Patents

Literature

150 results about "Duroplast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Duroplast is a composite thermosetting plastic, a close relative of Formica and Bakelite. It is a resin plastic reinforced with fibers (either cotton or wool) making it a fiber-reinforced plastic similar to fiberglass.

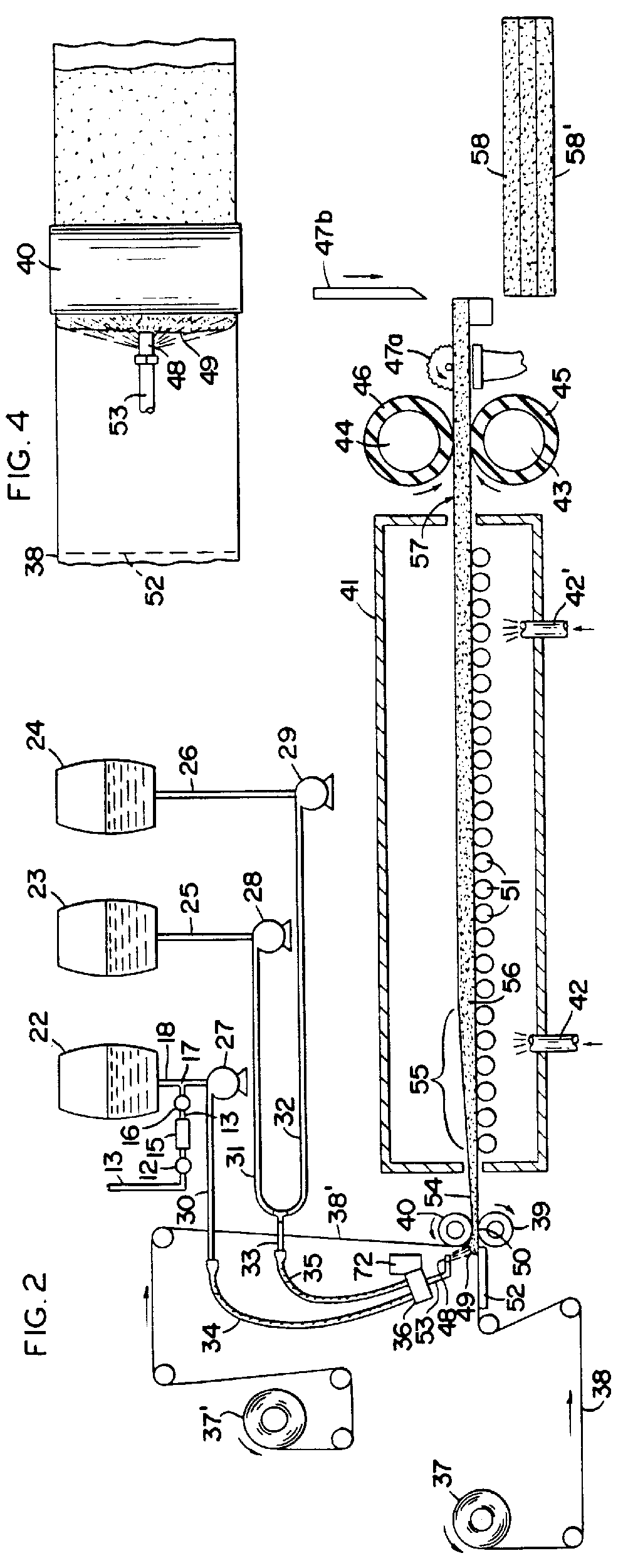

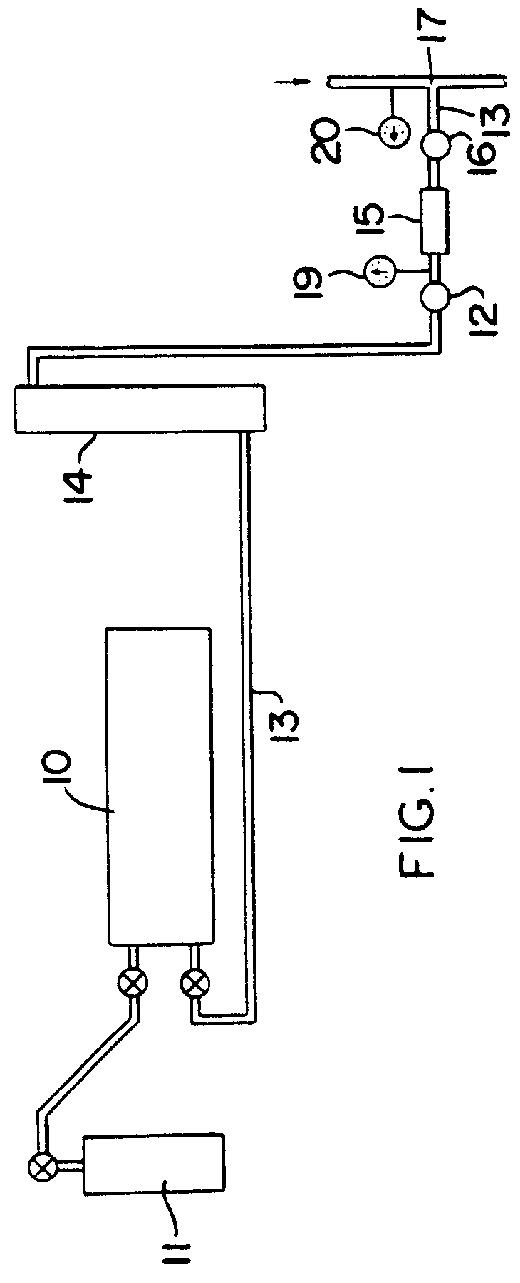

Faced foam insulation board and froth-foaming method for making same

InactiveUSRE36674E1Big lossSimple and economical mannerConfectionerySweetmeatsProduction lineEngineering

A method for continuously producing an insulation board comprising a rigid plastic foam core having two major surfaces and a facing material on one or both of the major surfaces, the method including conveying a facing material along a production line, depositing a partially expanded froth foam of a plastic mixture, which contains at least one frothing agent, on the facing material, and further expanding and curing the froth foam in contact wiht the facing material to form the insulation board. The board is particularly useful as roof insulation.

Owner:THE DOW CHEM CO

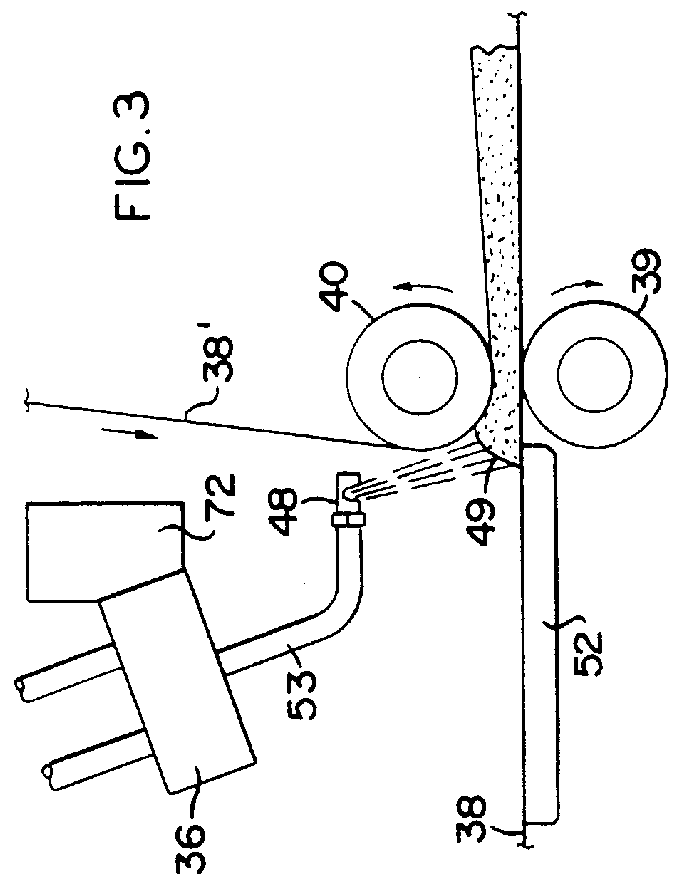

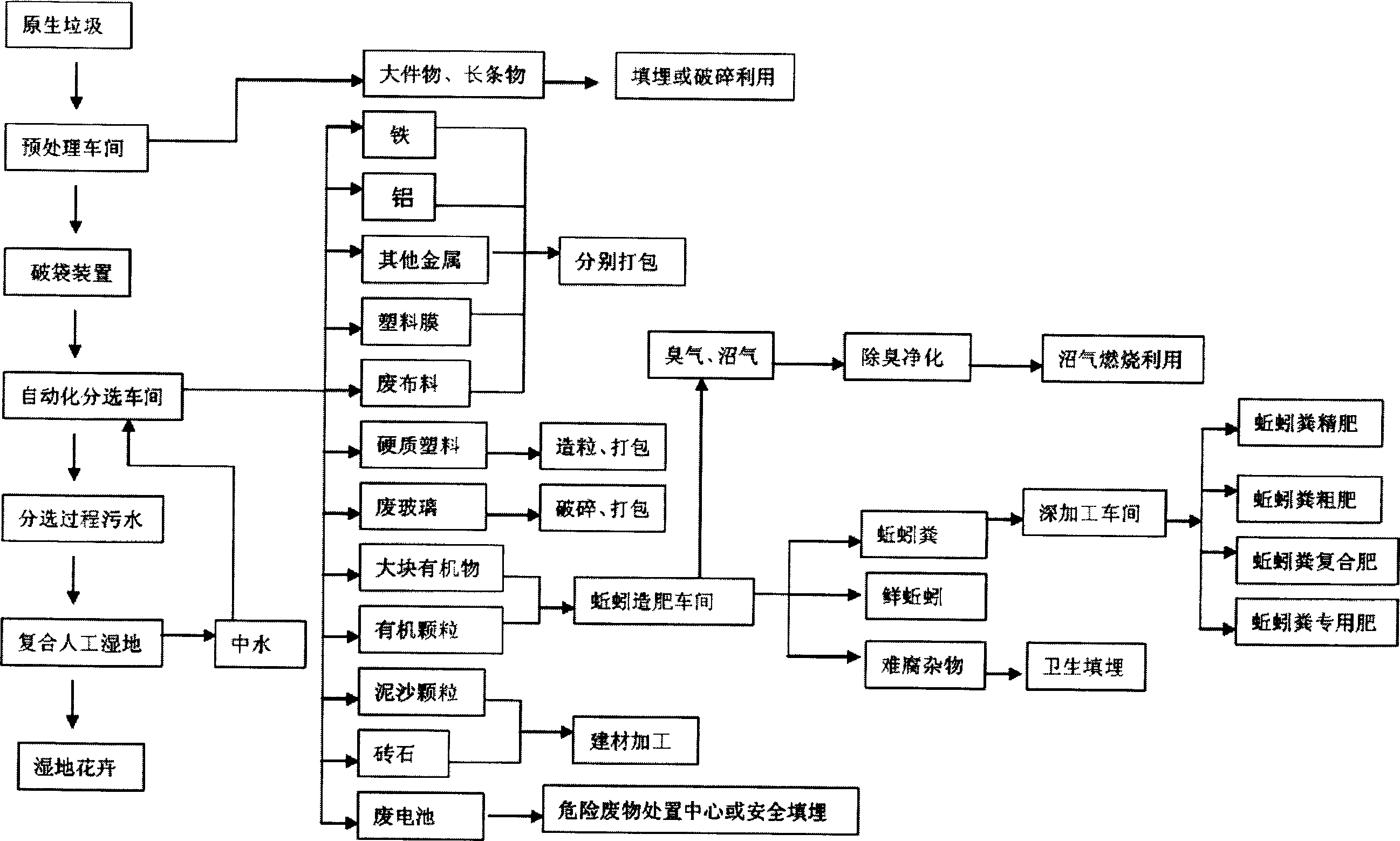

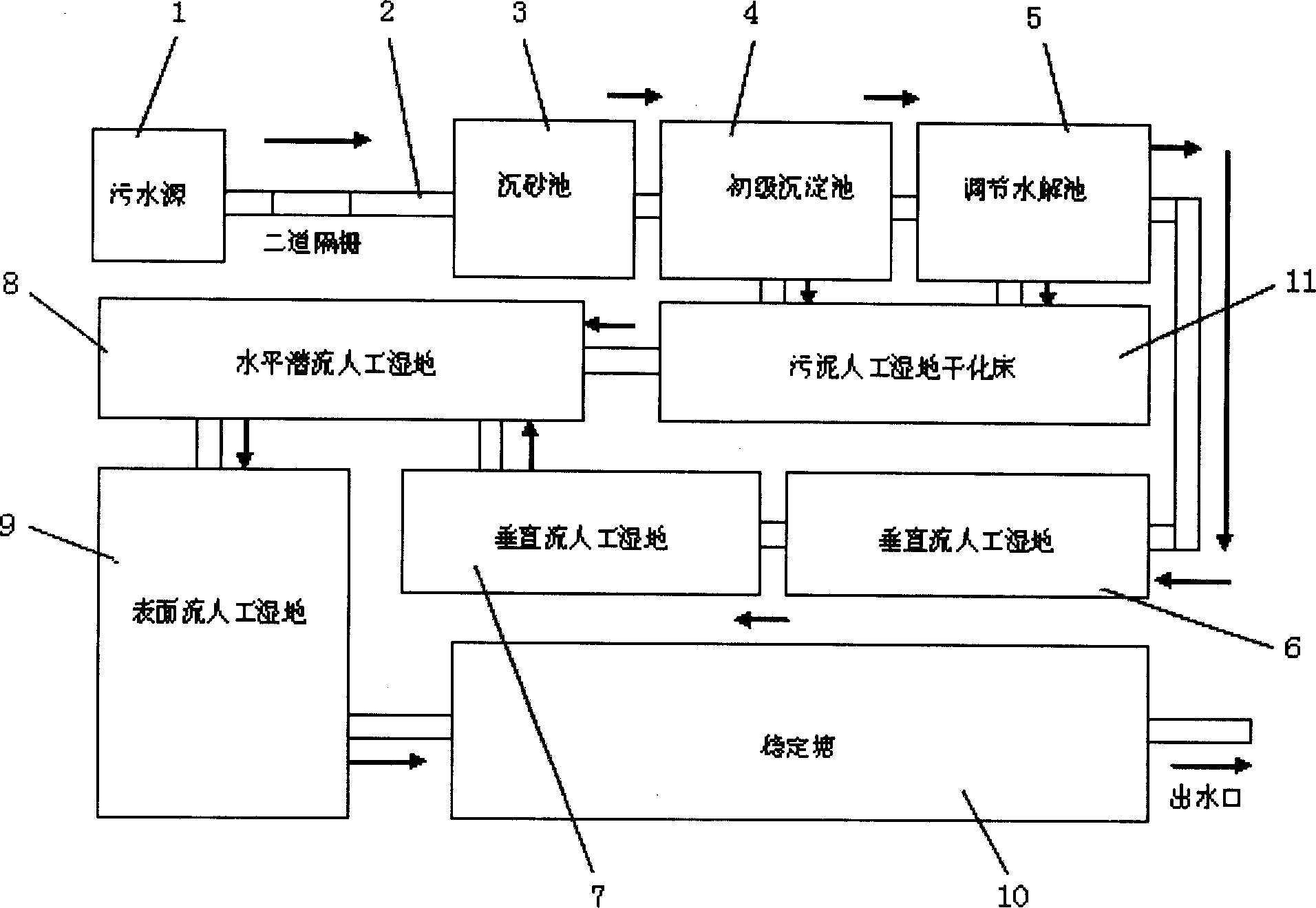

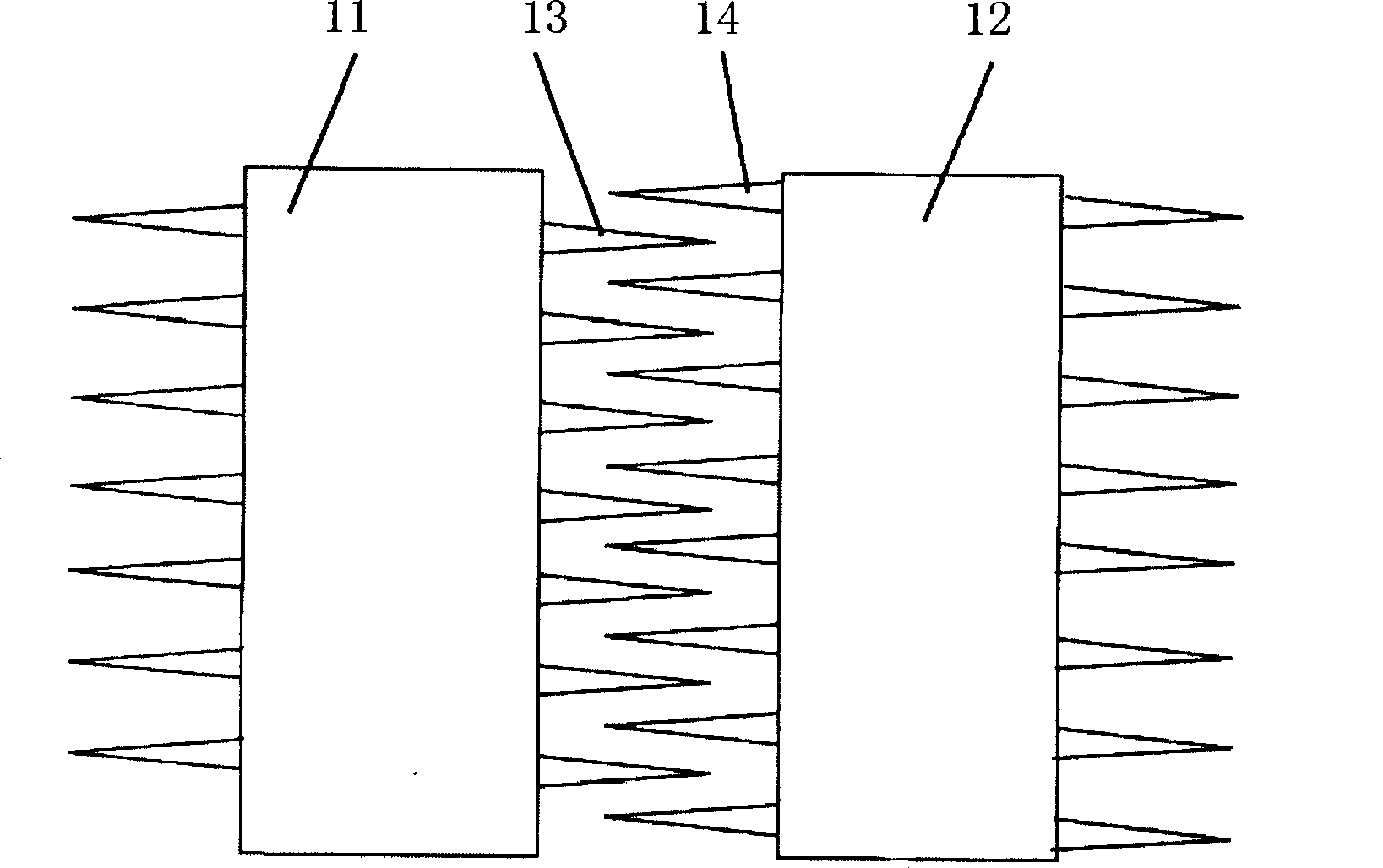

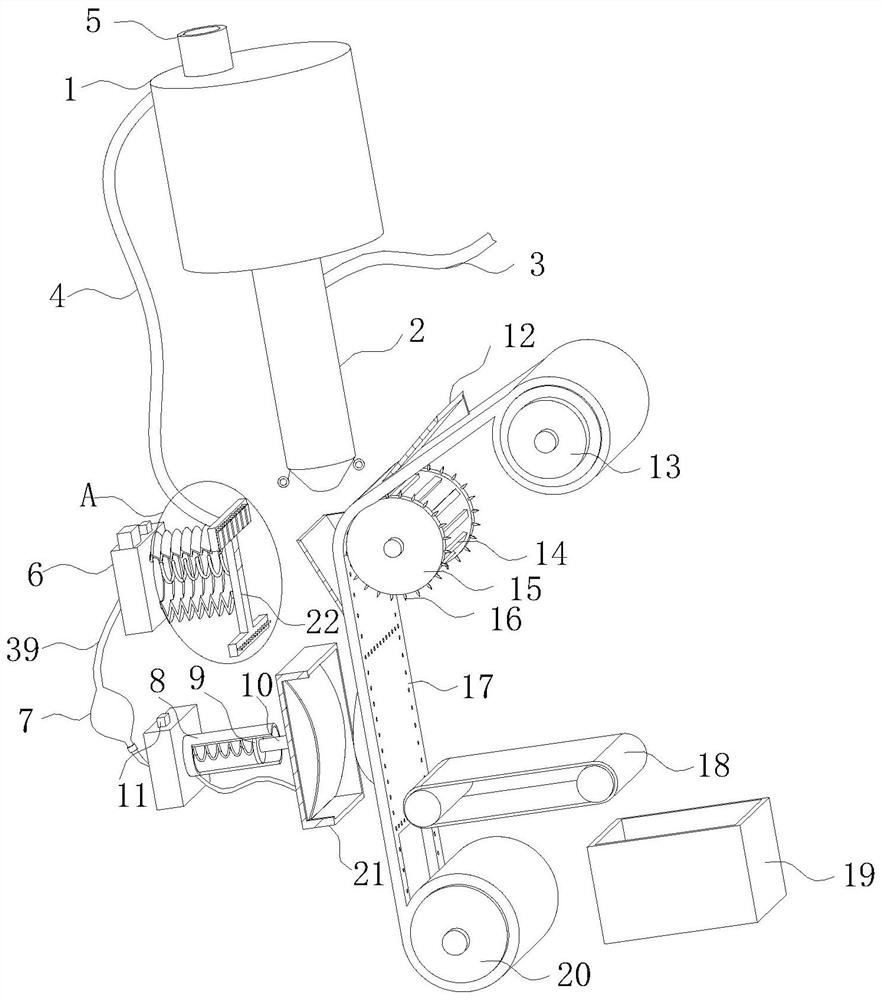

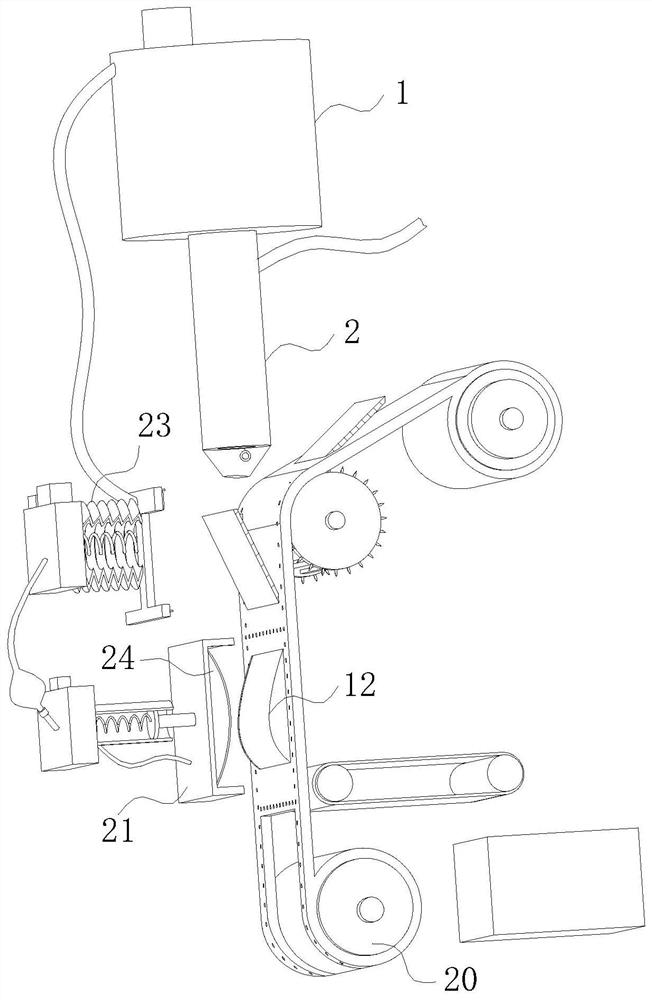

Garbage comprehensive treatment method and apparatus

InactiveCN1850365ABio-organic fraction processingSolid waste disposalConstructed wetlandChemical solution

The present invention relates to a comprehensive treatment method of refuse. Said method includes the following several steps: spraying biological chemical solution, deodorizing by using ozone, UV ray sterilization, separation, including biological solution separation, magnetic separation, pneumatic separation, vortex flow separation, drum sieve separation and vibration sieve separation, so that the refuse can be separated into 10-odd substances of iron, aluminium, other metal, plastic film, hard plastics, waste fabric, waste glass, organics, broken brick and waste battery, etc. The above-mentioned wastes can be used for making fertilizer, can be recovered and can be made into other useful resources.

