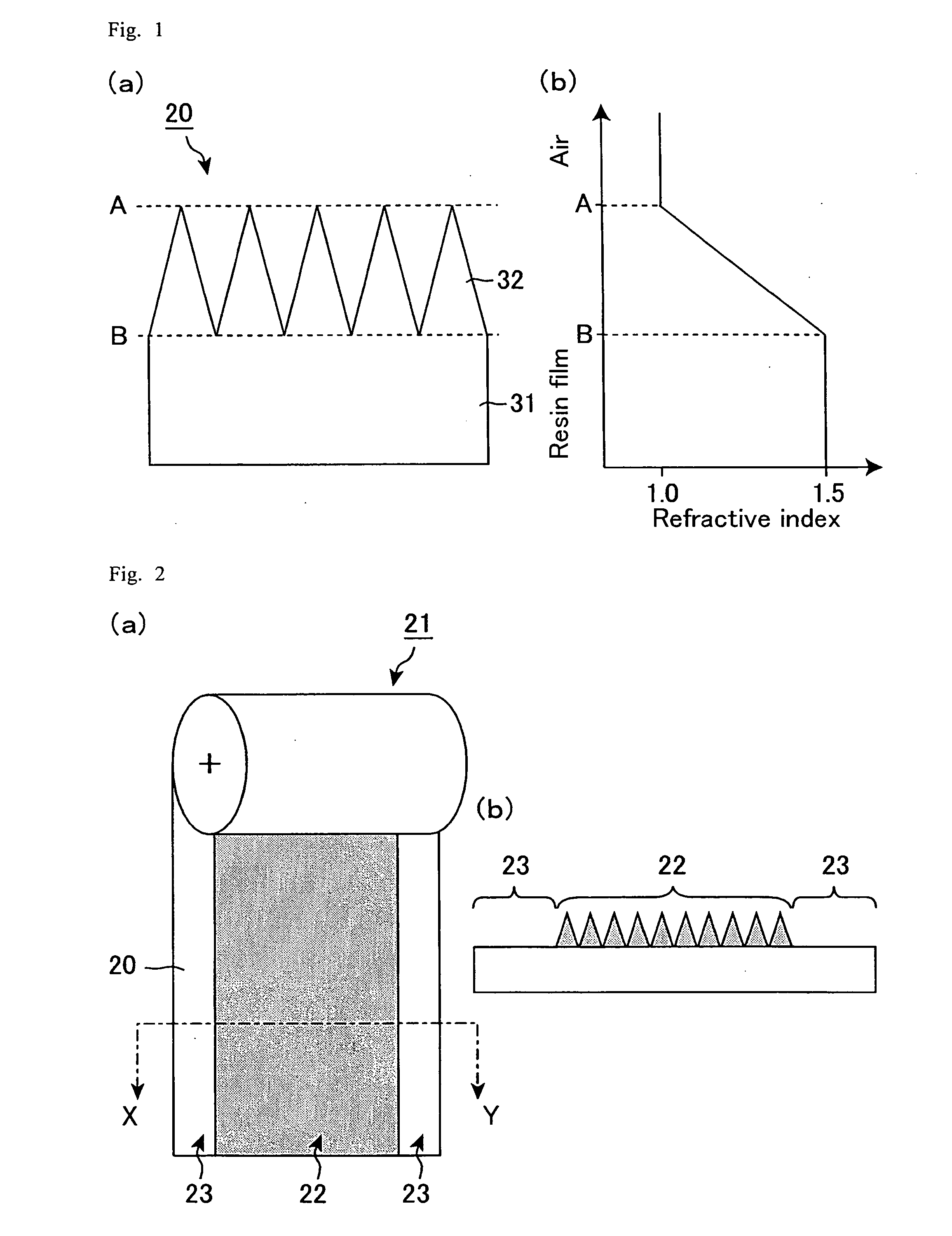

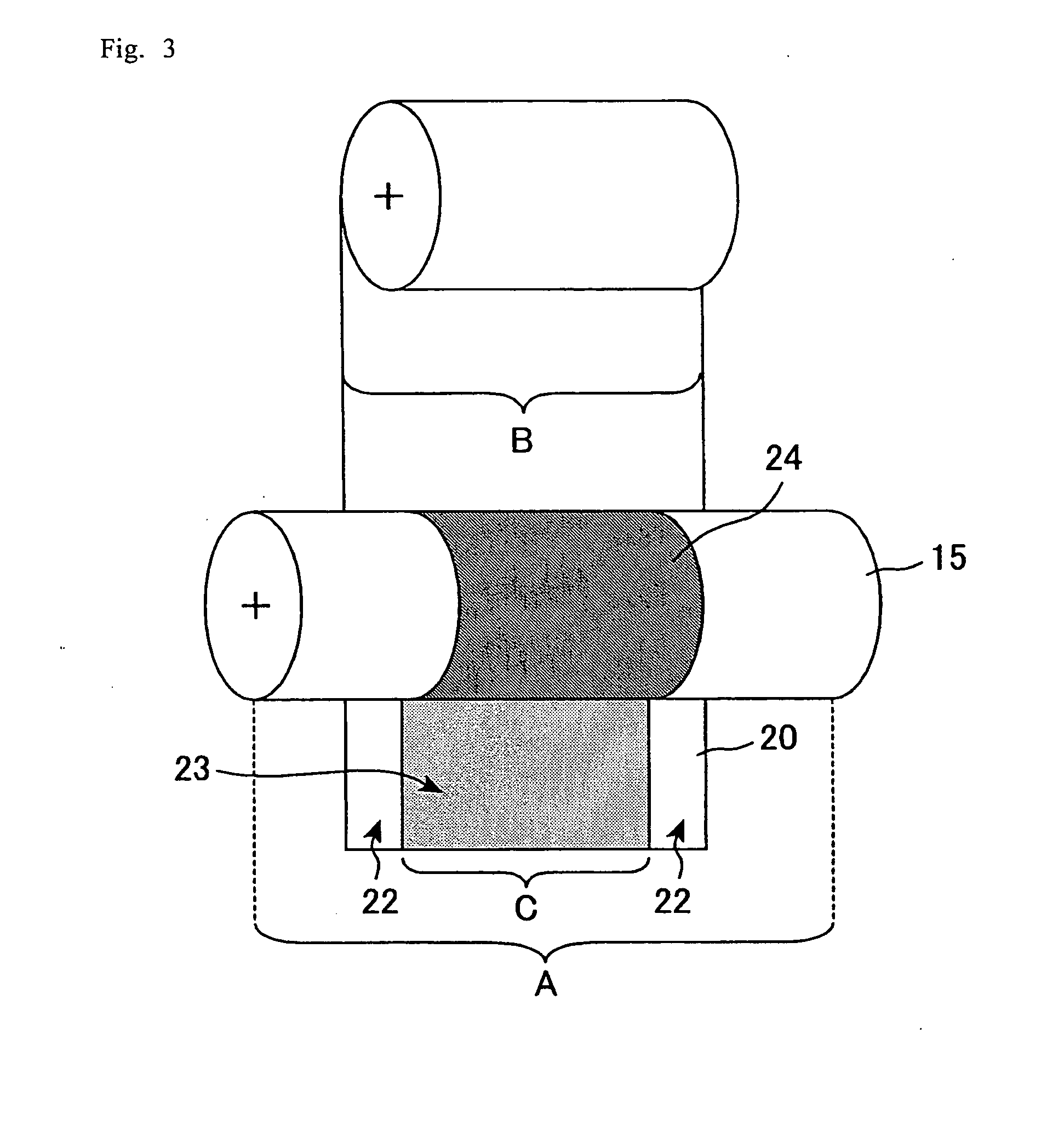

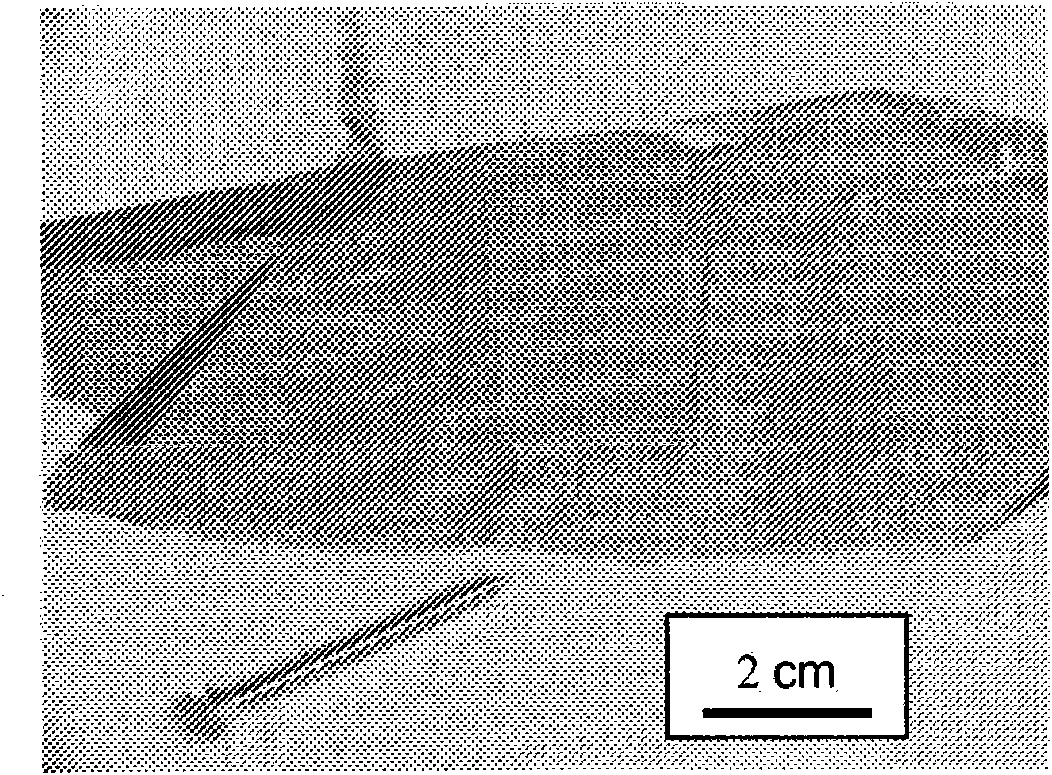

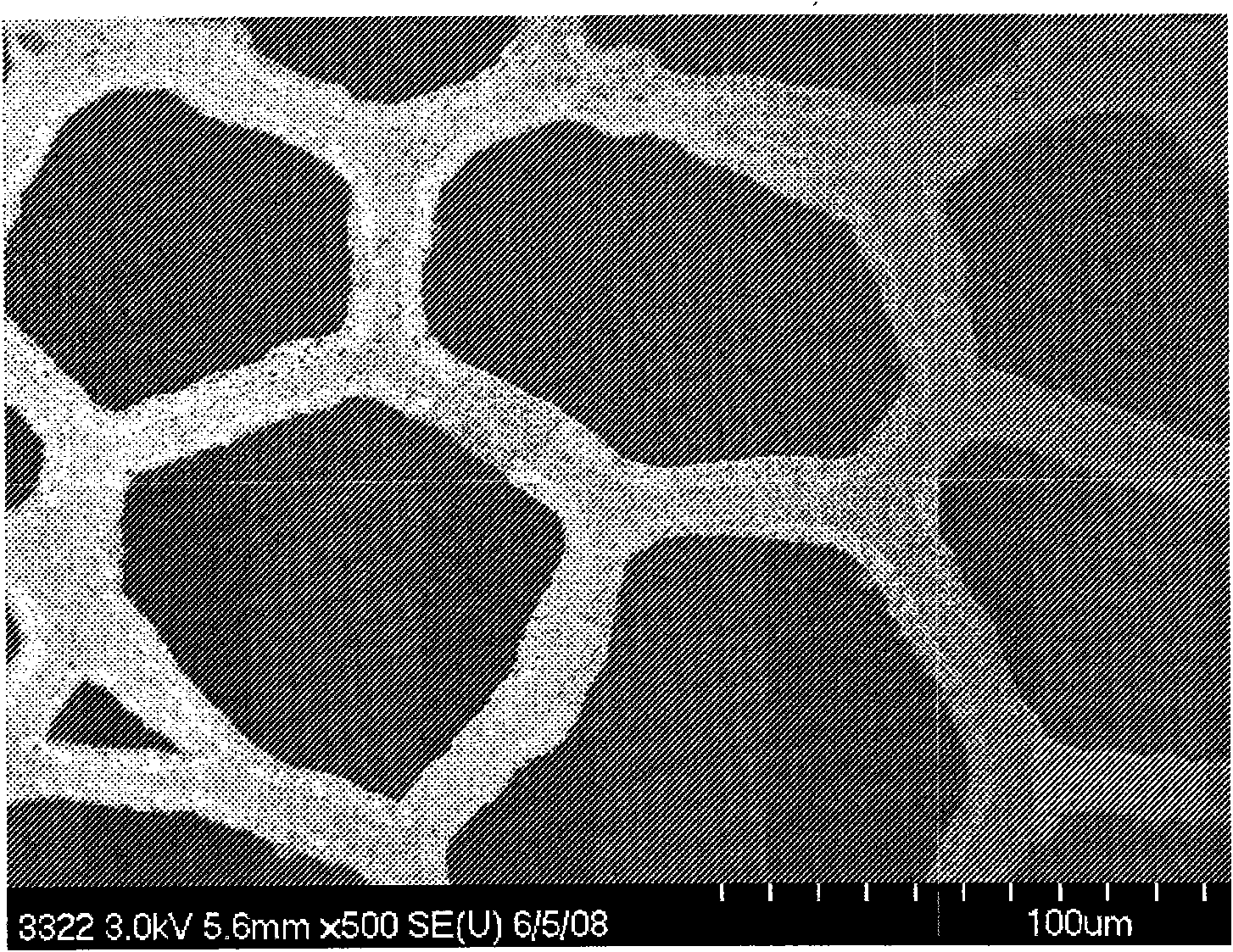

Optical element, roller type nanoprinting apparatus, and process for producing die roll

ActiveUS20100284087A1Improve adhesionIncrease productionDecorative surface effectsNanoinformaticsThin membraneNanostructure

To provide an optical element having excellent adhesion to a lamination film, a roller nanoimprint apparatus, and a production method of a mold roller are disclosed. In at least one embodiment of the present invention, an optical element includes a nanostructure film including recesses and protrusions in nanometer size formed continuously on a surface of the nanostructure film and a lamination film laminated on the nanostructure film. The nanostructure film includes a nanostructure-free region free from the recesses and protrusions in nanometer size in both ends along a longitudinal direction of the nanostructure film.

