Patents

Literature

34results about How to "Efficient granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

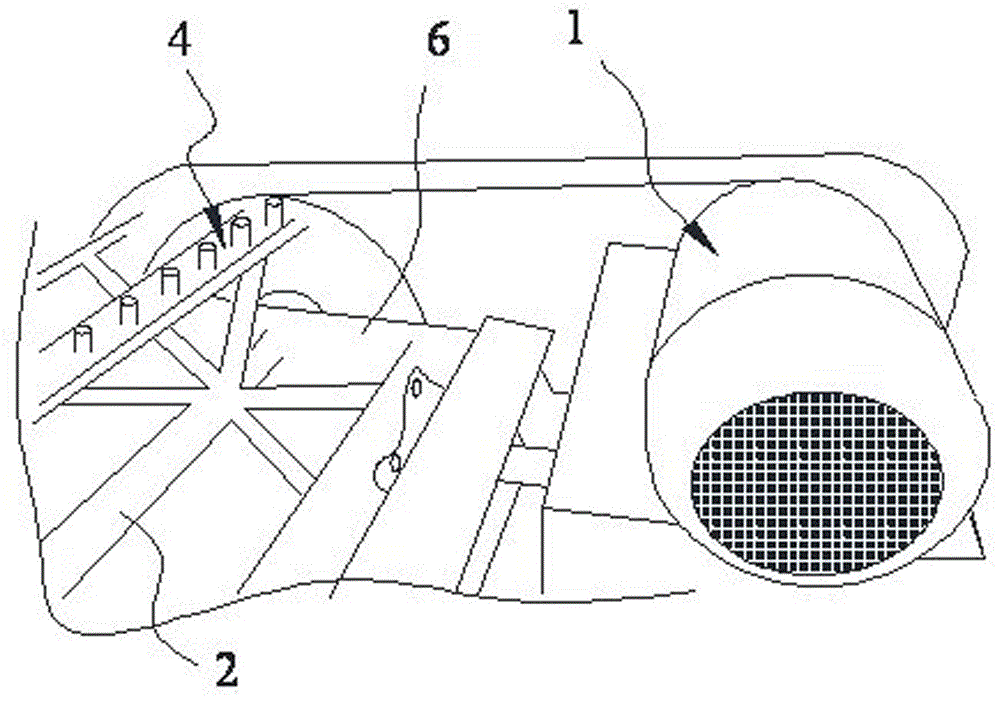

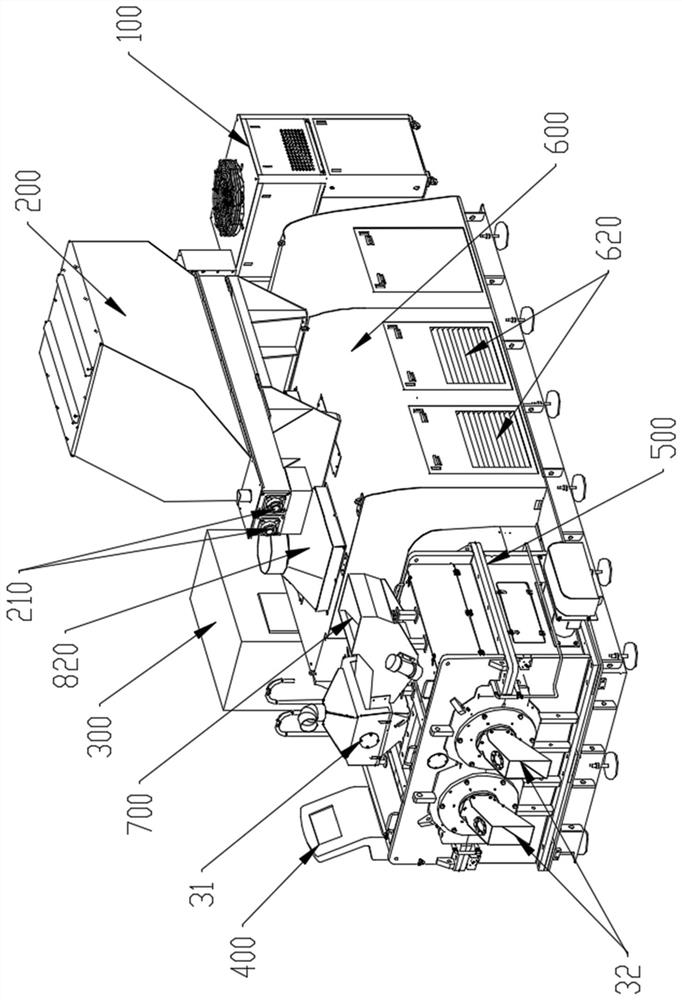

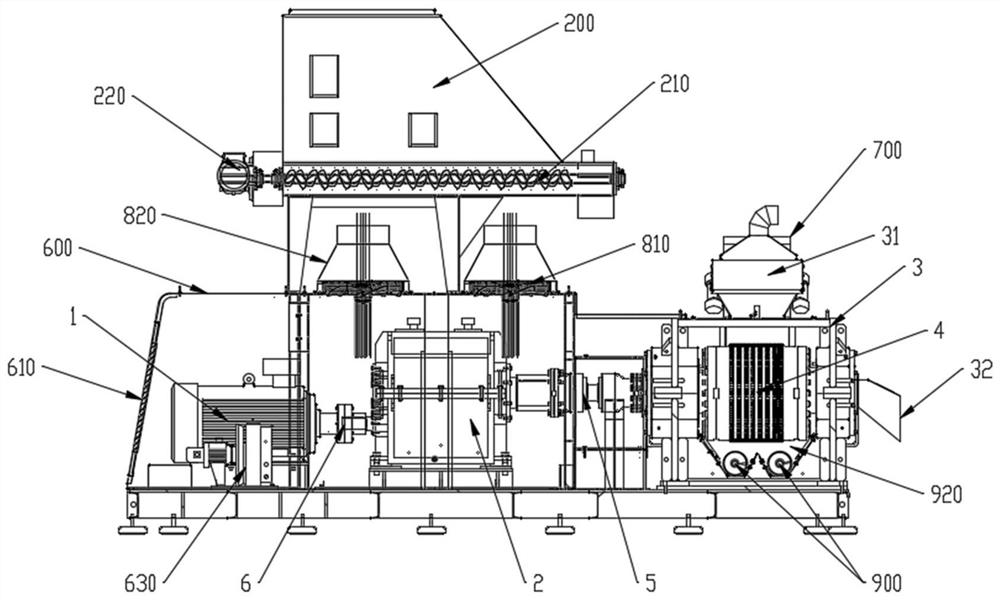

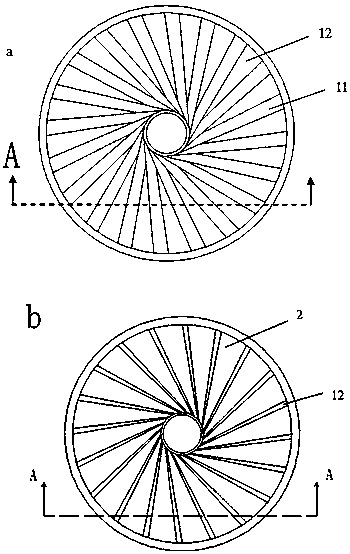

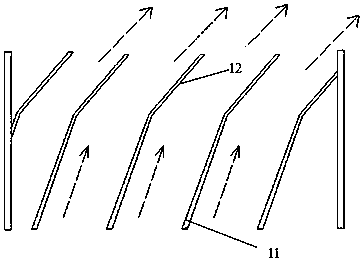

Liquid molten slag dry type centrifugal pelletization and waste heat recycling system

ActiveCN108359756AEfficient granulation and heat efficiencyEfficient granulationRecycling and recovery technologiesHandling discharged materialExhaust gasMoving bed

