Micro-nano electrochemical deposition machining method based on liquid drop Taylor cone

A micro-nano electrochemistry and droplet technology, applied in electroforming, electrolysis process, 3D structure electroforming, etc., can solve the problems of harsh equipment operating conditions and achieve the effect of deposition processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

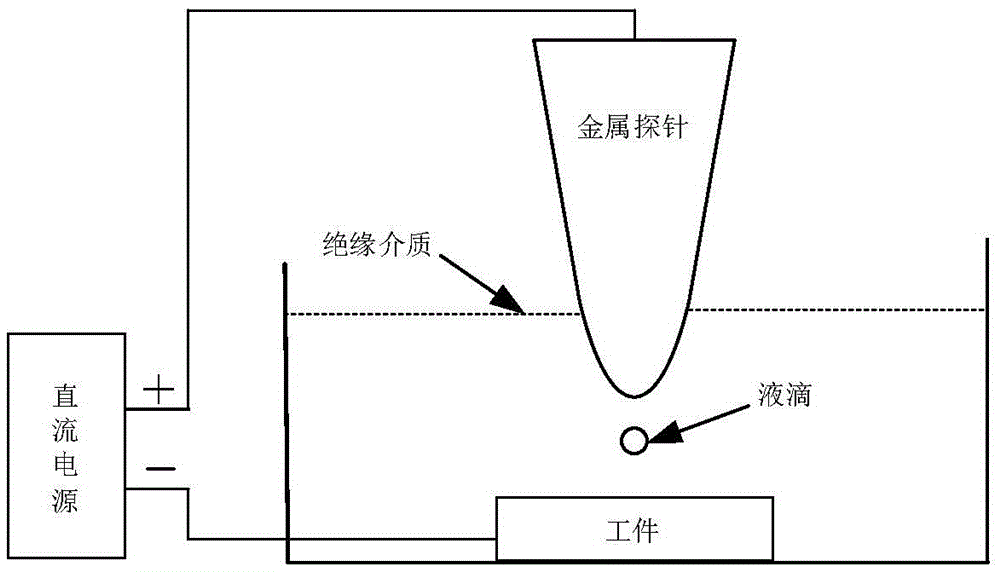

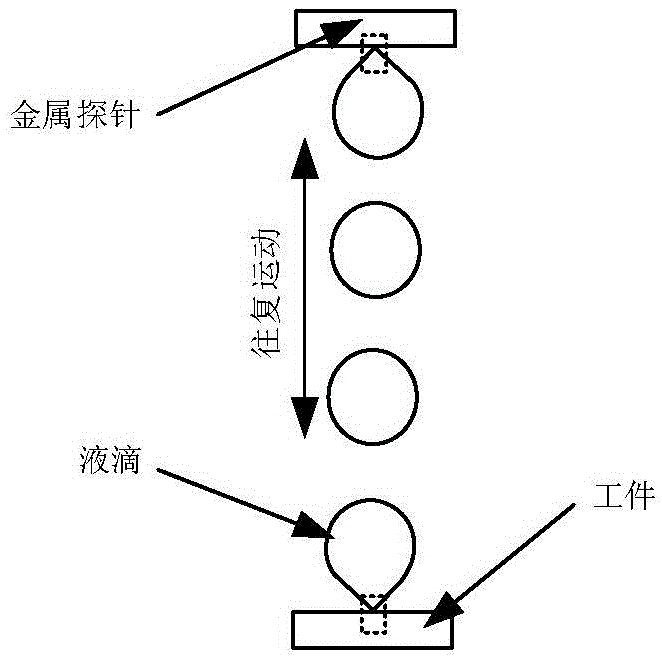

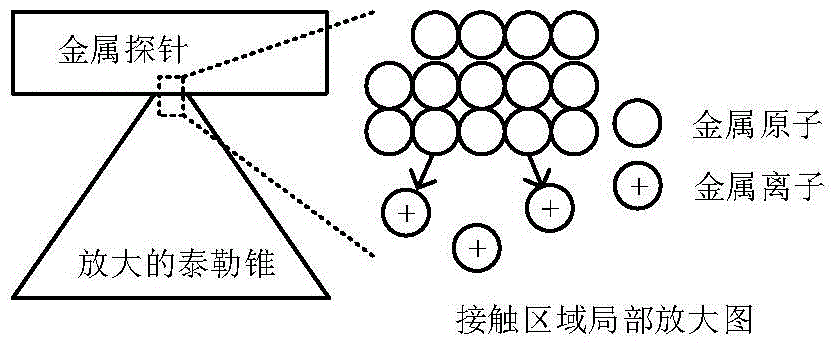

[0013] see figure 1 . The invented micro-nano electrochemical deposition processing method based on the droplet Taylor cone is to first place the droplet containing metal ions between the metal probe and the workpiece; both the metal probe and the workpiece are immersed in the insulating medium, and the insulating medium Incompatible with water; the probe and the workpiece are respectively connected to the positive and negative poles of the DC power supply, and an electric field is formed between the metal probe and the workpiece; the droplet reciprocates between the probe and the workpiece under the action of the electric field; When it is close to the probe and the workpiece, the surface of the droplet forms a Taylor cone under the action of the electric field, and the metal atoms of the metal probe are changed into metal cations into the liquid by using the electrochemical action of the Taylor cone of the droplet in contact with the metal probe and the workpiece. Then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com