Owner:SHARP KK

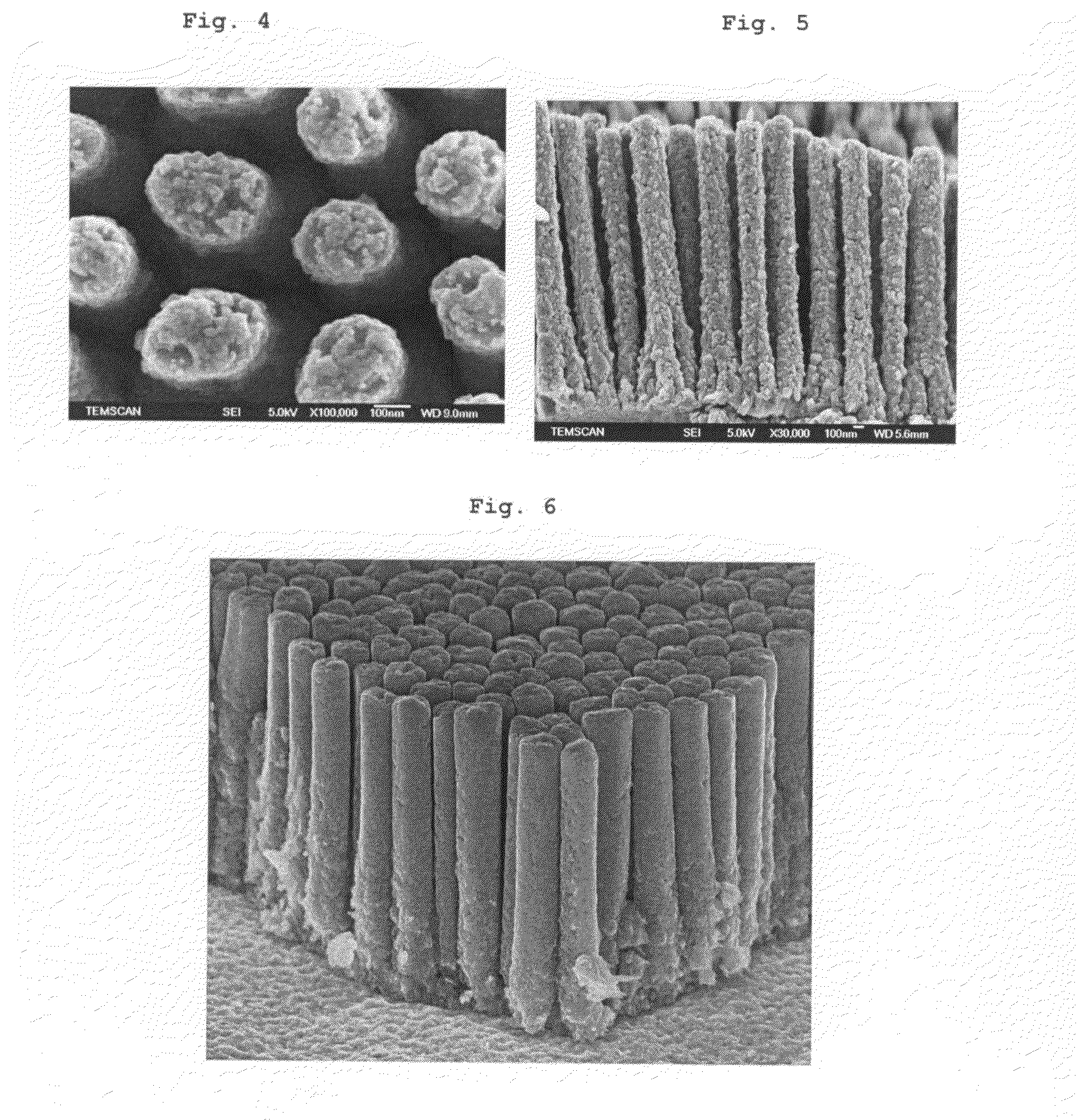

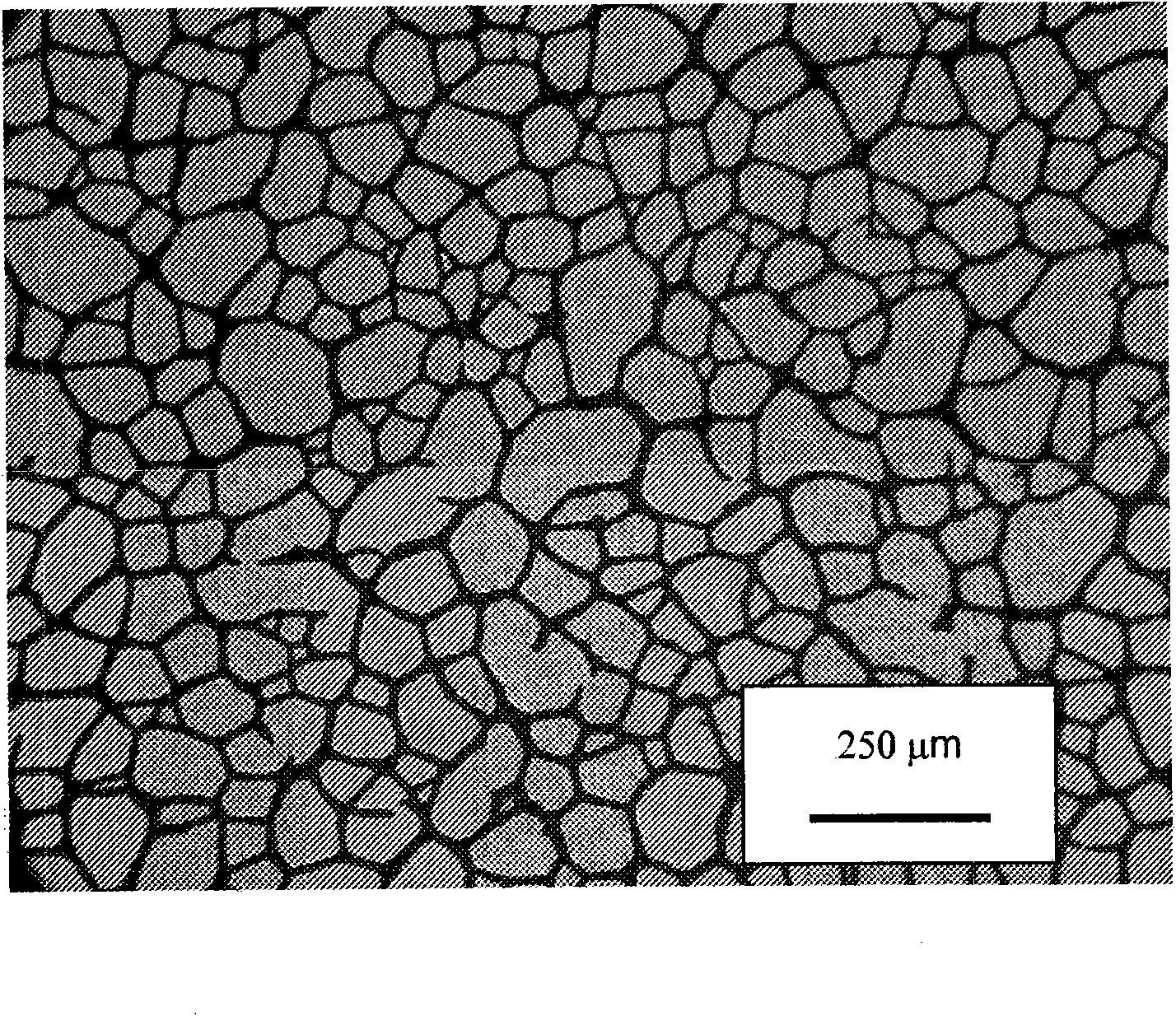

Microstructured material and process for its manufacture

A micro-structured article is disclosed comprising a free-standing network of interconnected traces surrounding randomly-shaped cells wherein the interconnected traces comprise at least partially-joined nanoparticles. In a preferred embodiment, the nanoparticles comprise a conductive metal. The article is preferably formed by coating a nanoparticle-containing emulsion onto a substrate and drying the emulsion. The nanoparticles self-assemble into the network pattern which is subsequently removed from the substrate. A preferred method of removing the network from the substrate comprises the steps of electroplating the traces and subsequently exposing the traces to acid to release the network from the substrate.

Owner:CIMA NANOTECH ISRAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com