A device for processing wood-plastic composite materials by using waste hard plastics and modified coconut bran

A technology of wood-plastic composite materials and hard plastics, which is applied in the field of plastic recycling, can solve the problems of poor mechanical properties of wood-plastic composite materials, low polarity of blends, and low impact resistance, so as to improve blending compatibility , Improve economic value and reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

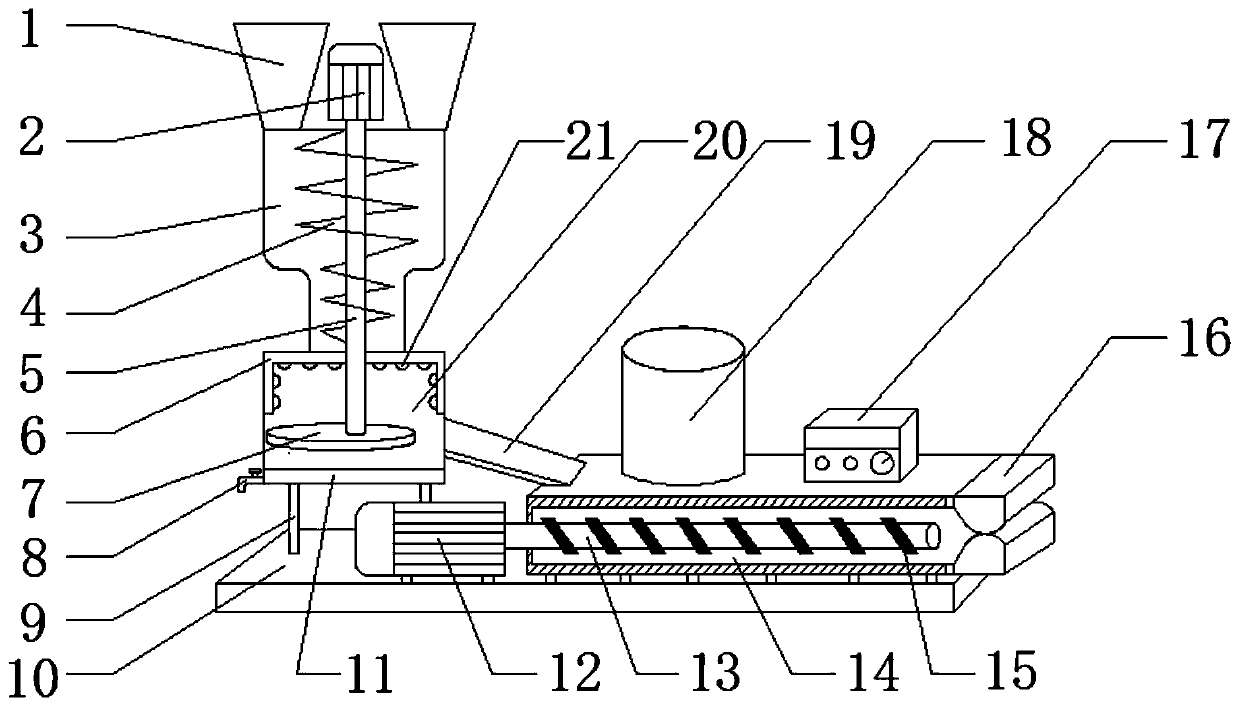

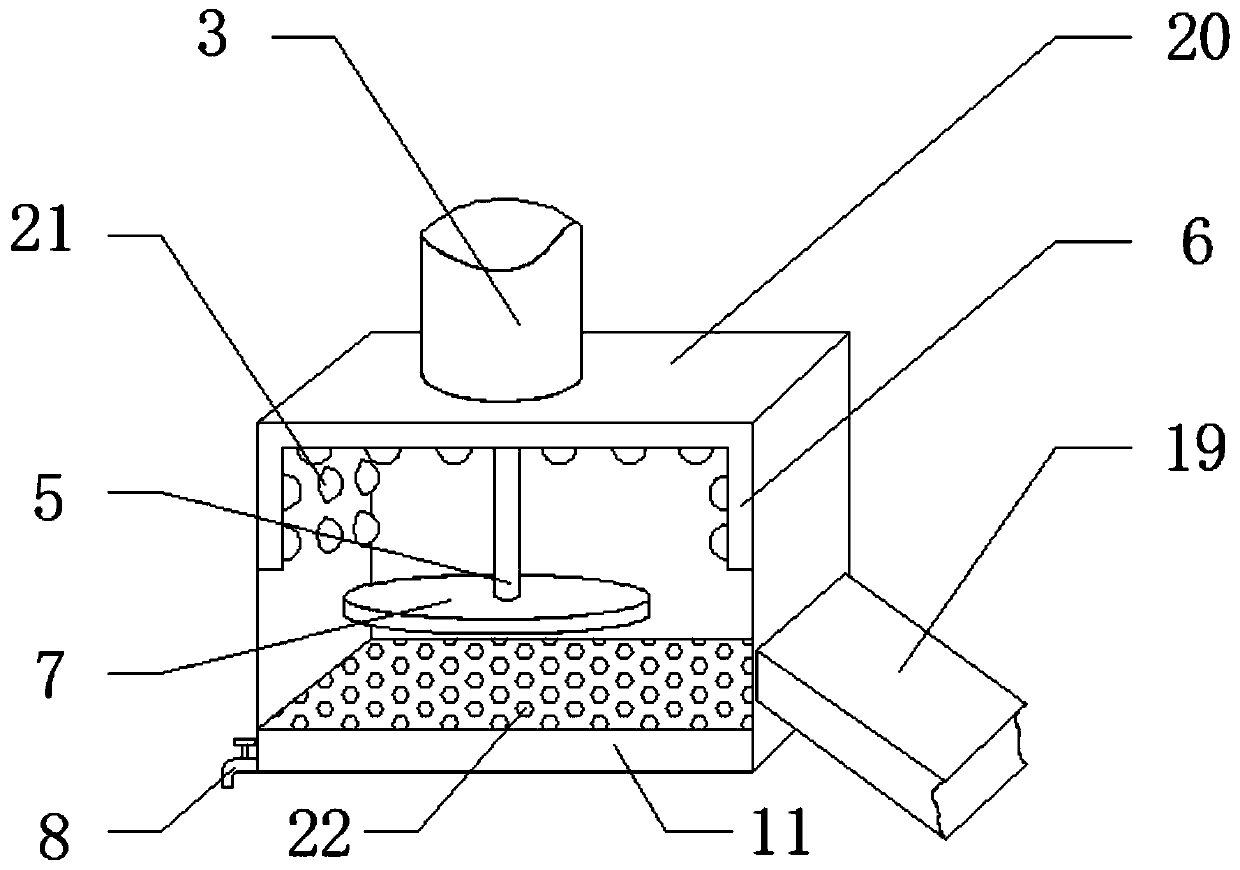

[0024] Such as figure 1 and figure 2 As shown, the device for processing wood-plastic composite materials by using waste and old hard plastics and modified coconut peat consists of a base (10), a crushing chamber (3), a cleaning chamber (20) and a composite chamber (14), and the crushing chamber is located at Above the cleaning chamber, a waste hard plastic feed bin (1) and a first motor (2) are arranged on the top of the crushing chamber, and a crushing shaft (5) driven by the first motor is arranged longitudinally inside the crushing chamber. There is a spiral cutter (4) and a washing table (7) is provided at the bottom end of the crushing shaft extending into the cleaning chamber, and a clean water tank (6) is provided at the top of the cleaning room, and the clean water tank sprays to the washing table through the spray head (21) Water, the bottom of the cleaning room is provided with a sewage tank (11), and the cleaning room is drained to the sewage tank through the see...

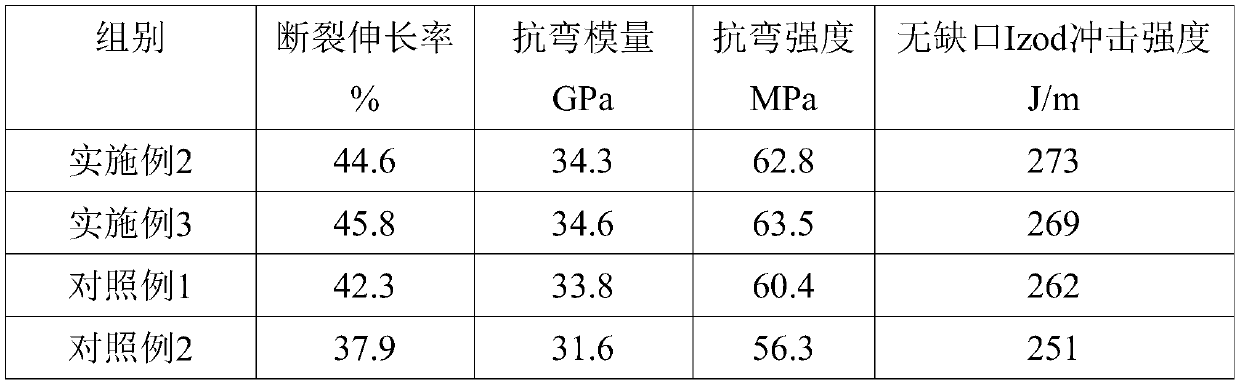

Embodiment 2

