Polycrystalline cuprous oxide nanowire array production method using low-temperature electrochemical growth

a nanowire array and polycrystalline technology, applied in the direction of electroforming nanostructures, cell components, coatings, etc., can solve the problems of high temperature and high pressure conditions for manufacturing monocrystalline nanowires or nanowire arrays, complicated and expensive manufacturing processes and equipment, etc., and achieve the effect of improving the crystallinity of nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0027]Example 1 was a step of manufacturing a nanopore membrane (anodized alumina (AAO)) from a high-purity aluminum (Al) sheet by using a two-step anodic oxidation method.

[0028]In other words, after a high-purity aluminum sheet having a desired size was prepared, the high-purity aluminum sheet was electrolytically polished at a temperature of 10° C. for 4 minutes by applying direct current (DC) voltage of +20 V thereto in an electrolytic polishing solution (including chloric acid (HClO4) and ethanol at a volume ratio of 1:4).

[0029]Primary anodic oxidation was performed onto the electrolytically polished aluminum sheet at a temperature of 10° C. for 12 hours by applying voltage of +20 V thereto in a 0.3 M sulfuric acid (H2SO4) aqueous solution or a 0.3 M oxalic acid (H2C2O4) aqueous solution.

[0030]A porous alumina layer formed by the primary anodic oxidation was etched and removed with a mixed solution of 6 wt % of phosphoric acid (H3PO4) and 1.8 wt % of chromic acid (CrO3) at a tem...

