Pine-tree solar cell landscape tree

A technology of solar cells and pine trees, applied in the field of solar photovoltaics, can solve the problems of large floor area and low utilization rate of sunlight by flat-panel cells, and achieve the effects of low cost, corrosion resistance, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

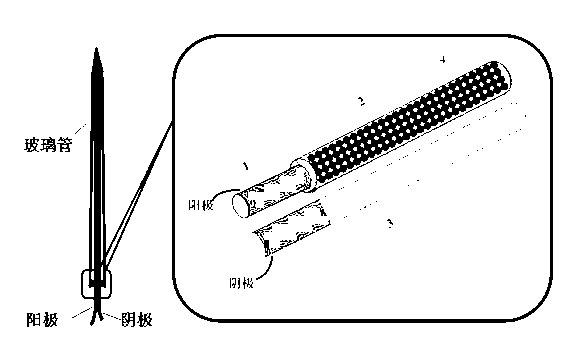

[0022] Will use polishing liquid (V (deionized water): V (HNO 3 ): V(HF)=5:4:1) The pretreated Ti wire is used as the anode, and the graphite sheet is used as the cathode, and the voltage is controlled by a DC stabilized power supply to 60V, containing 0.6wt% NH 4 F and 3.5v% H 2 The 150ml ethylene glycol solution of O is used as the electrolyte, anodized at room temperature and under magnetic stirring for 1 hour, and a layer of TiO can be coated on the surface of the Ti wire. 2 nanotube film. The anodized Ti wire (0.2-0.4 mm) was heat-treated at 450°C for 2 hours. After cooling to room temperature, with 0.2M TiCl 4 Treat in a water bath at 60°C for 1 hour, then heat-treat at 450°C for 30 minutes, cool naturally to 80°C, and put in 0.5 mM N719 dye solution in absolute ethanol to sensitize overnight to obtain sensitized TiO 2 nanotube film.

[0023] Conductive carbon fibers (0.4 mm in diameter) were ultrasonically cleaned with deionized water, absolute ethanol and acetone ...

Embodiment 2

[0028] Will use polishing fluid (V (deionized water): V (HNO 3 ): V(HF)=5:4:1) The pretreated Ti wire is used as the anode, and the graphite sheet is used as the cathode, and the voltage is controlled by a DC stabilized power supply to 60V, containing 0.6wt% NH 4 F and 3.5v% H 2 The 150ml ethylene glycol solution of O is used as the electrolyte, anodized at room temperature and under magnetic stirring for 1 hour, and a layer of TiO can be coated on the surface of the Ti wire. 2 nanotube film. The anodized Ti wire (0.2-0.4 mm) was heat-treated at 450°C for 2 hours. Naturally cooled to 80°C, put in 0.5 mM N719 dye solution in absolute ethanol and sensitized overnight to obtain sensitized TiO 2 nanotube film. The preparation process of counter electrode and pine leaf solar cell is as embodiment 1.

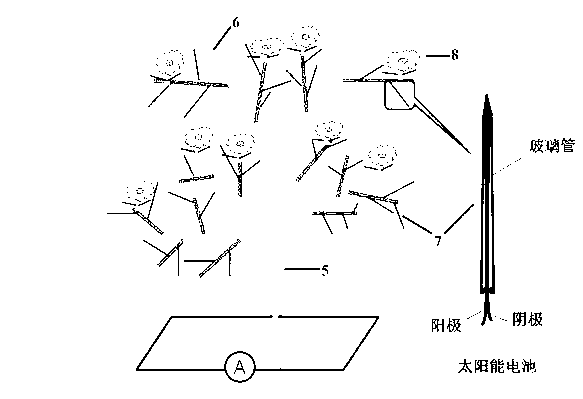

[0029] The trunk and 10 branches of the pine tree are made of hard plastic and soft plastic coated copper wire with good conductivity respectively. The dye-sensitized solar cell...

Embodiment 3

[0031] Dye-sensitized TiO 2 The preparation process of the nanotube film is as in Example 1. The outer surface is coated with dye-sensitized TiO 2 The Ti wire of the nanotube film was used as the working electrode, and the platinum sheet was used as the counter electrode. The electrochemical workstation was used to control the constant current of 0.0002A, and 0.1M CuSO 4 , 0.2M citric acid, 0.2M KSCN and deionized water were uniformly mixed as electrolyte, and electrochemically deposited under magnetic stirring at room temperature for 1800s. Dye-sensitized TiO 2 A transparent CuSCN film was deposited on the surface of the nanotube film. N 2 After being blown dry in the air flow, put it into a transparent glass tube in parallel with the platinum-loaded conductive carbon fiber, and seal it with silicon rubber to obtain a solid pine leaf-shaped dye-sensitized solar cell with a length of about 4 cm.

[0032] The trunk and four branches of the pine tree are made of hard plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com