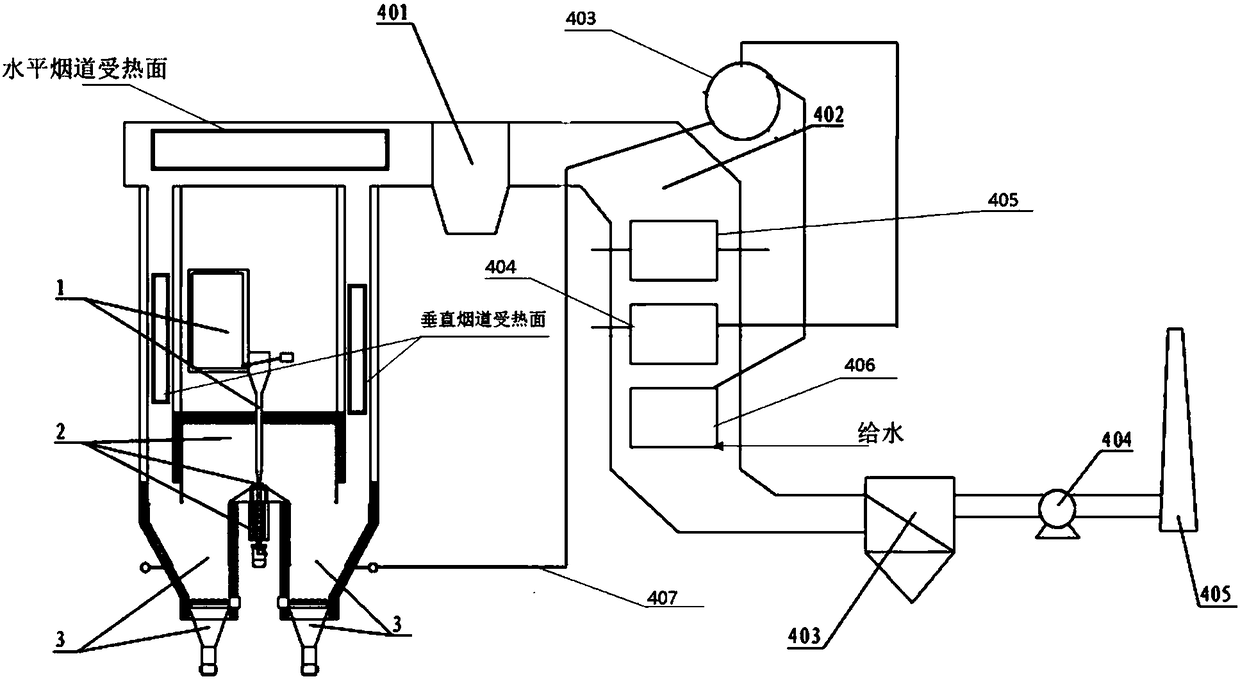

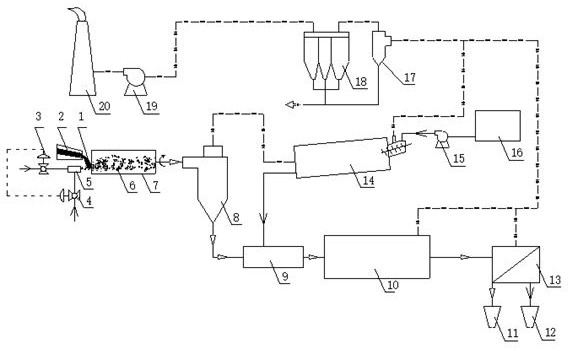

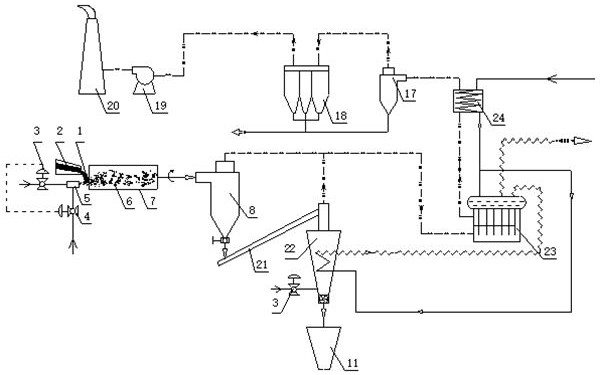

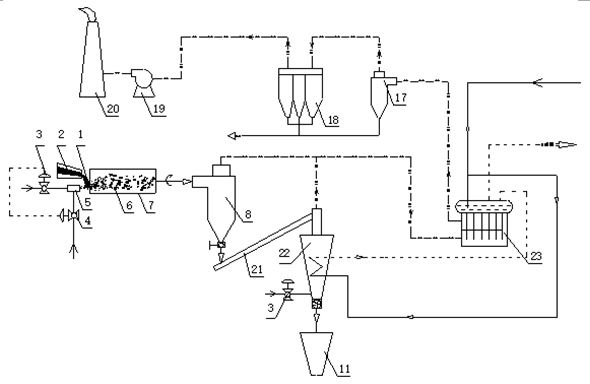

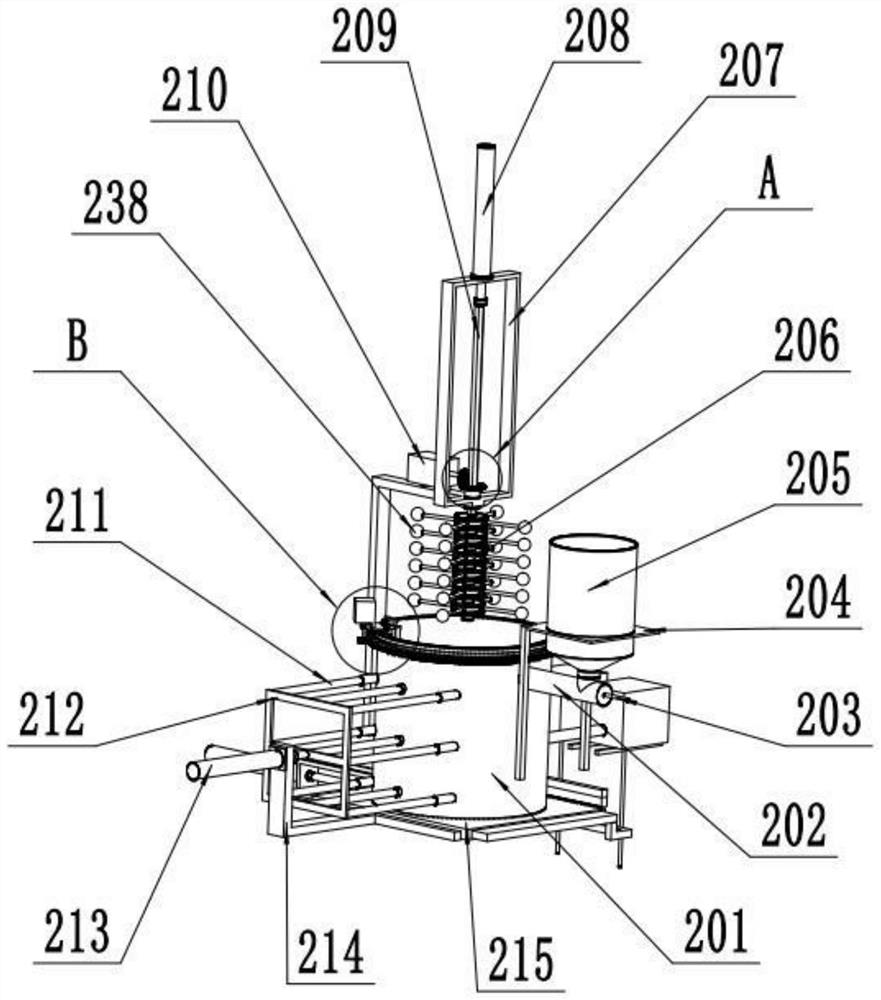

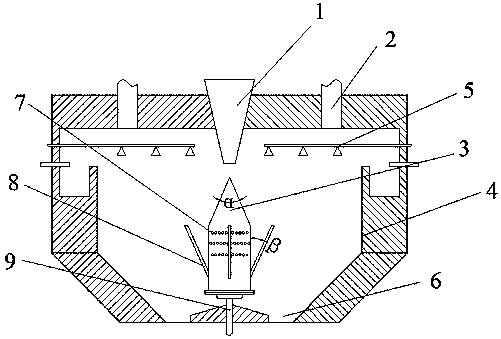

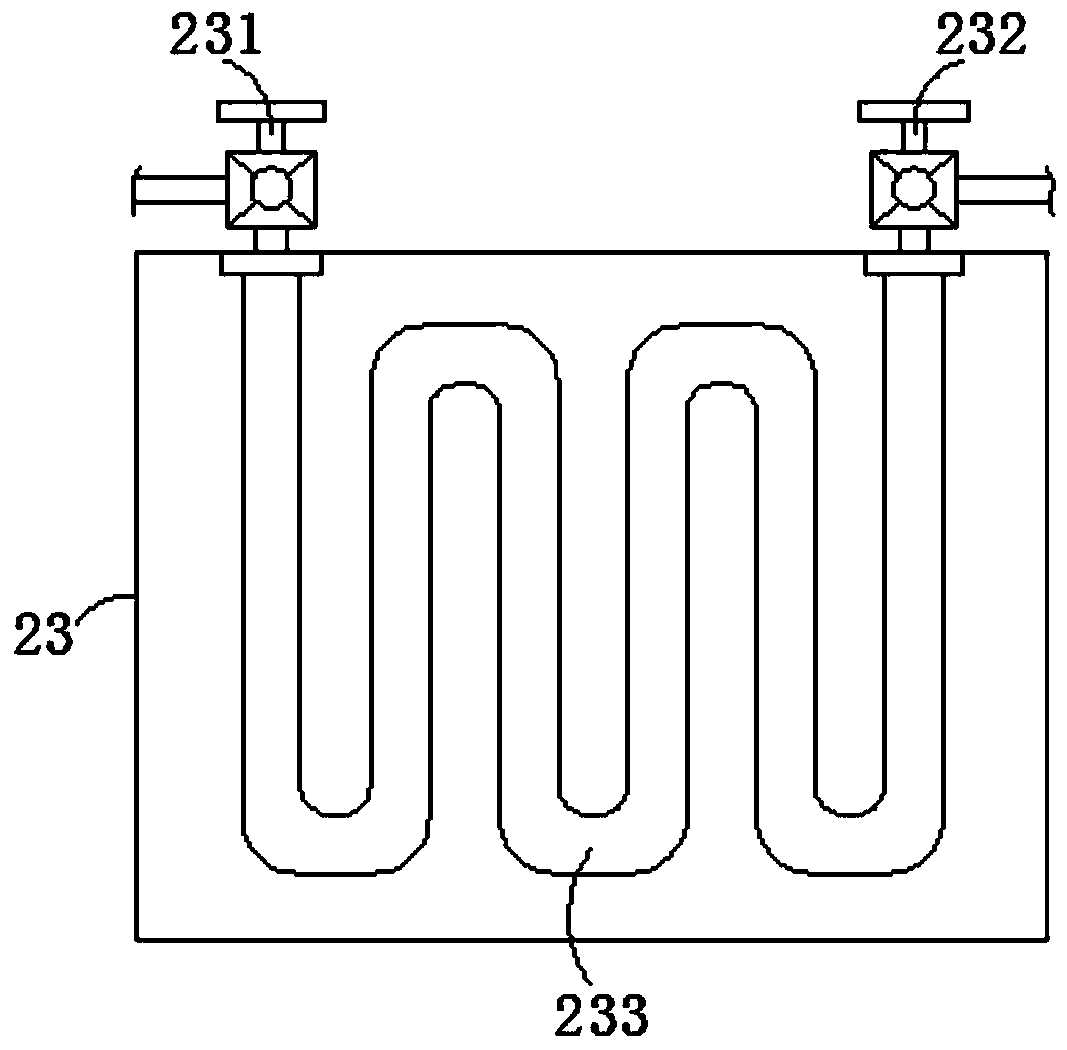

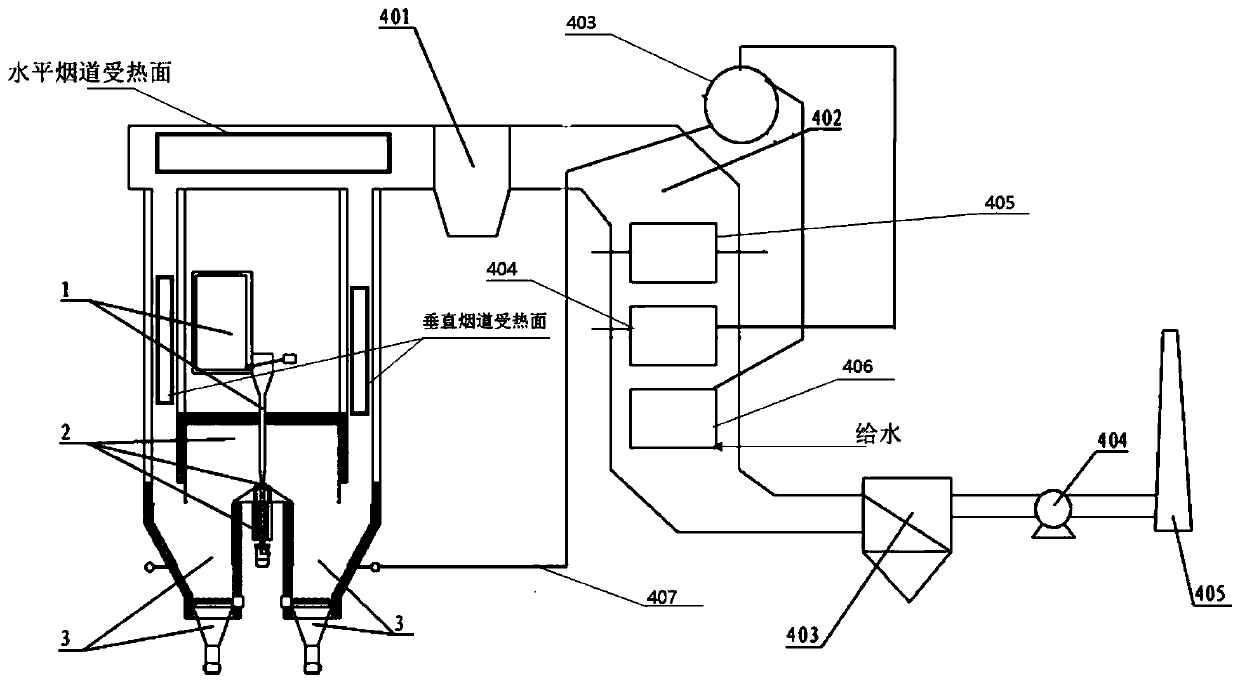

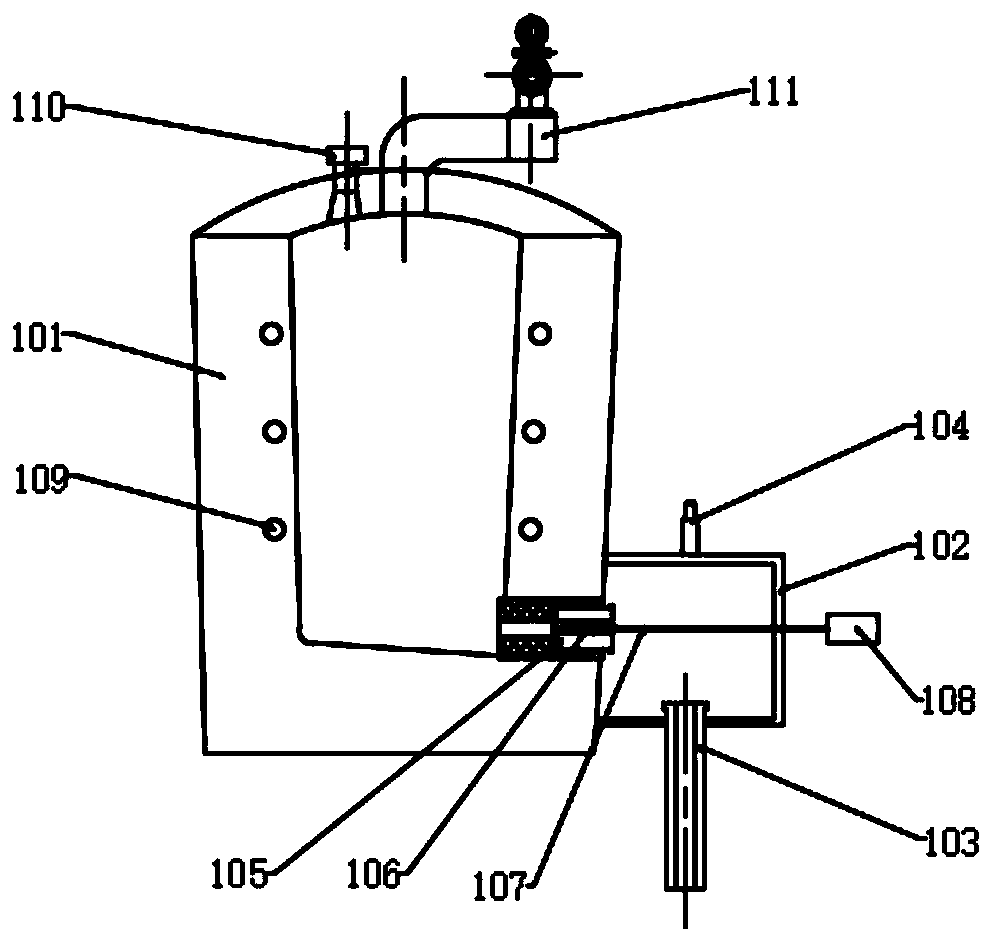

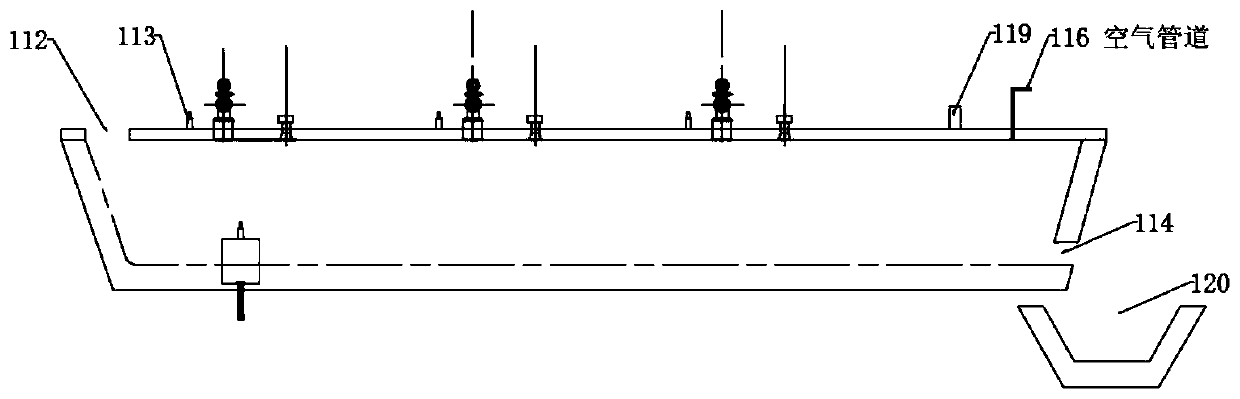

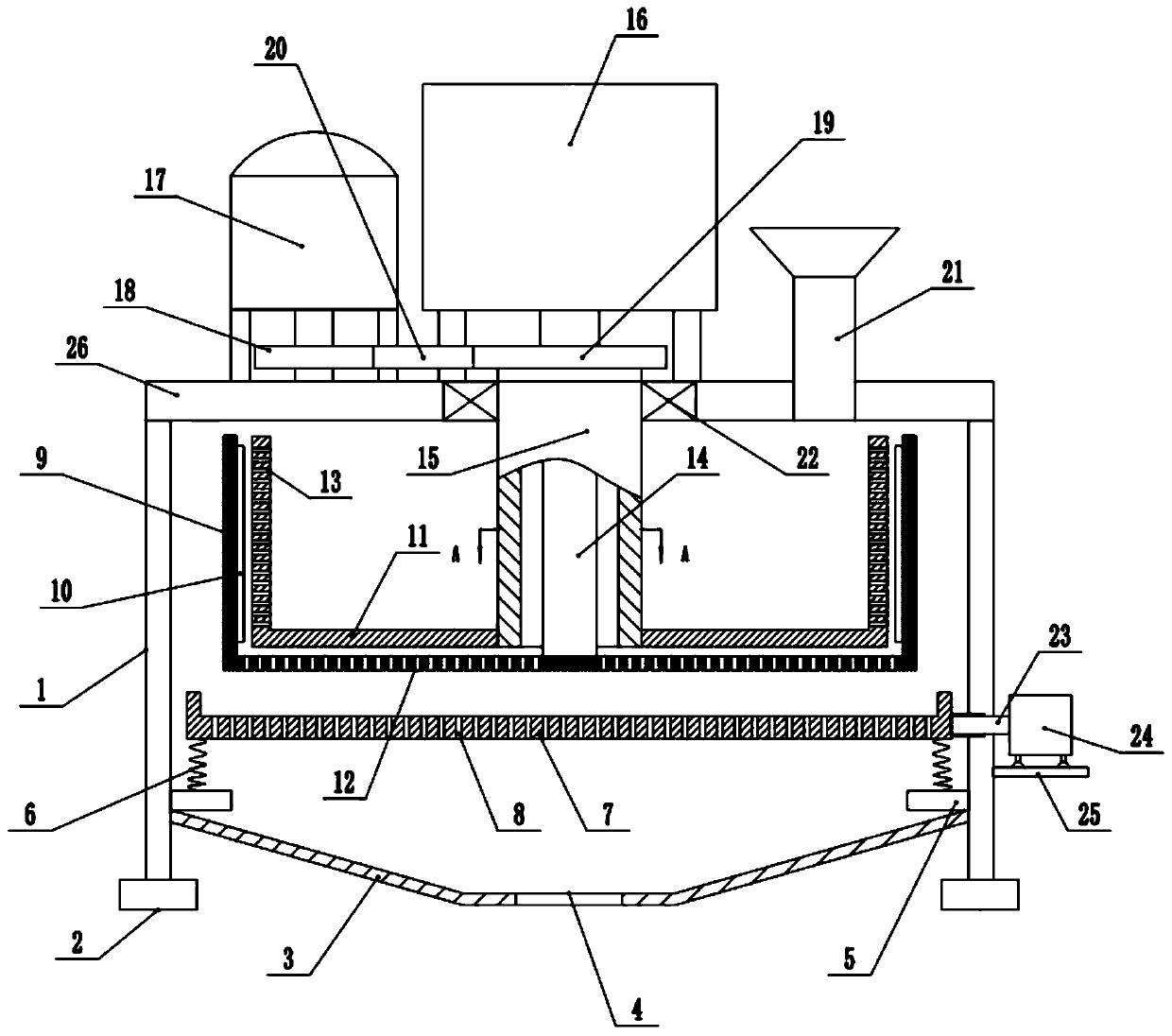

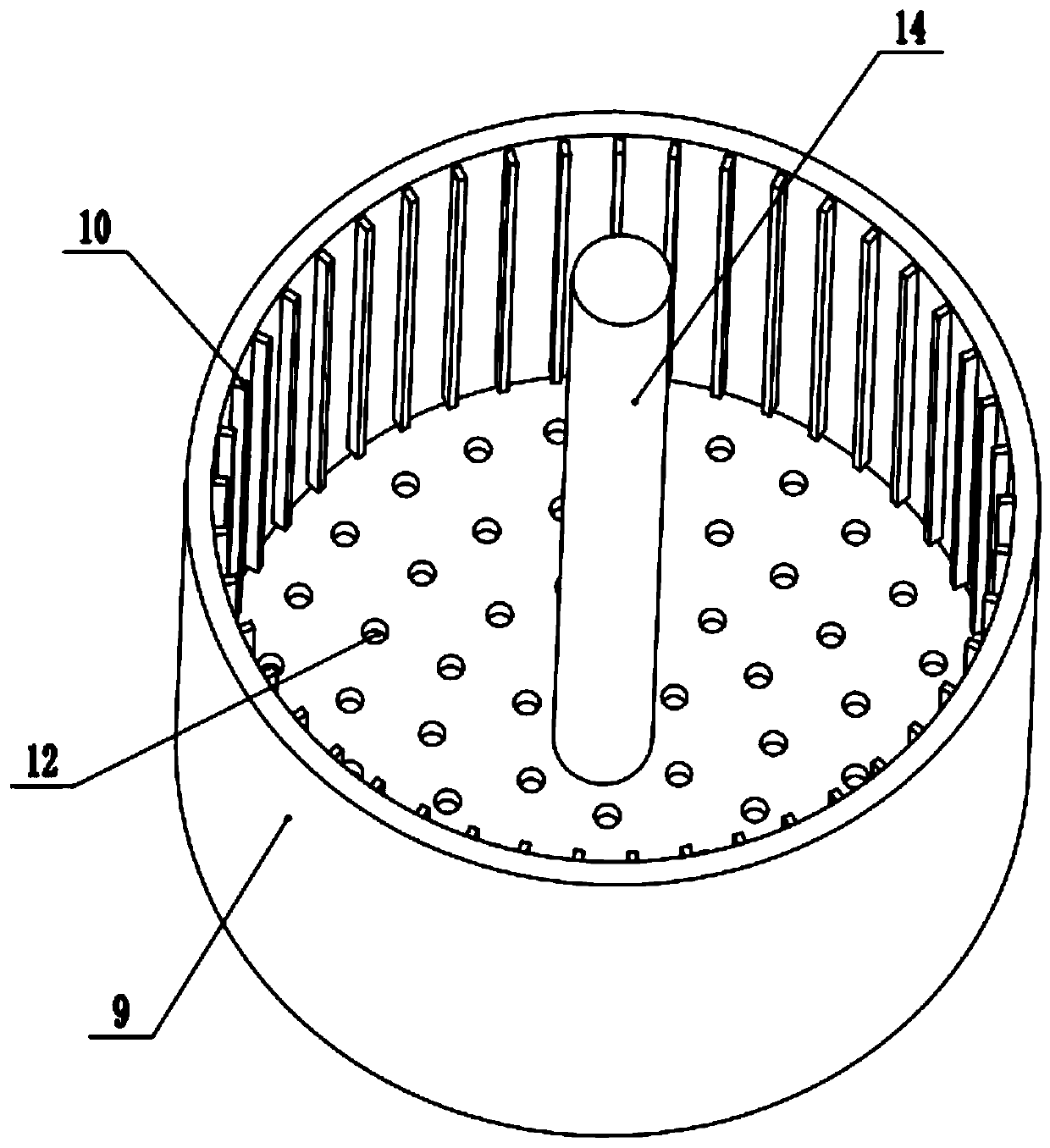

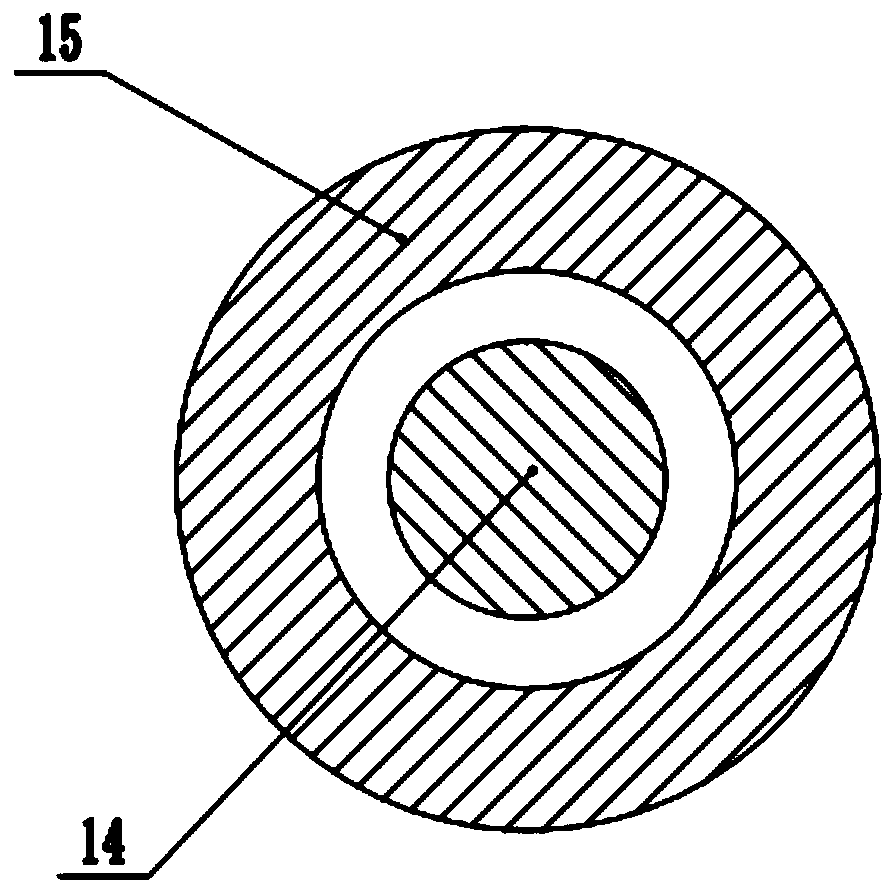

The invention discloses a liquid molten slag dry type centrifugal pelletization and waste heat recycling system. The liquid molten slag dry type centrifugal pelletization and waste heat recycling system comprises a molten slag temporary storage and flow control module, a molten slag centrifugal pelletization and waste heat recycling module, a molten slag moving bed heat exchange and waste heat recycling module and a high-temperature air waste heat utilization module. The system comprises a water vapor procedure, an air procedure, an exhaust gas procedure and a slag procedure and correspondingequipment thereof. By means of the modules and the various medium procedures, efficient pelletization of liquid molten slag and efficient recycling of heat can be guaranteed; and certain reference isprovided for industrial application of the liquid molten slag dry type centrifugal pelletization and waste heat recycling technology.