example 2

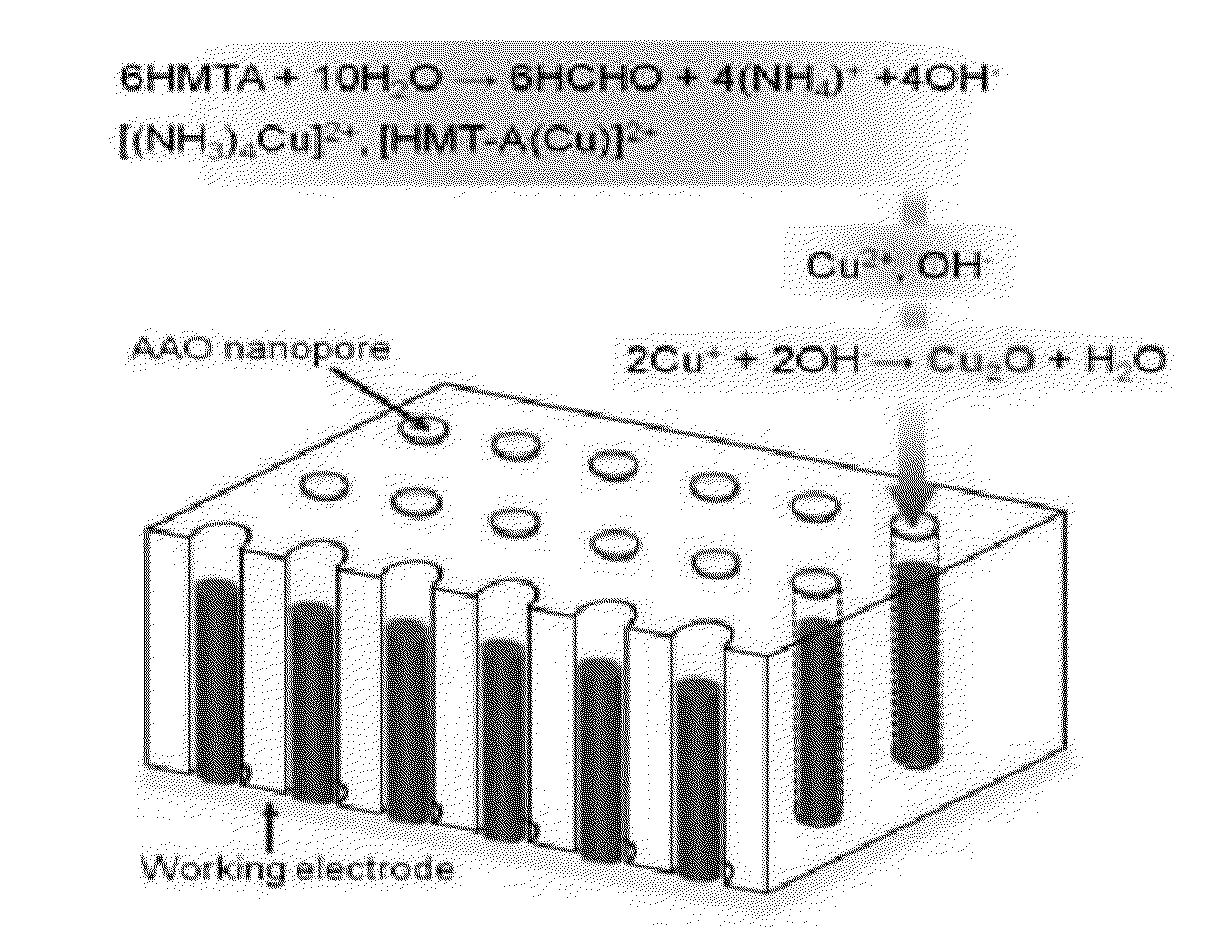

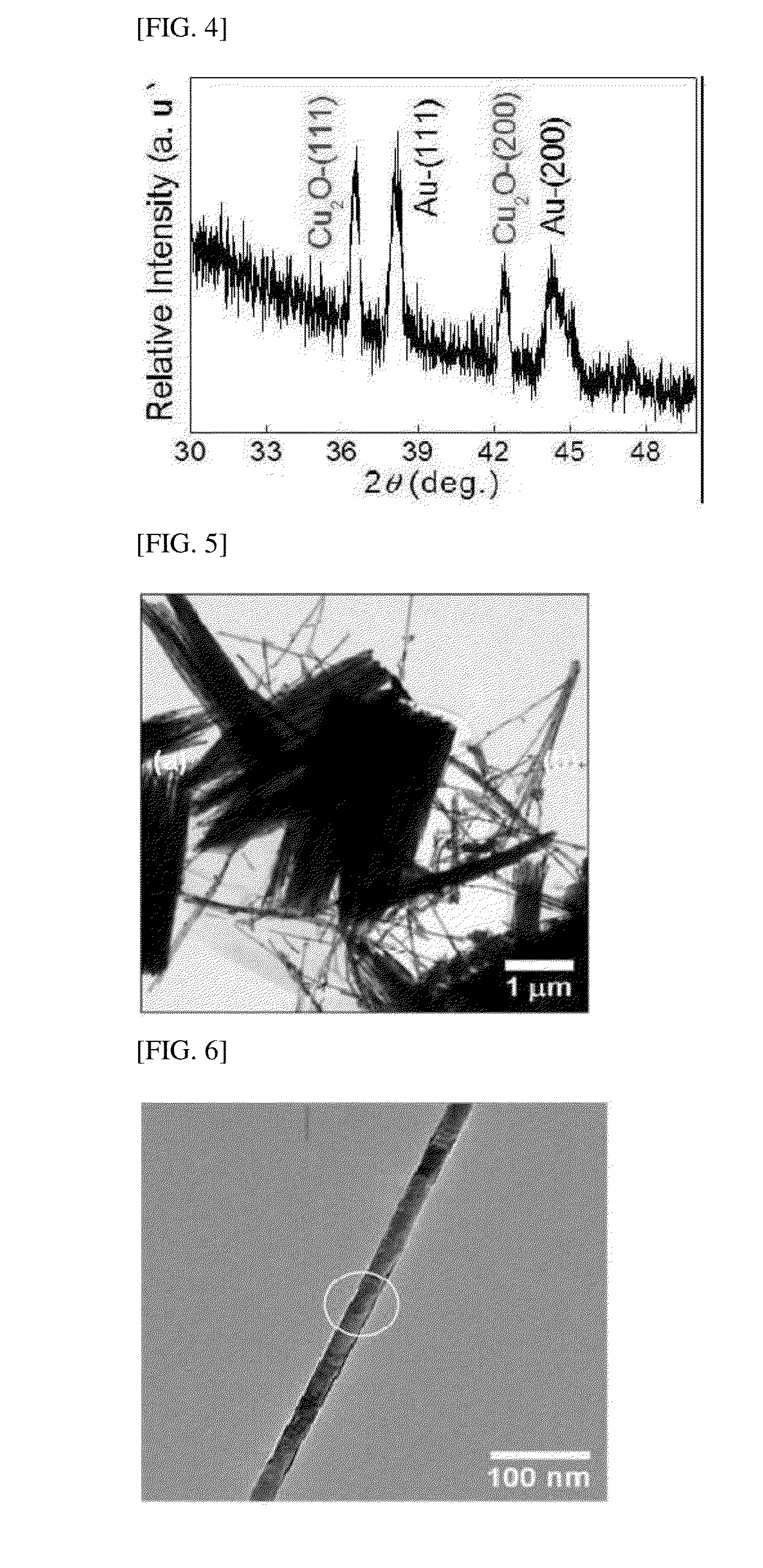

[0035]Example 2 was a step of manufacturing a monocrystalline copper oxide (I) nanowire array by using the nanopore alumina layer obtained from Example 1 as a nanopore molding flask. A 20 mM aqueous solution was prepared by mixing copper nitrate hydrate (Cu(NO3)2.2.5H2O) and hexamethylenetetramine.

[0036]Then, the prepared electrochemical deposition solution was heated in a boiling water bath until a temperature thereof reached 80° C. with stirring at a speed of 100 rpm.

[0037]Further, when the temperature of the electrochemical deposition solution reached 80° C., the electrochemical deposition solution was stirred at a speed of 100 rpm for 10 minutes.

[0038]Thereafter, a predetermined current density of 1 mA / cm2 was applied to the prepared nanopore molding flask in an electrochemical reaction solution for a desired time period.

[0039]Subsequently, an electrochemically grown nanowire was washed with ethanol and deionized water and then dried.

[0040]Then, a heat treatment was performed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com