A Vertical Machining Center with Composite Link Mechanism

A vertical machining center and link mechanism technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as strong motion coupling, difficult control modeling, and small working space, and simplify the machine tool. The effect of transmission chain, convenient movement and large processing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

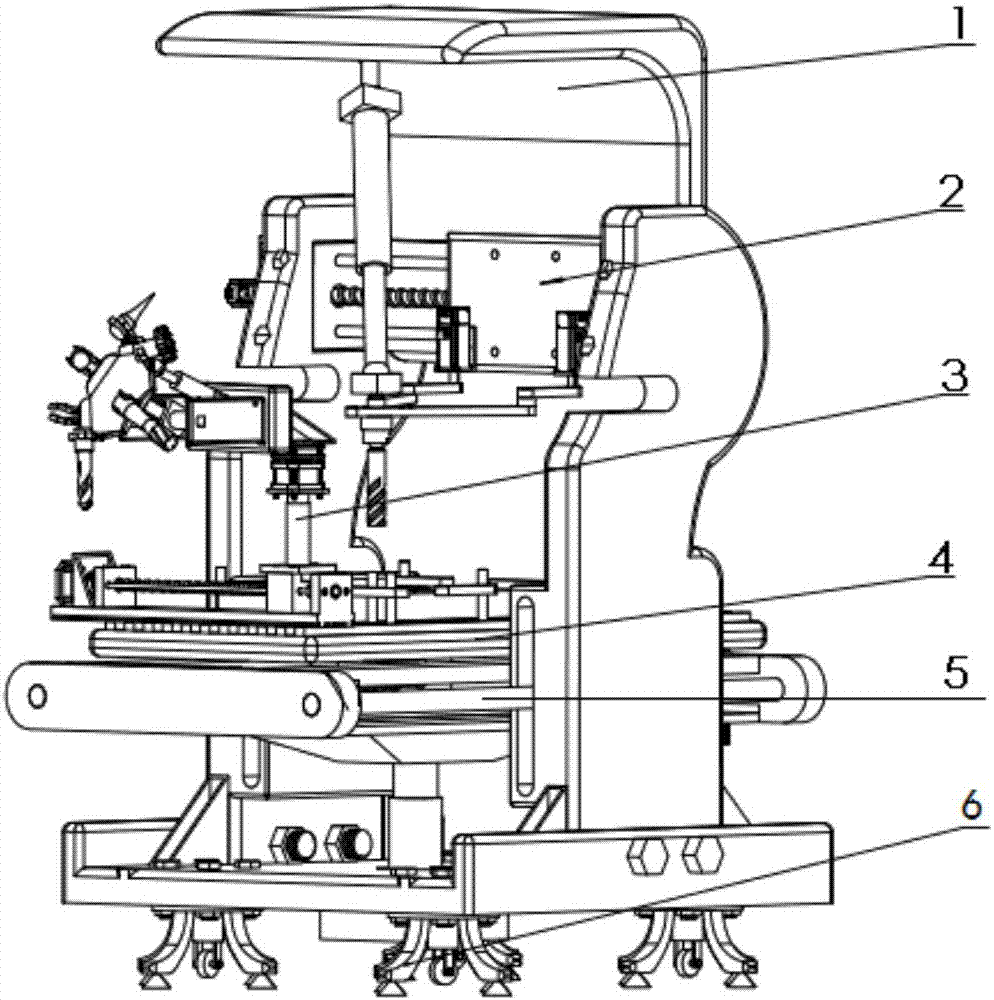

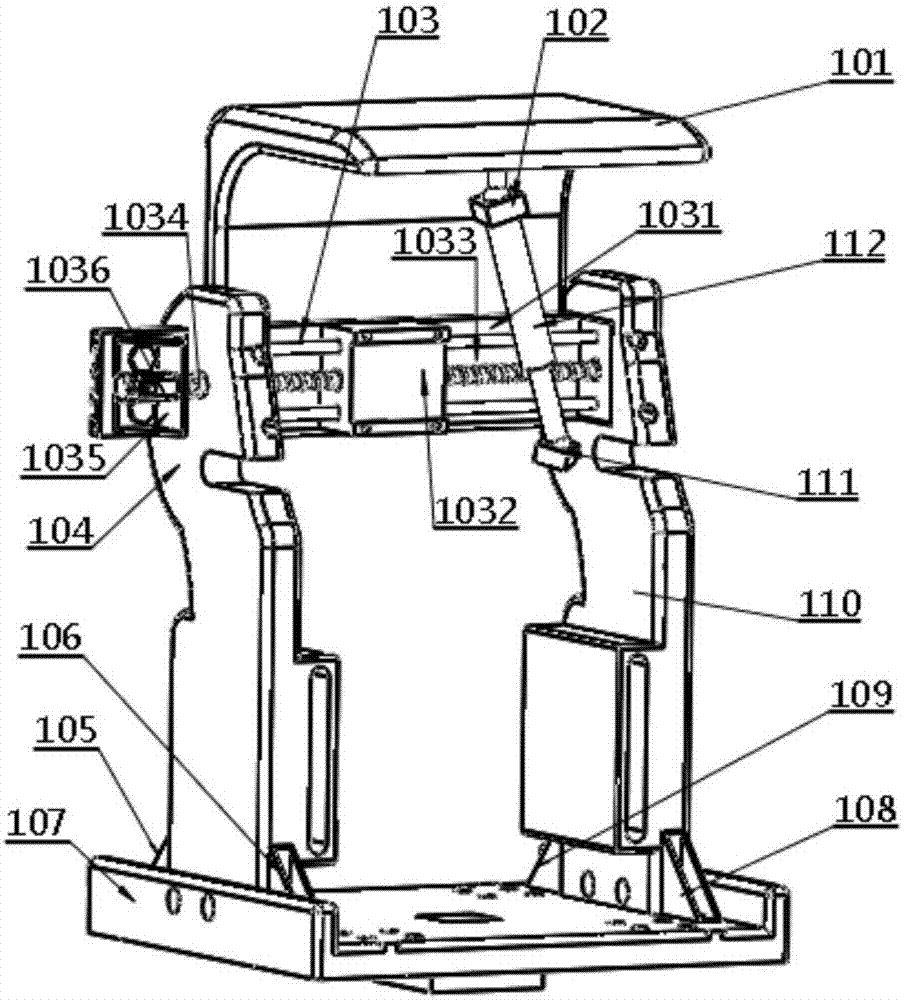

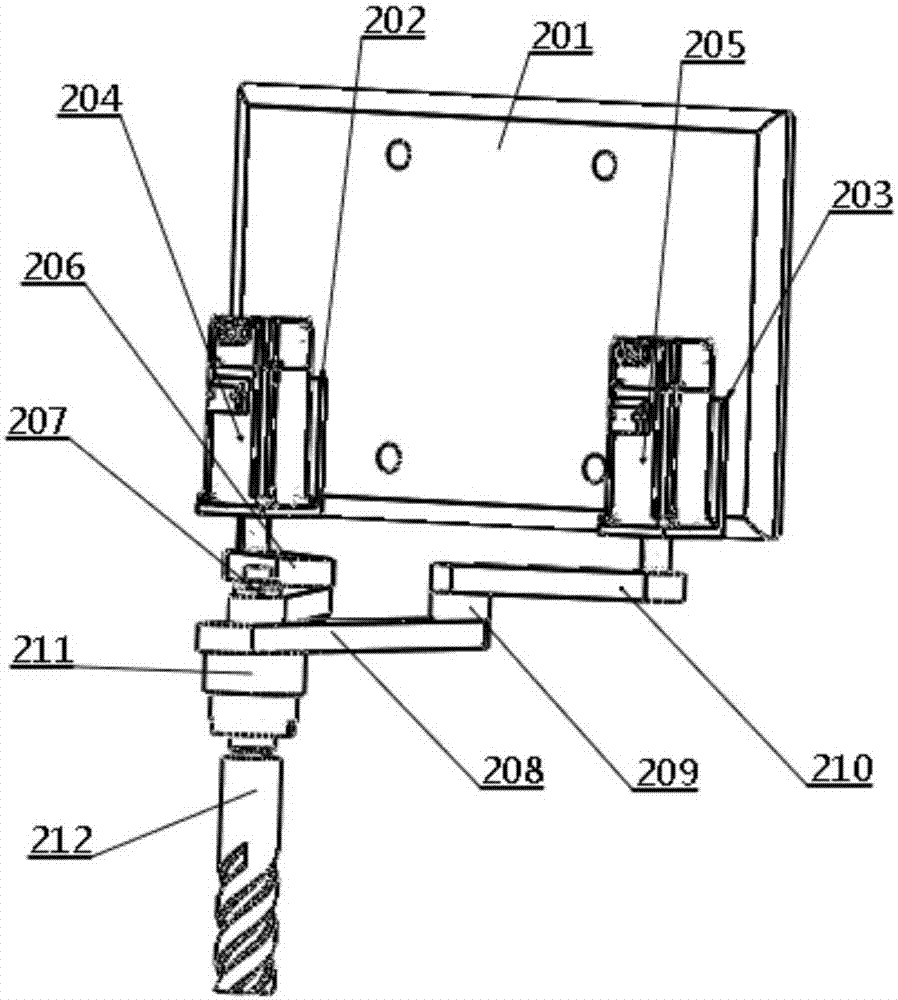

[0032] like figure 1 As shown, the present embodiment is a vertical machining center of a compound link mechanism, wherein: an outer frame device 1, a compound link processing device 2, a multi-degree-of-freedom tool change device 3, a liftable processing platform device 4, and a guide balance The shaft 5 and the base supporting device 6 are composed of six parts; the composite connecting rod processing device 2 and the outer frame device 1 pass through the first slide block 1032 in the outer frame device 1 and the composite connecting rod processing device The slider connecting plate 201 in 2 and the electric spindle 211 in the compound connecting rod processing device 2 are connected with the lower universal hinge 111 in the outer frame device 1; The processing platform device 4 is connected to the left end of the processing platform 405 in the lifting processing platform device 4 through the bottom surface of the second transverse sliding table 309 in the multi-degree-of-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com