Owner:XI AN JIAOTONG UNIV

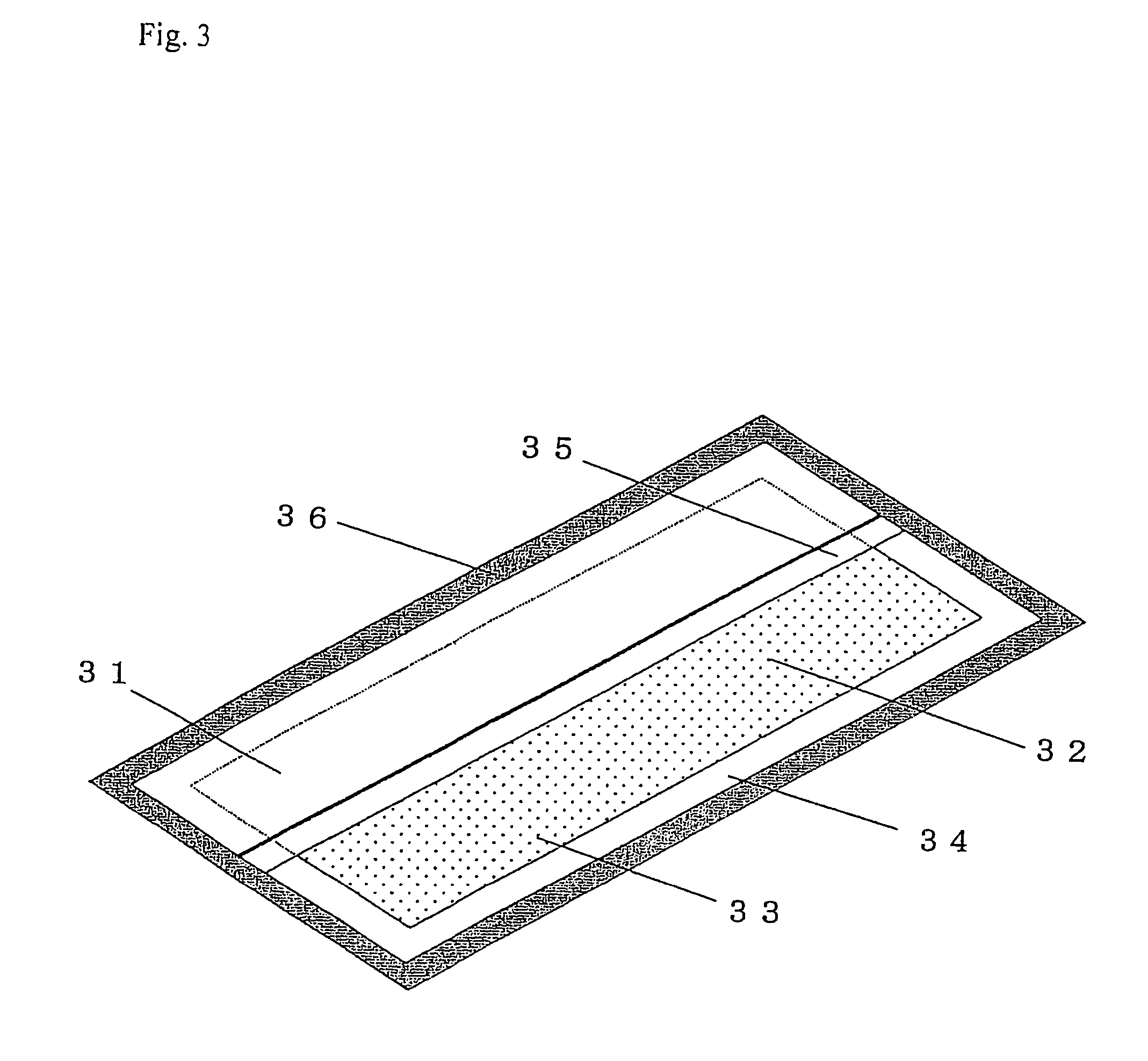

Absorbent structure, absorbent article, water-absorbent resin, and its production process and evaluation method

ActiveUS8426670B2Improve abilitiesExcellent liquid absorptionBaby linensTamponsLiquid diffusionPolymer science

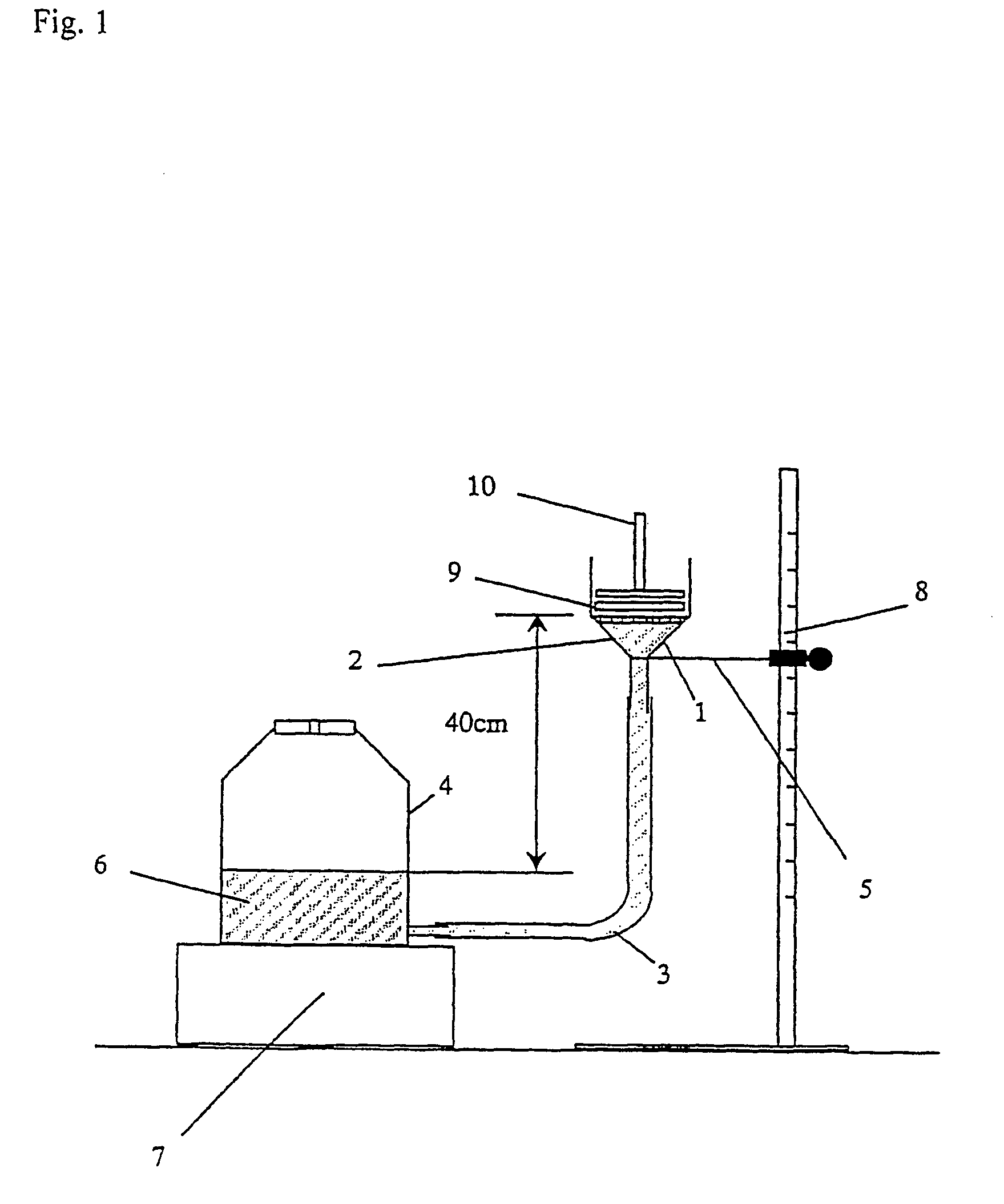

The present invention provides: an absorbent structure and an absorbent article, which are excellent in both liquid diffusion ability and liquid storage ability, and which are excellent in the dry feeling and the amount of wet back of the aqueous liquid, and which can realize the thinning and lightening more; and a water-absorbent resin fitly usable for the above absorbent structure and absorbent article. The absorbent structure, according to the present invention, comprises a liquid-diffusing member and a water-absorbent resin, with the absorbent structure being characterized in that when the capillary absorption index of the liquid-diffusing member at a height of 40 cm is referred to as A (A≧0.10), the capillary absorption index B of the water-absorbent resin at a height of 40 cm satisfies the following equation: B / A≧0.7 (equation 1).

