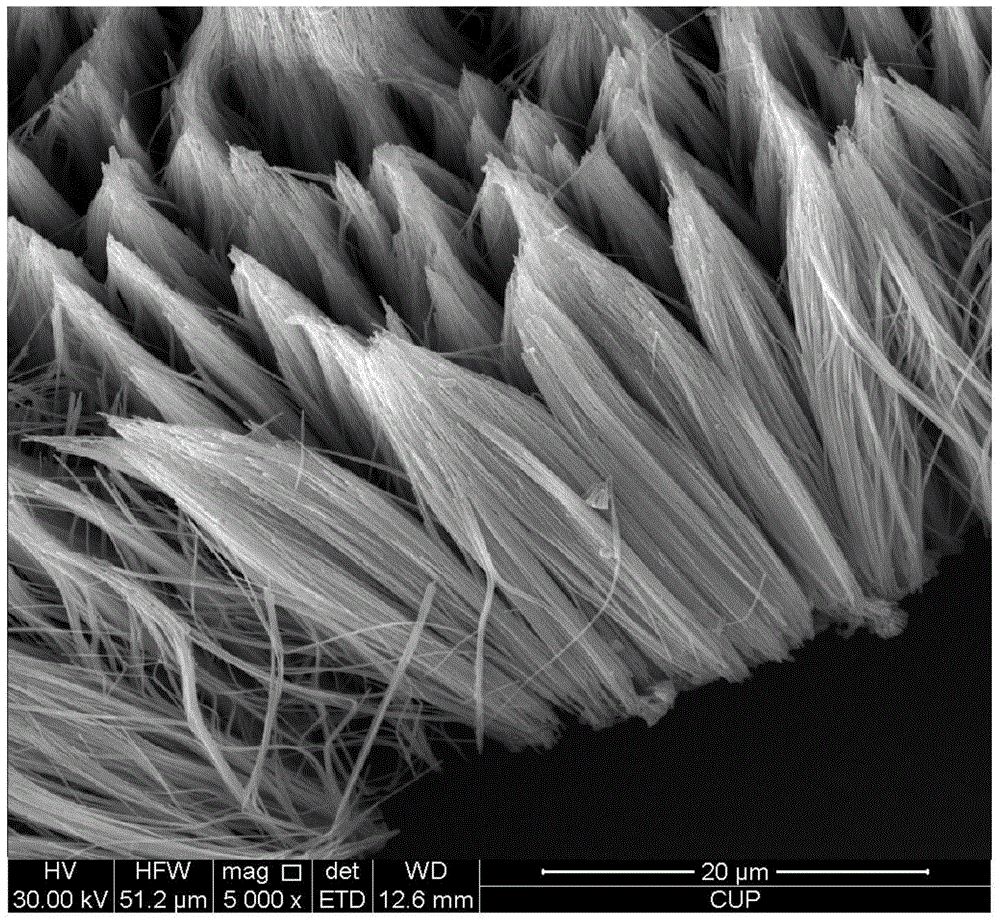

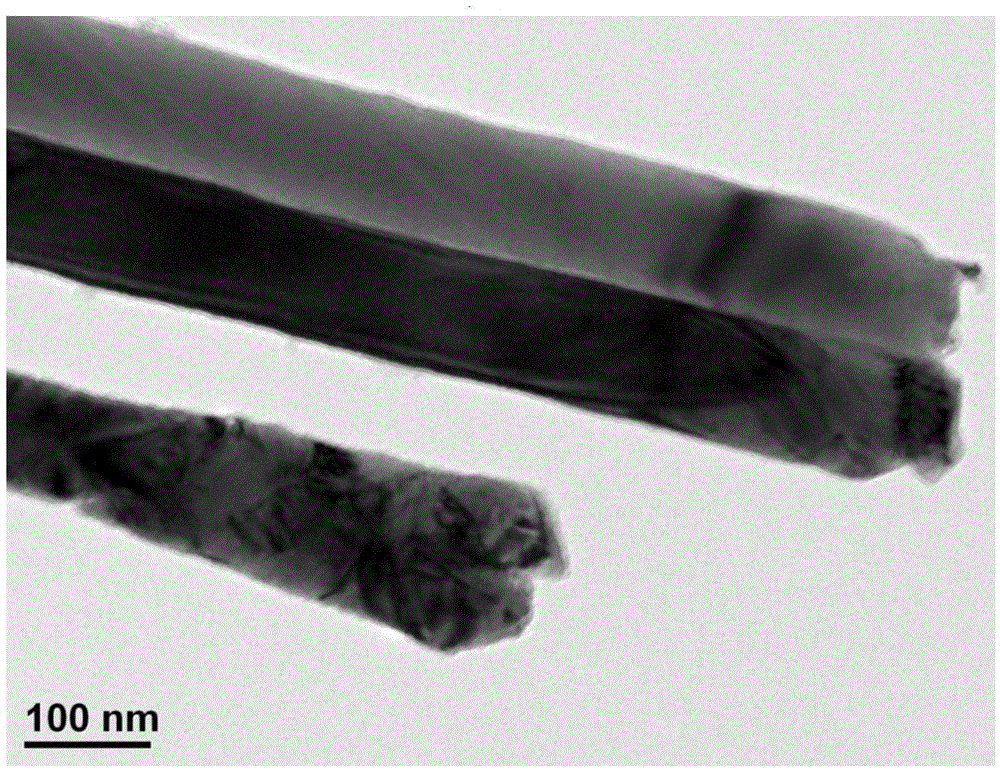

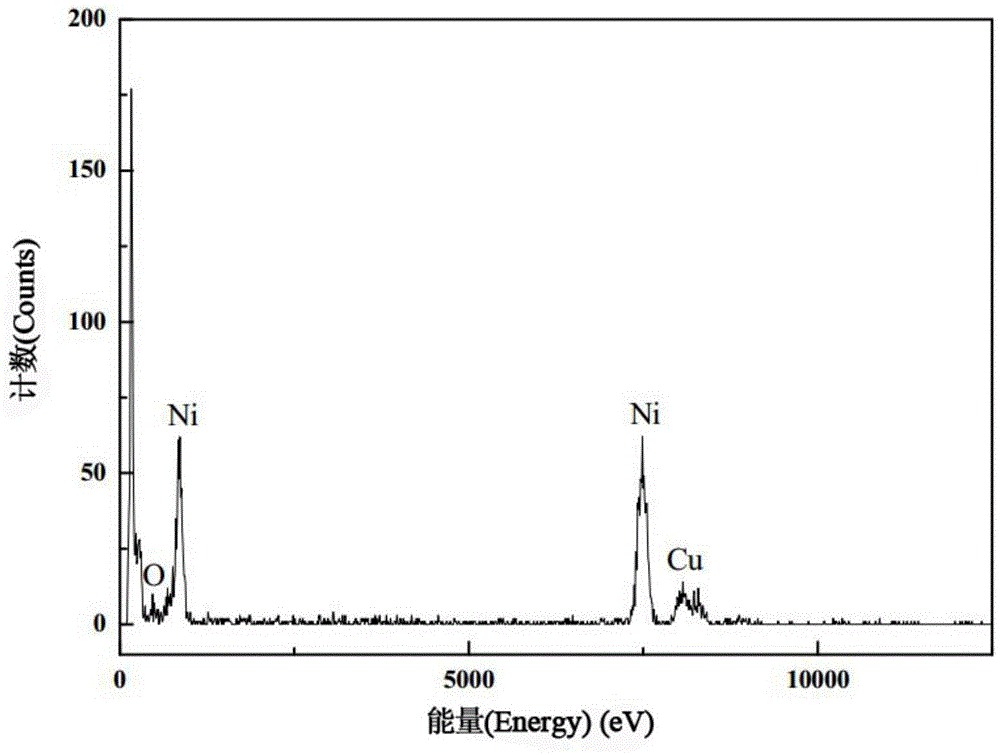

CuO/Ni core-shell nanowire and preparation method thereof

A technology of nanowires and nickel nanowires is applied in the field of CuO/Ni core-shell nanowires and their preparation, and achieves the effects of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing CuO / Ni core-shell nanowires, comprising the following steps:

[0028] (1) With the 80nm anodized aluminum template as the cathode and the carbon rod as the anode, an electrochemical deposition method is used to deposit copper nanowire arrays in the anodized aluminum template; wherein before the deposition, the anodized aluminum template is preformed For processing, use the method of magnetron sputtering to sputter a layer of Ag layer with a thickness of 200nm on its back as a conductive electrode; each liter of electrolyte for depositing copper nanowire arrays contains 90g of CuSO 4 ·5H 2 O, 45g of H 2 SO 4 ; The deposition voltage was 2V.

[0029] (2) The anodized aluminum template containing the copper nanowire array obtained in step (1) is immersed in a phosphoric acid solution with a mass fraction of 5% for hole expansion, and the template after hole expansion for 10 min is placed in a heat treatment furnace at 80° ...

Embodiment 2

[0035] This embodiment provides a method for preparing CuO / Ni core-shell nanowires, comprising the following steps:

[0036] (1) Using an anodized aluminum template with a pore size of 30nm as the cathode and a carbon rod as the anode, an electrochemical deposition method is used to deposit copper nanowire arrays in the anodized aluminum template; wherein before the deposition, the anodized aluminum template is pre-treated. For processing, use the method of magnetron sputtering to sputter a layer of Ag layer with a thickness of 200nm on its back as a conductive electrode; each liter of electrolyte for depositing copper nanowire arrays contains 90g of CuSO 4 ·5H 2 O, 45g of H 2 SO 4 ; The deposition voltage was 2V.

[0037] (2) The anodized aluminum template containing the copper nanowire array obtained in step (1) is immersed in a phosphoric acid solution with a mass fraction of 5% for hole expansion, and the template after hole expansion for 15 minutes is placed in a heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com