High-frequency torsional fatigue testing method and device for hard plastic pieces

A hard plastic, torsional fatigue technology, applied in the direction of measuring devices, analysis materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

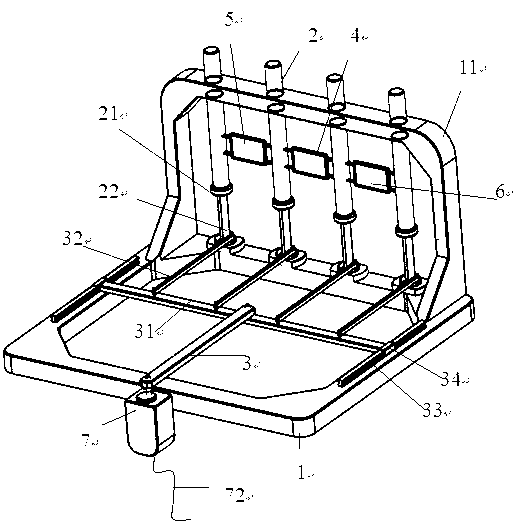

Image

Examples

example 1

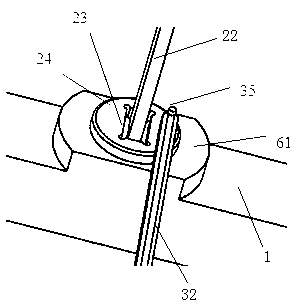

[0061] The following are specific examples:

[0062] Place 4 standard splines of 80×10×4mm made of polypropylene between the upper fixture 21 and the lower fixture 23, adjust the temperature and humidity of the test to make it reach the standard state, turn on the power switch of the device, and set the working frequency to 3Hz, fatigue time is set to 48h. Obtain the fatigue characteristic curve as Figure 4 As shown, the ordinate is the internal stress of the spline, and the abscissa is the fatigue times. Points A, B, C, and D in the figure are 0, 1,000, 10,000, and 200,000 times respectively.

[0063] The following table shows the tensile strength of the spline before and after fatigue (in the table, A represents before fatigue, B represents after fatigue):

[0064] Table 1

[0065] sample Tensile strength (MPa) sample Tensile strength (MPa) A1 31.82 B1 26.37 A2 32.35 B2 27.03 A3 31.46 B3 26.52 A4 32.21 B4 26.74

example 2

[0067] The spline specification in embodiment 1 is changed into the standard spline of 125 * 13 * 13mm, according to the same operating method as in embodiment 1, obtain fatigue curve such as Figure 5 As shown, the ordinate is the internal stress of the spline, and the abscissa is the fatigue times. Points A, B, C, and D in the figure are 0, 1,000, 10,000, and 200,000 times respectively.

[0068] The following table shows the tensile strength of the spline before and after fatigue (in the table, A represents before fatigue, B represents after fatigue):

[0069] Table 2

[0070] sample Tensile strength (MPa) sample Tensile strength (MPa) A1 79.22 B1 63.85 A2 80.07 B2 63.67 A3 78.48 B3 64.44 A4 81.23 B4 65.19

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com