Method and device for processing nano structures by utilizing controllable pulse lasers

A pulsed laser and nanostructure technology, applied in microstructure devices, manufacturing microstructure devices, nanotechnology, etc., can solve the problems of difficult promotion, high cost, and difficult control, and achieve good application effects, simple methods, and easy industrialization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

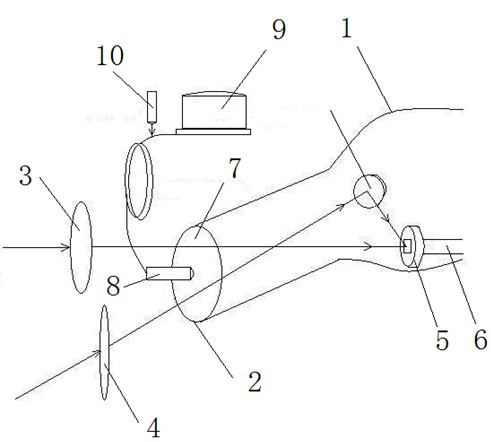

[0021] Embodiment 1 of the present invention: the structure of a device for processing nanostructures using a controllable pulsed laser is as follows figure 1 As shown, a vacuum chamber 1 is included, a laser window 2 is provided on the side of the vacuum chamber 1, a cavity incident mirror 7 is provided on the laser window 2, a PLE laser lens 3 is provided outside the laser window 2, and a laser window 2 is provided on the side of the vacuum chamber 2. 1 is provided with a sample stage 5, the sample stage 5 corresponds to the optical path of the PLE laser lens, and a sampling handle 6 is connected to the rear end of the sample stage 5; A spectrometer 9 is provided, and an optical fiber probe 8 is connected to the spectrometer 9; a PLD laser lens 4 is provided outside the laser window 2, and a target platform 7 is provided in the vacuum cavity 1, and the target platform 7 corresponds to the optical path of the PLD laser lens 4; The probe 8 is a bidirectional optical fiber prob...

Embodiment 2

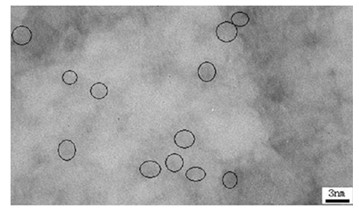

[0023] Embodiment 2 of the present invention: a method for processing nanostructures using a controllable pulse laser, placing a P-type single crystal silicon wafer on the sample stage 5, and installing a silicon target on the target stage 7, in the vacuum chamber 1 Vacuum up to 10 -5 Pa, and then control the multi-gas path of the vacuum chamber 1 to make the sample in a nitrogen atmosphere environment, select a nanosecond pulse laser head with a wavelength of 532nm, and install the PLE laser lens 3 and PLD laser lens 4 corresponding to the wavelength , so that the nanosecond pulsed laser head emits pulsed laser light, enters the vacuum cavity 1 from the laser window 2 through the PLE laser lens 3, and then converges on the surface of the P-type single crystal silicon wafer to etch the P-type single crystal silicon wafer. During the processing, the optical fiber probe 8 is used to detect the change of the electronic spectrum in the plasma glow generated by the pulse laser acti...

Embodiment 3

[0024] Embodiment 3 of the present invention: using a method for processing nanostructures with a controllable pulse laser, the semiconductor substrate sample is placed on the sample stage 5, and the silicon target is installed on the target stage 7, and vacuum is drawn in the vacuum chamber 1 , draw up to 10 -5Pa, and then control the multiple gas channels of the vacuum chamber 1 to make the sample in an oxygen atmosphere environment, select a nanosecond pulse laser head with a wavelength of 1064nm, and install the PLE laser lens 3 and PLD laser lens 4 corresponding to the wavelength , so that the nanosecond pulse laser head emits pulsed laser light, the pulsed laser light enters the vacuum cavity 1 from the laser window 2 through the PLE laser lens 3, and then converges on the sample surface for etching processing; during the processing, the optical fiber probe 8 Detect changes in the electronic spectrum in the plasma glow generated by the pulsed laser on the sample to contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com