Owner:广州德润环保科技发展有限公司

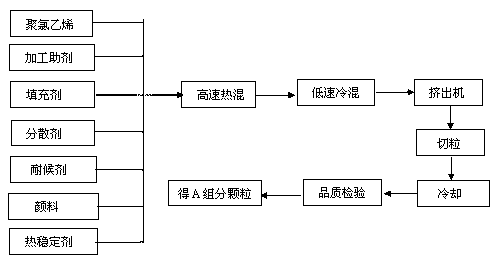

PVC (polyvinyl chloride) wood-like grain master batch and application thereof

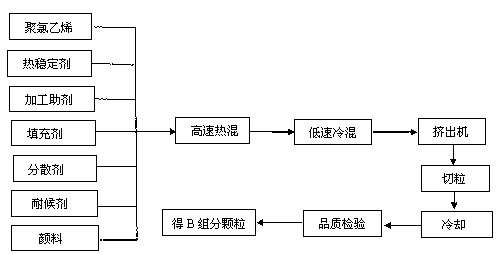

The invention discloses a PVC (polyvinyl chloride) wood-like grain master batch, comprising a component A and a component B, wherein the component A includes 0-80 parts by weight of PVC resin, 2.5-7.0 pars by weight of heat stabilizer, 5.0-15 parts by weight of processing agent, 0-25 parts by weight of filler, 0.5-15 parts by weight of dispersing agent, 0.2-5.0 parts by weight of weather-resistant agent, and 5.0-70 parts by weight of pigment; and the component B comprises 20-80 parts by weight of PVC resin, 2.5-7.0 by weight parts of heat stabilizer, 5.0-15 parts by weight of processing agent, 0-30 parts by weight of filler, 0.5-15 parts by weight of dispersing agent, 0.2-5.0 parts by weight of weather-resistant agent, and 5.0-40 parts by weight of pigment. By adopting the PVC wood-like grain master batch disclosed by the invention, the effects of bright colors, good weather resistance, excellent mechanical property, clear wood grain lines and vivid wood grains can be formed in the products such as different formula systems of hard PVC plastic materials, PVC doors and windows, PVC boards and the like.

Owner:GUANGDONG HUASHENG ELECTRICAL APPLIANCES CO LTD

PVC (polyvinyl chloride) colorful coextruded material and application thereof

InactiveCN103289235AColorfulGood weather resistanceSynthetic resin layered productsCoatingsPolymer scienceWeather resistance

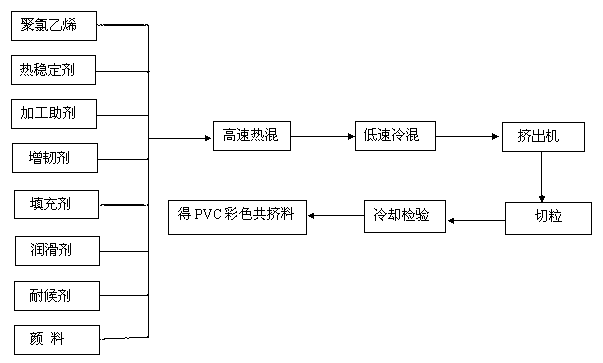

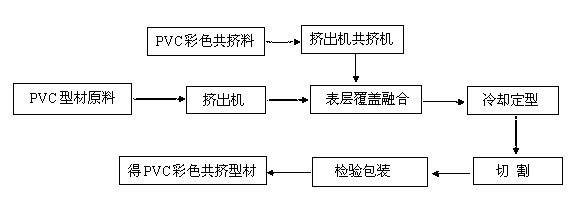

The invention discloses a PVC (polyvinyl chloride) colorful coextruded material and an application thereof, and the colorful coextruded material comprises the following materials in parts by weight: 70-100 parts of PVC resin, 4.0-7.5 parts of heat stabilizer, 0-8.0 parts of processing agent, 0-8.0 parts of flexibilizer, 0-15 parts of filler, 0.3-2.0 parts of lubricating agent, 0.1-1.5 parts of weather-resistant agent, and 0.1-5.0 parts of pigment. By adopting the PVC colorful coextruded material disclosed by the invention, surface co-extrusion layers with bright colors, good weather resistance and excellent mechanical property can be formed in the products such as different formula systems of hard PVC plastic materials, PVC doors and windows and the like.

