Parallel type three-axis main-shaft head structure

A spindle head and parallel technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of high cost, achieve high dynamic performance, meet high speed, and realize the effect of compound processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

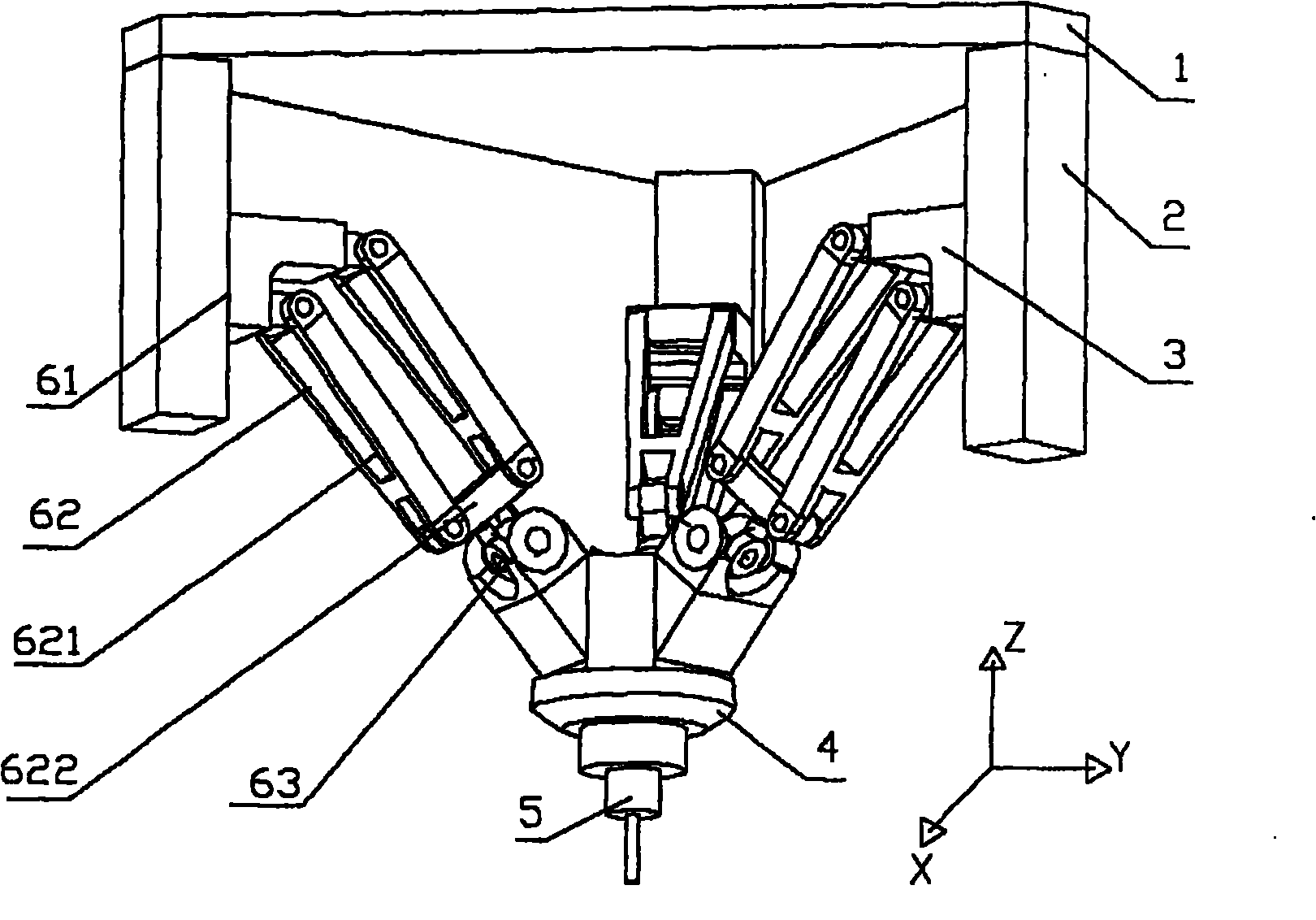

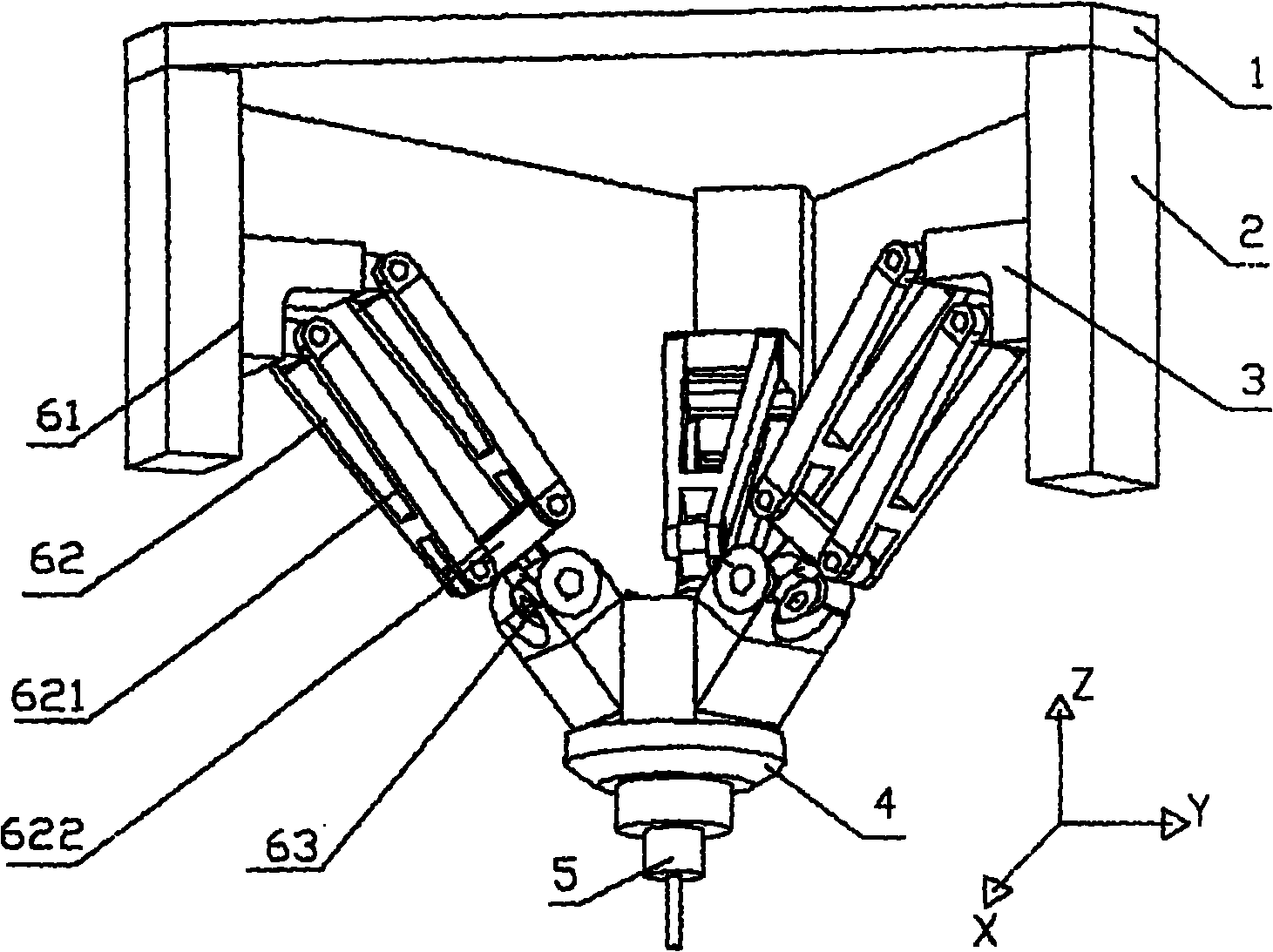

[0016] The structure of the parallel three-axis spindle head of the present embodiment, such as figure 1 As shown, the structure includes a main shaft 5 , a moving platform 4 , a fixed platform 1 and three triangularly arranged branches connecting the moving platform 4 and the fixed platform 1 , and the main shaft 5 is fixed on the moving platform 4 .

[0017] This each branch mechanism comprises mobile pair 61, planar parallelogram mechanism 62 and ball hinge 63; This mobile pair 61 comprises column 2 and input slide block 3, and this column 2 is equilateral triangle and is fixedly connected with fixed platform 1, and this column 2 When the input slider 3 moves in the guide surface of the column 2, one end of the ball hinge 63 is connected with the plane parallelogram mechanism 62, and the other end is connected with the moving platform 4; the plane parallelogram mechanism 62 includes two equal and parallel lengths The long rod 621, and the short rod 622 connected to one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com