Owner:NIPPON SHOKUBAI CO LTD

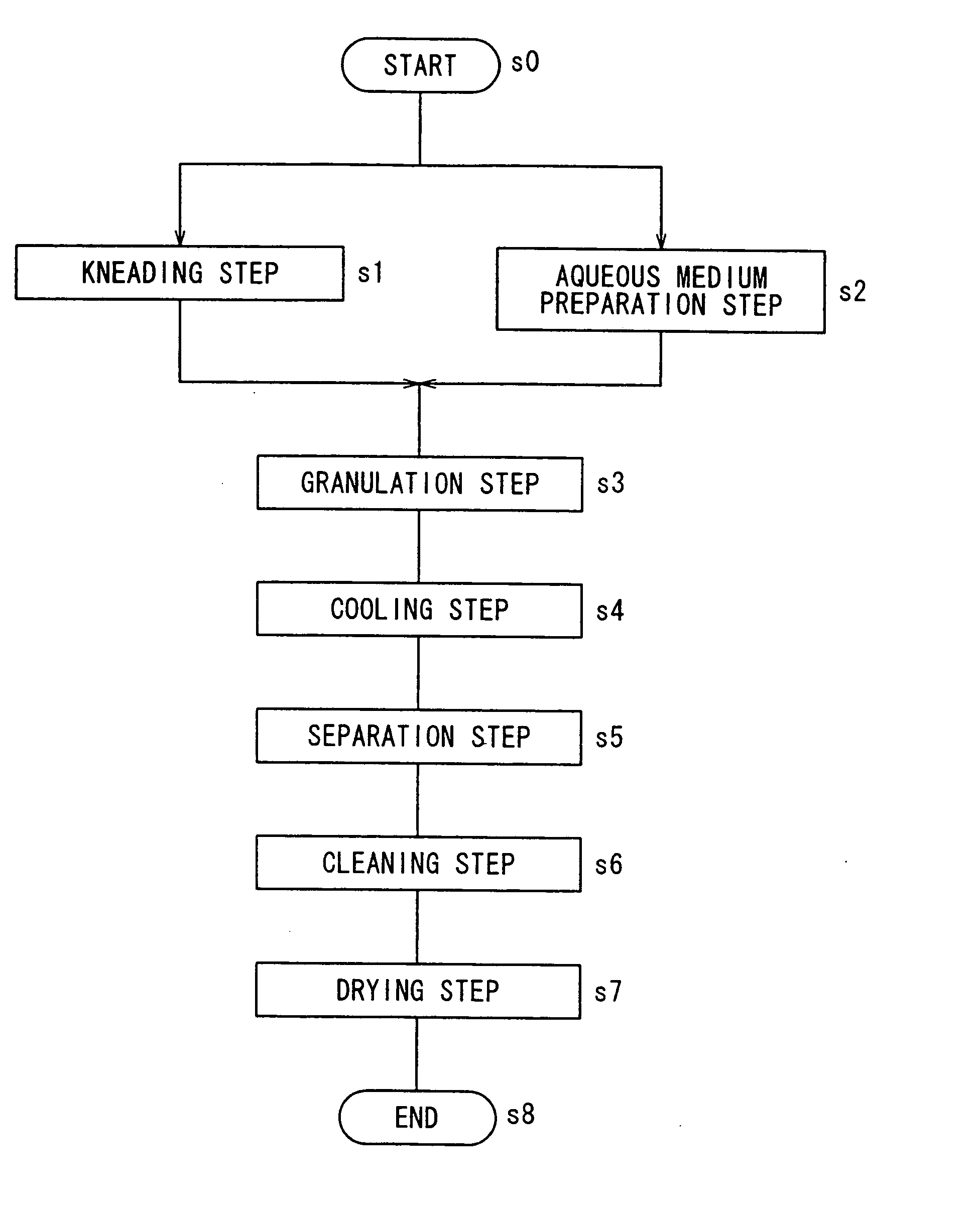

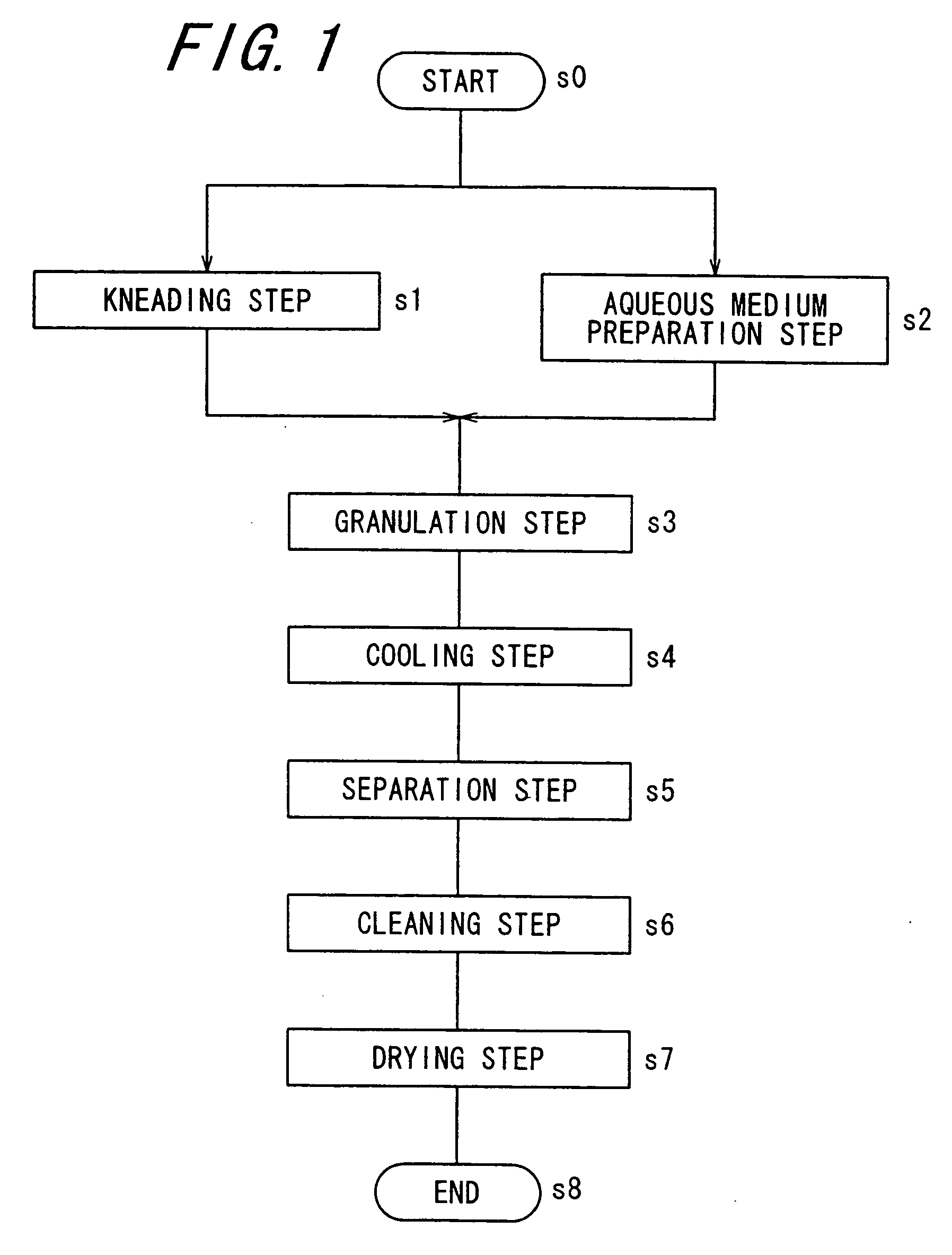

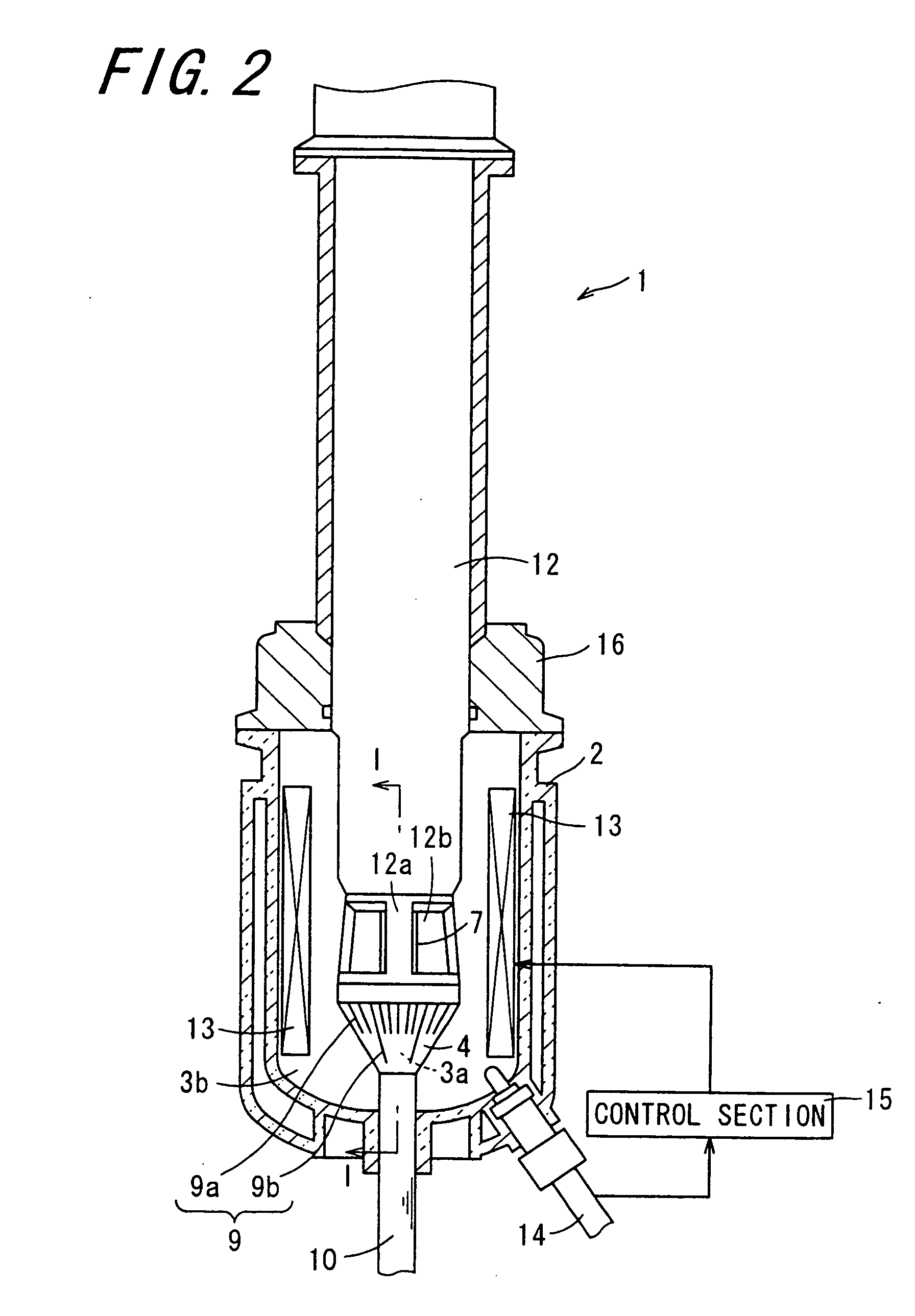

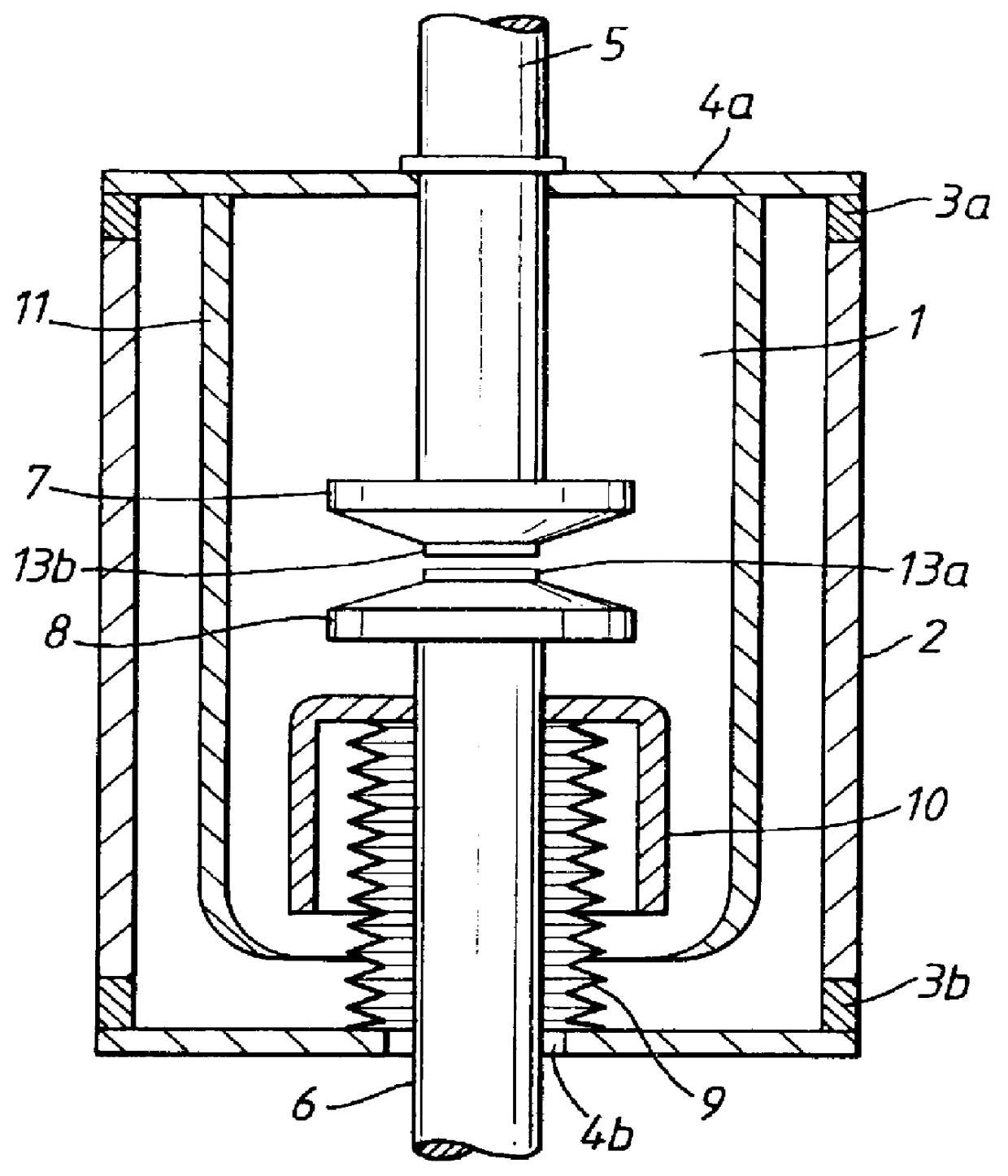

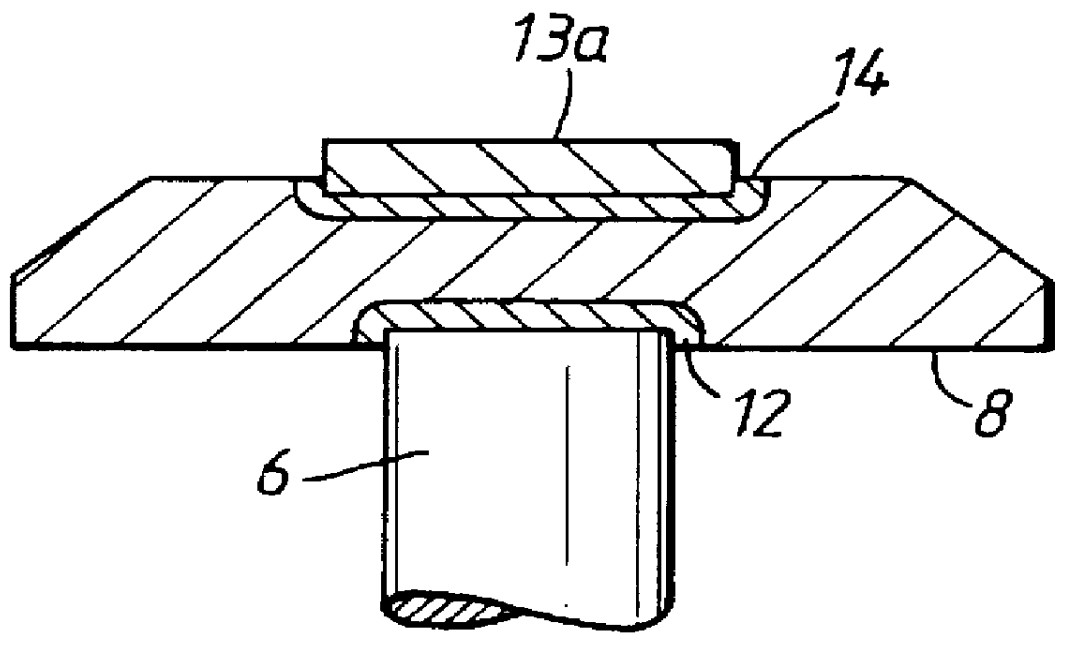

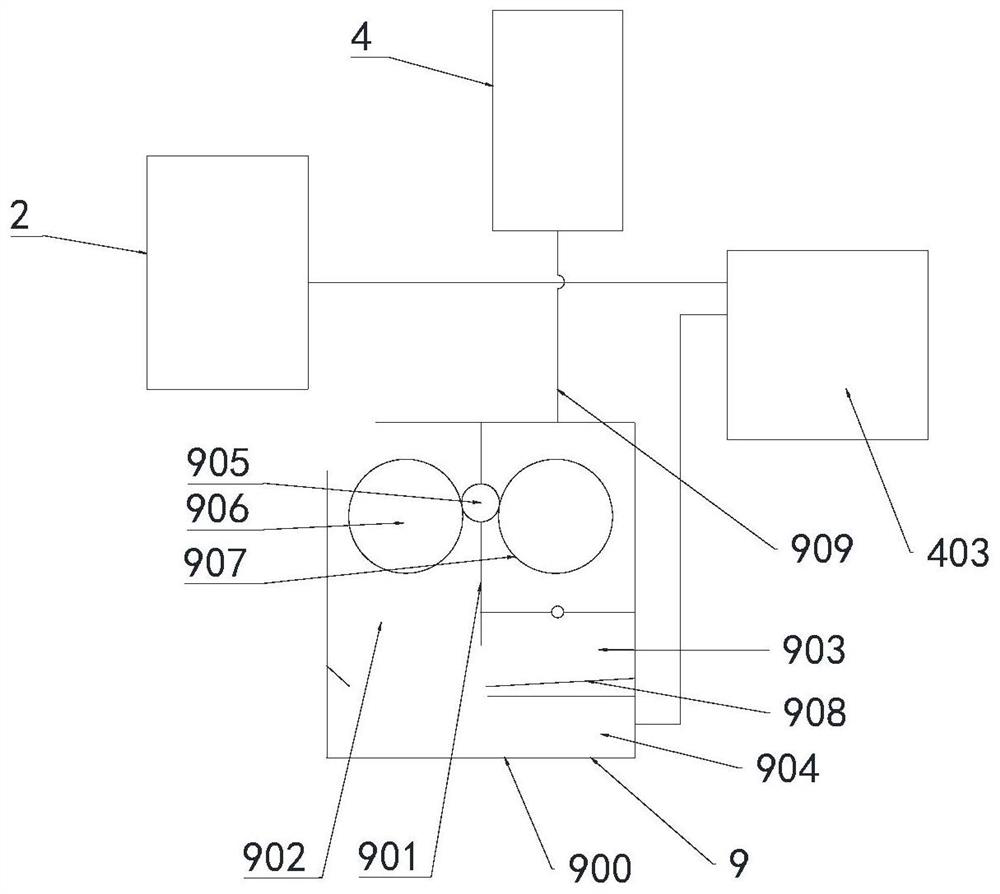

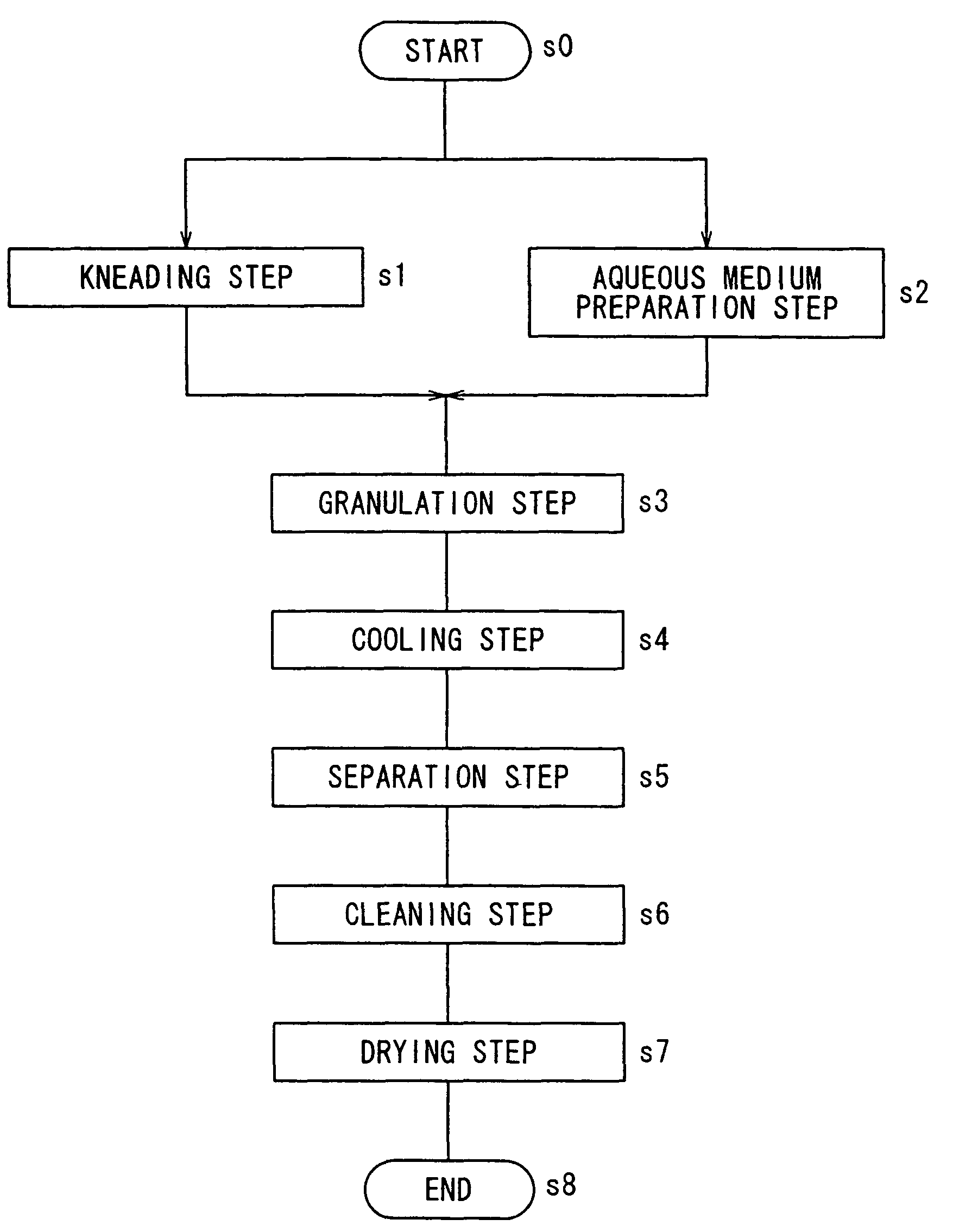

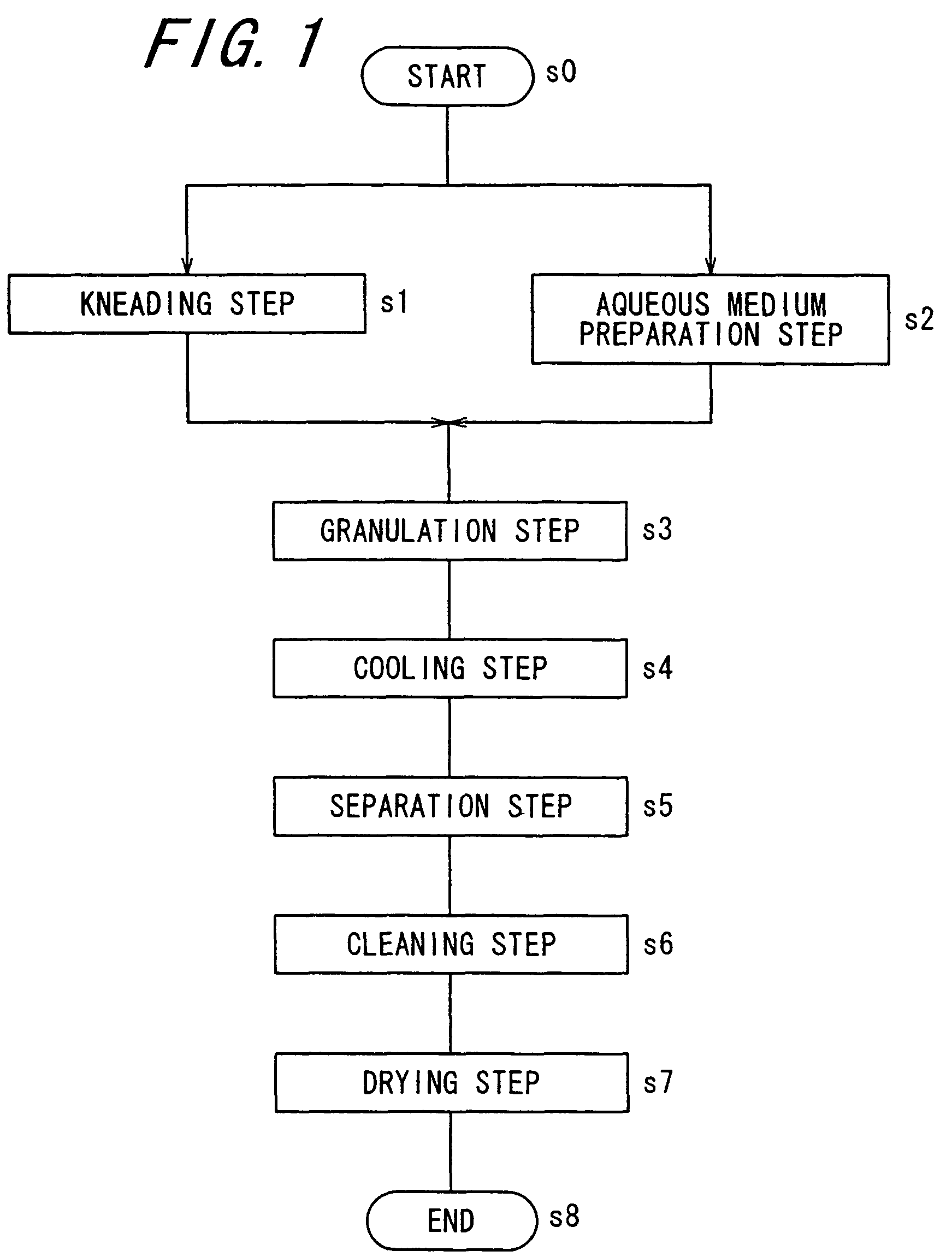

Toner manufacturing method

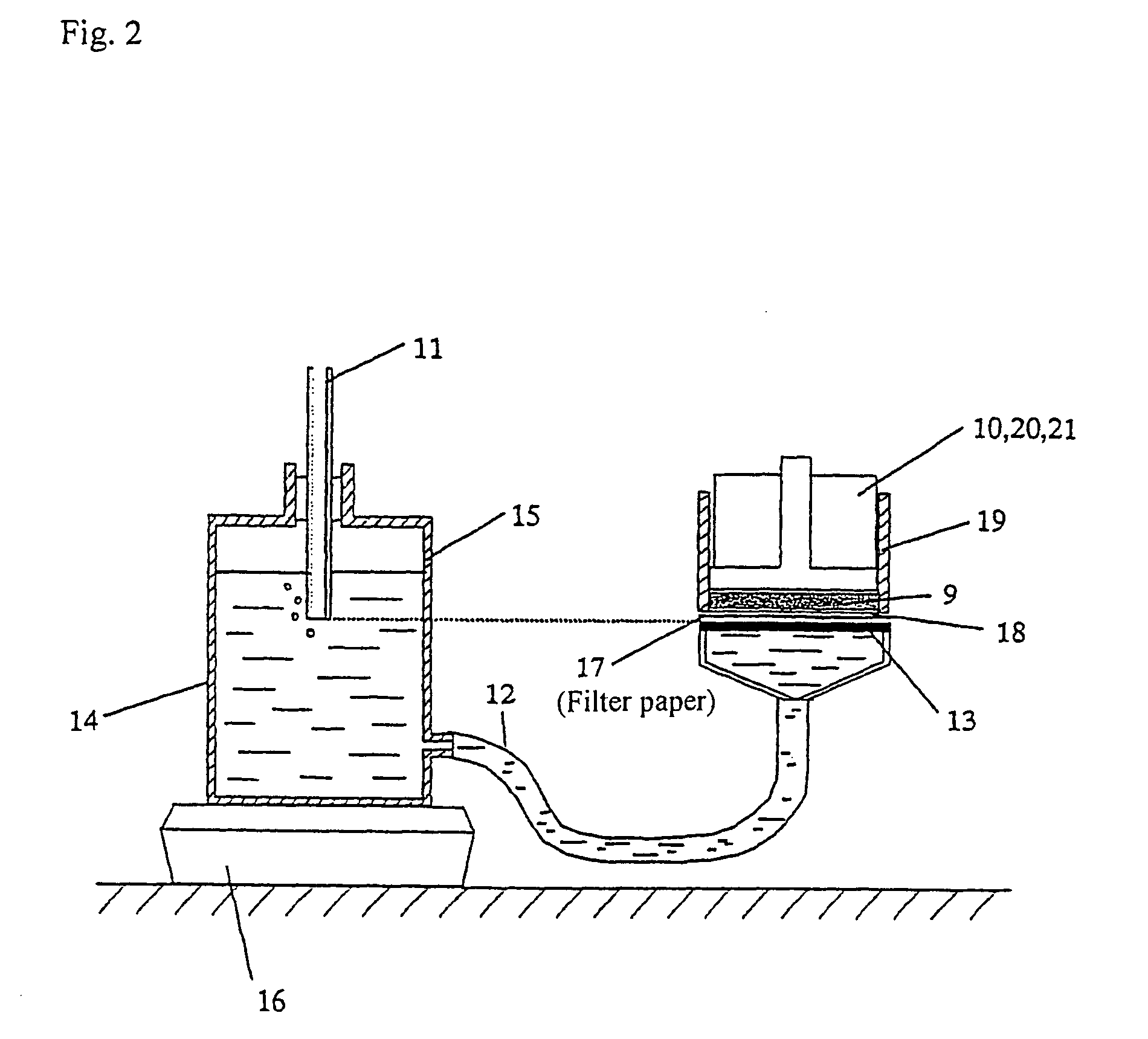

InactiveUS20070128537A1Efficient granulationUneven charging capabilityDevelopersEngineeringAqueous medium

A toner manufacturing method that allows production of toner having desired characteristics with stability in accordance with fusion emulsification technique for obtaining a toner by granulating a resin kneaded product while dispersing it in an aqueous medium. A resin kneaded product containing at least a binder resin and a colorant is mixed with a dispersant / water-containing aqueous medium. The resultant admixture is stirred by an stirring apparatus including a screen with an admixture discharge hole disposed internally of a vessel and a rotor disposed in an stirring space created by the screen.