[0027] Such as figure 1 and figure 2 As shown, the device for processing wood-plastic composite materials by using waste and old hard plastics and modified coconut peat consists of a base (10), a crushing chamber (3), a cleaning chamber (20) and a composite chamber (14), and the crushing chamber is located at Above the cleaning chamber, a waste hard plastic feed bin (1) and a first motor (2) are arranged on the top of the crushing chamber, and a crushing shaft (5) driven by the first motor is arranged longitudinally inside the crushing chamber. There is a spiral cutter (4) and a washing table (7) is provided at the bottom end of the crushing shaft extending into the cleaning chamber, and a clean water tank (6) is provided at the top of the cleaning room, and the clean water tank sprays to the washing table through the spray head (21) Water, the bottom of the cleaning room is provided with a sewage tank (11), and the cleaning room is drained to the sewage tank through the see...

Embodiment 3

[0032] Such as figure 1 and figure 2As shown, the device for processing wood-plastic composite materials by using waste and old hard plastics and modified coconut peat consists of a base (10), a crushing chamber (3), a cleaning chamber (20) and a composite chamber (14), and the crushing chamber is located at Above the cleaning chamber, a waste hard plastic feed bin (1) and a first motor (2) are arranged on the top of the crushing chamber, and a crushing shaft (5) driven by the first motor is arranged longitudinally inside the crushing chamber. There is a spiral cutter (4) and a washing table (7) is provided at the bottom end of the crushing shaft extending into the cleaning chamber, and a clean water tank (6) is provided at the top of the cleaning room, and the clean water tank sprays to the washing table through the spray head (21) Water, the bottom of the cleaning room is provided with a sewage tank (11), and the cleaning room is drained to the sewage tank through the seep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com