Owner:GUANGDONG HUASHENG ELECTRICAL APPLIANCES CO LTD

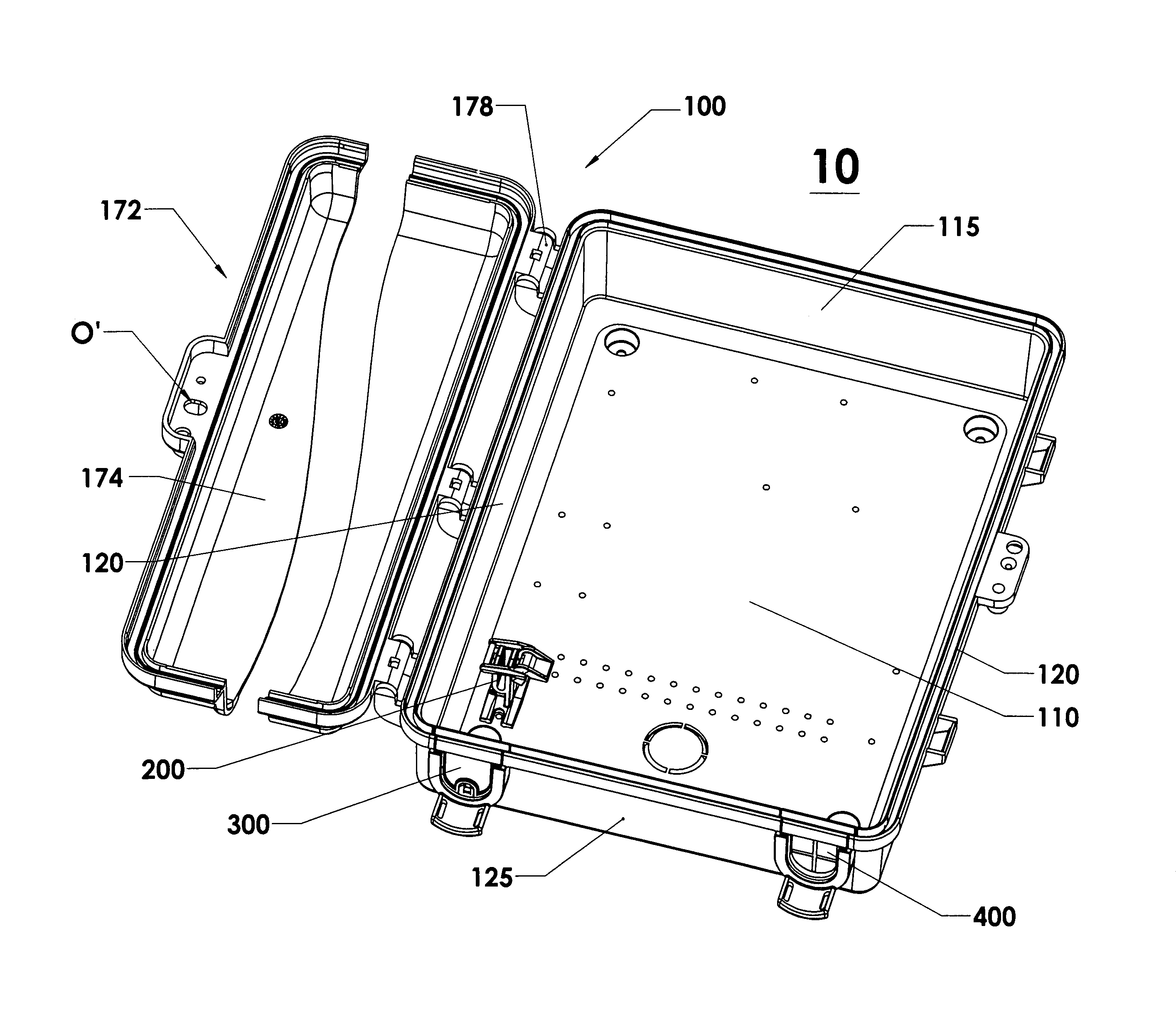

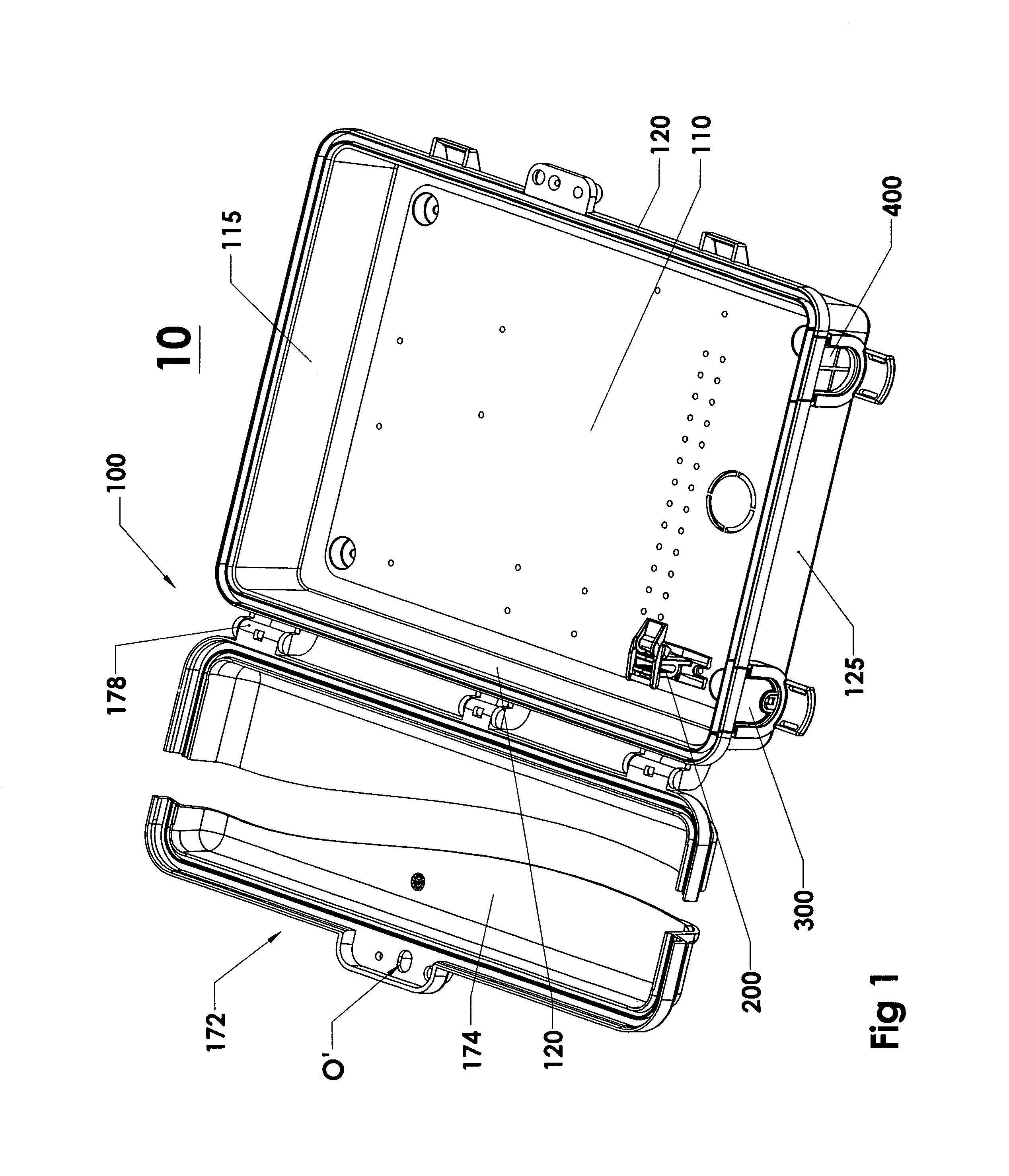

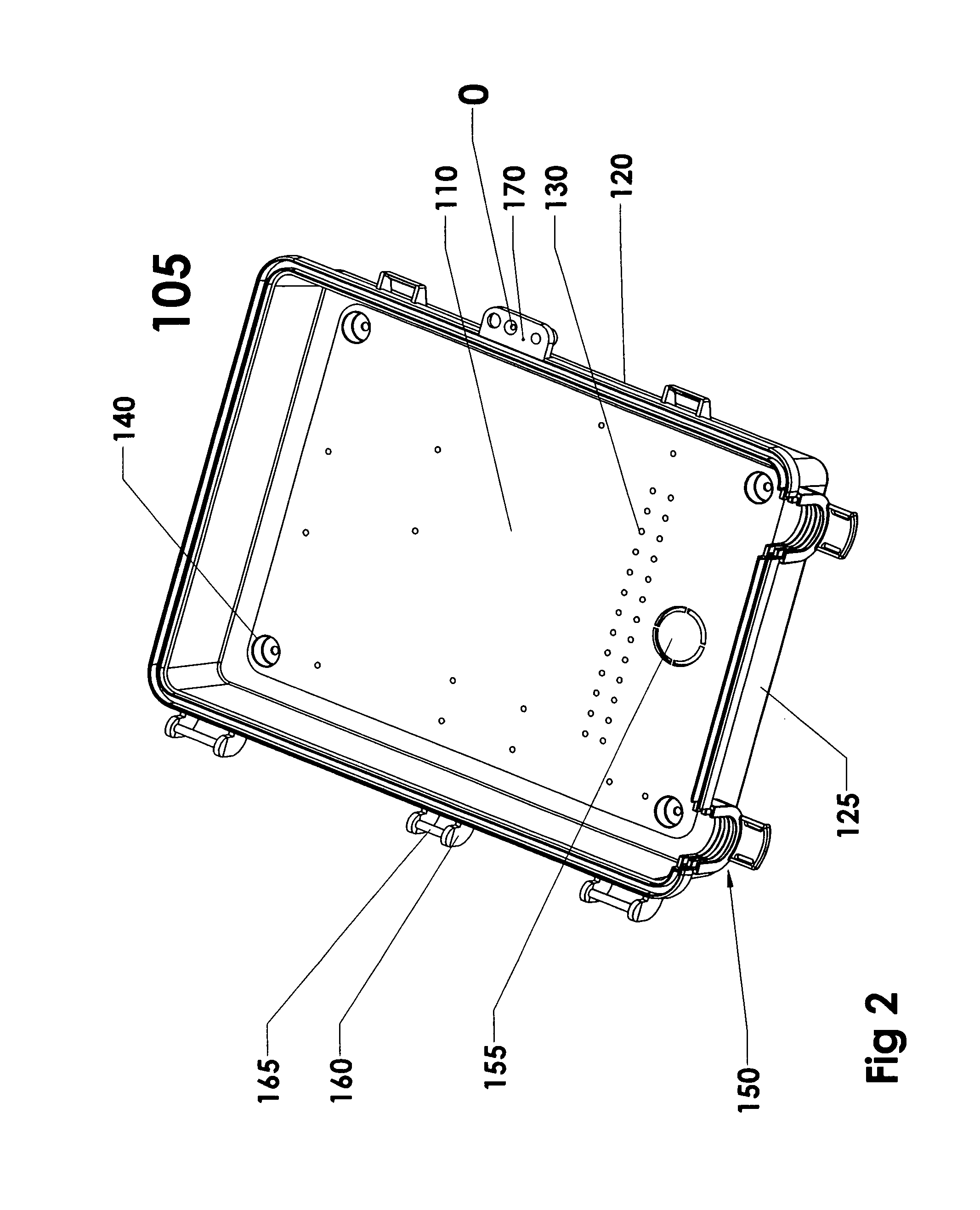

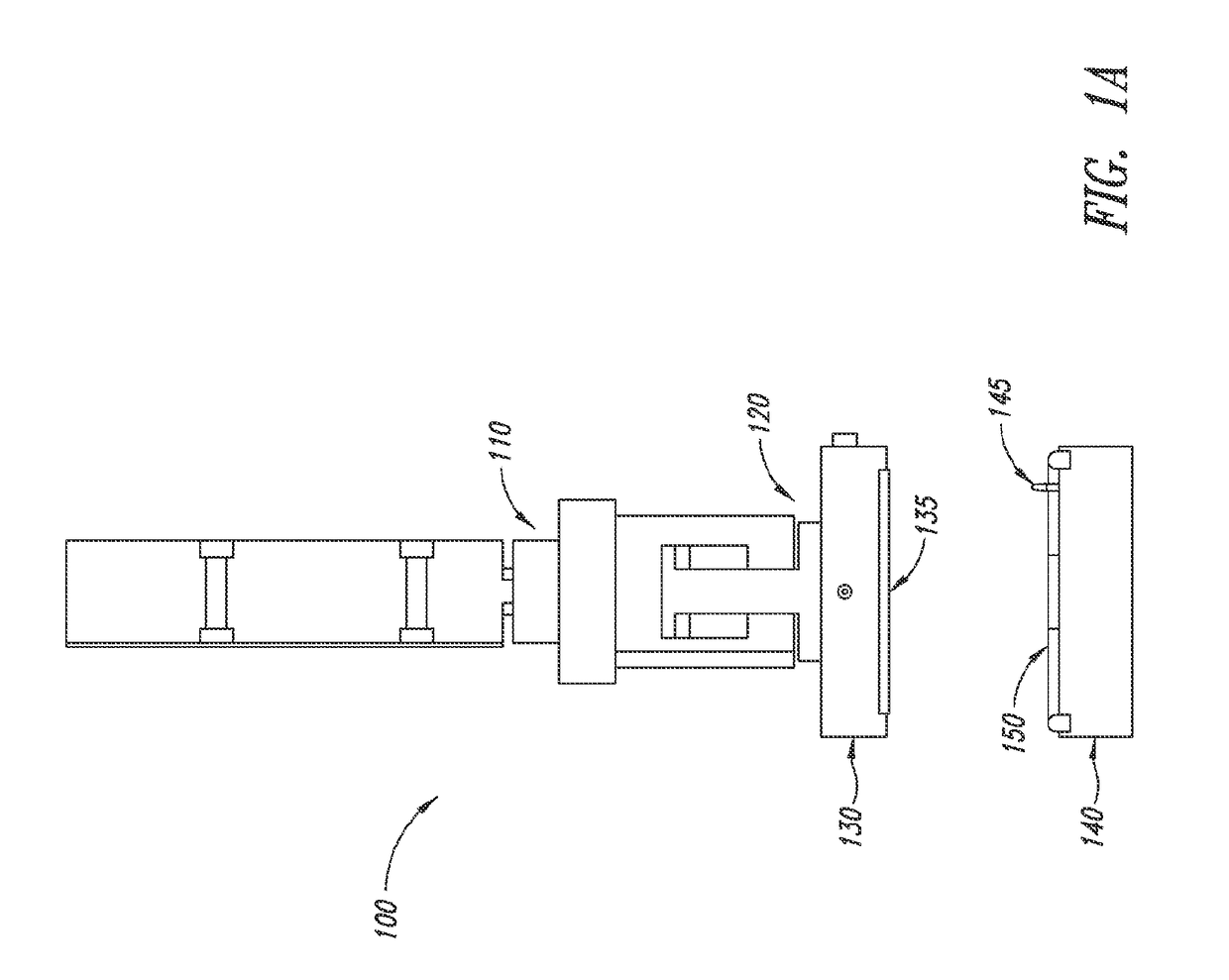

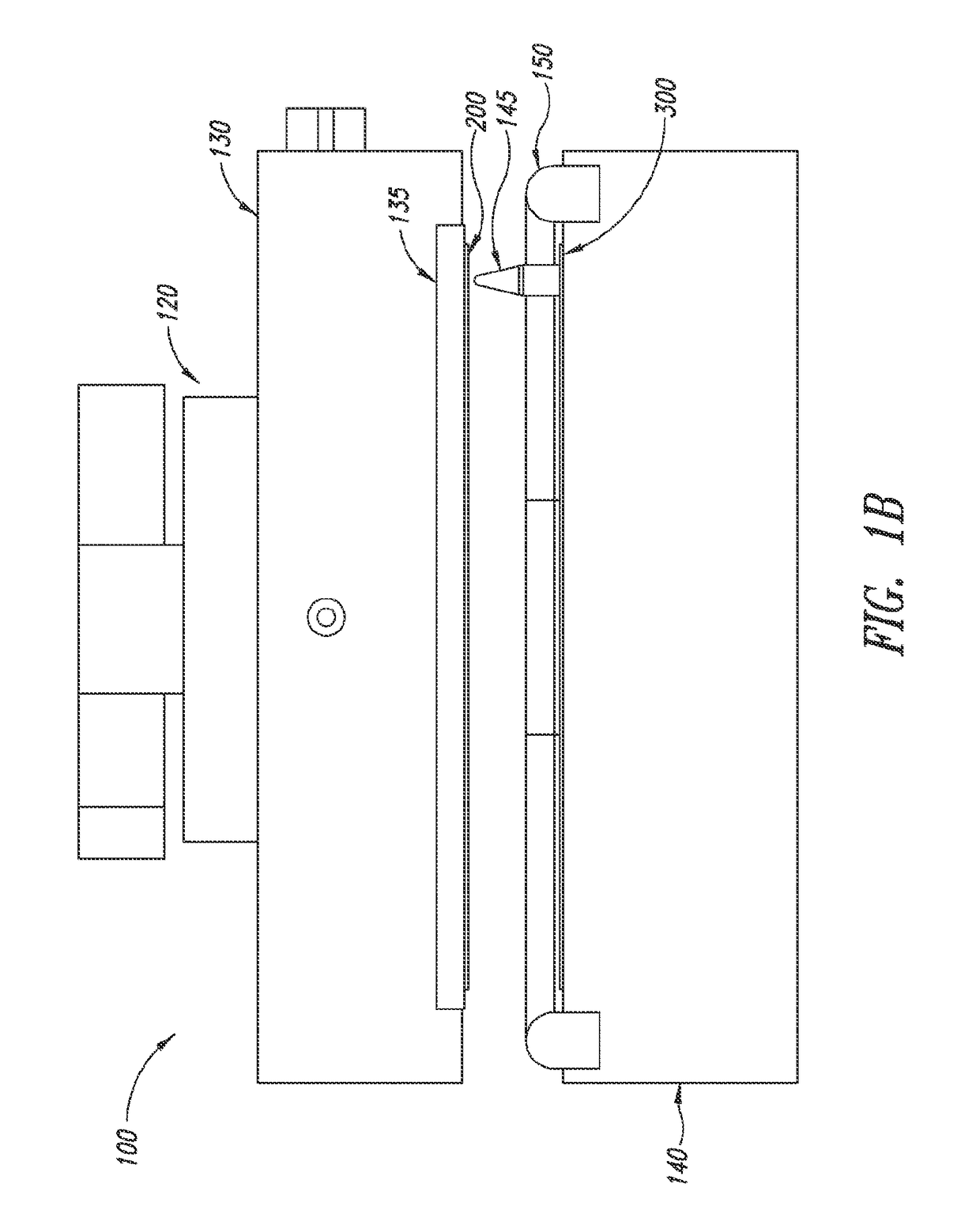

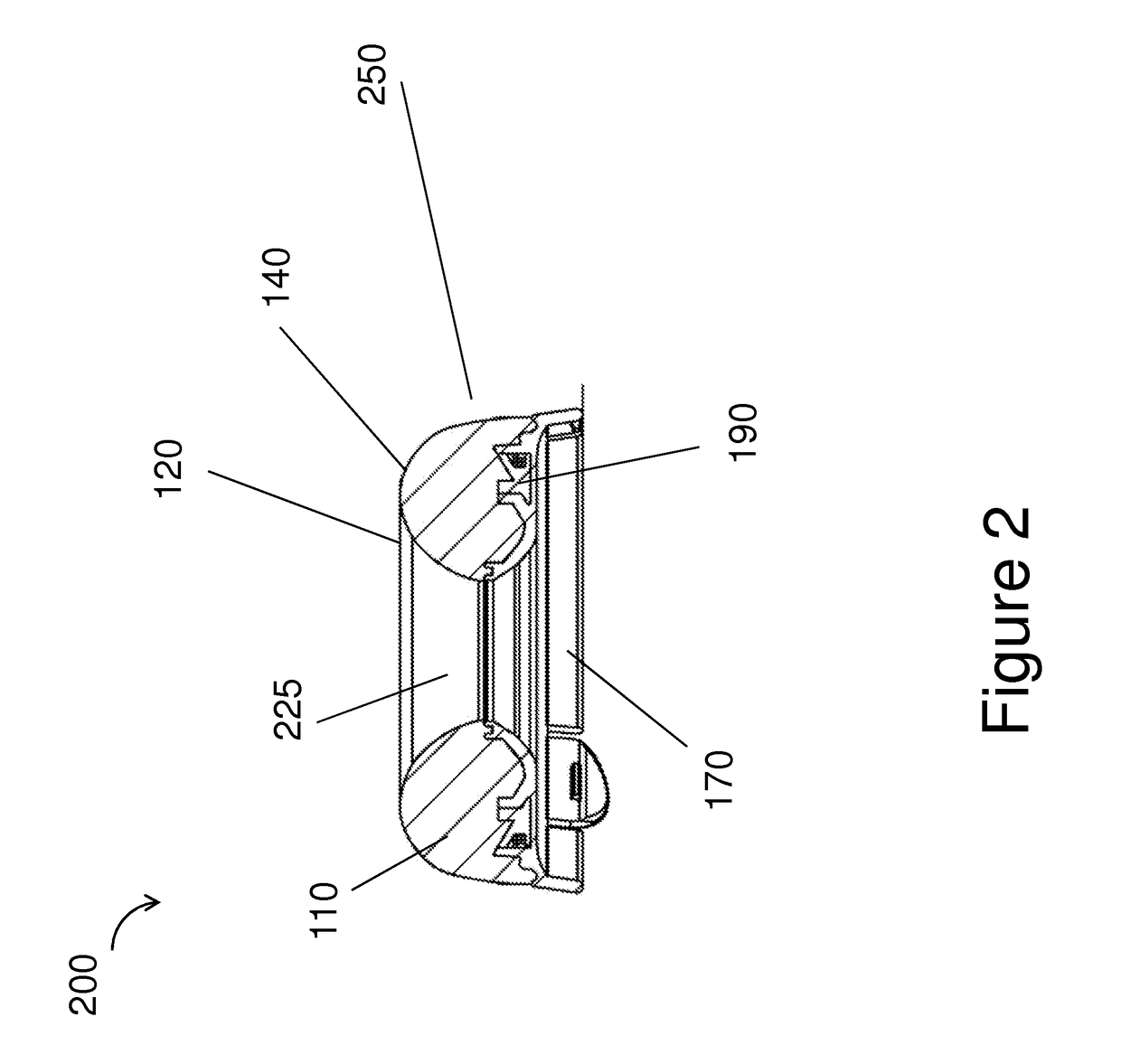

Retaining enclosure for above-ground fiber optic/cable network terminal

The unit for retaining / securing a fiber optic cable comprises an enclosure including a tray having a back base plate, a top and a bottom sides and a unit for retaining / securing a fiber optic cable, disposed in an interior of the enclosure. The bottom side is provided with a pair of identical apertures. Each aperture resembles to a flat shovel having an upper rectangular shape continued by a circular sector; the aperture is so profiled as to engage alternatively a biting-retaining fixture for inserting a cable or an exit grommet for a leaving cable; the former is made of a rigid plastic, while the second—of a soft, elastic polymer. The unit for retaining / securing a fiber optic cable is actuated by a shifting lever, having a shape of an angled, cantilevered part with a longitudinal axis of symmetry bent generally at 90 degrees.

Owner:PRIMEX MFG

Photocurable resin composition and resin composition for plastics comprising the same

A photocurable resin composition comprises a cationic polymerizable compound (A), an acrylic resin (B) and a cationic photopolymerization initiator (C), in which the acrylic resin (B) has a cationic polymerizable functional group, and the content of the component (A) is 30 to 95 parts by mass and the content of the component (B) is 5 to 70 parts by mass, based on 100 parts by mass of the total amount of the components (A) and (B). In addition, the functional group of the acrylic resin (B) preferably contains at least one of a cyclic ether group, a vinyloxy group, an acid adduct of a vinyloxy group, and an active hydrogen group, with the active hydrogen group preferably being a hydroxyl group. The photocurable resin composition has sufficient curability and sufficient adhesiveness to rigid plastics such as polycarbonate and PET having poor adhesive property.

Owner:MITSUI CHEM INC

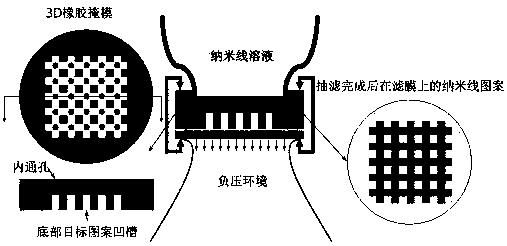

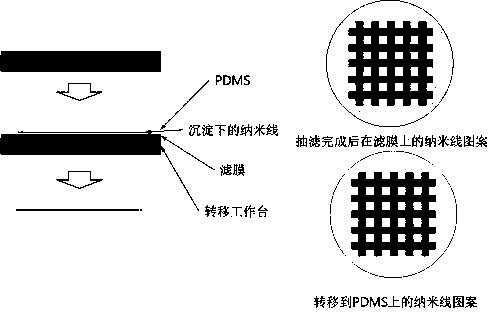

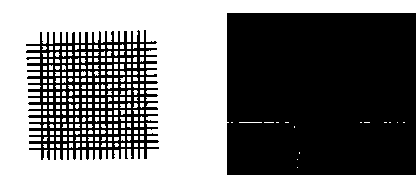

Preparation method of flexible electrode complex pattern based on nanowire material

ActiveCN110950301AIncrease profitPrecise depositionDecorative surface effectsNanotechnologyNanowireFlexible electronics

The invention relates to the field of flexible electronic material manufacturing, and discloses a novel nanowire-based electrode pattern preparation method. The method mainly comprises the following steps: (1) covering a suction filtration port of a negative pressure environment container with a filter membrane, covering the filter membrane with a 3D rubber mask with an inner hole structure, pressing a tubular container with a smooth bottom on the 3D rubber mask, fixing the tubular container with a clamp, and pouring a nanowire solution into the container at the top for suction filtration; (2)after all the liquid is subjected to suction filtration, sequentially taking down the top container and the 3D rubber mask, then transferring the filter membrane to a workbench through tweezers, wherein the workbench can be made of glass or hard plastic or the like, and a double faced adhesive tape is attached to the upper surface of the workbench; and (3) after the filter membrane is completelydried, coating the filter membrane with the liquid organic resin material to be cured and the like, and tearing off the organic resin after the liquid organic resin material to be cured and the like are cured, so as to obtain the nanowire / organic resin flexible electrode with a specific pattern. The 3D rubber mask with the inner through hole structure is innovatively designed, in combination witha vacuum filtration system, complex electrode patterns with clear boundaries can be efficiently prepared, the material utilization rate can reach 95% or above, and the method is suitable for large-scale production of flexible electronic materials and has wide application prospects.

Owner:HARBIN INST OF TECH AT WEIHAI

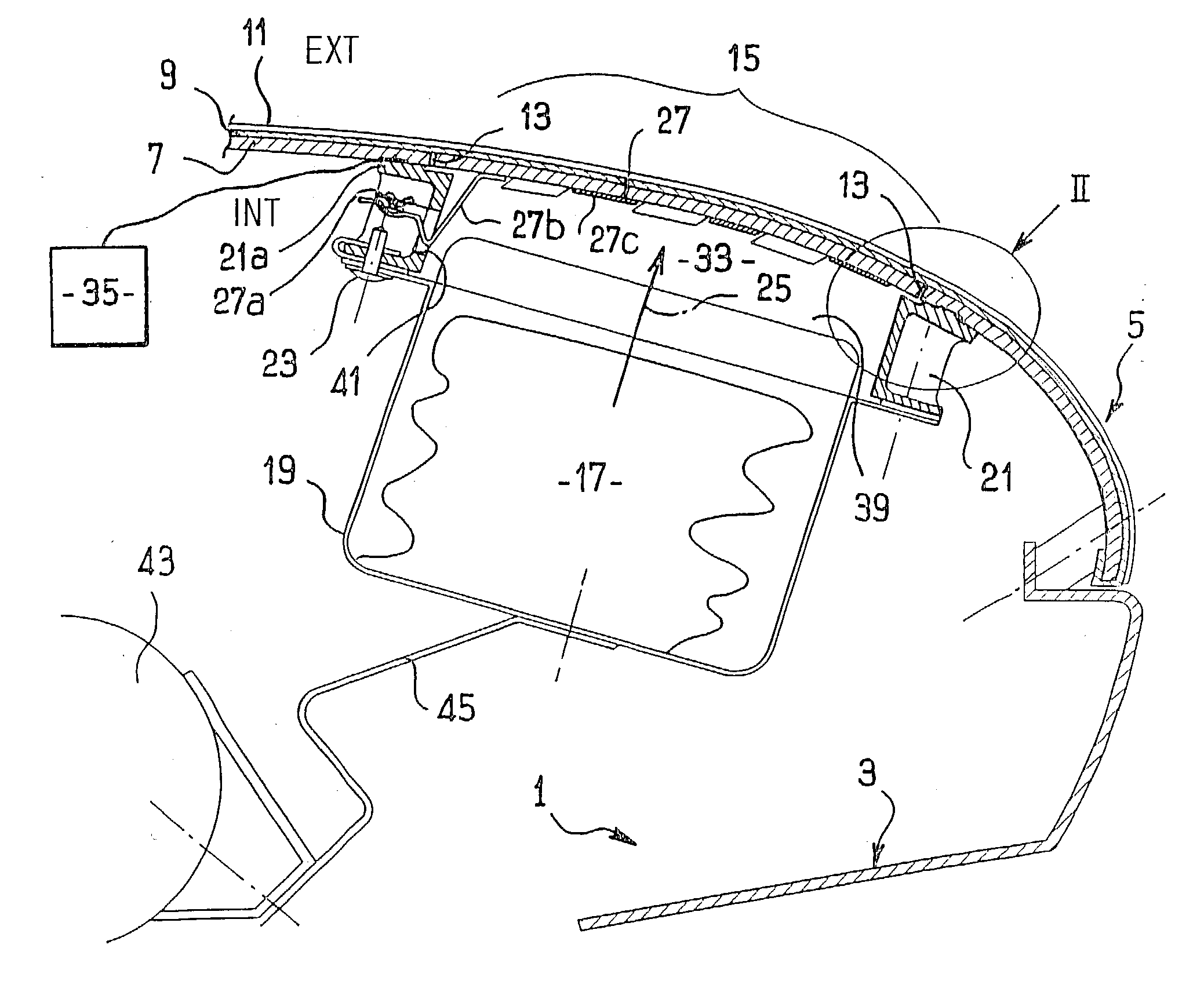

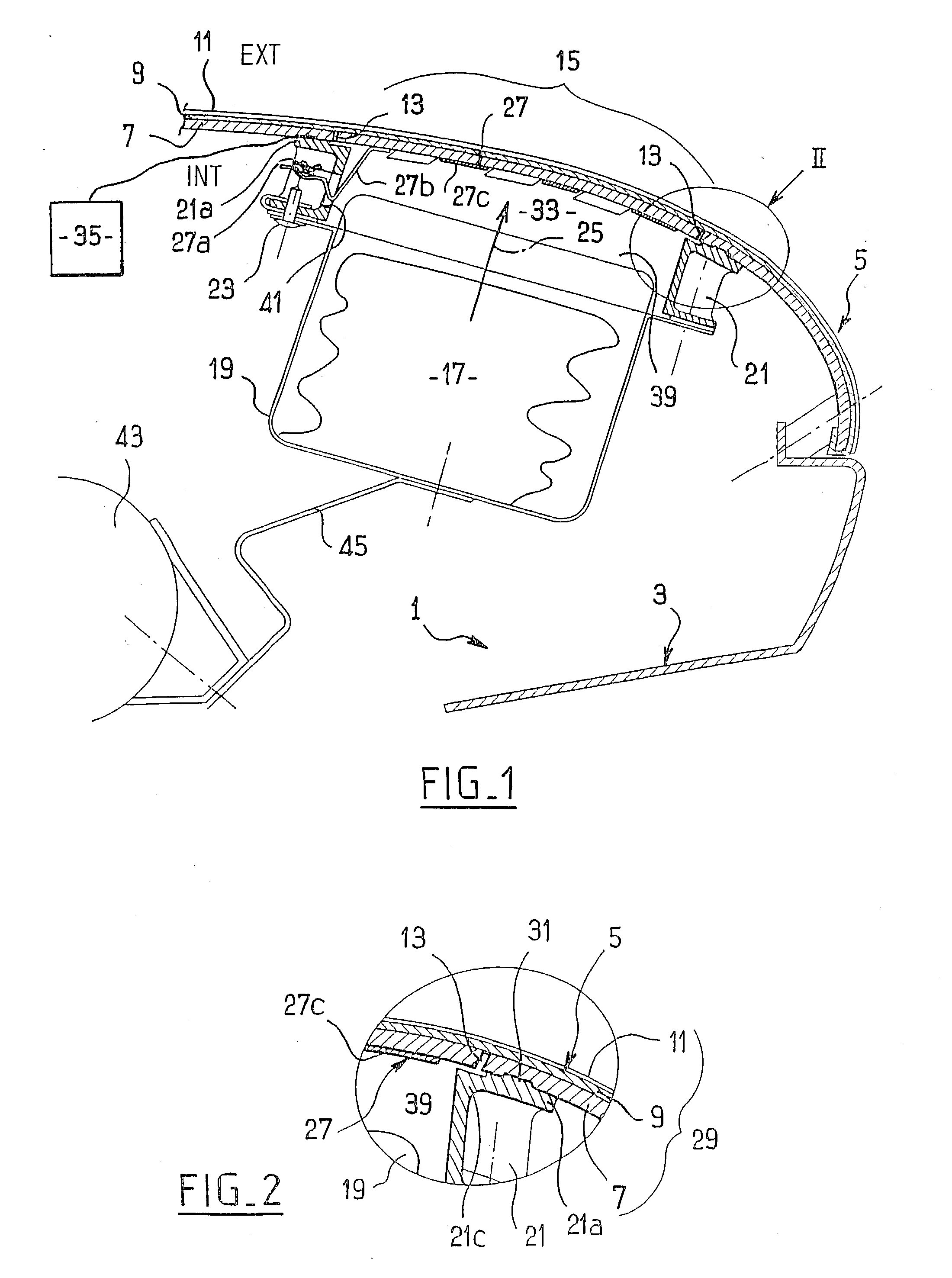

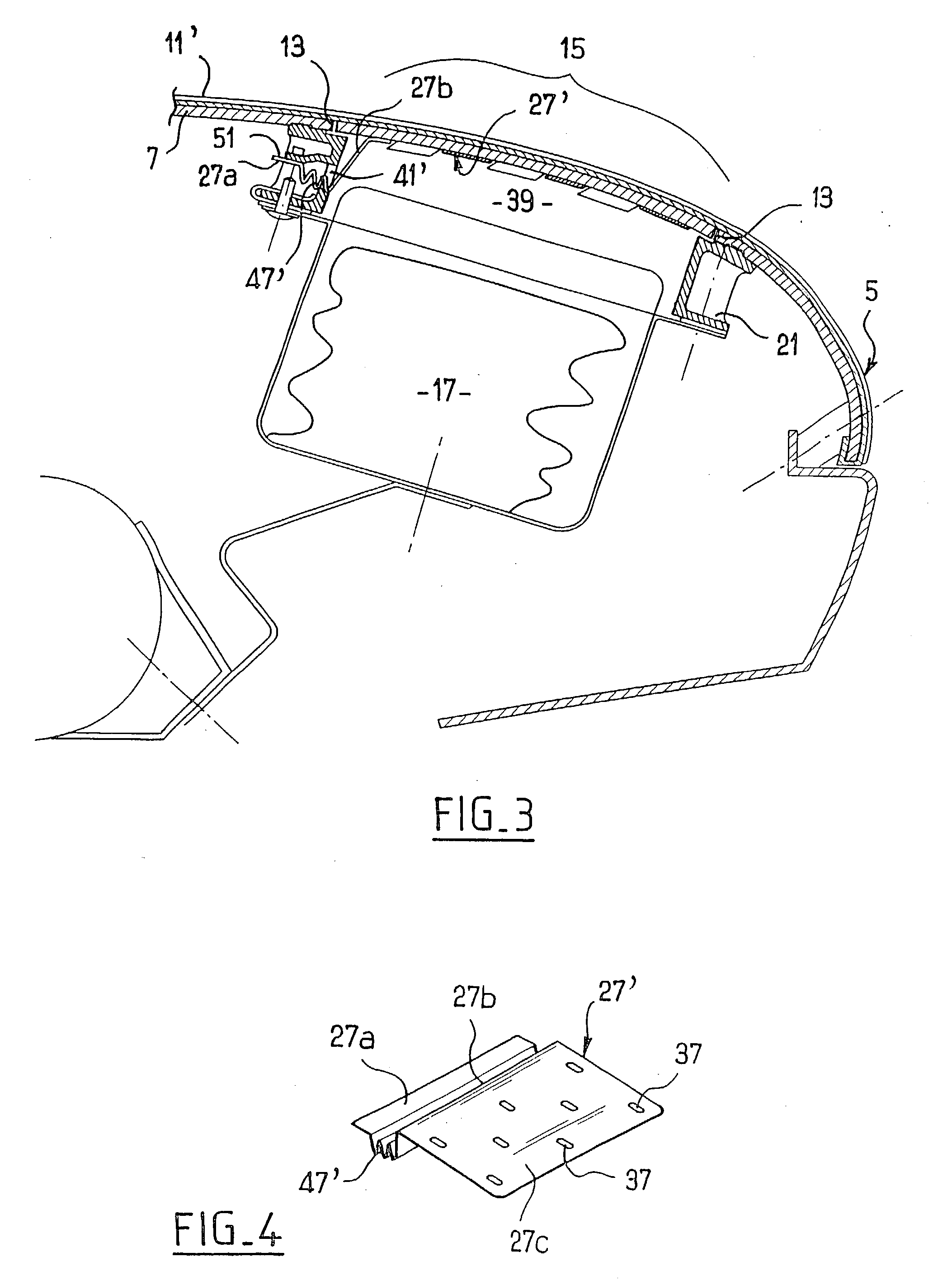

Method of manufacturing a dashboard portion fitted with an air bag

InactiveUS20040026009A1High riskReduce manufacturing costPedestrian/occupant safety arrangementLaminationDashboardPlastic materials

A dashboard is made that presents a cover for an air bag protection system, the cover being invisible from the outside and being defined by an inside line of weakness in the wall of the dashboard, the line of weakness defining an opening for the air bag. A layer of hard plastics material is injected molded; the line of weakness is cut locally inside the wall; the outside of the plastics layer is covered with a decorative covering; a tab with a hinge for hinging the cover is fastened to the cover; the reinforcing frame is fastened to the plastics layer, and prior to welding, it is ensured that a vibratory discontinuity exists between the frame and the tab so that during welding some of the vibration generated is absorbed away from the line of weakness; and the tab is fastened to the reinforcing frame.