Owner:SHARP KK

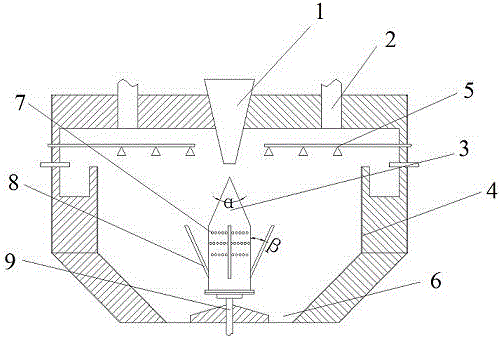

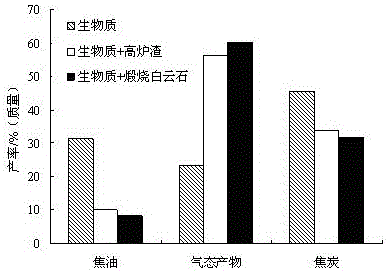

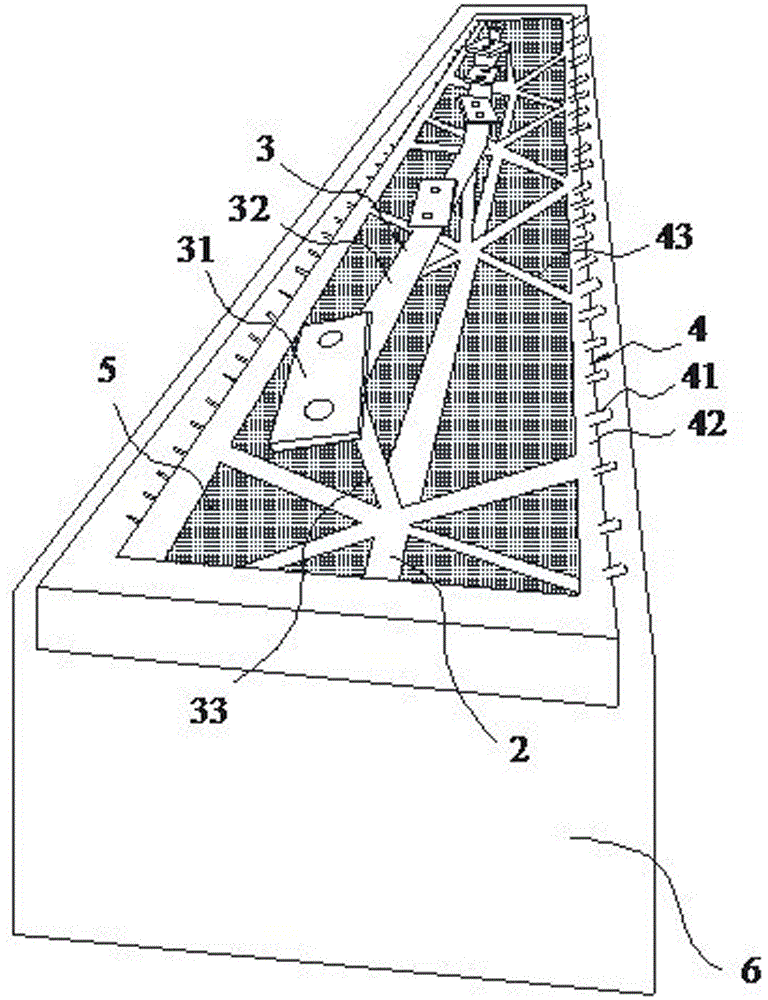

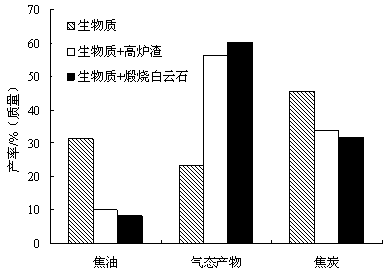

Method and device for preparing tar cracking catalyst through liquid blast furnace slag granulation

ActiveCN106423168AAccelerated liquid-solid phase transitionSave spaceCatalytic crackingRecycling and recovery technologiesMechanical crushingActive component

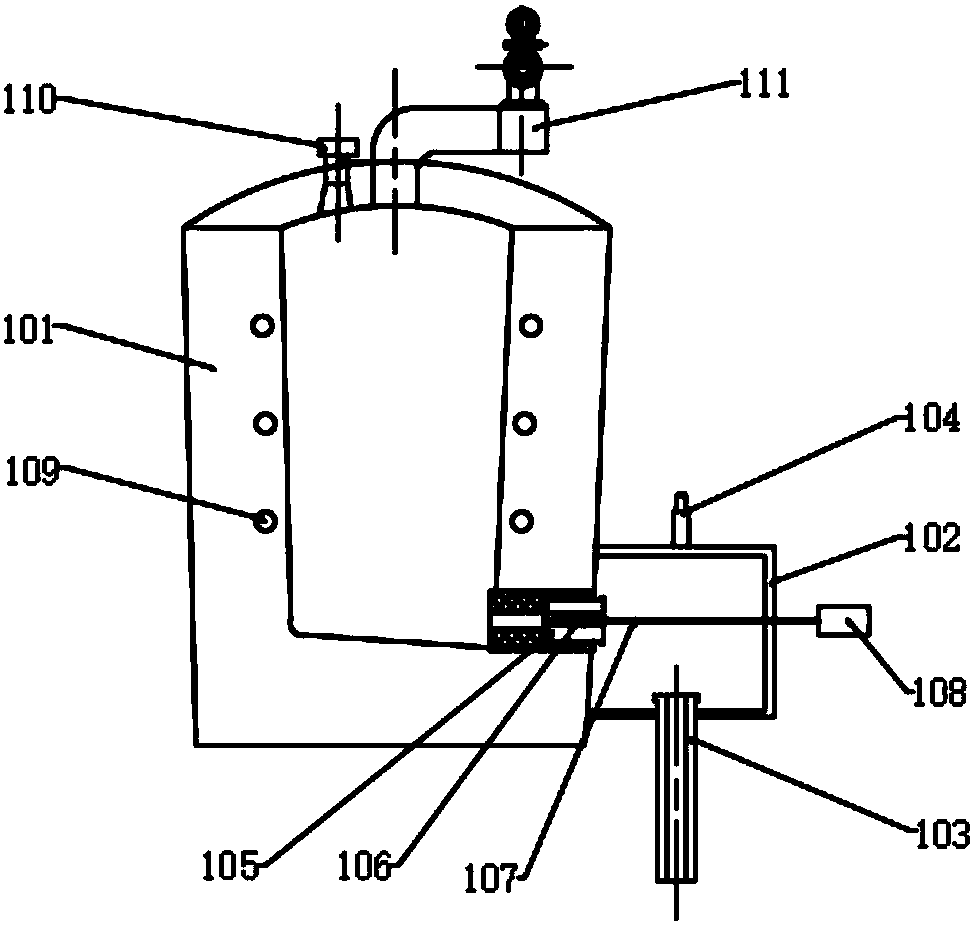

The invention provides a method and device for preparing a tar cracking catalyst through liquid blast furnace slag granulation. The device is characterized by comprising a conical granulating device, a spraying device and an overflow type water cooling wall, iron ore powder with the mass fraction of 10%-20% is added to slag before granulation, the slag extends on the surface of the conical granulating device to form a film in the granulating process, the film is air-quenched into small particle drops under the effect of a high-pressure jet flow, then bumps with crushing blades for secondary crushing, is further air-quenched and granulated by a spirally rising airflow and finally falls onto the surface of the overflow type water cooling wall to perform heat exchange with a flowing water film for cooling. The device is compact in structure, integrates centrifugal granulation, mechanical crushing, air quenching and water cooling modes and can achieve efficient granulation and rapid heat exchange of liquid slag, and no mutual bonding occurs in the granulated slag output process. The slag granulating rate is 90% or above by adopting the method, a surface pore structure is developed, the active component content is high, and the tar cracking catalyst is an efficient biomass tar cracking catalyst.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

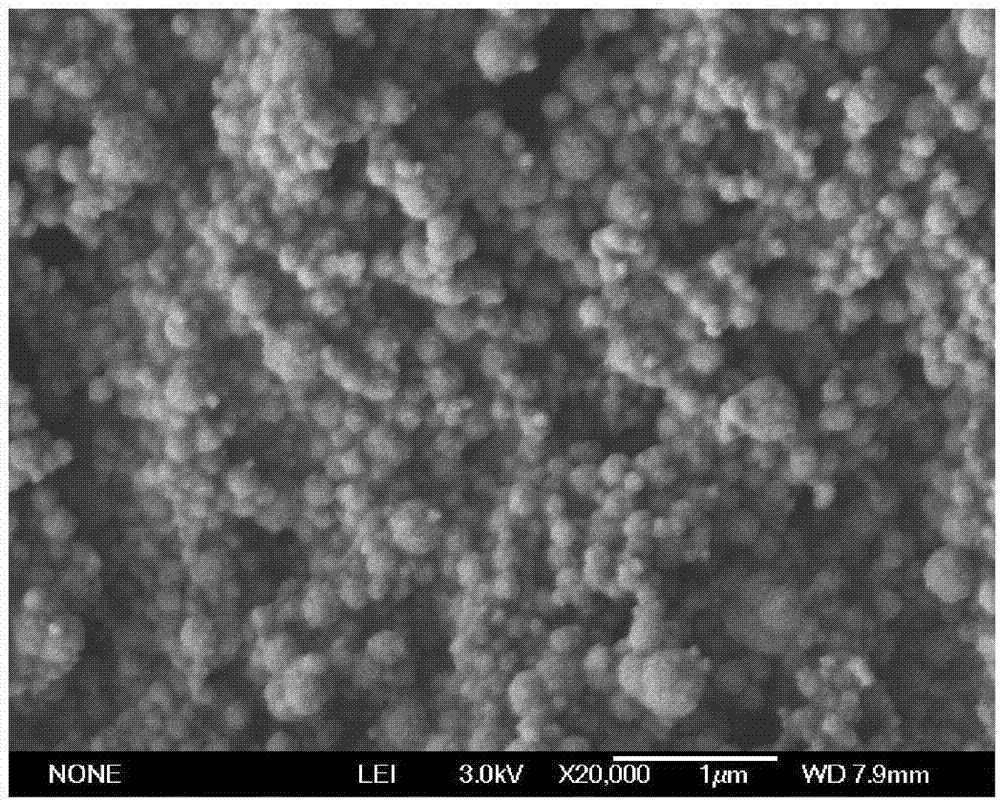

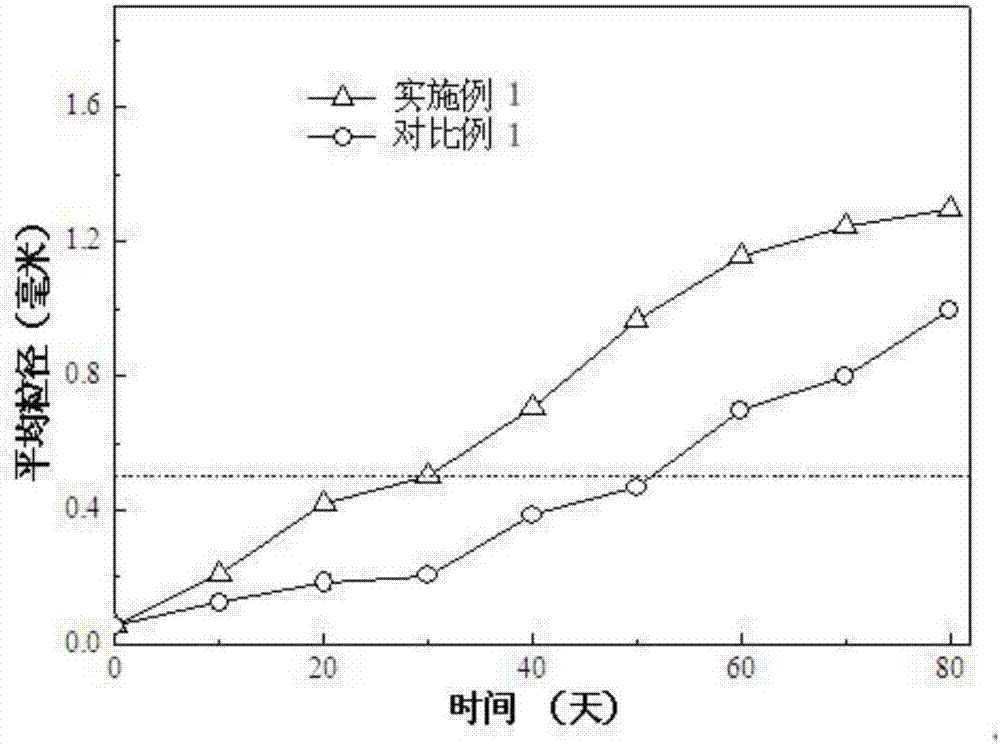

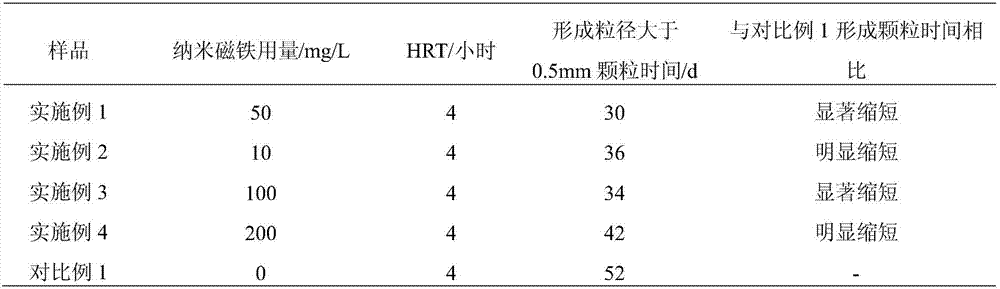

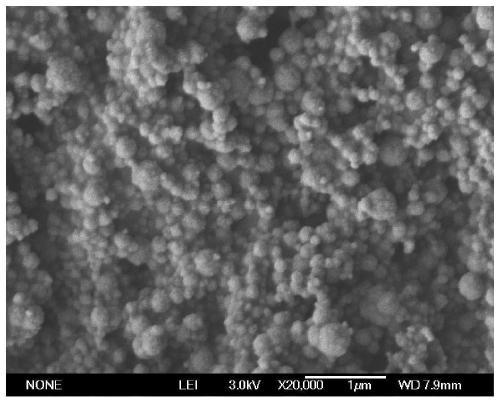

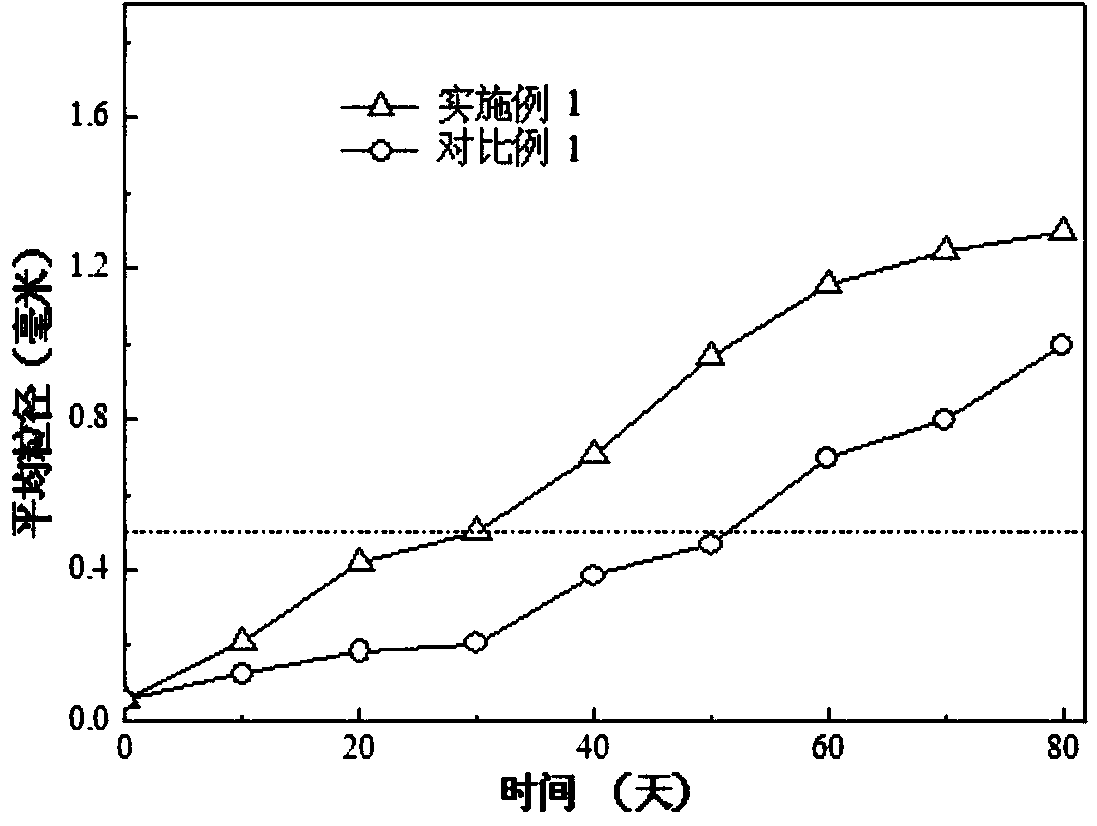

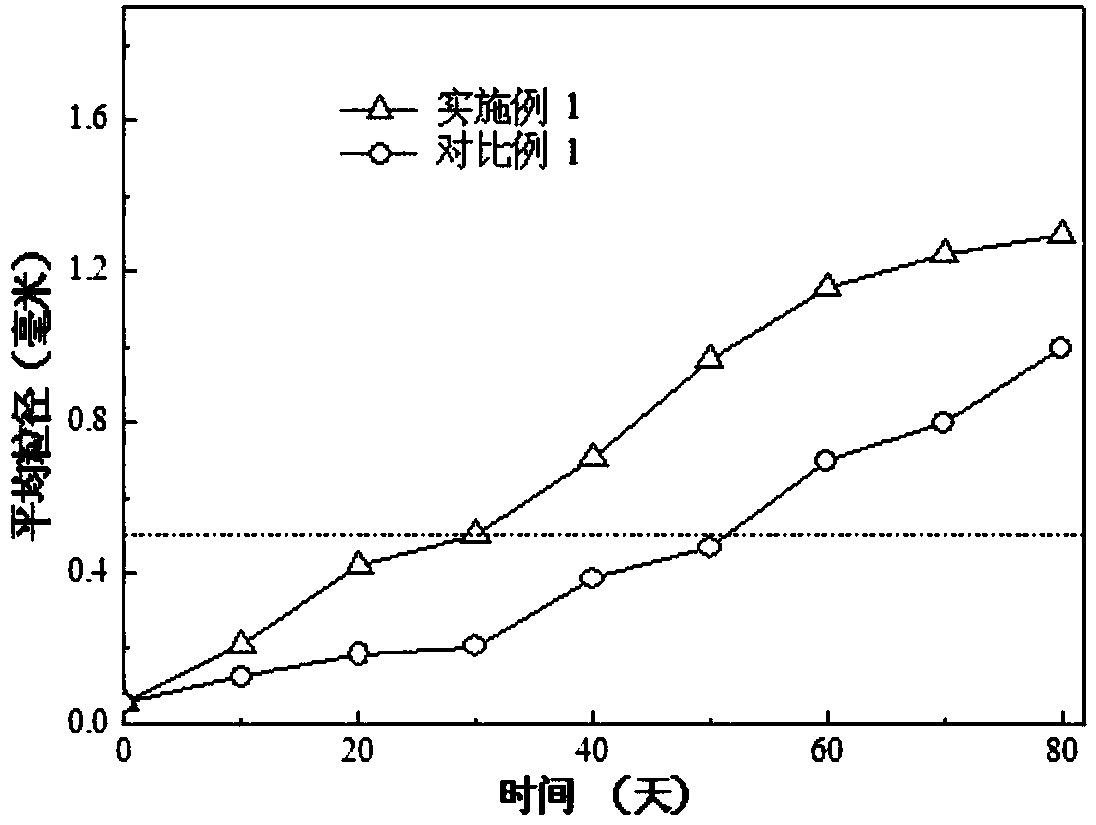

Method for promoting granulation of flocculent activated sludge by applying nano magnet

ActiveCN107235552AUnique superparamagnetic propertiesWith adsorptionBiological treatment apparatusSustainable biological treatmentActivated sludgeNanodot

The invention relates to a method for promoting the granulation of flocculent activated sludge by applying nano magnet. The method comprises the following steps: mixing the flocculent activated sludge, the nano magnet and sewage; promoting the granulation of the flocculent activated sludge by interaction between the nanodots and the flocculent activated sludge; performing the granulation process at room temperature according to a cycle, and sufficiently aerating within each cycle. According to the method disclosed by the invention, the granulation process of the activated sludge can be effectively shortened; by adding a small amount of the nano magnet, the granulation time of the sludge can be effectively shortened and the cost is low; in addition, obtained particles are denser and better in stability. The method disclosed by the invention has the advantages of simple process, mild reaction conditions, safety and no toxicity to environment and facilitation for engineering application; the method can be performed at normal temperature and normal pressure.