Owner:FAURECIA INTERIEUR IND

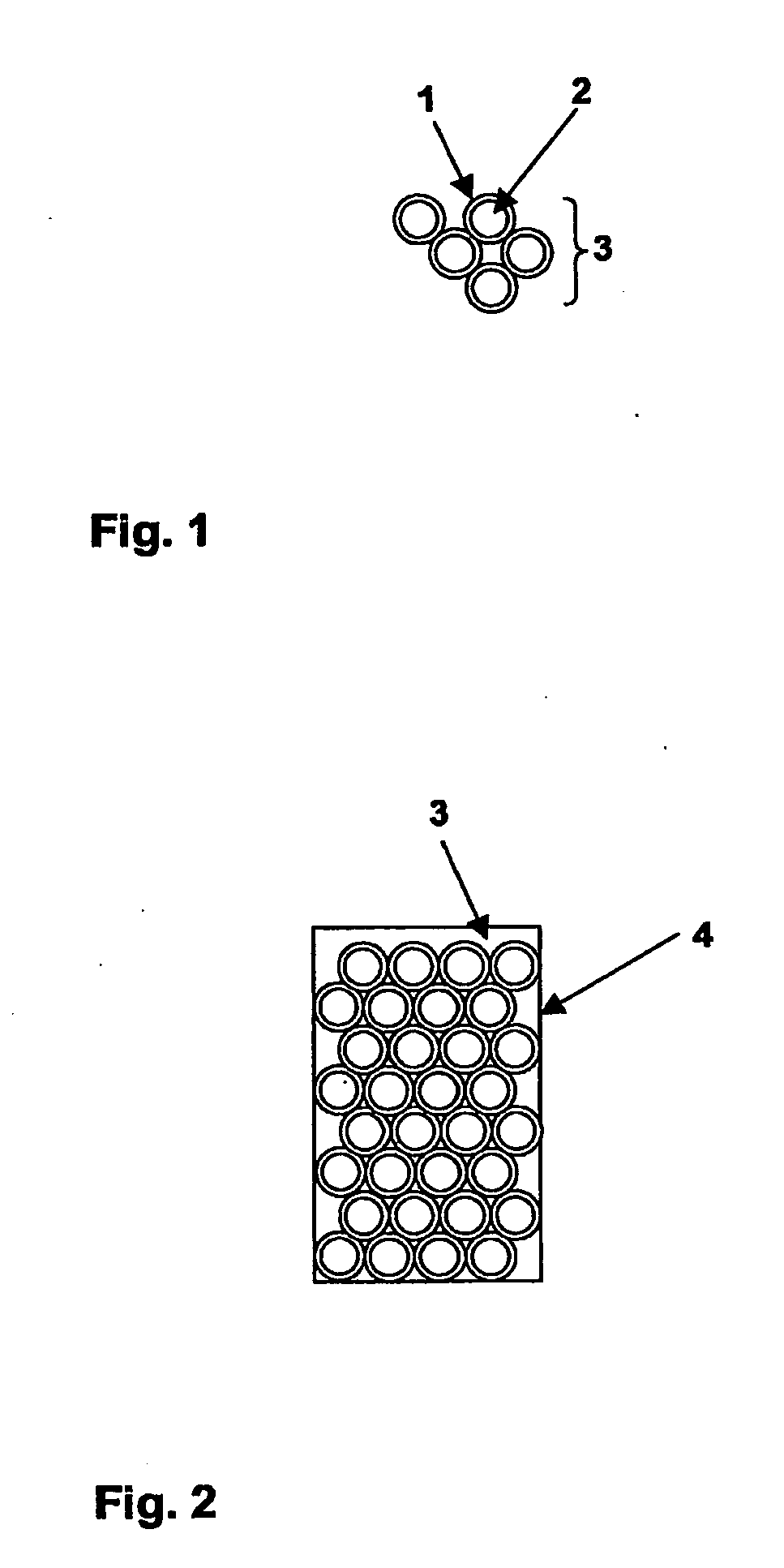

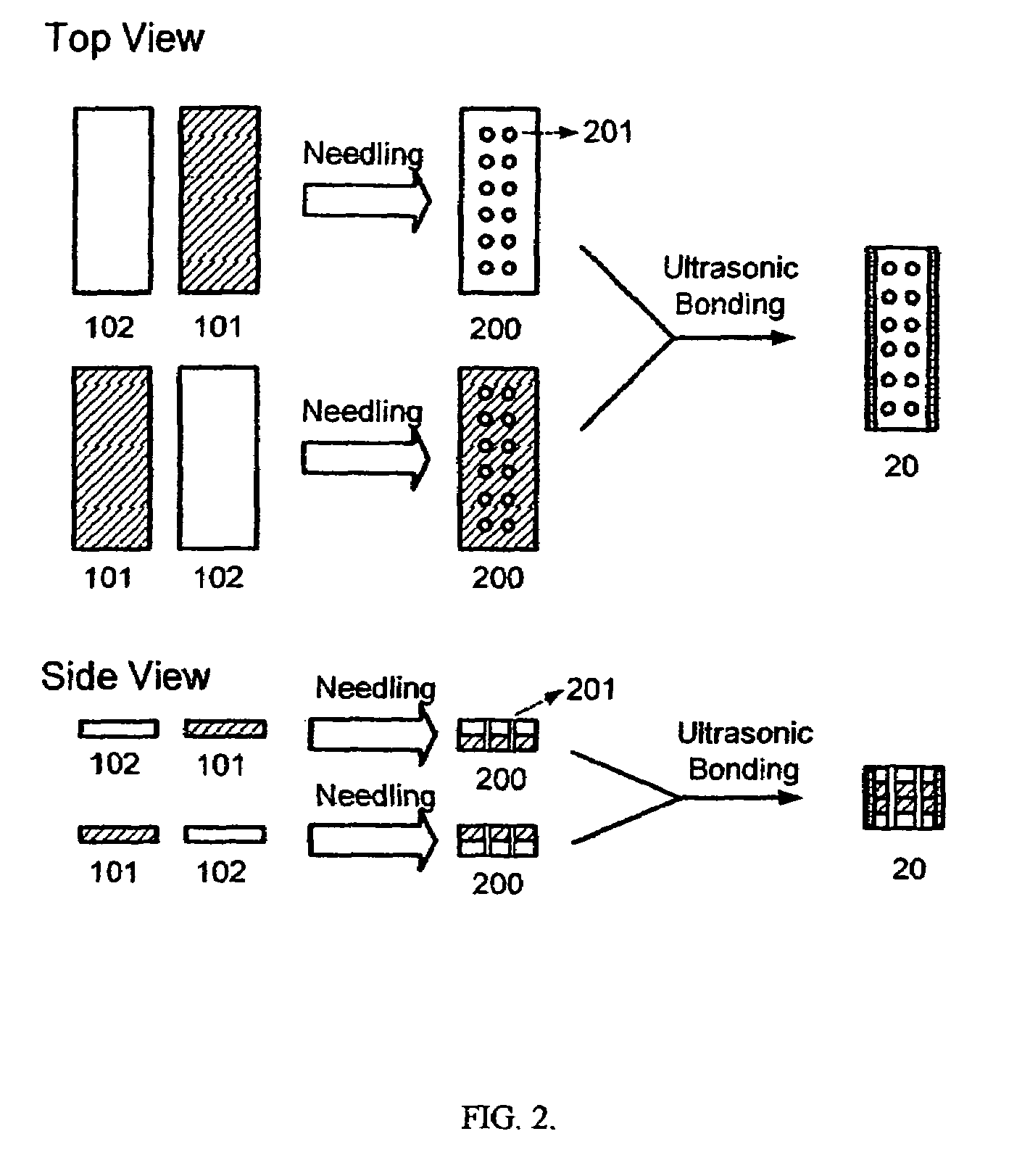

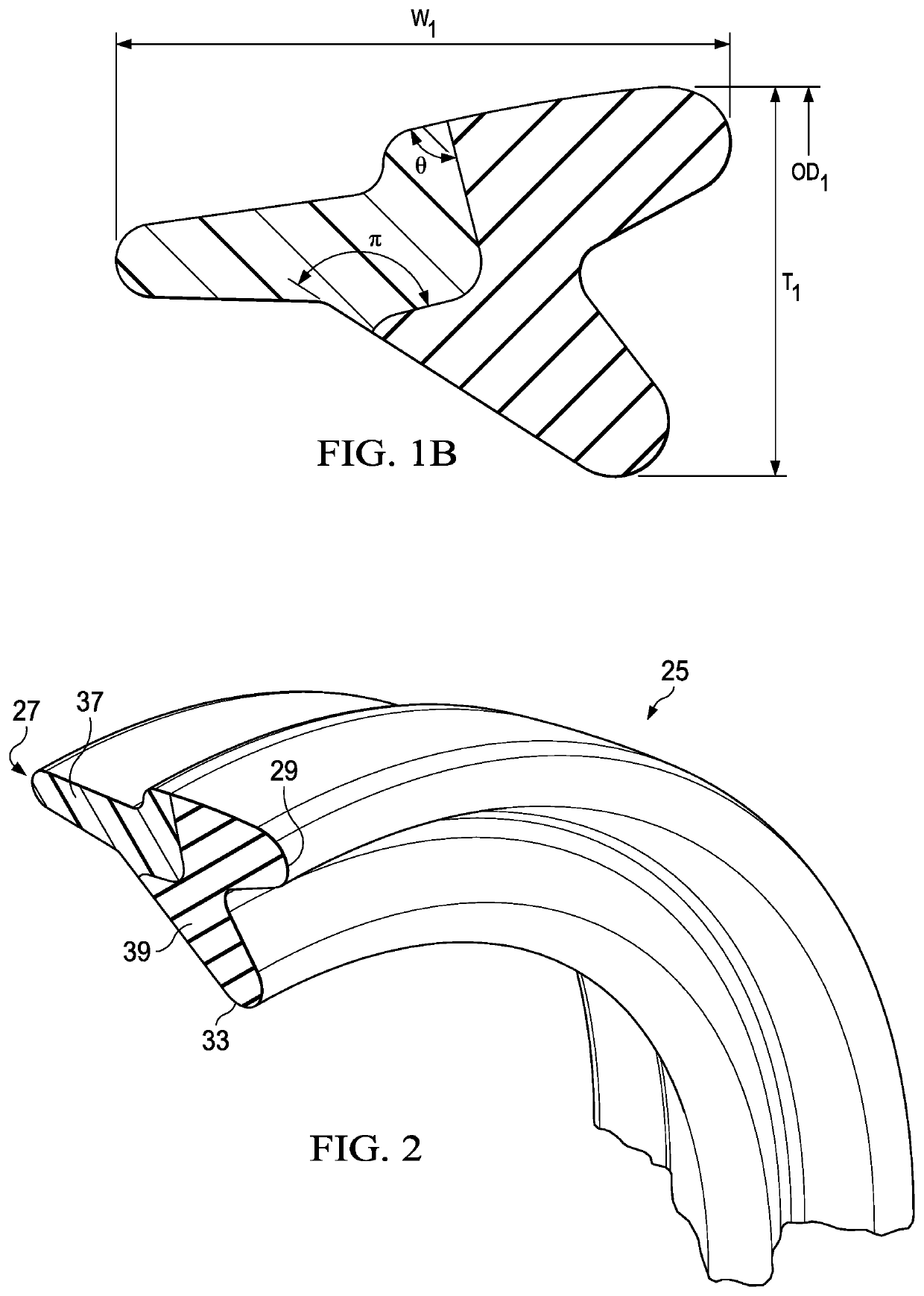

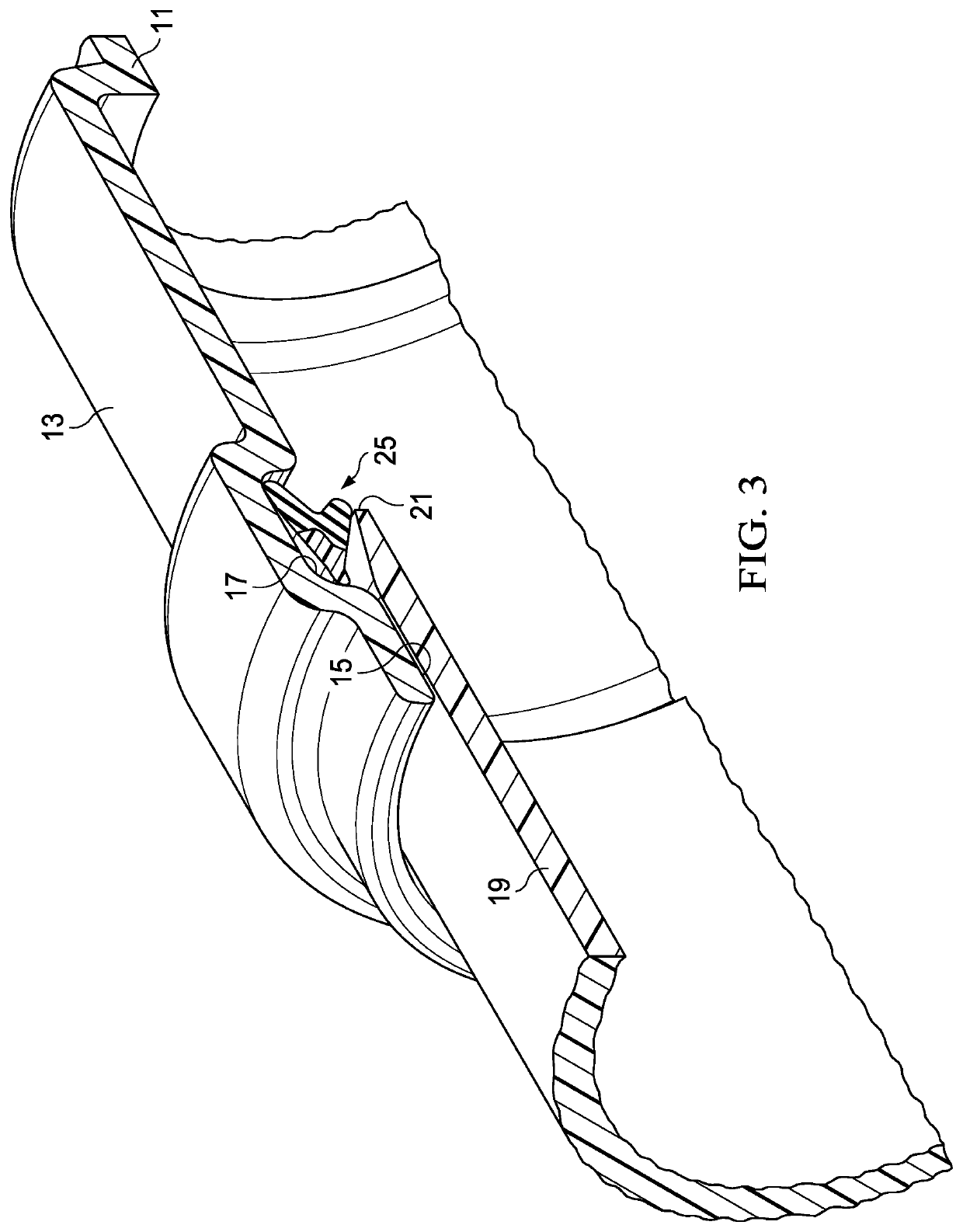

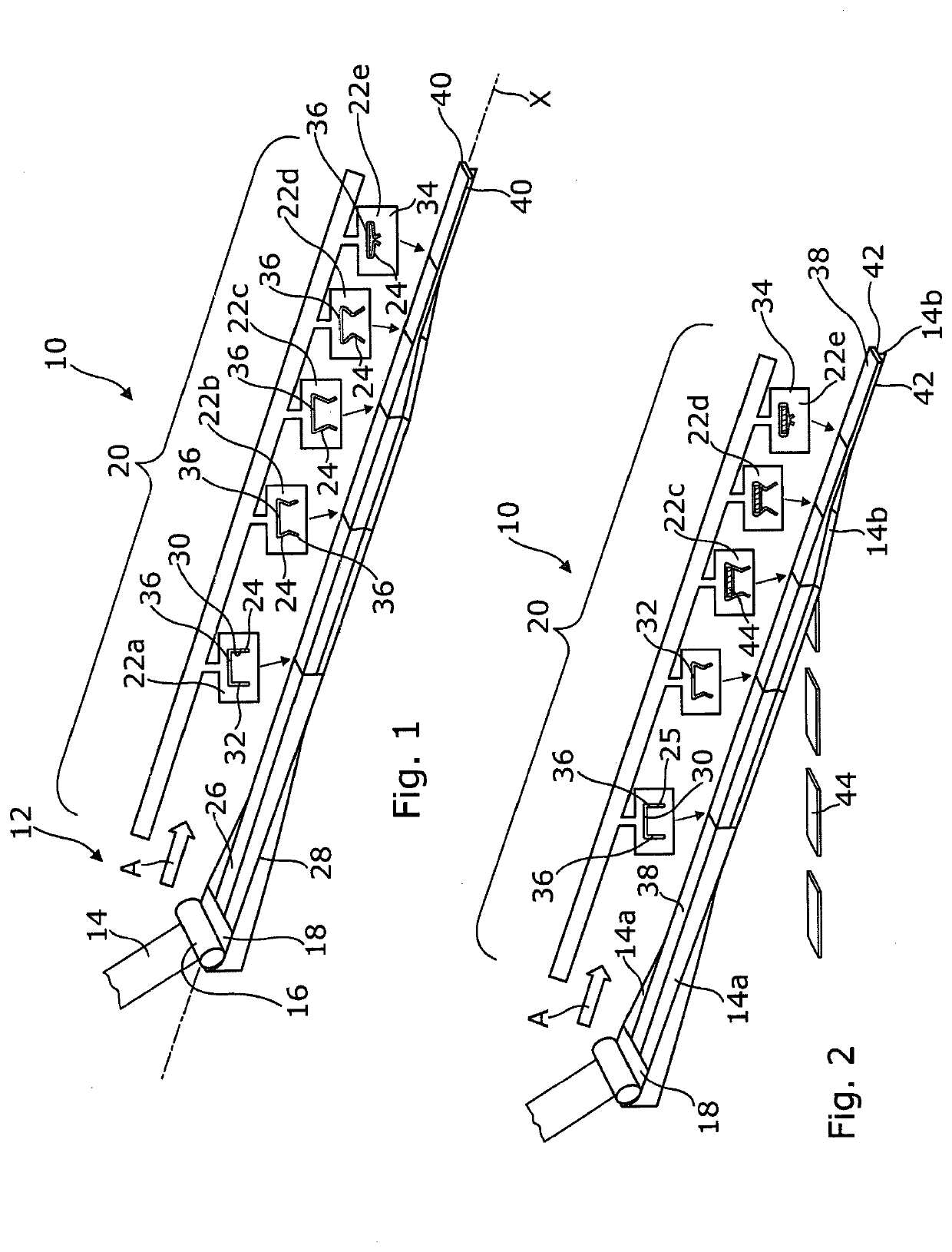

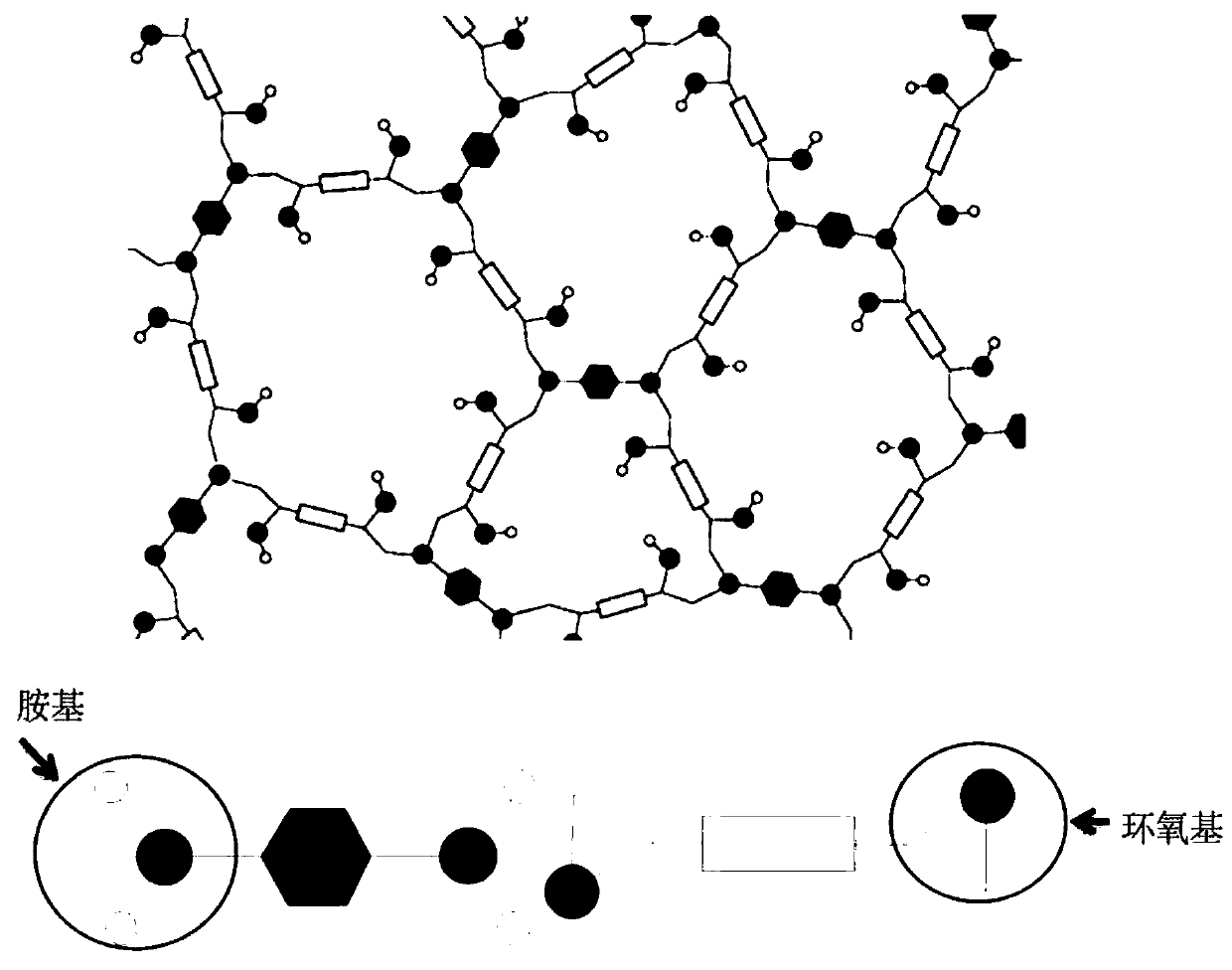

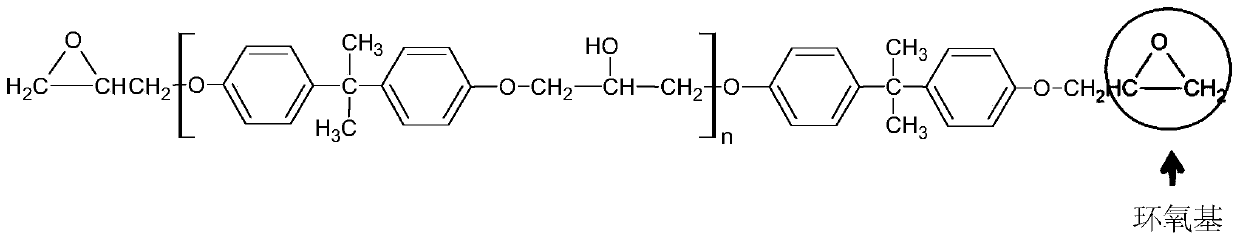

Filler material, especially for filling cavities, especially of structural elements, method of production and structural element

InactiveUS20090042013A1Synthetic resin layered productsCellulosic plastic layered productsFilling materialsRoom temperature

The invention relates to a filler material, especially for filling cavities, especially of structural elements, to a method of production and to a structural element. The inventive filler material comprises particles that are coated with a reactive duroplast, whereby the reactive duroplast is non-viscous at room temperature when not yet reacted.