Owner:SHANDONG UNIV

Contact material for vacuum interrupter and method for producing the same

InactiveUS6027821AImprove featuresLower average currentContact materialsMetal-working apparatusCarbideVacuum interrupter

A contact material for a vacuum interrupter including, a conductive component including at least Cu, and an arc-proof component including at least one selected from the group consisting of carbides of W, Zr, Hf, V and Ti. An amount of the conductive component in the contact material is 40-50 vol %, an amount of the arc-proof component in the contact material is 50-60 vol %, and a grain size of the arc-proof component is 3 mu m or less. A total amount of a sintering activator including at least one selected from the group consisting of Co, Fe and Ni melted in the conductive component is 0.1% or less of the amount of the conductive component.

Owner:KK TOSHIBA

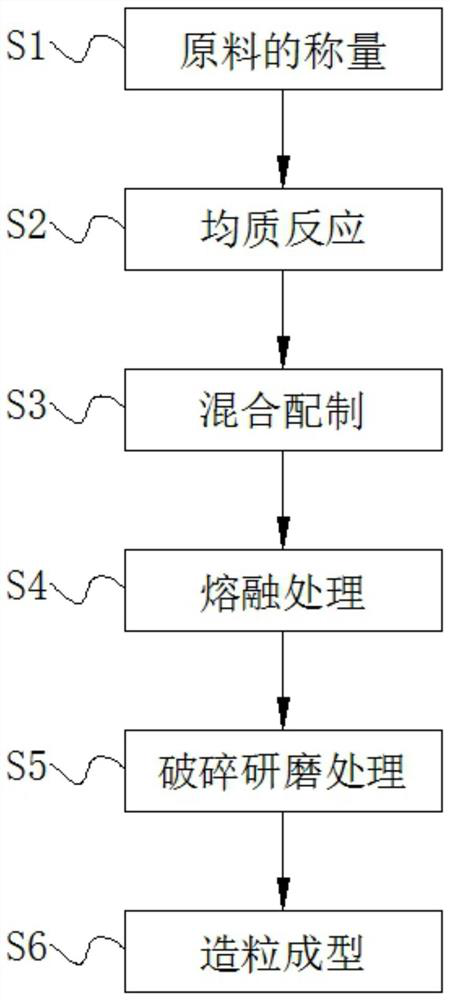

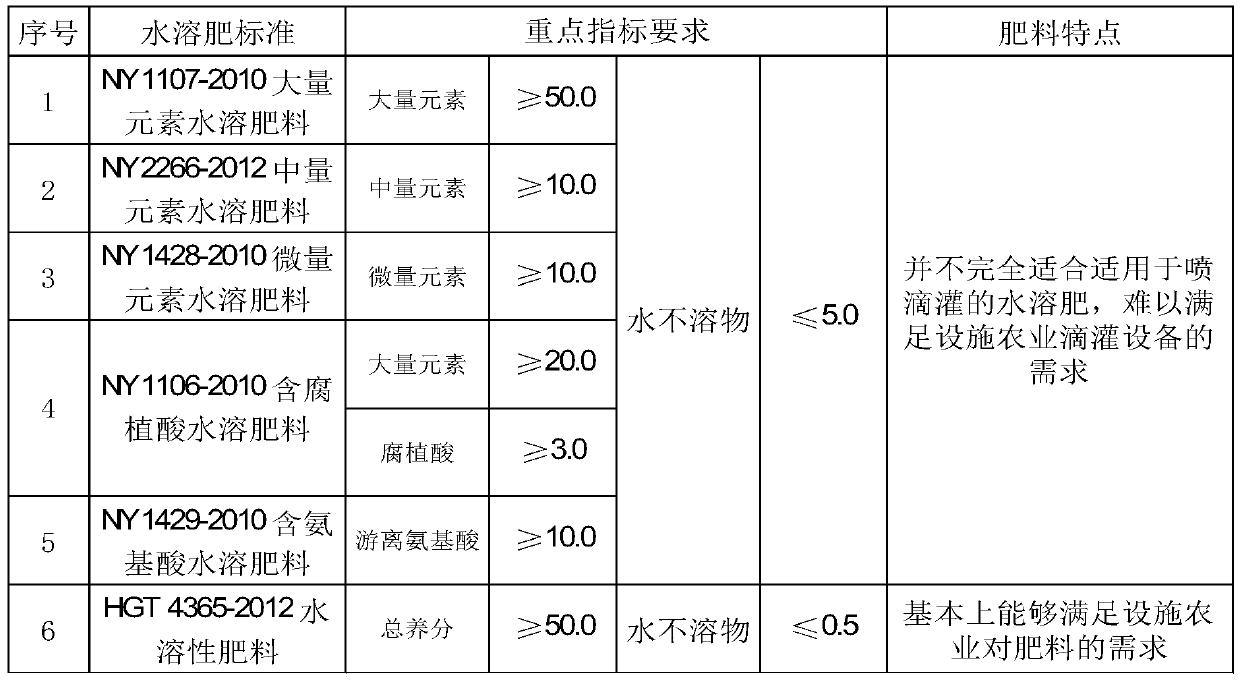

Granulation molding process of secondary element water-soluble fertilizer

InactiveCN111675566AReduce workloadFast granulationCalcareous fertilisersMagnesium fertilisersFertilizerPelletizing

The invention discloses a granulation forming process of a secondary element water-soluble fertilizer, which specifically comprises the following steps: S1, weighing raw materials: respectively weighing the raw materials in required parts by weight through batching equipment, and respectively storing the weighed components into a storage tank for later use, S2, carrying out homogenizing reaction,S3, carrying out mixing and preparing, S4, carrying out melting treatment, S5, carrying out crushing and grinding treatment, and S6, carrying out granulating and molding. The invention relates to thetechnical field of fertilizer processing. According to the granulation forming process of a secondary element water-soluble fertilizer, rapid granulation can be carried out by adopting a one-step heating, melting, granulating and forming method, the purpose of rapid and efficient granulation is well achieved, the granulation process is simple, a large amount of working time of production personneldoes not need to be spent in evaporating the water and fertilizer solution, the workload of the production personnel is greatly reduced, the production efficiency is improved, and thus the water andfertilizer production by people is greatly facilitated.

Owner:HENAN JIENONG BIOLOGICAL & CHEM CO LTD

Street fallen leaf recycling system and using method thereof

PendingCN113073594AEasy to handleKeep dryElectrostatic separationTransportation and packagingControl systemAgricultural engineering

The invention relates to a street fallen leaf recycling system and a using method thereof. The street fallen leaf recycling system comprises a vehicle shell, a plurality of suction pipes are connected to the bottom of the vehicle shell, a draught fan and a control system are arranged on the top of the vehicle shell, and a drying device, a smashing device, a stirring device, a granulating device and a storage box are connected into the vehicle shell; the draught fan controls the suction pipes to discharge sucked garbage into the drying device to be dried, the crushing device crushes the garbage discharged out of the drying device to form powder, the powder is introduced into the stirring device to be humidified and stirred, and the fully stirred powder is introduced into the granulating device to generate fine particles. The storage box is used for storing the particles, the storage box is connected with a discharging system, the discharging system can discharge the particles out of the vehicle shell to serve as fertilizer, fallen leaves can be recycled and reused through the fallen leaf recycling device, the utilization efficiency after collection is improved, meanwhile, resources are saved, the sweeping efficiency is improved, and the labor cost is reduced.

Owner:ZHEJIANG WEIDUN MACHINERY TECH

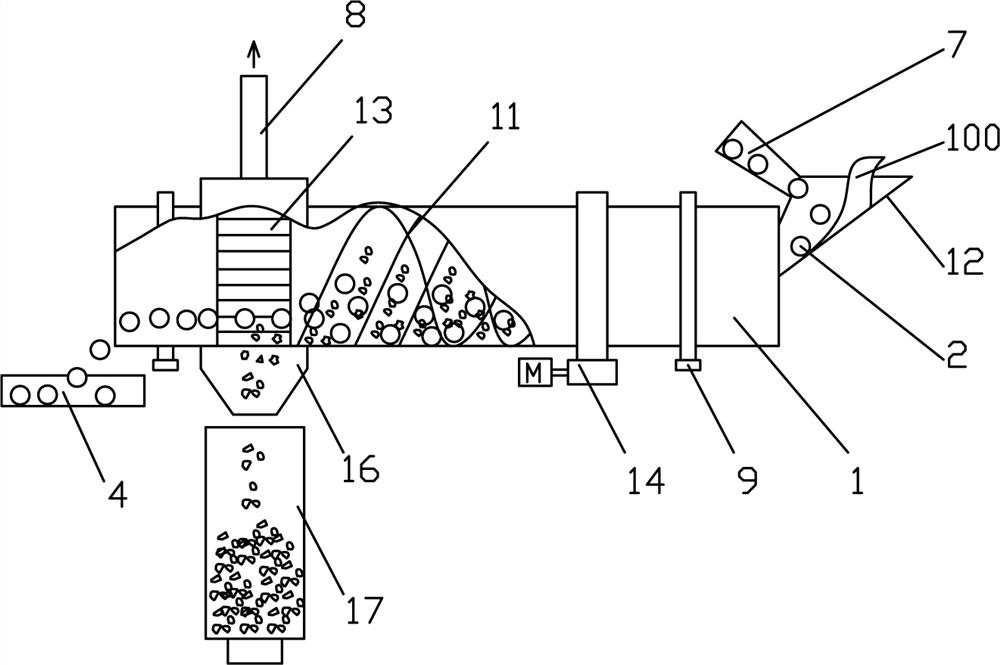

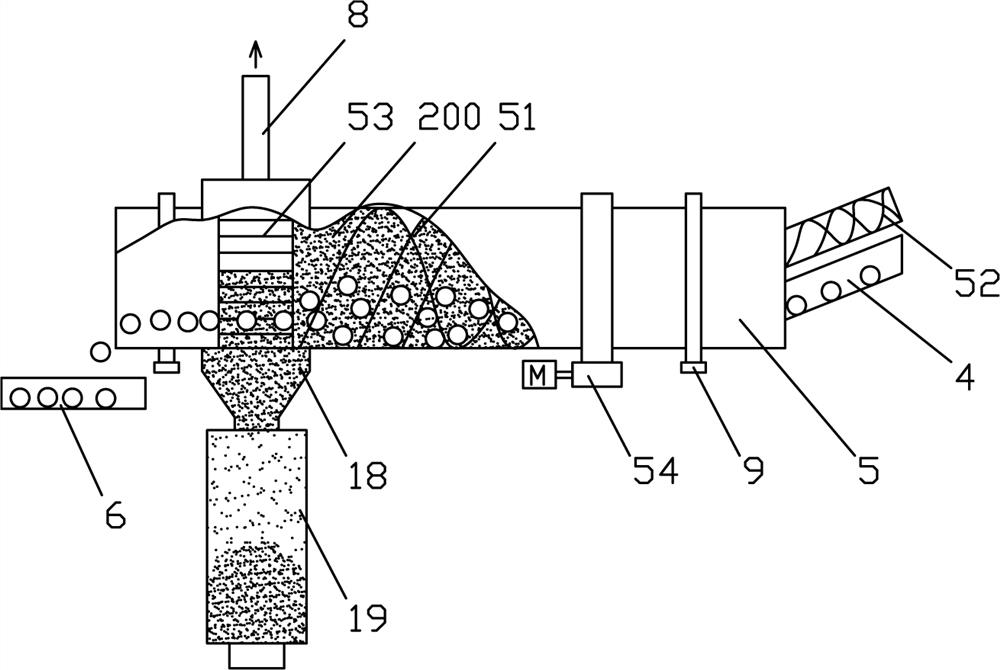

Dry-type granulated slag and sludge coupling drying process and device

ActiveCN114058747ASolve effective useImprove cooling effectSludge treatment by de-watering/drying/thickeningDrying solid materials with heatSludgeSteel ball

The invention discloses a dry-type granulated slag and sludge coupling drying process and device, and the process comprises the following steps: 1) mixing and soaking slags and balls, and fully mixing and exchanging heat of high-temperature slags and steel balls, so that the heat of the high-temperature slags is rapidly absorbed by the steel balls and the high-temperature slags are cooled and crushed to form granular slags, and the temperature of the steel balls rises by absorbing the heat of the high-temperature slags; and 2) sludge drying: conveying the high-temperature steel balls to a sludge drying device, mixing the high-temperature steel balls with the injected sludge, drying the sludge, separating the steel balls from the sludge when the water content of the sludge reaches a set value, and respectively discharging the steel balls and the sludge. According to the invention, the temperature of the steel balls is increased by using the waste heat of the high-temperature molten slags, and the sludge is dried by the heated steel balls, so that the cooperative treatment of molten slag cooling, granulating and sludge drying is realized, the two problems of molten slag cooling and sludge drying are solved, and the recycling rate of the waste heat of the high-temperature molten slag is greatly increased.

Owner:BAOSHAN IRON & STEEL CO LTD

Attapulgite modified urea-ammonium nitrogen fertilizer

InactiveCN109320322APlay the role of energy saving and emission reductionIncrease profitAmmonium salt fertilisersUrea compound fertilisersSulfurAmmonium nitrogen

The invention relates to attapulgite modified urea-ammonium nitrogen fertilizer which is characterized by comprising sulfur-based nitrogen fertilizer and chlorine-based nitrogen fertilizer, wherein the sulfur-based nitrogen fertilizer is prepared by mixing the following components in percentage by weight: 10-20% of attapulgite powder, 25-35% of urea, 50-60% of ammonium sulfate and 5-8% of urea sulfate; the chlorine-based nitrogen fertilizer is prepared by mixing the following components in percentage by weight: 10-20% of attapulgite powder, 20-30% of urea, 55-65% of ammonium chloride and 5-8%of urea sulfate. The attapulgite modified urea-ammonium nitrogen fertilizer provided by the invention has a good soil improving effect; meanwhile, by utilizing the colloidality and the adsorbability of attapulgite, the fertilizer is easy to pelletize and has good commodity; by utilizing the inhibitive ability of the urea sulfate, fertilizer efficiency is slowly released and thus is prolonged. Theattapulgite modified urea-ammonium nitrogen fertilizer has a wide application range and is applicable to multiple economic crops and grain crops.