Owner:SIKA TECH AG

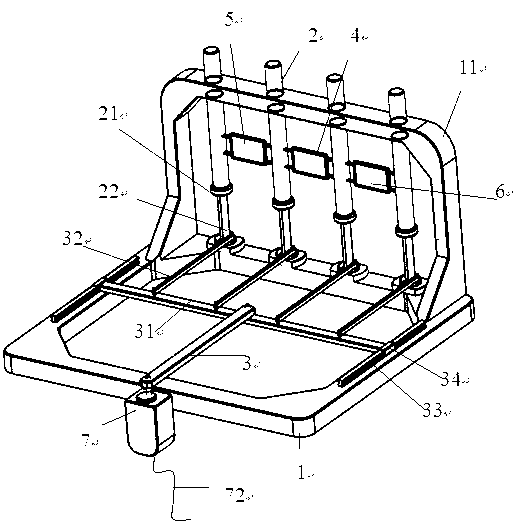

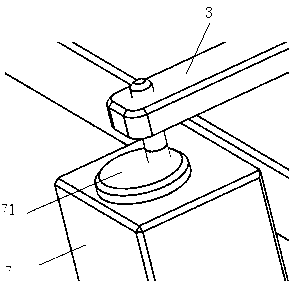

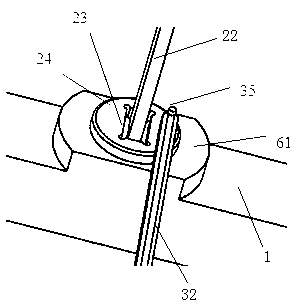

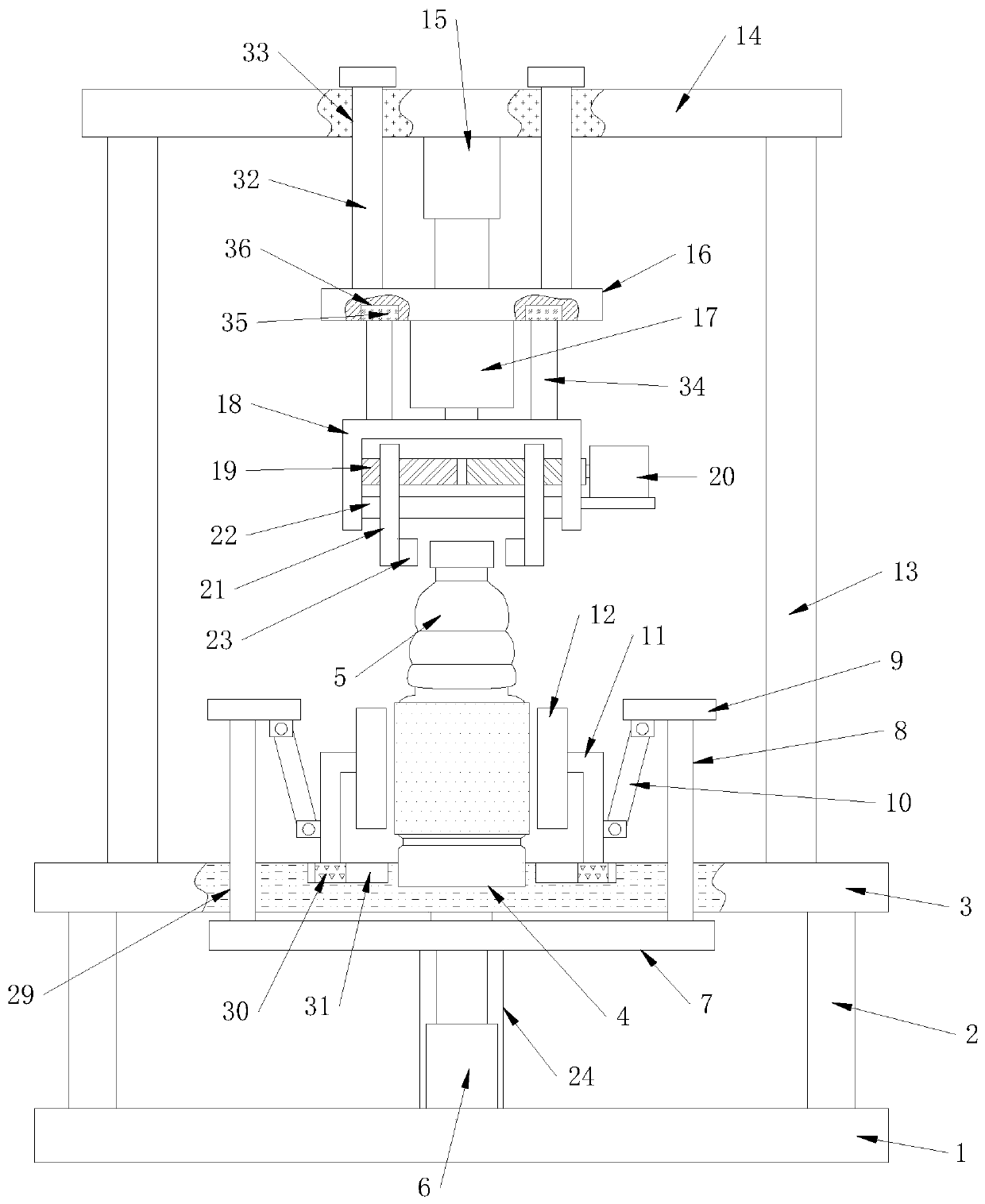

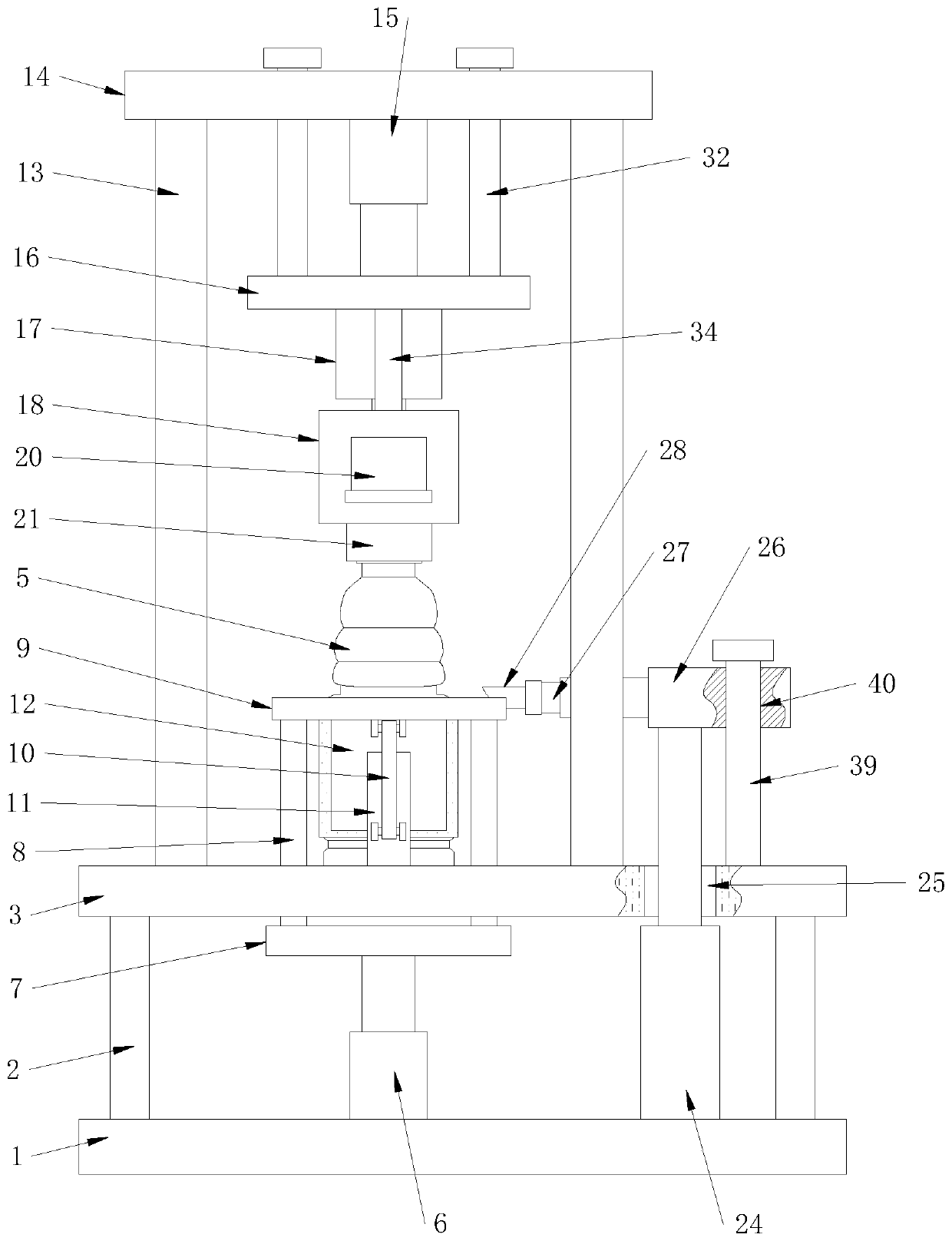

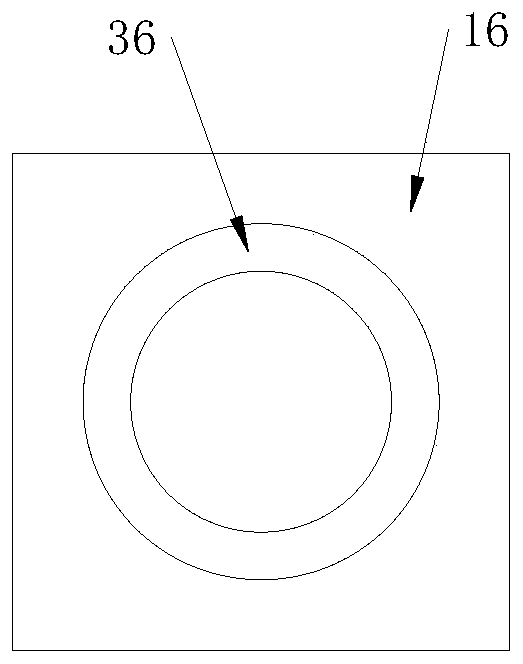

High-frequency torsional fatigue testing method and device for hard plastic pieces

InactiveCN103018118AMeet different conditionsImprove test efficiencyStrength propertiesFatigue IntensityTest efficiency

The invention discloses a high-frequency torsional fatigue testing device and a high-frequency torsional fatigue testing method for hard plastic pieces. The high-frequency torsional fatigue testing device comprises a fixing device, multiple groups of clamp device units, a transmission unit, a torsion and environment monitoring unit, a PLC (programmable logic controller) unit, an angle and frequency control unit, a driving unit and a power supply unit, wherein multiple hard plastic pieces are clamped on the clamp device units respectively; the power supply unit supplies power to the driving unit; the driving unit drives the transmission unit to do reciprocating motion along sliding rails to drive torsion of one end of each of the hard plastic test pieces loaded on each clamp device unit; torsions of the hard plastic pieces and environmental temperature and humidity are acquired by the torsion and the environment monitoring unit; and the PLC unit receives analog signals acquired by the torsion and the environment monitoring unit and outputs a fatigue curve. By the device and the method, multiple groups of test pieces can be tested at high frequency at the same time, parameters can be directly converted into a fatigue strength curve through a system and displayed to a user, real-time printing is supported, and the testing efficiency is improved.

Owner:SUZHOU UNIV

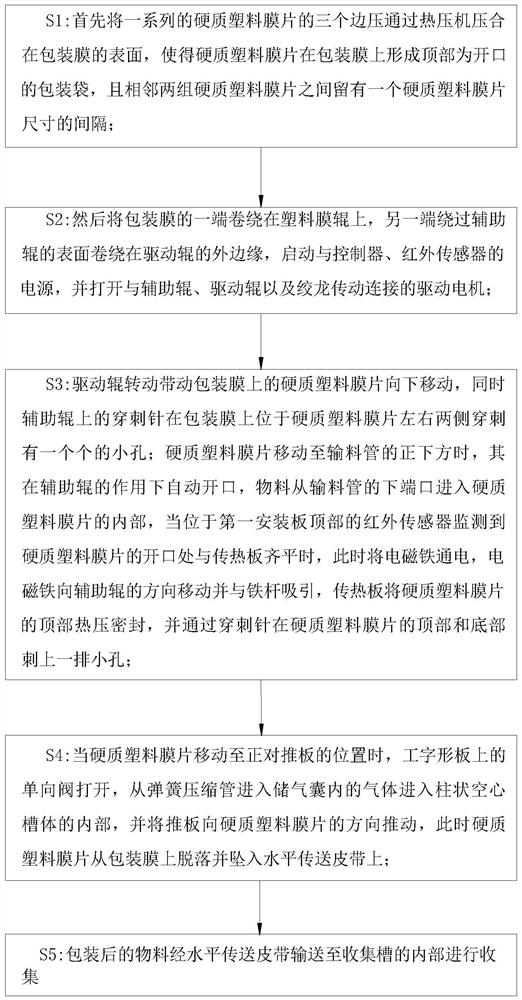

Food packaging equipment and food packaging method

InactiveCN111776348ALarge openingEasy to useWrapper twisting/gatheringPackaging foodstuffsFood packagingPlastic film

The invention belongs to the technical field of packaging equipment, in particular to food packaging equipment and a food packaging method. The food packaging equipment comprises a high-temperature material barrel, a packaging film and a driving roller; the packaging film is wound on the outer surface of a plastic film roller; the free end of the packaging film is wound on the surface of the driving roller; a hard plastic film is arranged on the surface of the packaging film; three edges of the hard plastic film are pressed on the surface of the packaging film through hot pressing, and an opening is formed in the top of the hard plastic film; an auxiliary roller is arranged between the plastic film roller and the driving roller; the packaging film passes through the surface of the auxiliary roller; the auxiliary roller consists of two circular plates and a plurality of groups of iron rods; and the two circular plates are fixedly connected by the iron rods. According to the food packaging equipment and the food packaging method, the opening of the hard plastic film can be opened without an additional opening device, so that the process flow can be simplified; and meanwhile, hot airinside the high-temperature material barrel can heat a heat transfer plate through an elastic heat conduction pipe for heat sealing at the opening, so that an electric heating plate does not need to be used, and waste heat is recycled while the electric energy is saved.

Owner:安徽百安包装材料有限公司

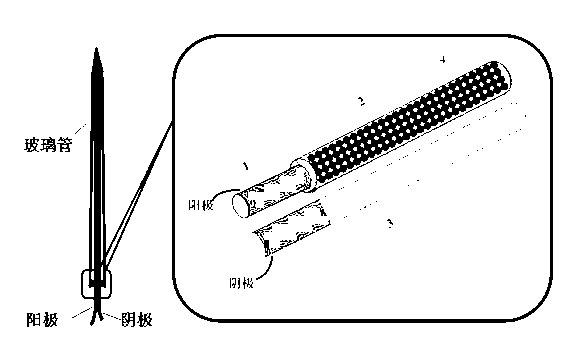

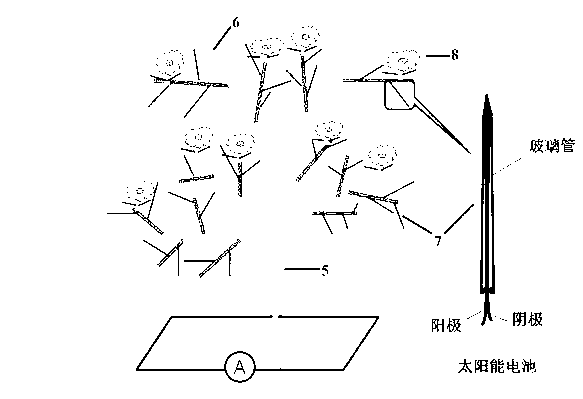

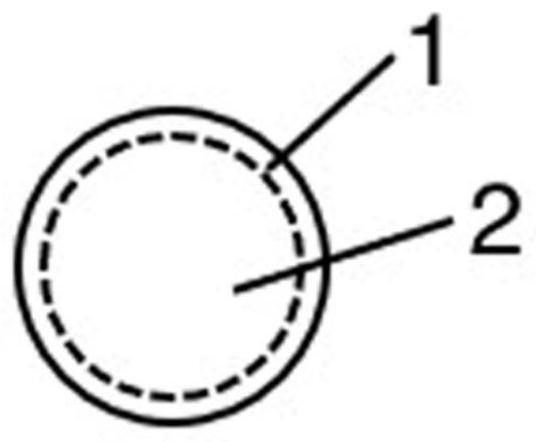

Pine-tree solar cell landscape tree

InactiveCN102842439AOvercome the disadvantage of large footprintImprove utilization efficiencyLight-sensitive devicesArtificial flowers and garlandsCopper wireEngineering

The invention in particular provides a pine-tree solar cell landscape tree, which belongs to the field of solar photovoltaic. The pine-tree solar cell landscape tree comprises a trunk, branches and leaves, wherein the trunk, the branches and the leaves are sealed by high molecular rubbers and connected with each other by reserved ports; the trunk is a copper wire coated by hard plastic; the branches are copper wires coated by soft plastics; the leaves are dye-sensitized solar cells packaged by transparent glass tubes or plastic tubes; the cells are connected with each other in parallel; and the dye-sensitized solar cells among different branches are connected with each other in parallel. The pine-tree solar cell landscape tree provided by the invention can be used for collecting lights from each spatial direction, so that the sunlight utilization efficiency is increased; a defect of larger space usage of a flat-plate solar cell in the large-area application process is overcome; a making process is simple; meanwhile, the solar cell tree can be used as landscape trees for beautifying environments outdoors.

Owner:FUDAN UNIV

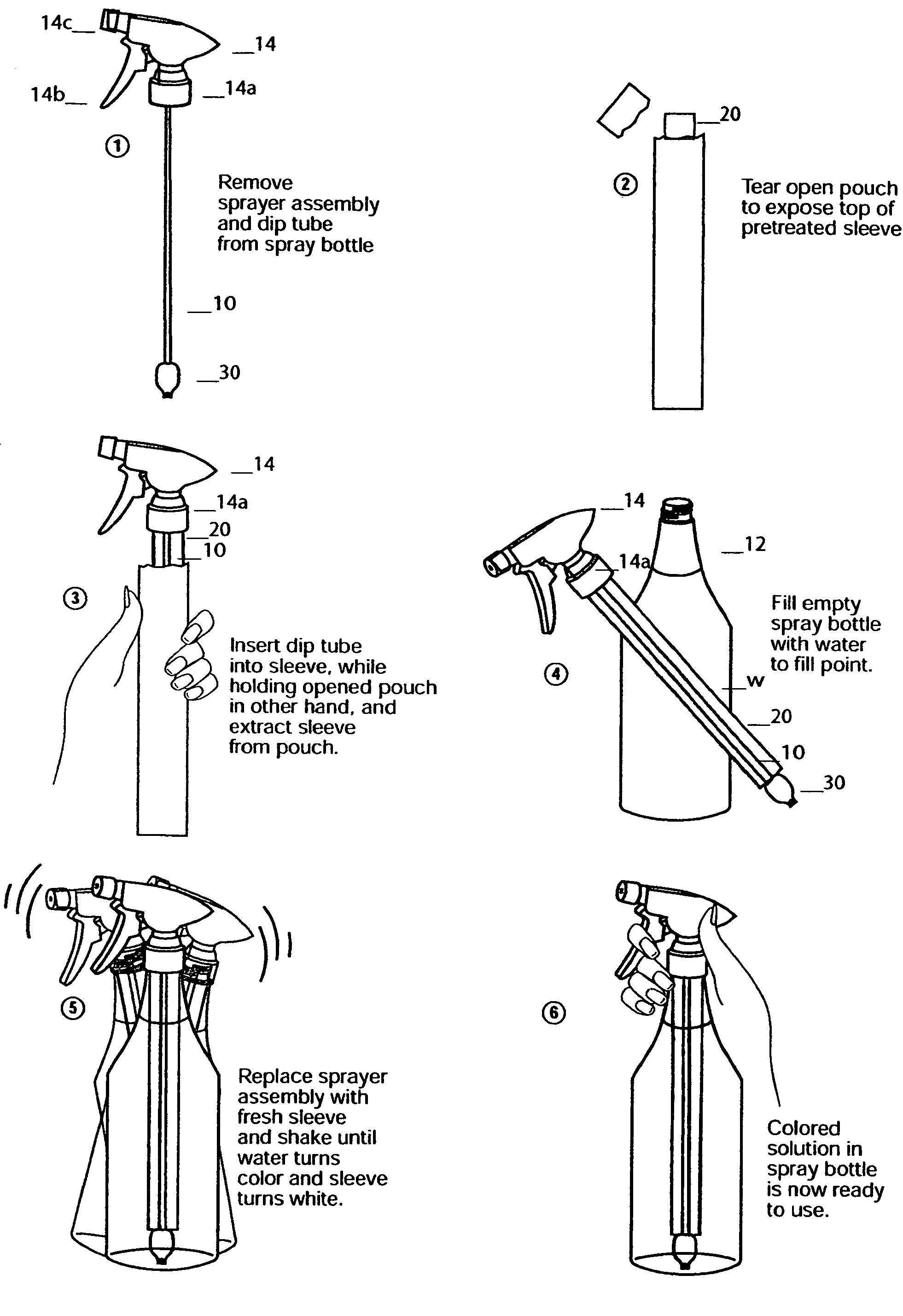

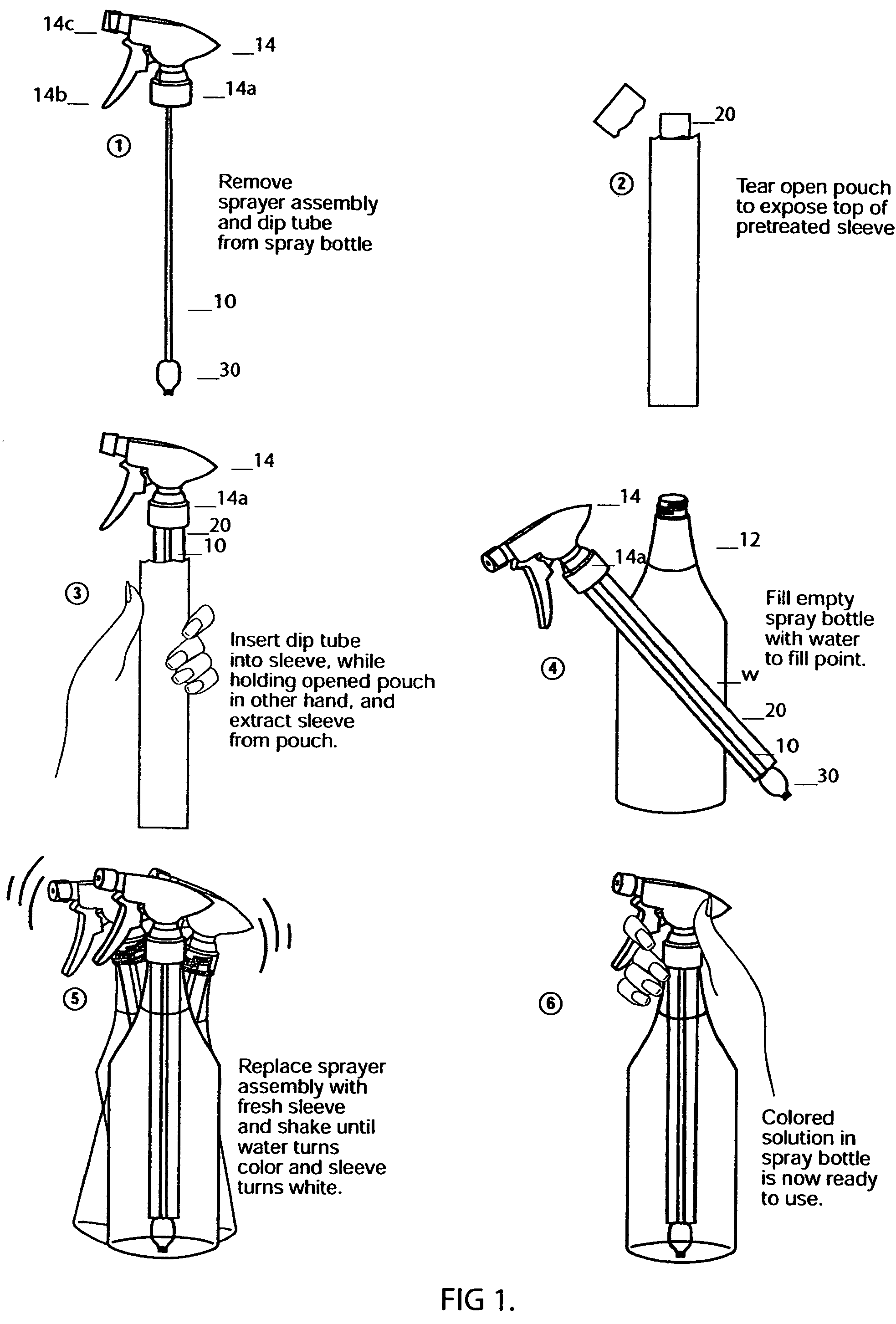

Retainer for sleeve for recharging a cleaning, sanitizing or disinfectant fluid spray system

InactiveUS7708170B2Easy extractionEasy to insertLiquid transferring devicesCleaning using toolsChemical compositionDisinfectant

A recharge sleeve for use with a spray dispenser device, made of a matrix comprises an absorptive material impregnated with a chemical composition that dissolves in solution created when the sleeve is contacted with a diluent fluid such as water. The recharge sleeve is elongated in shape with a center opening parallel to the long edges of the sleeve for mounting on the diptube of the spray dispenser device. A conically shaped retainer formed of rigid plastic is attached or provided for attachment to the lower end of the diptube for stabilizing the diptube and retaining the recharge sleeve clear of the bottom of the retainer after the sleeve has been applied to the diptube. When of the spray dispenser device is sealed and the spray dispenser device is shaken, the fluid penetrates into the matrix material, and the chemical composition dissolves in the fluid creating a cleaning, sanitizing, or disinfectant solution that will remain stable and fully active in use.

Owner:KELLY ALBERT R +1

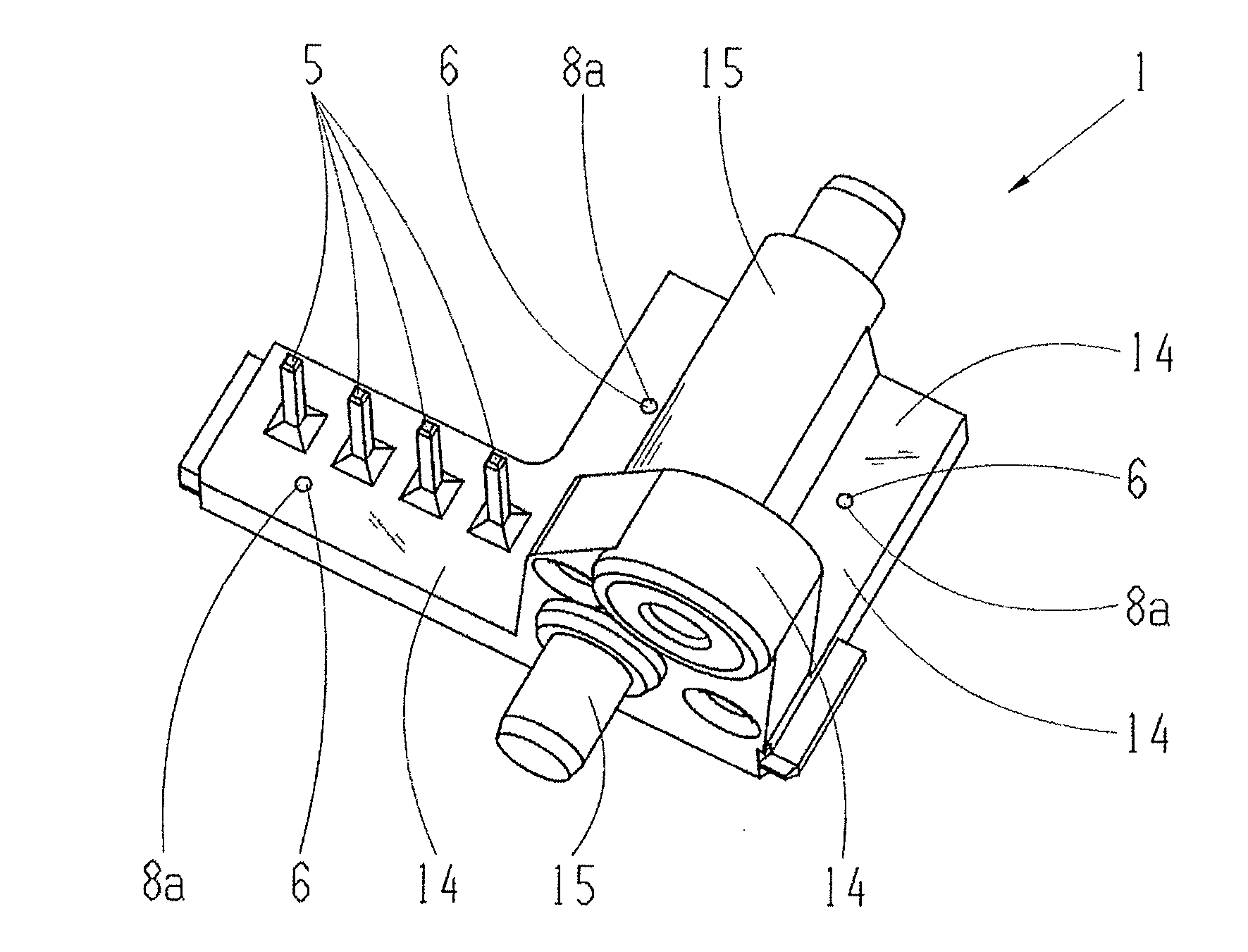

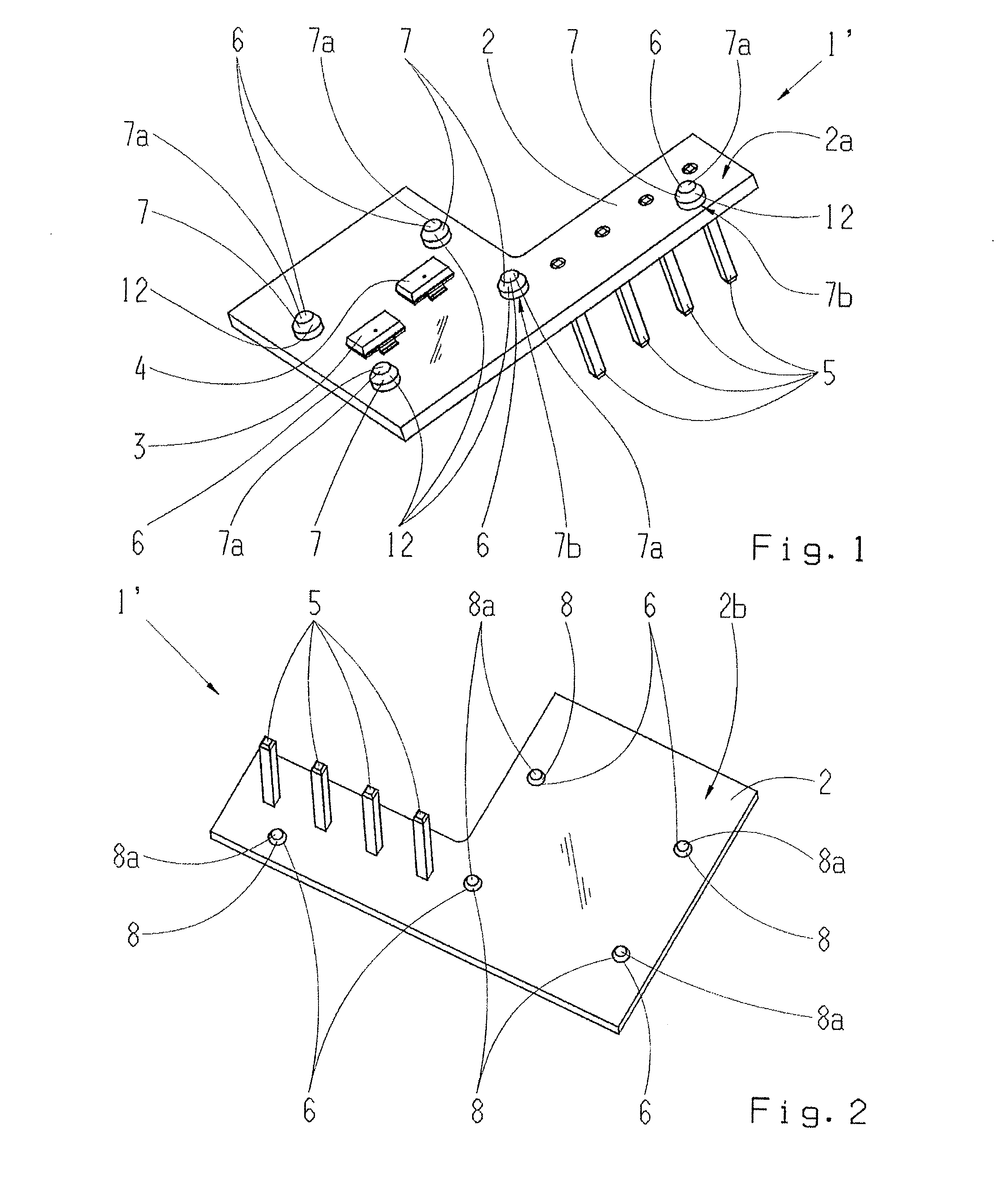

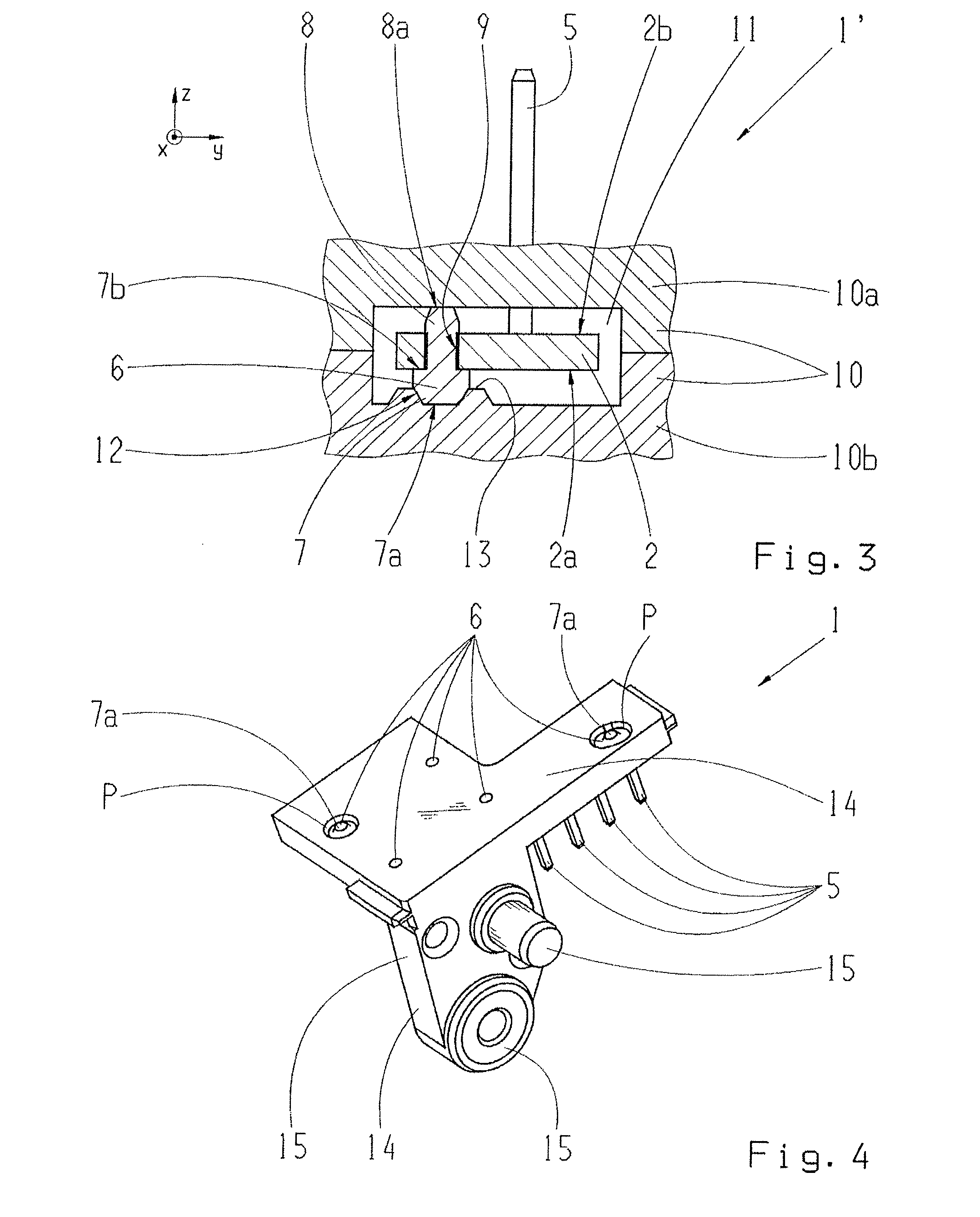

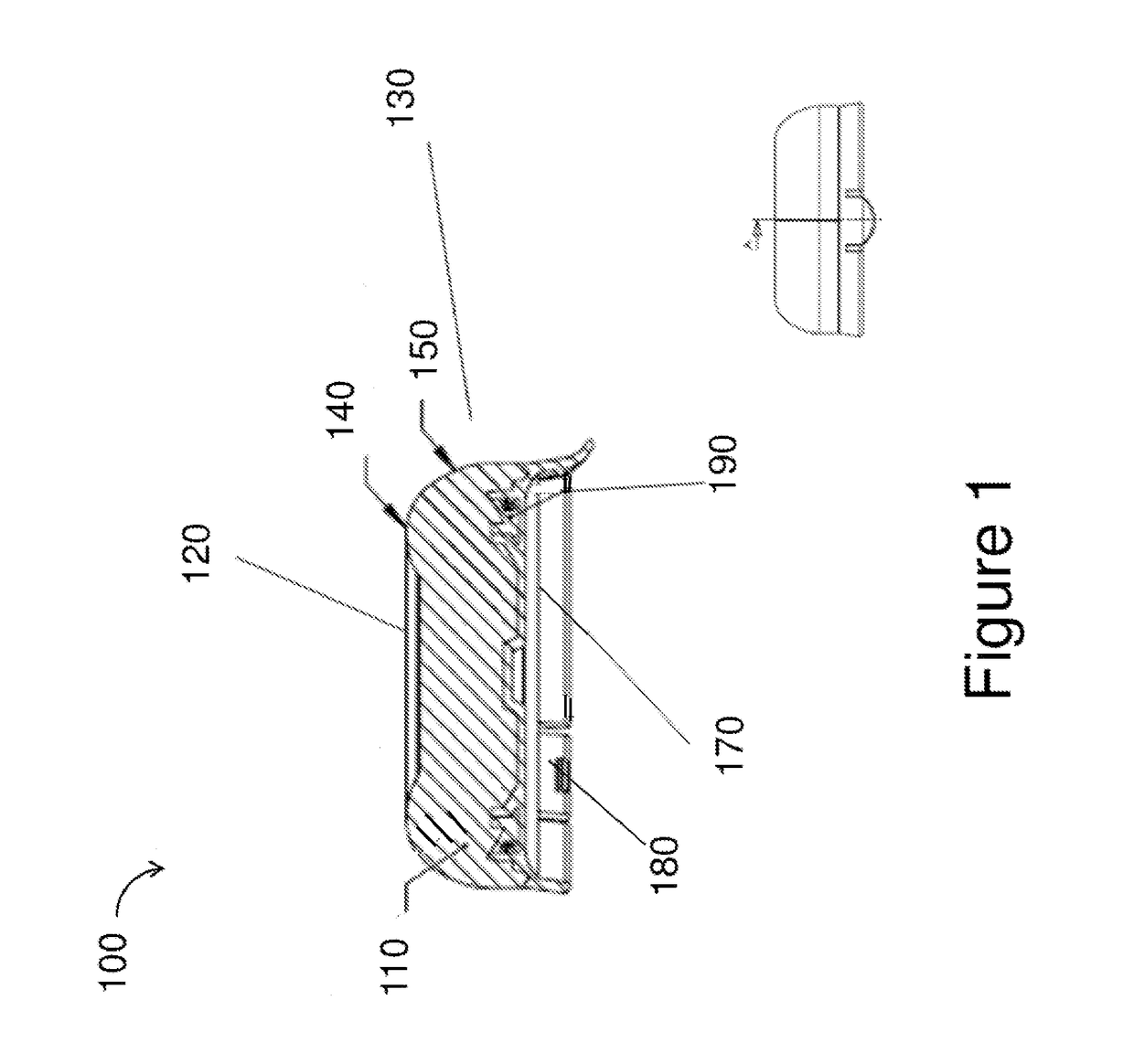

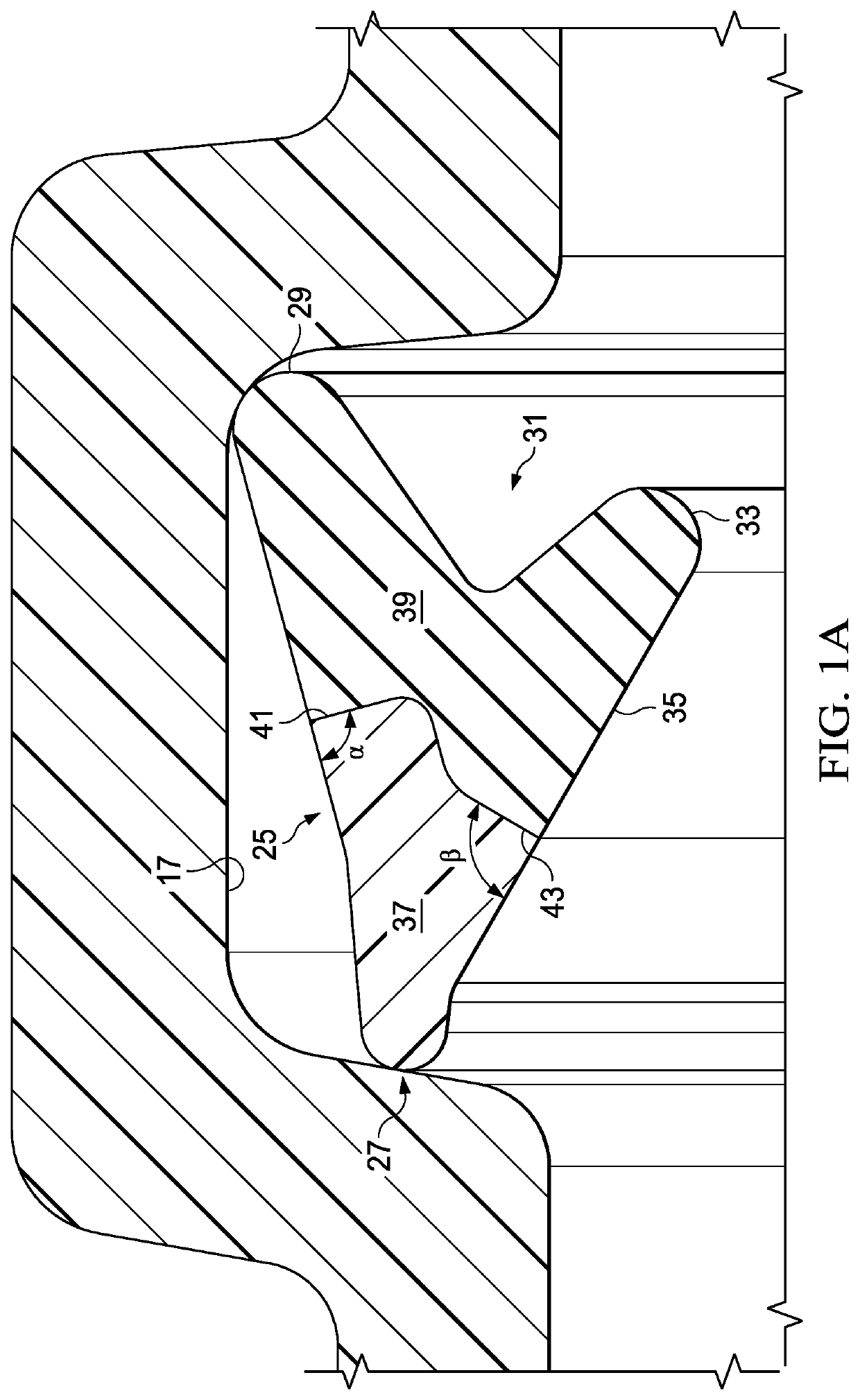

Method of manufacturing a molded sensor subassembly

InactiveUS20130133412A1Negatively affect the sensorEasy to useWave amplification devicesMachine gearing/transmission testingDuroplastElectrical and Electronics engineering

A method of producing an insert molded sensor assembly having at least one sensor element accommodated on a first side of a circuit board of the sensor assembly. During a first step, a plurality of pins are introduced and penetrate through the circuit board. The circuit board, including the at least one sensor element, is then disposed, during a second step, into a two-part insert mold tool so that the pins are supported on both sides of the circuit board in a direction transverse to a plane defined by the circuit board. A defined spacing distance, between a surface of the sensor element and the insert mold tool, is produced by the pins. During a third step of the method, the insert mold tool is filled with insert molding material, particularly a duroplast.

Owner:ZF FRIEDRICHSHAFEN AG

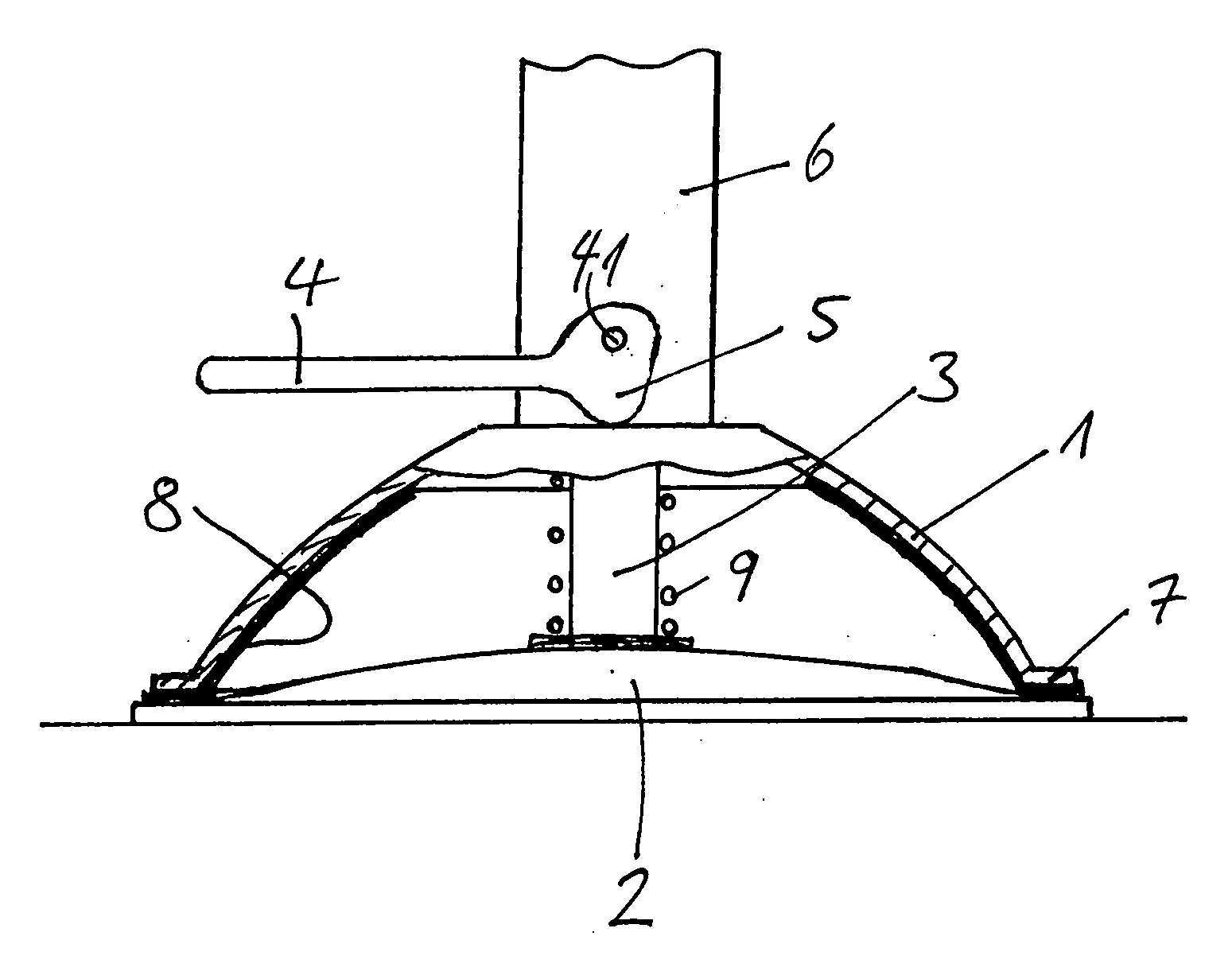

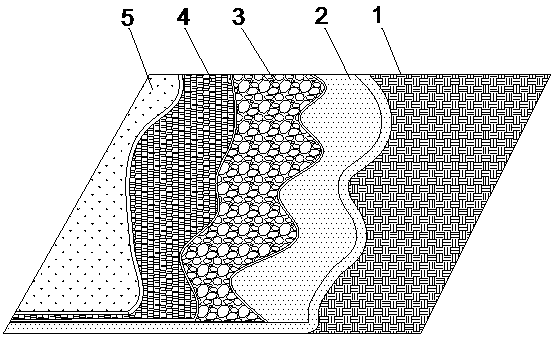

Super-high performance concrete compound pipeline preparation method

InactiveCN104908157AHigh strengthIncreased durabilitySurface layering apparatusManufacturing technologyPlastic pipework

The invention discloses a super-high performance concrete compound pipeline preparation method. A compound pipeline is composed of an outer layer super-high performance concrete pipeline and an inner layer plastic pipeline, and the pipeline forming die adopted comprises a steel outer die and a hard plastic inner die. The method comprises the steps that 1, the dies are assembled, a pumping machine is made to be connected with the dies, and the sealing property of the pumping machine is tested; 2, a super-high performance concrete mixture is prepared; 3, the super-high performance concrete mixture is added into the pumping machine, and a pumping ejecting technology is adopted for pipeline forming; 4, after the pumping is finished, a grouting hole of the assembled dies is sealed in time; 5, entire maintenance is conducted on the dies in the pipeline belt, and die removal can be conducted when super-high performance concrete reaches the die removal intensity; 6, the dies are removed, the steel outer die is removed, and the hard plastic inner die is remained; 7, the pipeline is subjected to wet and heat maintenance or natural maintenance after the die removal is conducted until the intensity meets the requirement. Compared with other traditional pipelines, the pipeline prepared by the super-high performance concrete compound pipeline preparation method has the advantages that the durability is good, the intensity is high, the wall thickness is small, the inner wall is smooth, floatation is not prone to occurring, the sealing performance is good, the inner die is not needed to be removed in the forming process, and the manufacturing technology is simple.