Owner:白银丰宝农化科技有限公司

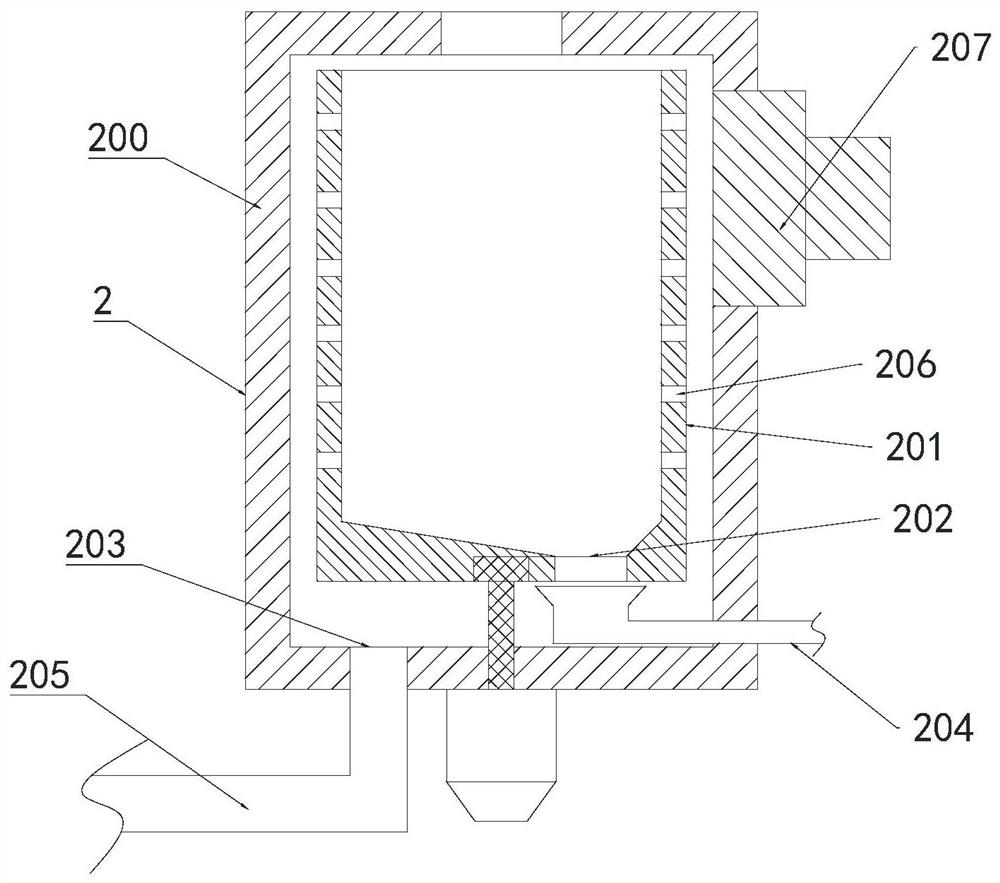

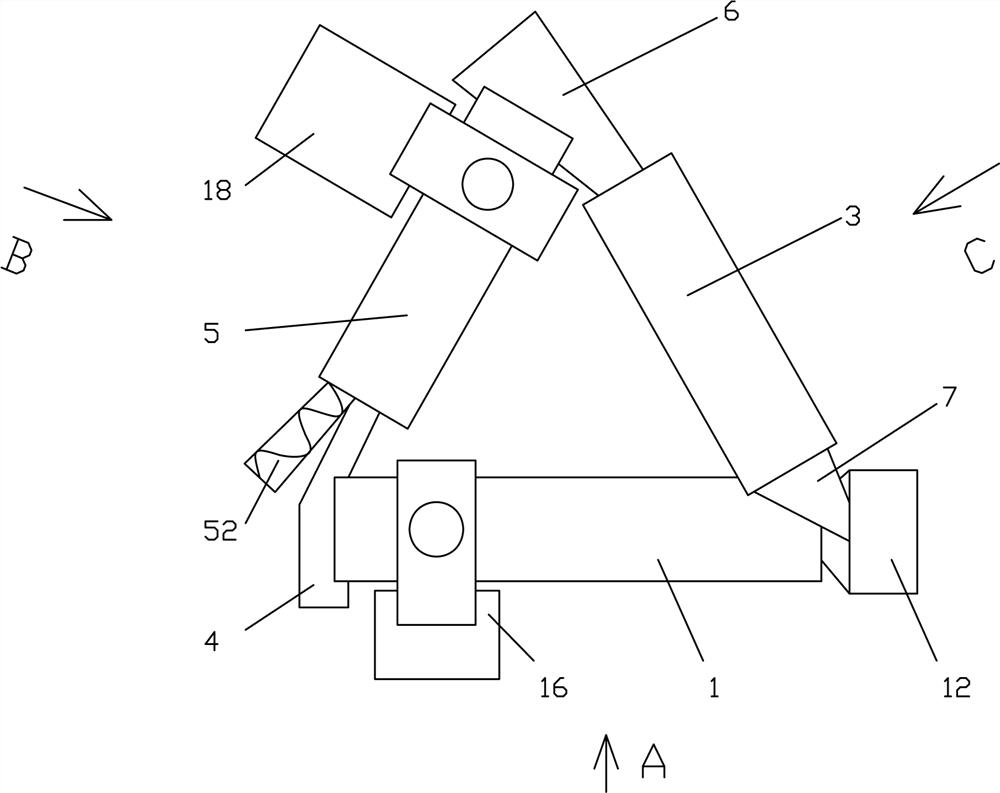

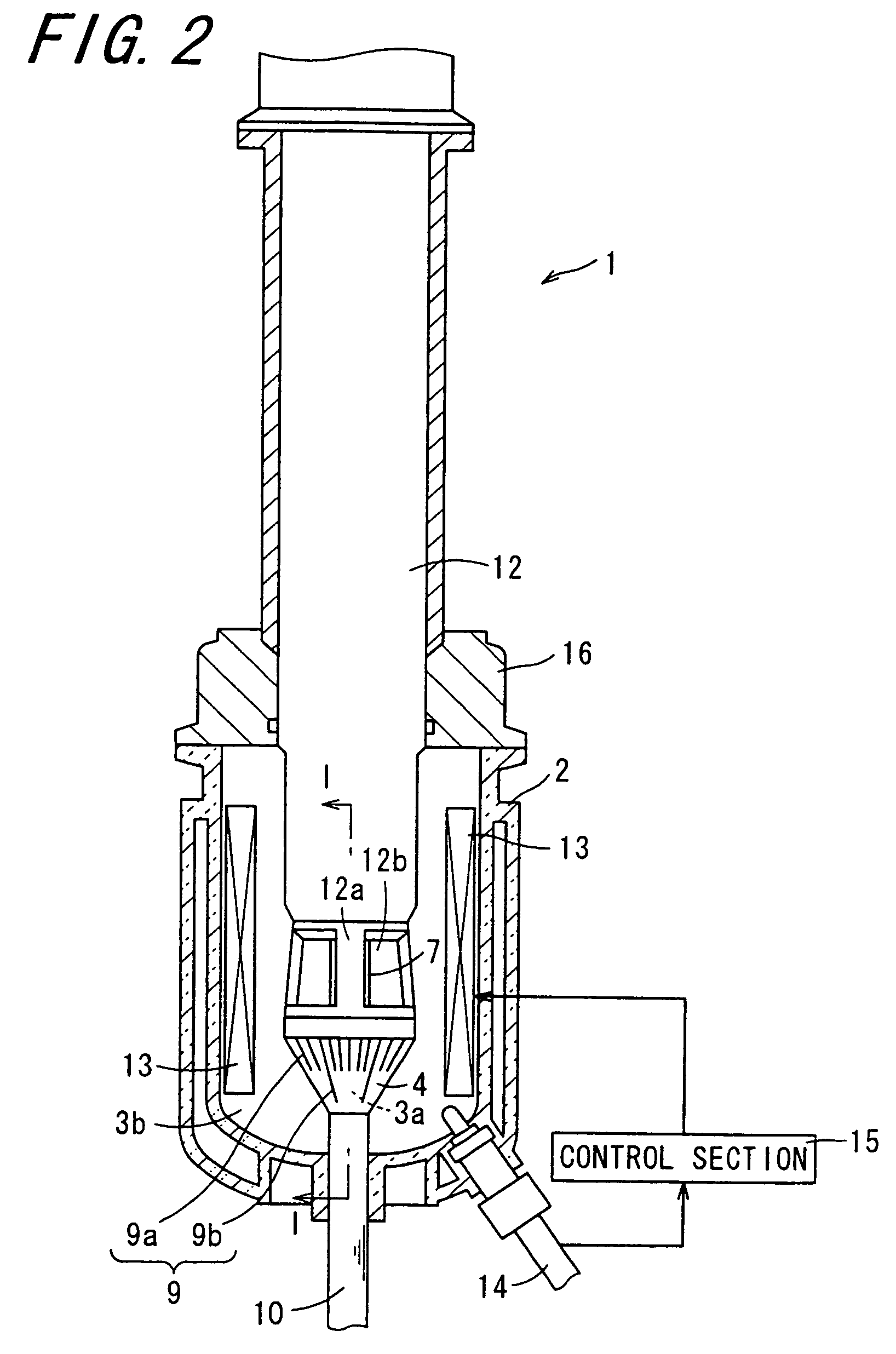

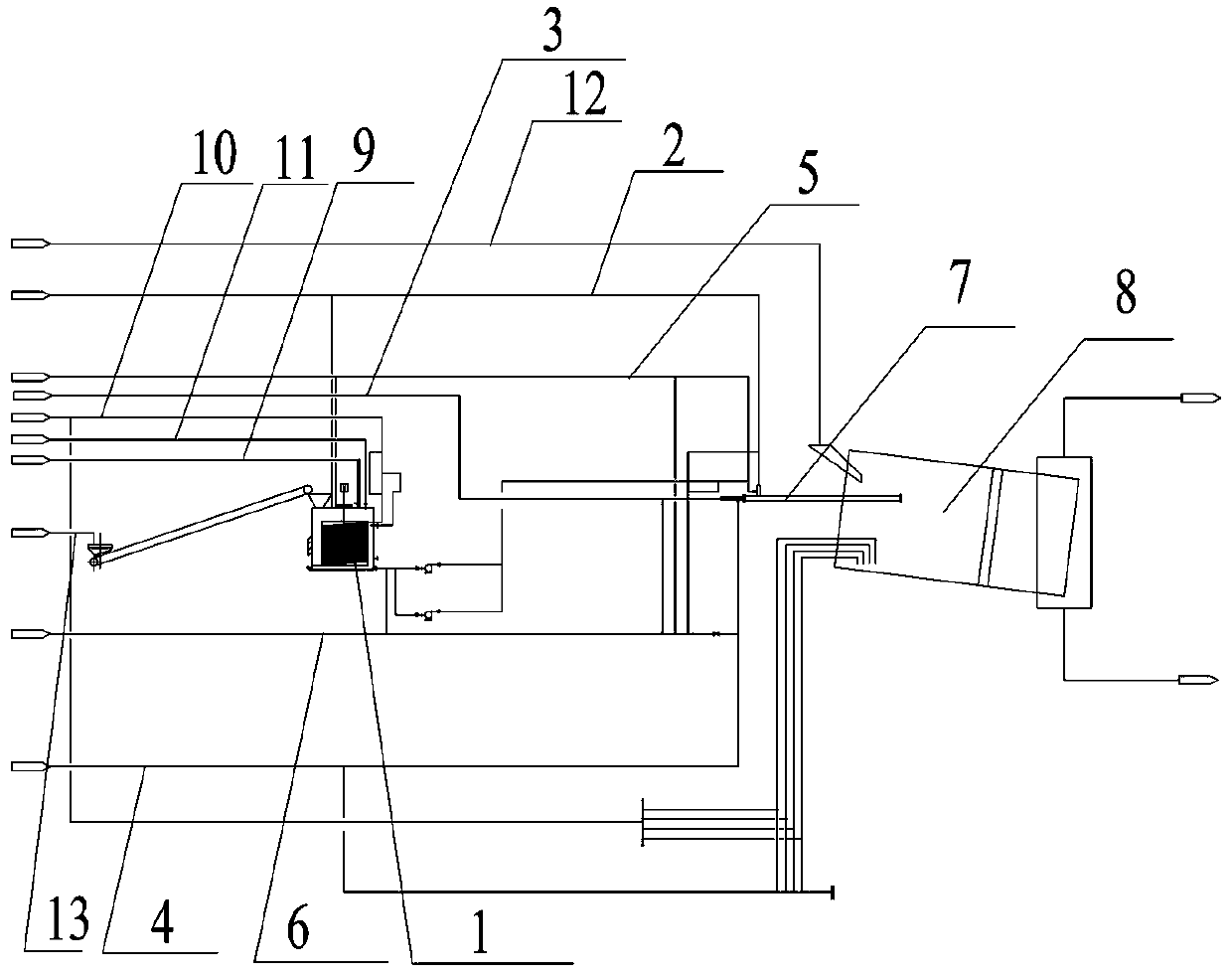

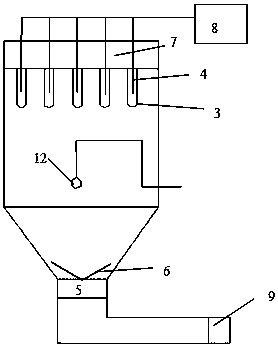

Device and method for granulating blast furnace slag and recycling waste heat

PendingCN113322360AAvoid it happening againImprove waste heat recovery efficiencyBlast furnace componentsBlast furnace detailsSludgeAerosol Mist

The invention discloses a device and method for granulating blast furnace slag and recycling waste heat. The device comprises an aerial fog granulation nozzle assembly, a fluid director (7), a cyclone separator (8) and a waste heat recoverer. The aerial fog granulation nozzle assembly comprises a slag flow controller (2), a compressed air flow control valve (3), a water quantity control valve (4) and an aerial fog spray gun (5). Mixing heat exchange of medium-temperature gas and high-temperature granular slag (6) and solidification of the high-temperature granular slag are realized in the fluid director, and the medium-high-temperature gas and the high-temperature granular slag after heat exchange are guided into the cyclone separator. The cyclone separator is used for separating medium-high-temperature gas and high-temperature granular slag and conveying the medium-high-temperature gas and the high-temperature granular slag into the waste heat recoverer. Complete granulation of the blast furnace slag is achieved, slag sensible heat recovery is organically coupled with sludge drying, high-temperature steam preparation, power generation and low-temperature hot water preparation, waste heat recovery of medium-temperature gas and high-temperature granulated slag in the slag granulation treatment process is achieved, and the waste heat recovery and utilization efficiency is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

A method of applying nano-magnets to promote granulation of flocculent activated sludge

ActiveCN107235552BUnique superparamagnetic propertiesWith adsorptionBiological treatment apparatusSustainable biological treatmentActivated sludgeMetallurgy

The invention relates to a method for promoting the granulation of flocculent activated sludge by applying nano magnet. The method comprises the following steps: mixing the flocculent activated sludge, the nano magnet and sewage; promoting the granulation of the flocculent activated sludge by interaction between the nanodots and the flocculent activated sludge; performing the granulation process at room temperature according to a cycle, and sufficiently aerating within each cycle. According to the method disclosed by the invention, the granulation process of the activated sludge can be effectively shortened; by adding a small amount of the nano magnet, the granulation time of the sludge can be effectively shortened and the cost is low; in addition, obtained particles are denser and better in stability. The method disclosed by the invention has the advantages of simple process, mild reaction conditions, safety and no toxicity to environment and facilitation for engineering application; the method can be performed at normal temperature and normal pressure.

Owner:SHANDONG UNIV

Environment-friendly recycled plastic particles and preparation method thereof

InactiveCN111791388AExcellent environmental protection and regeneration performanceImprove granulation efficiencyPlastic recyclingPolycarbonatePelletizing