Owner:SOUTH CHINA UNIV OF TECH

Methods and apparatus for lamination of rigid substrates by sequential application of vacuum and mechanical force

ActiveUS20170182758A1Lamination ancillary operationsLayered product treatmentMechanical engineeringAir bubble

Method and apparatus for lamination of substrates, e.g. rigid plastic layers, to manufacture laminated products. The methods include the sequential application of vacuum and mechanical force through a two-stroke process performed by a lamination apparatus having one or more force-producing stroke cylinders. Actuation of a cylinder to produce a first stroke creates a sealed chamber within the apparatus, enclosing a stack of substrates to be laminated. The sealed chamber may be evacuated of air by application of a vacuum. Subsequent actuation of a cylinder to produce a second stroke applies mechanical force to the sealed chamber, which compresses the substrates into a laminated product substantially free of air bubbles or voids.

Owner:PERKINELMER HEALTH SCIENCES INC

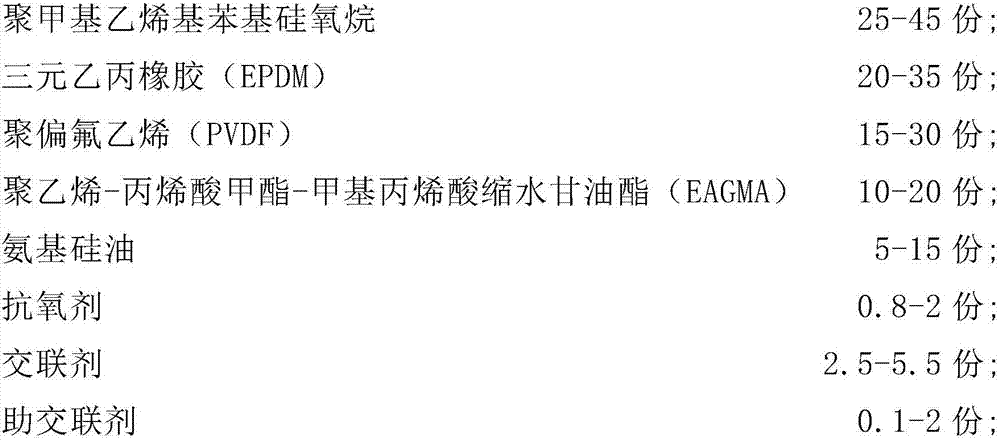

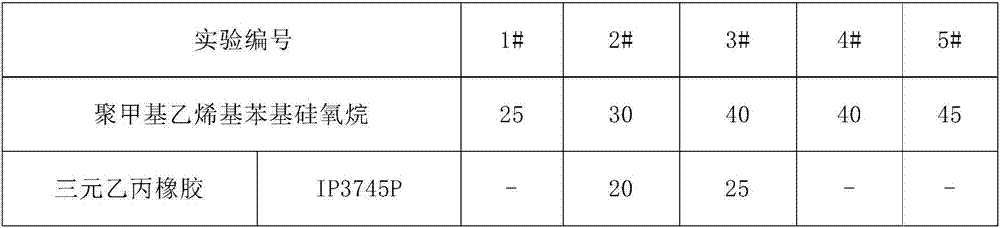

Special high-temperature-resisting and radiation-resisting insulating material for nuclear power station and preparation method of special high-temperature-resisting and radiation-resisting insulating material

InactiveCN107227025AGood compatibilityRaise the ratioRubber insulatorsPolyvinylidene fluorideAntioxidant

The invention discloses a special high-temperature-resisting and radiation-resisting insulating material for a nuclear power station and a preparation method of the special high-temperature-resisting and radiation-resisting insulating material. The special high-temperature-resisting and radiation-resisting insulating material is prepared from the following raw materials in parts by weight: 25 to 45 parts of polymethyl vinyl phenylsiloxane, 20 to 35 parts of ethylene-propylene-diene monomer, 15 to 30 parts of polyvinylidene fluoride, 10 to 20 parts of polyethylene-methylacrylate-glycidyl methacrylate, 5 to 15 parts of amino silicon oil, 0.8 to 2 parts of antioxidant, 2.5 to 5.5 parts of crosslinking agent and 0.1 to 2 parts of assistant crosslinker. The preparation method of the insulating material comprises the following steps: firstly, sufficiently banburying rubber and a compatilizer at a certain temperature by adopting an internal mixer; secondly, adding hard plastic and part of powder banburied agglomerated materials into screws by a two-cone forced feeding machine, adjusting the screw compression ratio, extrusion speed and extrusion temperature of the two screws, dynamically vulcanizing the insulating material, and enabling PVDF (Polyvinylidene Fluoride) to be dispersed in a continuous phase of blended rubber to form a sea island structure. The obtained insulating material has the advantages of elasticity of the rubber, certain tensile strength, and excellent high temperature resisting property and irradiation resisting property, and is particularly suitable for cable insulating materials of the nuclear power station.

Owner:上海至正新材料有限公司

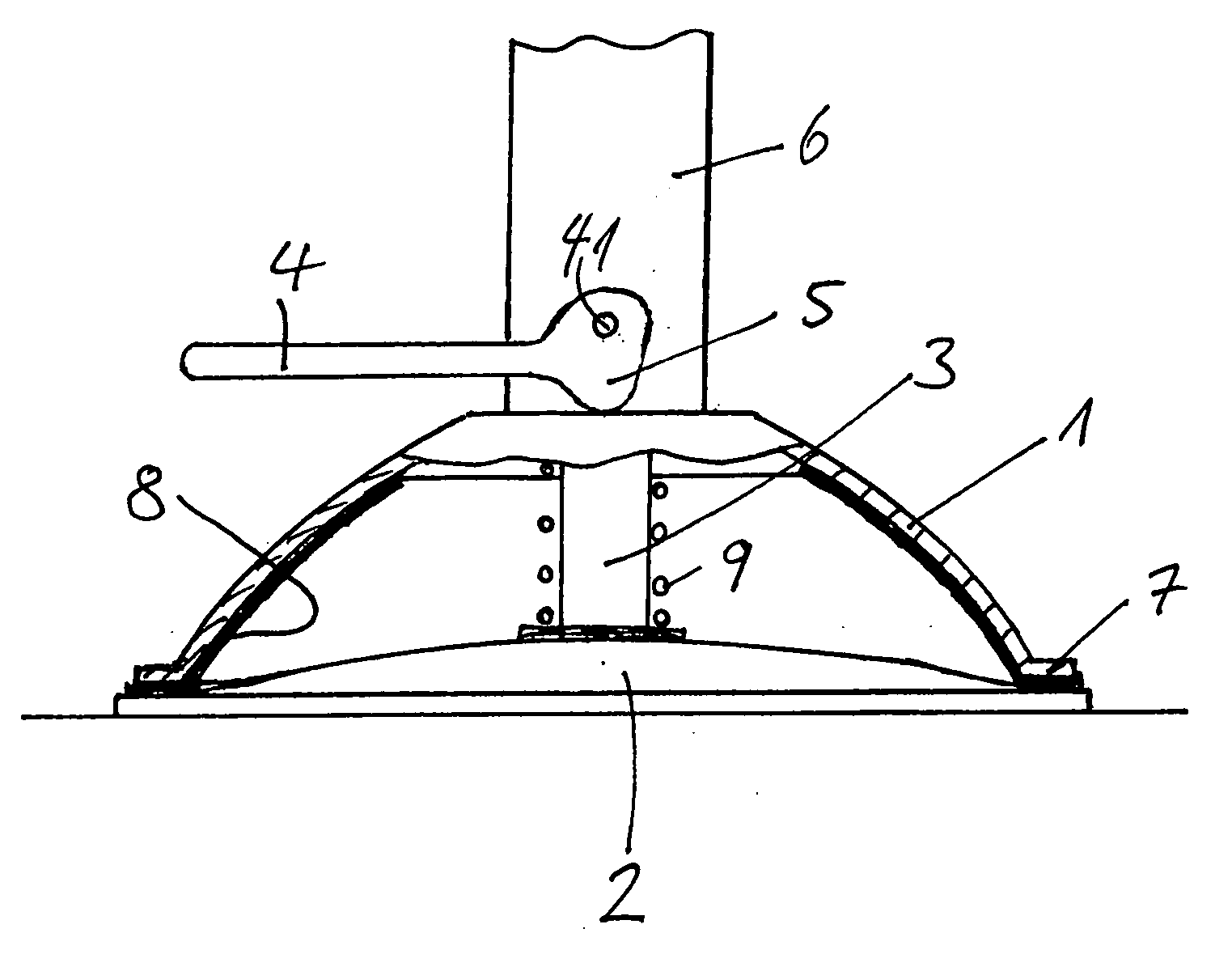

Suction base for an apparatus support device

InactiveUS20070051859A1Avoid stickingReduce thermal effectsStands/trestlesKitchen equipmentPlasticizerPlastic materials

In a suction base for the support of an apparatus, comprising a housing consisting of a hard plastic material and having an opening surrounded by a housing support edge and a suction membrane of PVC disposed in the housing so as to extend across the housing opening and being movable between a release position and an operating position in which the suction membrane is pulled into the housing and a vacuum is generated between the membrane and a support surface such that the support base is firmly pressed into contact with the support surface via the circumferential edge area of the membrane, a separating element is disposed between the housing and the suction membrane to prevent sticking of the membrane to the housing edge upon exposure of the suction base to heat and the release of plasticizer from the suction membrane.

Owner:RSM RICHTER CHAMBERLAND

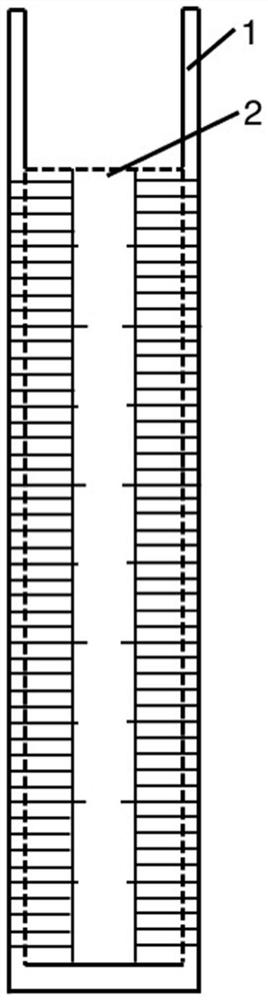

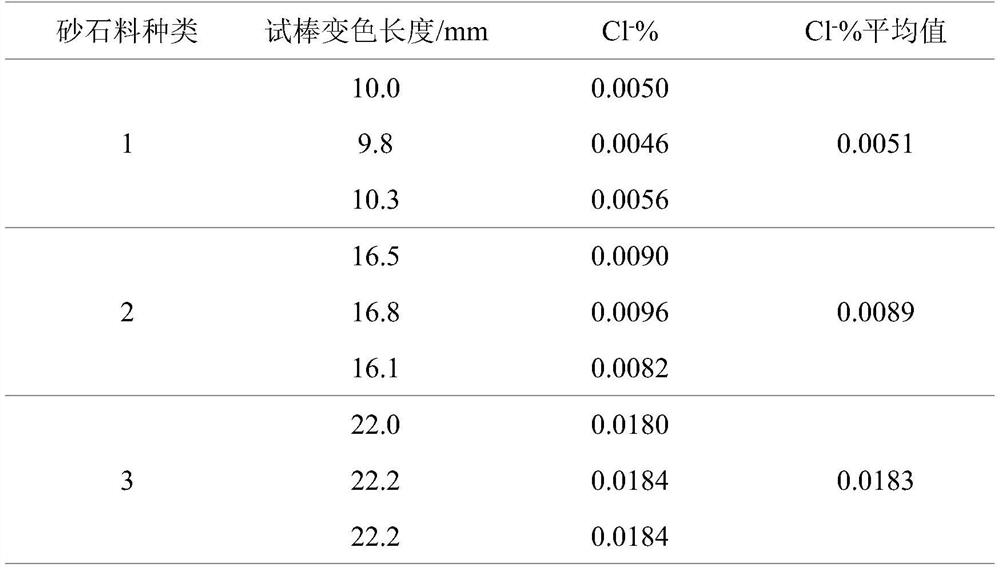

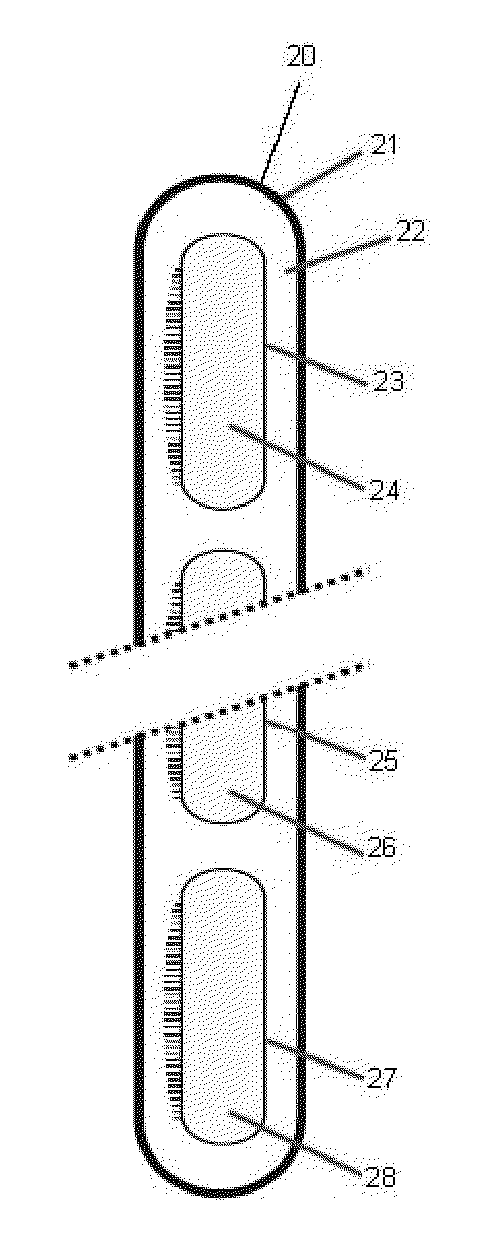

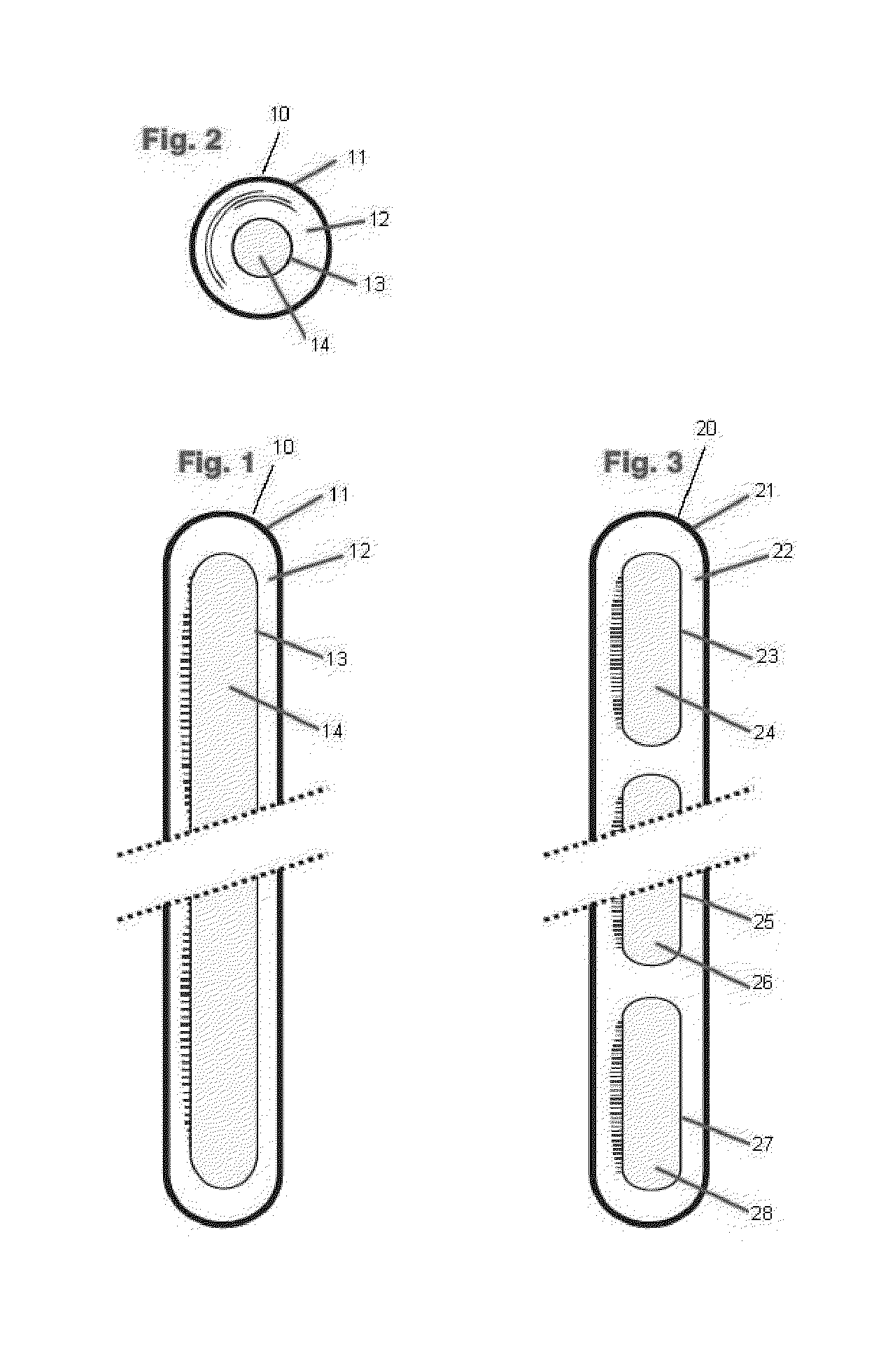

Gravity adsorption type test rod for rapidly detecting content of chloride ions in sandstone material, preparation method and application thereof

PendingCN111781193AHigh-precision detectionAvoid Adsorptive EffectsMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesFiberSilver chromate

The invention discloses a gravity adsorption type test rod for rapidly detecting the content of chloride ions in a sandstone material, a preparation method and application thereof. The test rod comprises a hard plastic shell with scales and a test rod body wrapped in the hard plastic shell, the test rod body is composed of cotton fibers, allochroic silica gel, silver chromate and a polycarboxylicacid water reducing agent, one end of the hard plastic shell is closed and used for fixing the test rod body, and the other end of the hard plastic shell is in an open state. Filtrate filtered from the sandstone material is sucked by a suction pipe, the filtrate is dripped into a vertically placed test rod body through an opening end, the color change length of the test rod body is read after thecolor of the allochroic silica gel at the bottom of the test rod body changes, and is compared with the color change length data of the sample, thereby obtaining the content of chloride ions in the sandstone slurry. The test rod disclosed by the invention has the characteristics of small size, convenient use, high stability, low cost and the like, is large in monitoring range and wide in application range, and has a good development prospect.

Owner:HOHAI UNIV

Reprocessed plastic classification recycling method and device

InactiveCN110948738AAchieve unscrewAchieve scratchHollow article cleaningPlastic recyclingElectric machineSlide plate

The invention discloses a reprocessed plastic classification recycling method. The method comprises the following steps of S1, firstly, sifting out a hard plastic bottle body; and S2, placing the hardplastic bottle body on a recycling device, and clamping and fixing the hard plastic bottle body with the recycling device. The invention furthermore discloses a reprocessed plastic classification recycling device. The reprocessed plastic classification recycling device is provided with a supporting plate, a first electric push rod, a transverse plate, vertical rods, connecting plates, connectionrods, L-shaped blocks and arc-shaped clamping plates, and in this way, the plastic bottle body can be conveniently and quickly clamped and fixed. Through the arrangement of a second electric push rod,a mounting plate, a servo motor, a U-shaped plate, a two-way threaded rod, a stepping motor, slide plates, a transverse rod and arc-shaped clamping blocks, a bottle cap of the plastic bottle body canbe unscrewed. Through the arrangement of a third electric push rod, a mounting block, a fourth electric push rod and a blade, a bottle label of the plastic bottle body can be scratched, so that the bottle label is conveniently torn down, the time and labor are saved, and the recycling efficiency is improved.

Owner:清远市佳易新材料科技有限公司

Method for sorting waste paper pulp, plastic and dust impurities from urban garbage

InactiveCN103639176ASolve the disadvantages that only a single product can be extractedIncrease profitSolid waste disposalFiberProcess engineering

The invention discloses a method for sorting waste paper pulp, plastic and dust impurities from urban garbage. The method comprises the following steps: firstly, carrying out sterilization and deodorization on the garbage, then putting the processed mixed garbage into clean water, adequately stirring the mixed garbage by utilizing a hinge type stirrer, and standing for a plurality of minutes so as to separate light plastic (such as films and foams) from the mixed garbage; secondly, adding a hydrogen dioxide solution into a precipitated mixture of the paper pulp, dust and other heavy plastic (such as rigid plastic fragments), and continuously stirring by utilizing the stirrer, so as to separate the paper pulp from the mixture; finally, separating the dust from the mixture of the heavy plastic and dust particles by utilizing a slag separator, so as to obtain the heavy plastic. According to the method, the high-purity paper pulp and plastic products can be further respectively obtained when dust impurities are removed and can be further machined into secondary fibers and regenerated plastic particles; the repeated recycling of garbage resources is realized, and the comprehensive utilization ratio of urban garbage raw materials is substantially increased.

Owner:青岛福创环境科技有限公司

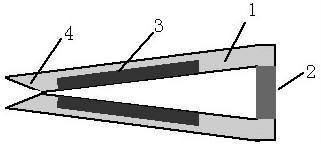

Magnetic folder

The invention discloses a magnetic folder, which comprises hard plastic sheets and platy magnets, wherein the platy magnets are mounted on the inner sides of the rigid plastic sheets, the tail end of each rigid plastic sheet is provided with a notch, and the top ends of the rigid plastic sheets are connected together through an elastic plastic sheet. The magnetic folder is capable of firmly clamping documents without looseness, not easy to be damaged, and convenient in folding without space occupancy.

Owner:SUZHOU INST OF TRADE & COMMERCE

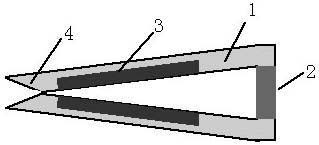

Cosmetic applicator with sponge to absorb substance and to prevent leakage thereof

ActiveUS9615646B2Prevent leakageMedical devicesMedical applicatorsSkin surfaceVolumetric Mass Density

A cosmetic applicator, comprising a sponge to absorb substance and prevent leakage thereof is provided herein. The sponge having an elastic open-cell of a three-dimensional membrane structure of elastic polymer and is double over molded in combination with the rigid plastic base. The sponge has predefined density enabling to absorb the substance and skin surface having predefined thickness to prevent a spontaneous release of the substance. The substance may be squeezed out of the sponge only when applying pressure on the sponge. A Radio Frequency Identification (RFID) tag is integrated to the rigid plastic base to allow information related storage.

Owner:SYNOIA TECH

Lowered exotherm thermoset compositions

InactiveUS7750072B2Lowered exothermCosmetic preparationsNon-fibrous pulp additionPolymer scienceAcrylic resin

Owner:DE NEEF CONSTR CHEM +1

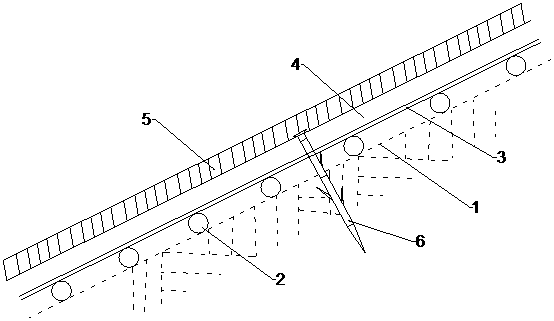

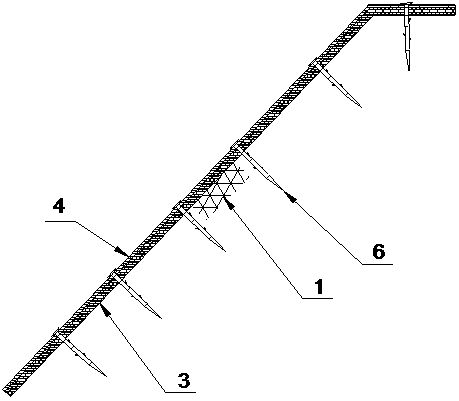

Degradable ecological vegetative blanket and preparation method thereof

InactiveCN110663507AStable growthLong term greeningHops/wine cultivationGrowth substratesAdhesiveEnvironmental engineering

The invention discloses a degradable ecological vegetative blanket and a preparation method thereof. According to the technical scheme, the degradable ecological vegetative blanket is characterized bycomprising a polyethylene net and a thin sponge which are sequentially arranged from top to bottom, seeds, fertilizer and a soil improving agent which are attached to the thin sponge, and hard plastic piles used for fixing, wherein the polyethylene net is connected with the thin sponge through an adhesive. The vegetative blanket is laid on a current-situation-soil construction slope and fixed bythe hard plastic piles, sandy soil is laid on the surface layer of the polyethylene net, and the thin sponge is a natural degradable material. The preparation method includes: removing weeds, gravels,capping mass and sundries on the slope; embedding the thin sponge and the polyethylene net into a position, 10cm in depth, at the top of the slope, and allowing the rest part of the vegetative blanket to attach to the slope and spread; when a second vegetative blanket is need, arranging a first vegetative blanket on the second vegetative blanket in an overlapping manner, wherein the thickness ofthe two overlapped vegetative blanket is 10cm; driving the hard plastic piles into the vegetative blanket to perform fixation, and laying the sandy soil at the upper end of the polyethylene net. Thedegradable ecological vegetative blanket is simple in construction and capable of fast achieving slope greening.

Owner:苏州日植环境技术有限公司

Sealing joint for low pressure pipe systems and method of manufacture

A method and sealing gasket are shown for providing a sealing joint between a spigot section and a socket section of low pressure plastic pipe, such as drain waste vent pipe that require a minimum of tools and operational steps to complete. The sealing gasket is installed in one of the sections to be joined and the spigot section is inserted within a mouth opening of the socket section with the sections being pressed together in a single operation, thereby forming both the joint and the seal. The sealing gasket is a composite gasket made with one section of a hard plastic material and one section of a thermoplastic elastomer material. No glue or adhesive is required.

Owner:S & B TECHN PRODS

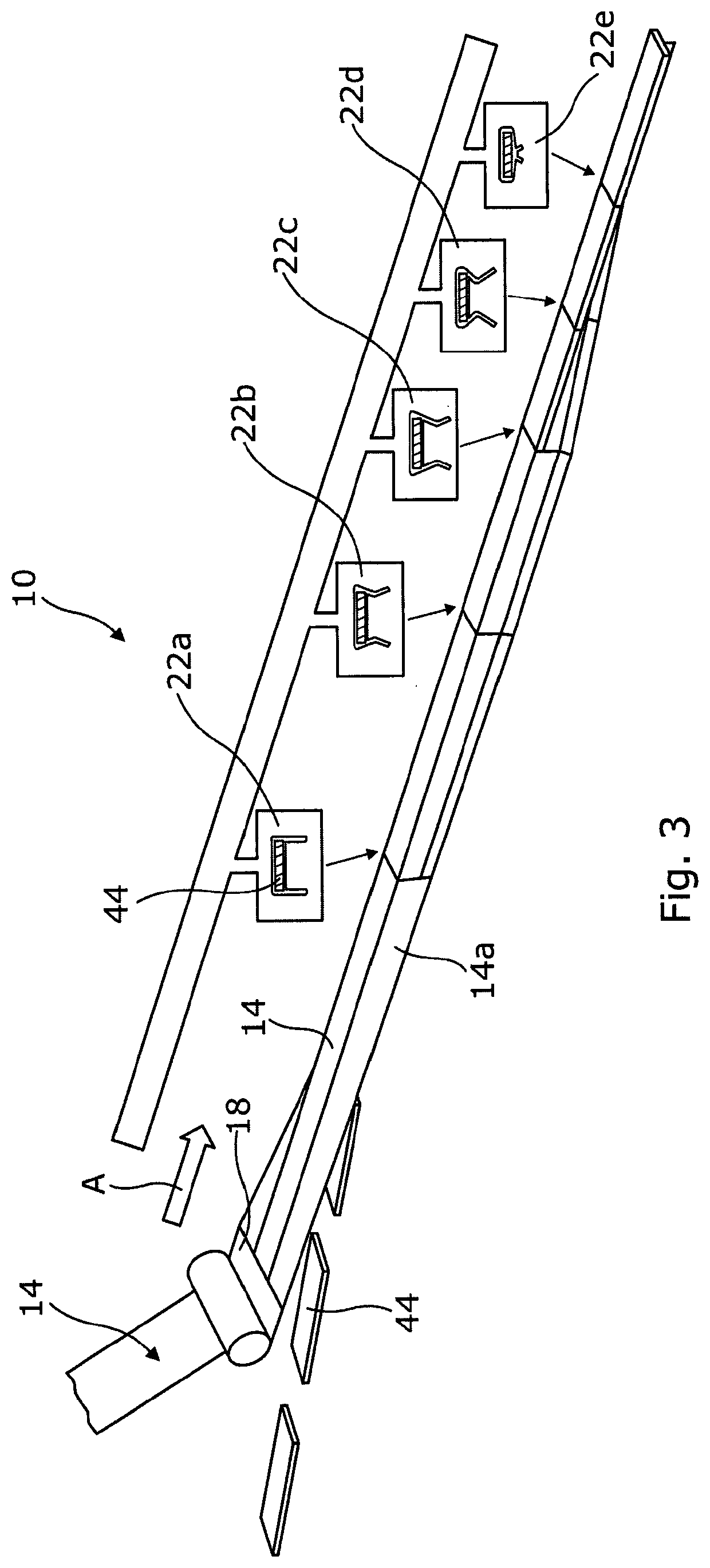

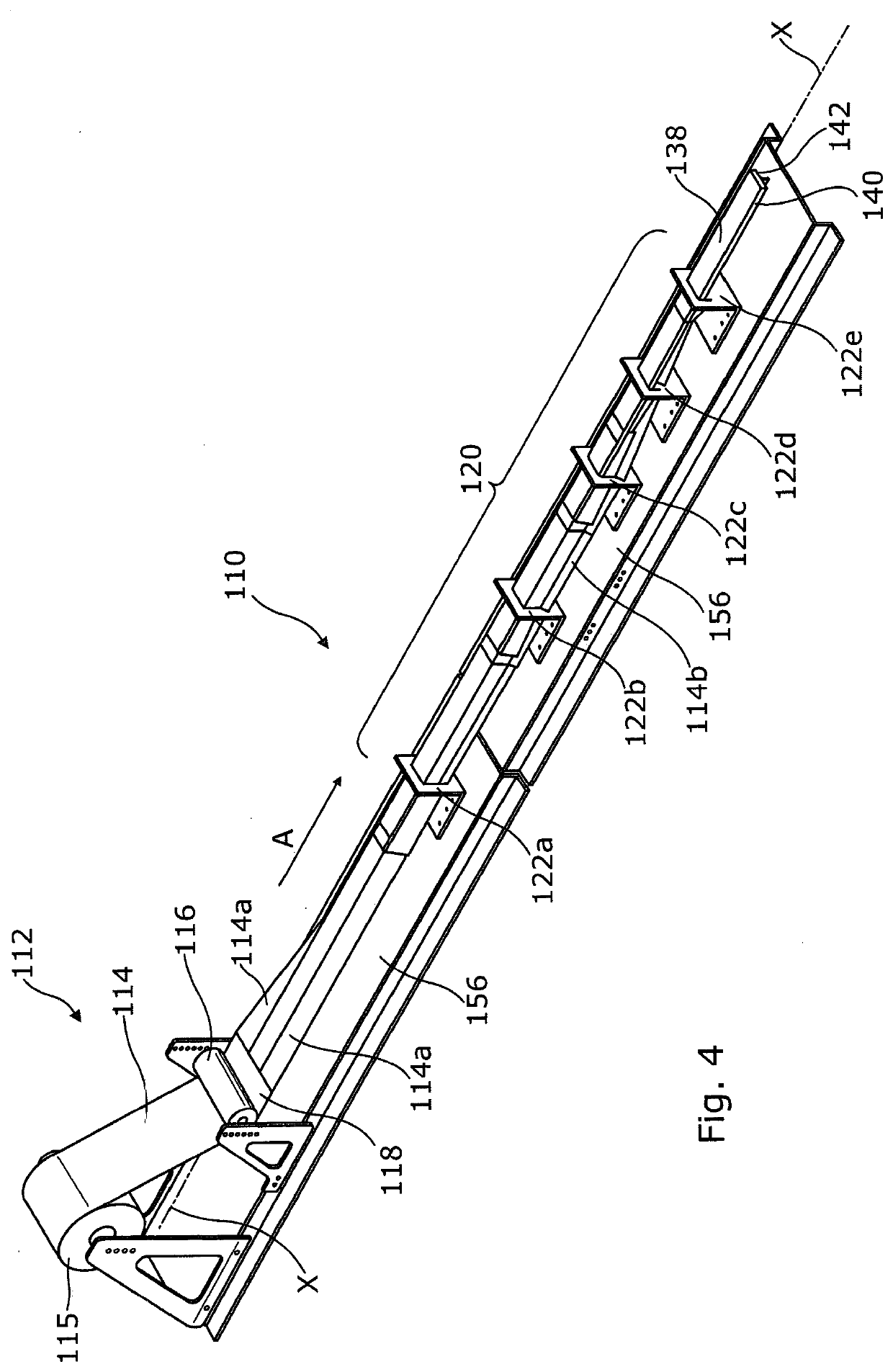

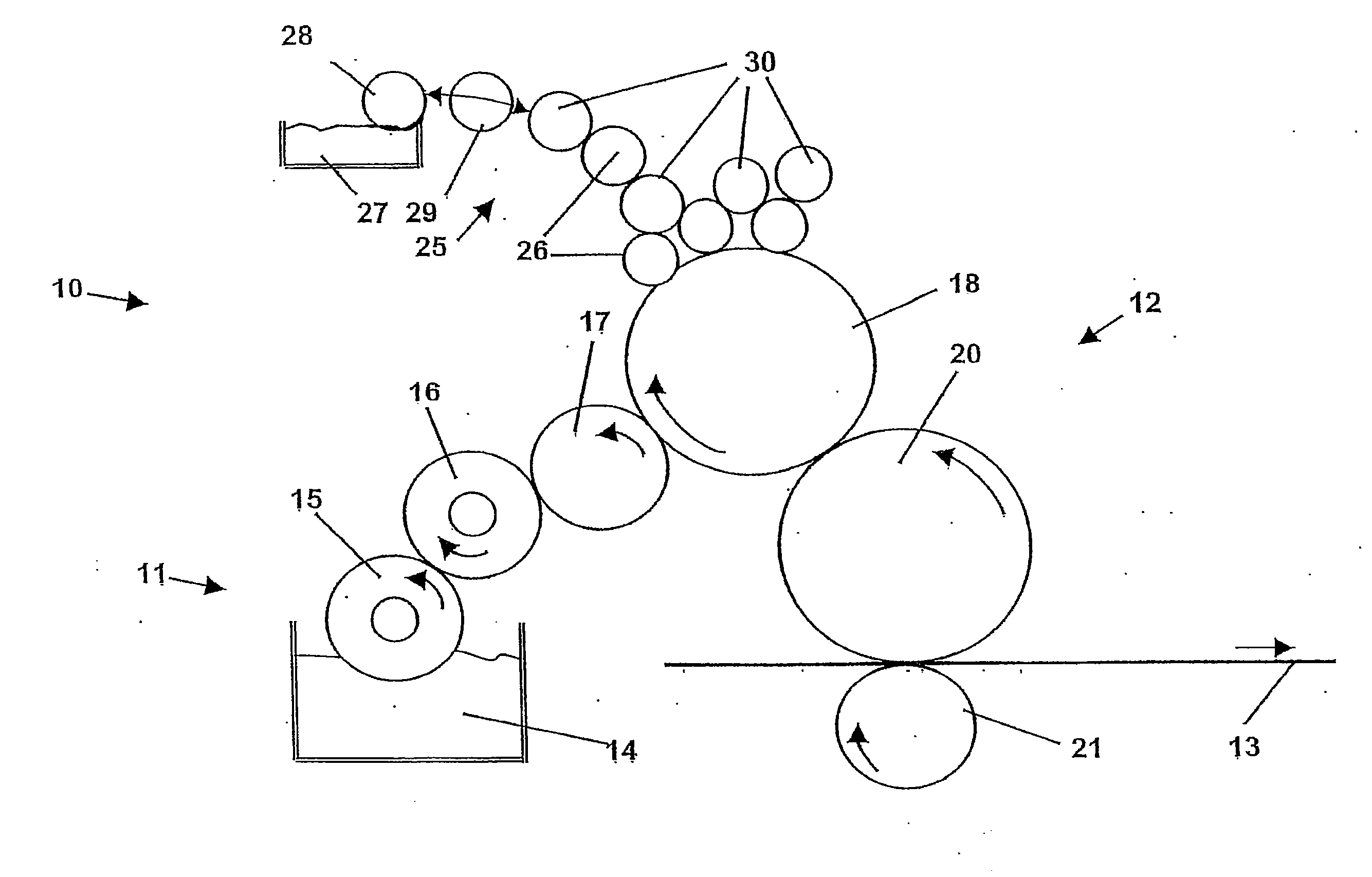

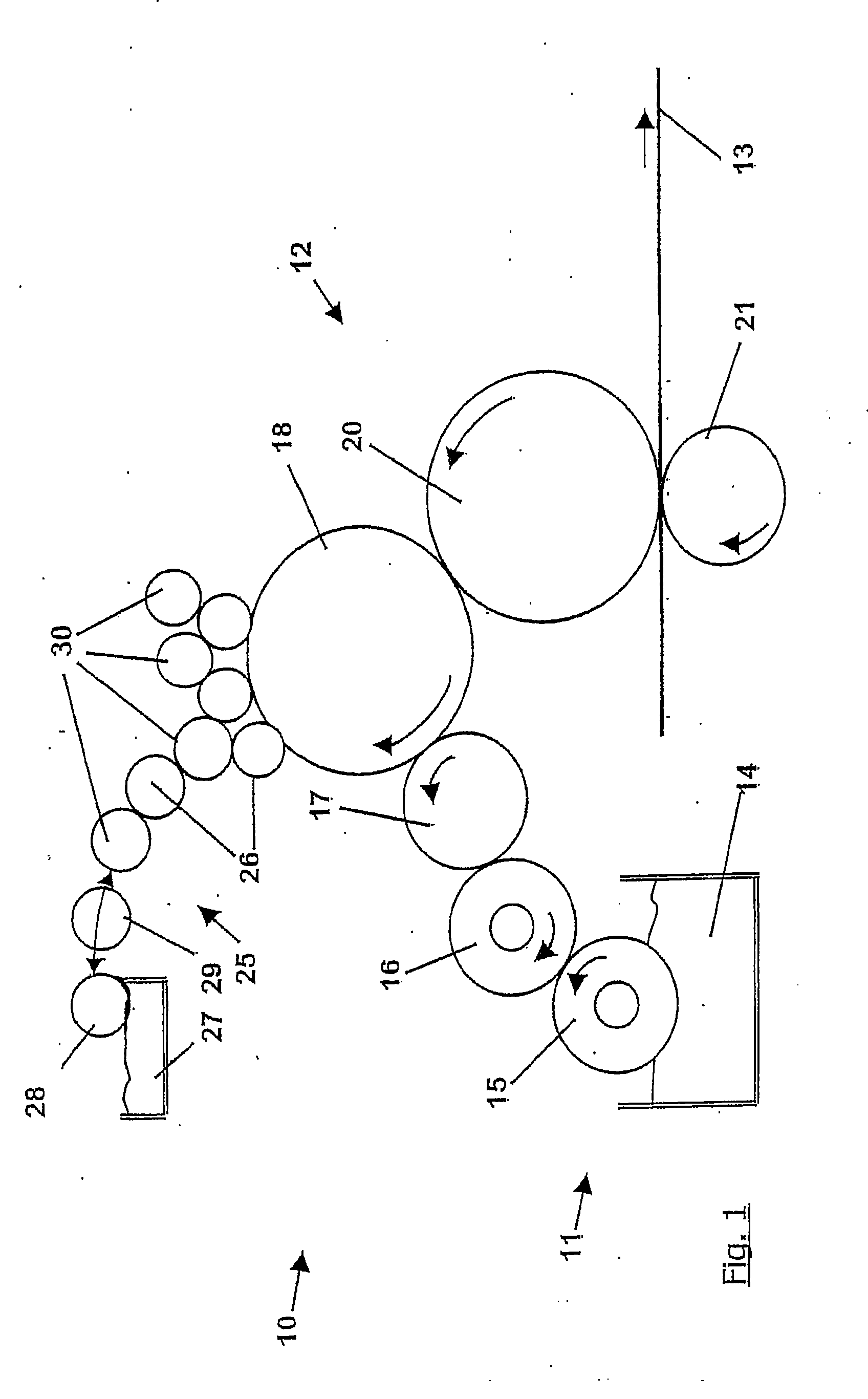

Apparatus and methods for producing tubular packages

PendingUS20210403185A1Easy to manufactureEasy to set upSuccessive articlesPaperboardStructural engineering

Apparatus (10) for producing tubular packages includes a packaging material dispenser (12) and a forming section (20). The forming section (20) comprises a series of package formers (22a-22e) aligned in the machine direction, each defining a packaging material folding channel (24) through which the packaging material passes. The channels (24) of the package formers in the series vary in shape such that as the packaging material passes through the forming section it is gradually folded about a longitudinal axis from a planar configuration into a tubular structure. A series of items (44) to be packaged is conveyed in the machine direction and may be sequentially introduced proximal to the packaging material (14) at a location such that the packaging material is subsequently folded about each item in turn as it continues through the forming section. The apparatus may be a horizontal or vertical form, fill seal type apparatus. The packaging material (14) may be a semi-rigid packaging material such as paperboard, cartonboard, or semi-rigid plastics.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Use of thermosetting polymeric powder composition

ActiveCN110494492AAdditive manufacturing apparatus3D object support structuresPolymer sciencePolymer chemistry

The present invention relates to the use of a thermosetting polymeric powder composition in a 3D dry printing process to produce a 3D duroplast object, the composition comprising at least one curablepolymeric binder material with free functional groups, wherein during the 3D dry printing process the formed object is only partially cured to a curing degree of below 90 %, preferably below 60 %, most preferably between 35 % and 60 %, and the printing process is being followed by a post treatment comprising a heat treatment step to fully cure the printed object into a 3D duroplast object.

Owner:TIGERWERK LACK & FARBENFAB

Exothermic semi-rigid plastic stick

InactiveUS20110290232A1Negates risk of shock and likeExothermal chemical reaction heat productionOther heat production devicesEngineeringChemical reaction

Owner:GROUP JDS CORP

Contact or transfer roller

InactiveUS20110041713A1Reduce surface tensionIncrease surface tensionPrinting roller shellsPrinting blanketsEpoxyLacquer

A distributor or transfer roller is provided for printing machines, in particular for offset printing machines. The roller has at least a substantially rigid core and a cover made of a polymeric material applied on and permanently fixed to the core. The cover is applied directly on the core or on a hard-elastic intermediate layer having a hardness of ≧10 Shore D, optionally by an adhesion promoting layer. The cover is at least substantially made of a fluorinated polymer and has a hardness of ≧15 Shore D and / or a scratch hardness according to ISO 15184 of 6B or harder. The polymeric material can be a duroplastic material, a fluorinated polyurethane resin, polyester resin, epoxy resin, acrylate resin and / or polyether resin, a highly cross-linked non-elastic fluoropolymer, a fluorothermoplastic, a polymeric non-elastic fluorosilicone, or a fluoropolymer lacquer.

Owner:WEROS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com