Owner:安徽东锦环保科技有限公司

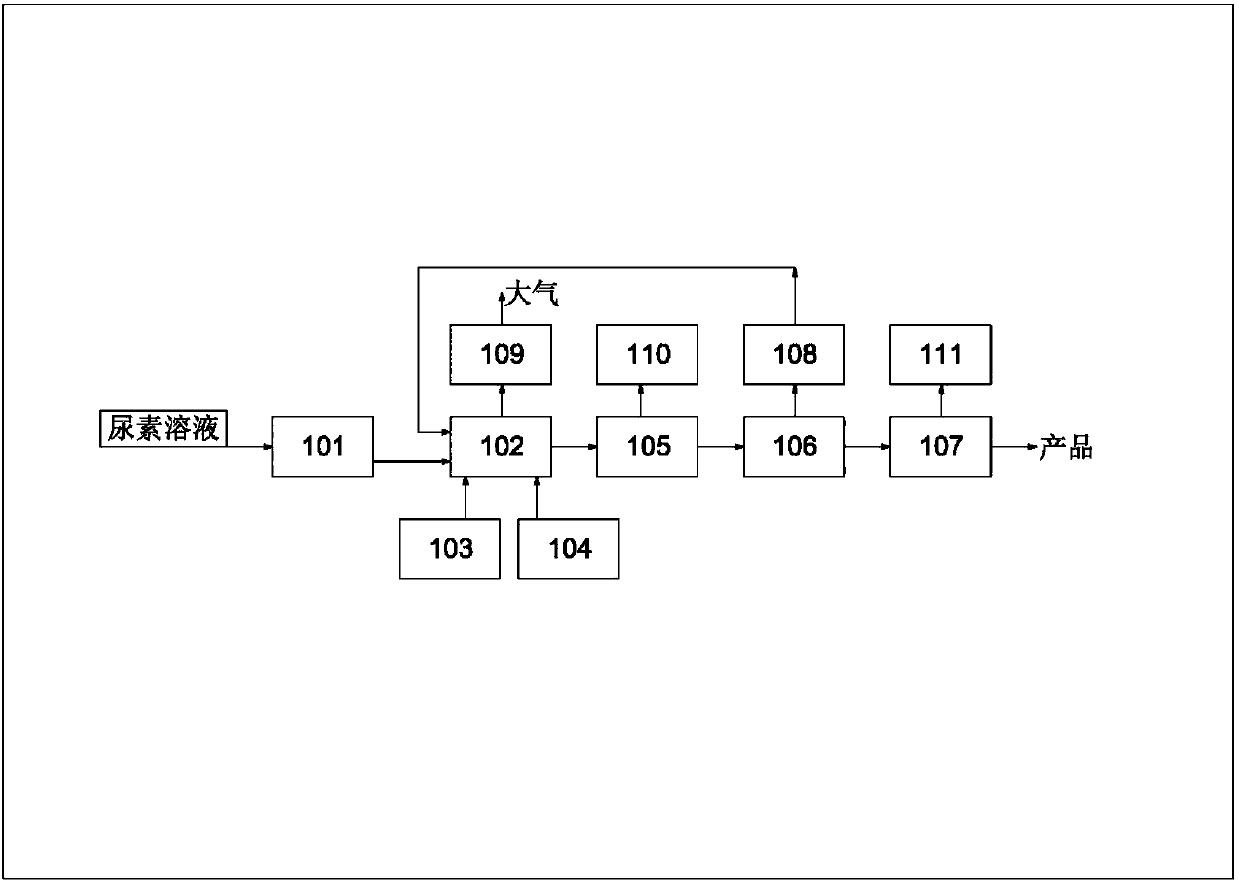

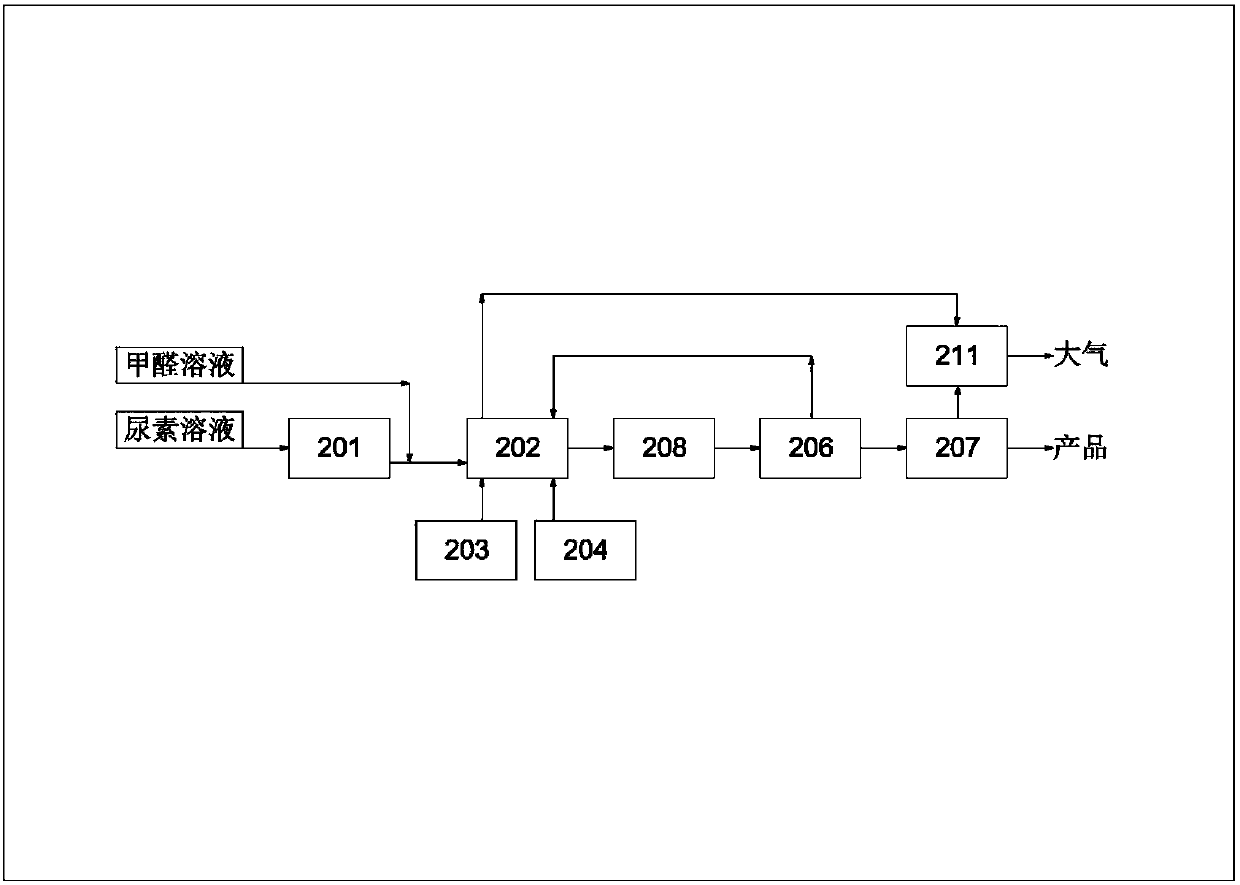

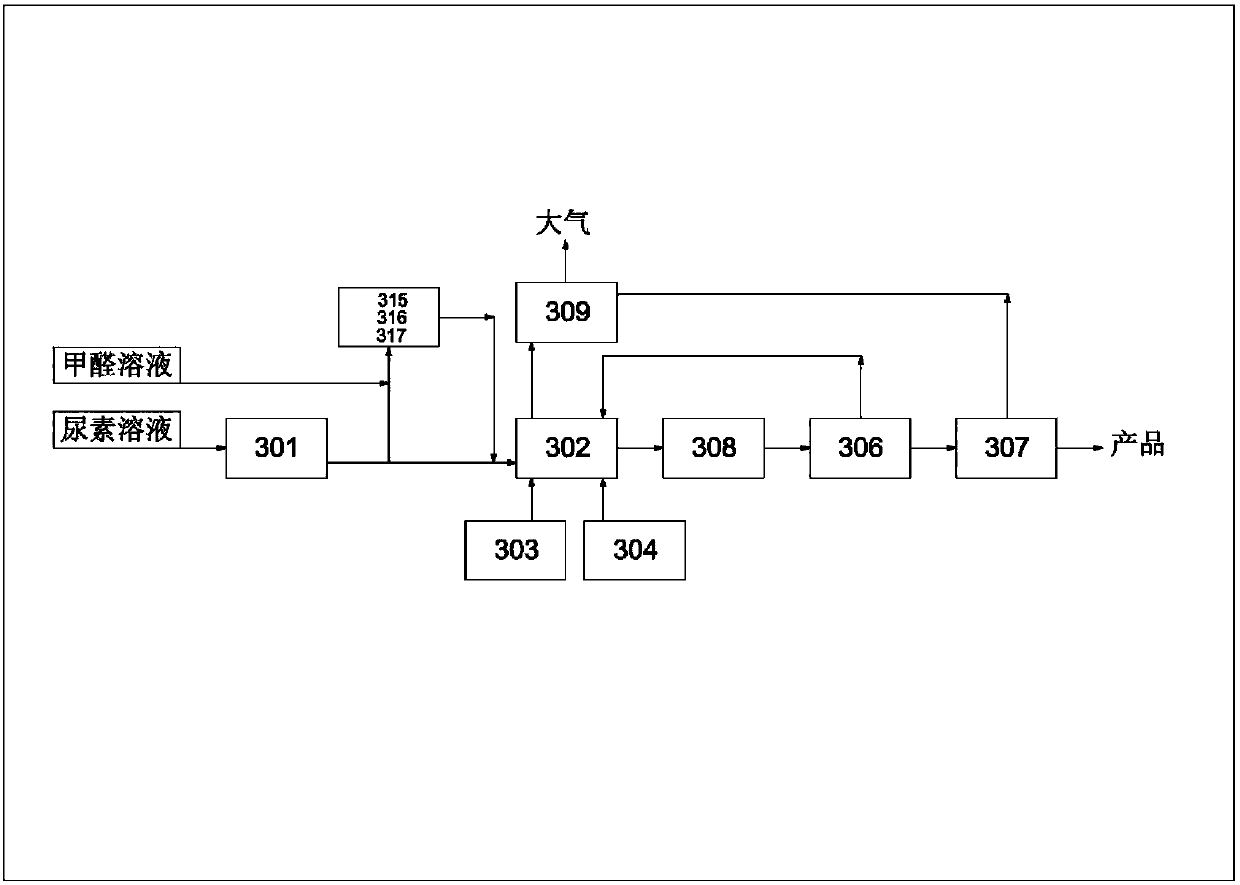

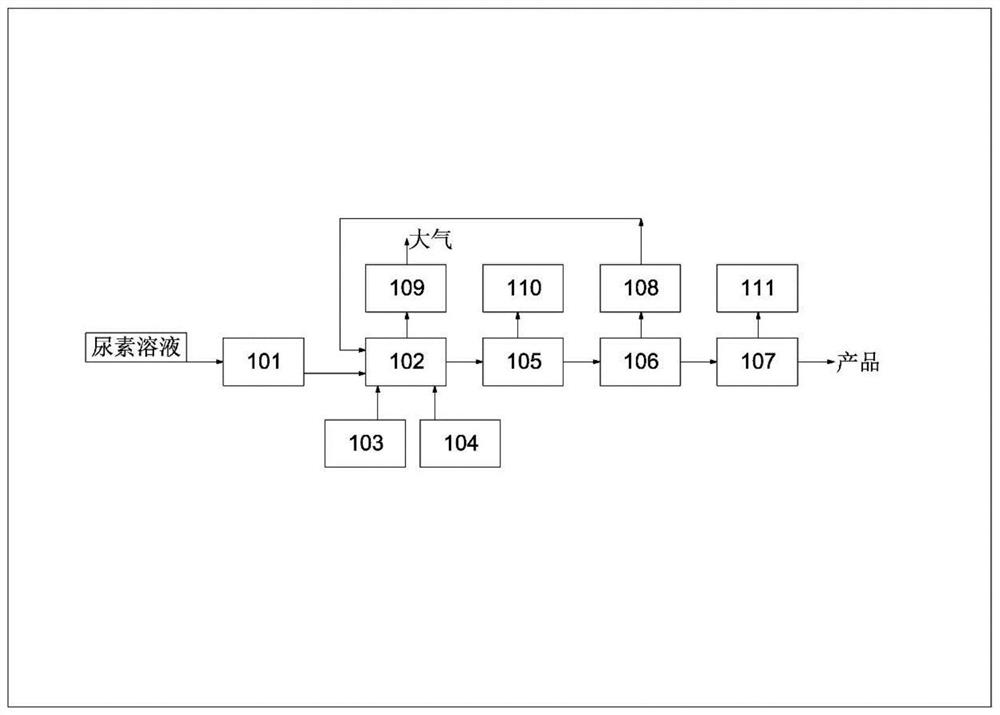

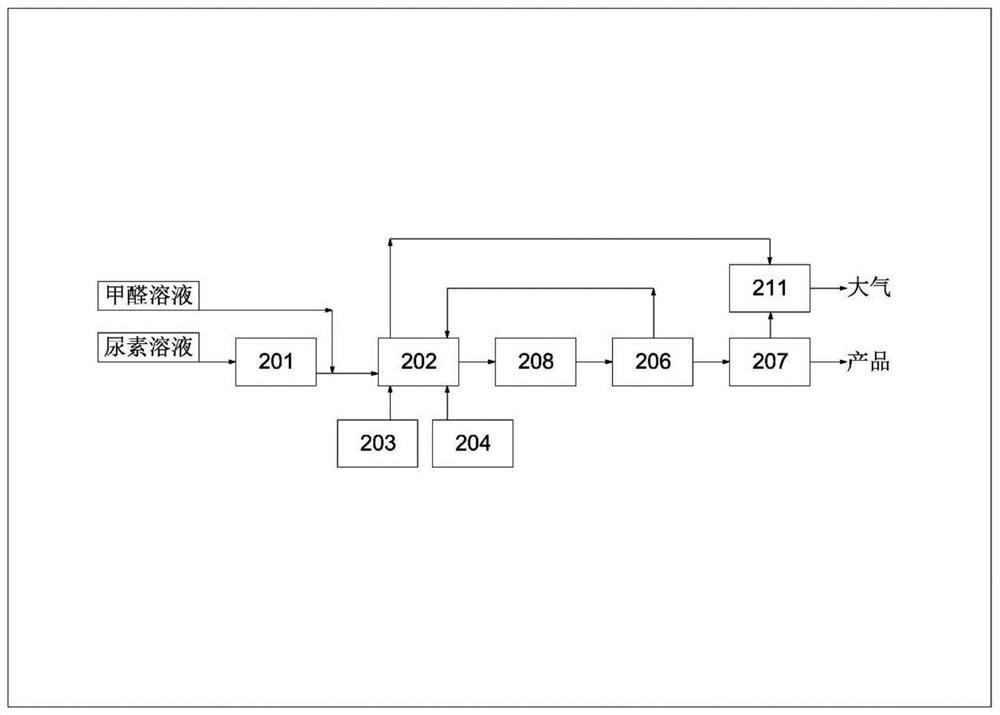

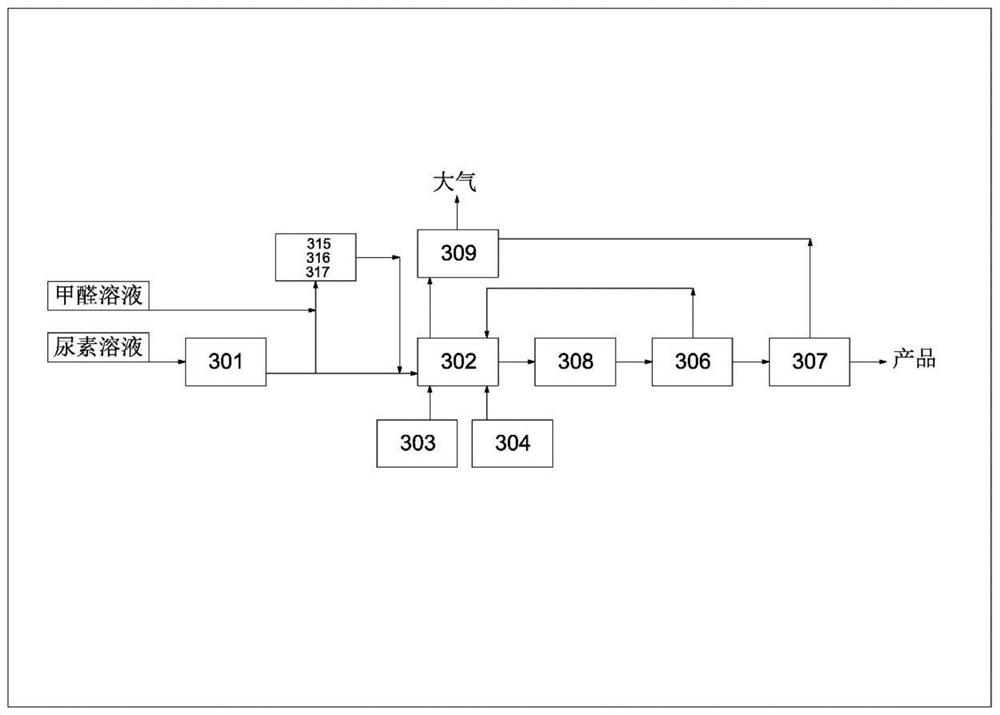

Formaldehyde-adding-free urea granulation process

ActiveCN106984243AGet rid of dependenceEfficient granulationUsing liquid separation agentGranulation by liquid drop formationPrillNitrogen

The present invention relates to a formaldehyde-adding-free urea granulation process. According to the formaldehyde-adding-free urea granulation process, when large formaldehyde-free urea particles are produced, a 75-99% (wt) urea solution is conveyed into a granulator without the addition of a formaldehyde solution, granulation is performed through a atomized fluidized bed granulation process, and drying and cooling are performed to prepare the large particle urea, wherein the urea-dust-containing air discharged during the production process is respectively subjected to standard dry dust removing treatment and standard wet dust removing treatment at a normal temperature under a normal pressure. According to the present invention, the nitrogen content of the obtained large-particle formaldehyde-free urea can be up to 46.5% and is superior to the national standard of urea (GB2440-2001) (excellent grade), and the obtained large-particle formaldehyde-free urea can completely and simultaneously meet industrial uses and agricultural uses, can be directly used for vehicle urea, and has characteristics of large particle, uniform particle, low Biuret content, high particle strength, good fluidity, breaking resistance, caking resistance, easy storage, and easy use.

Owner:CASALE SA

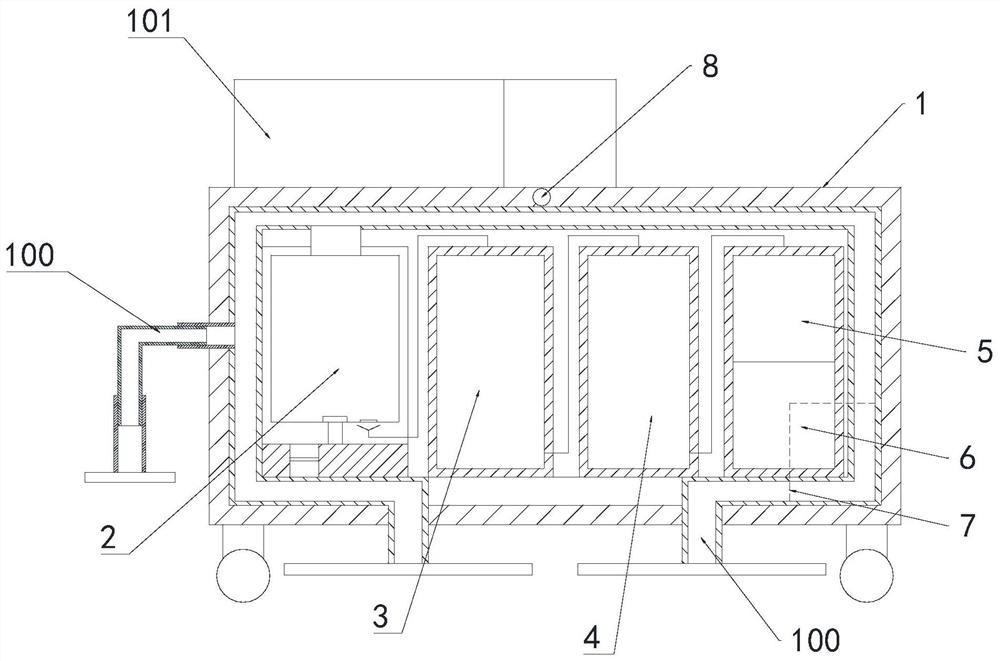

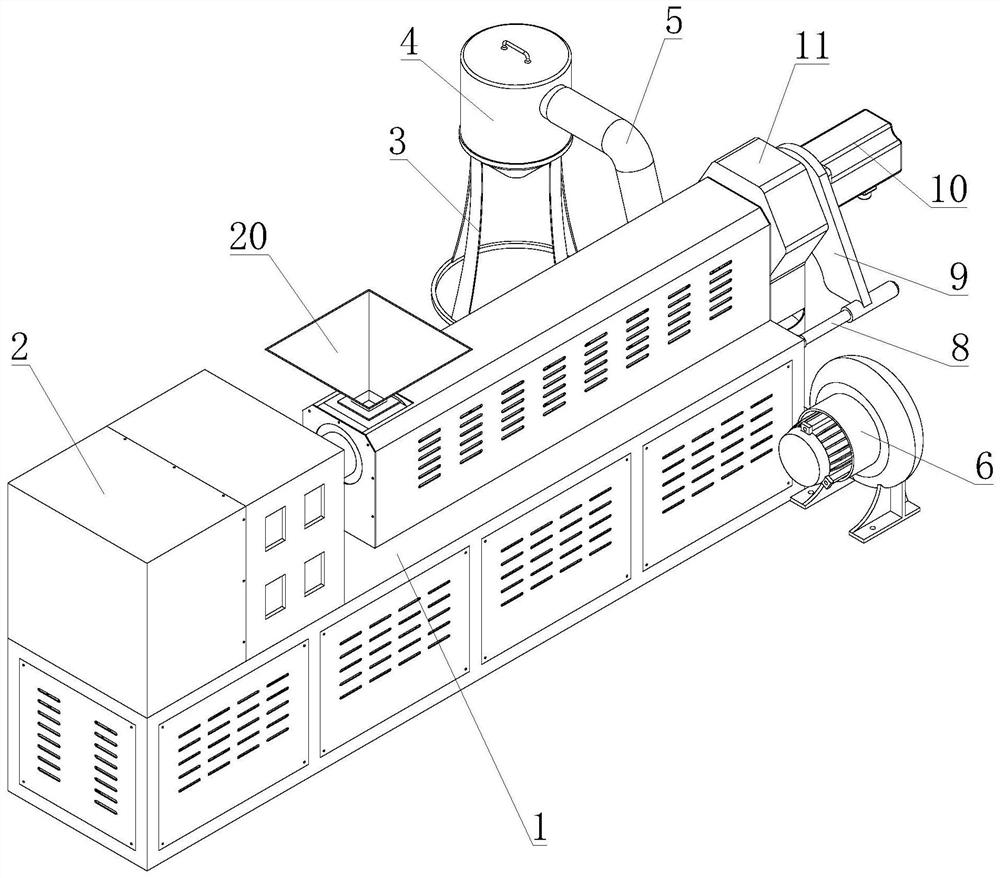

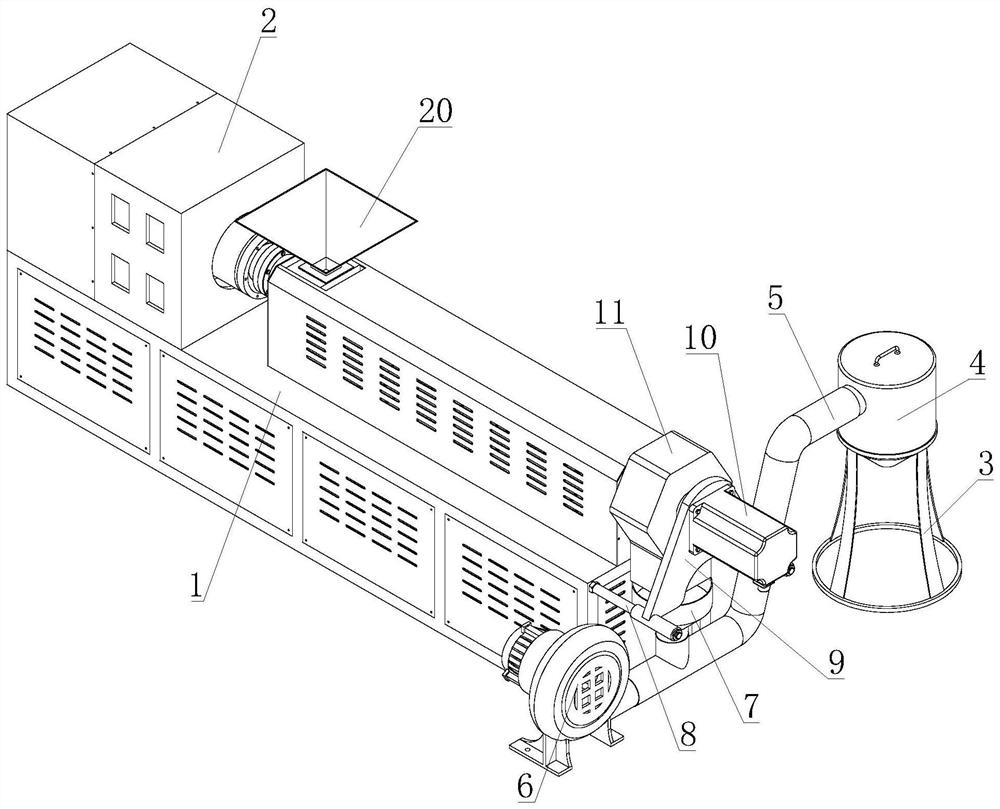

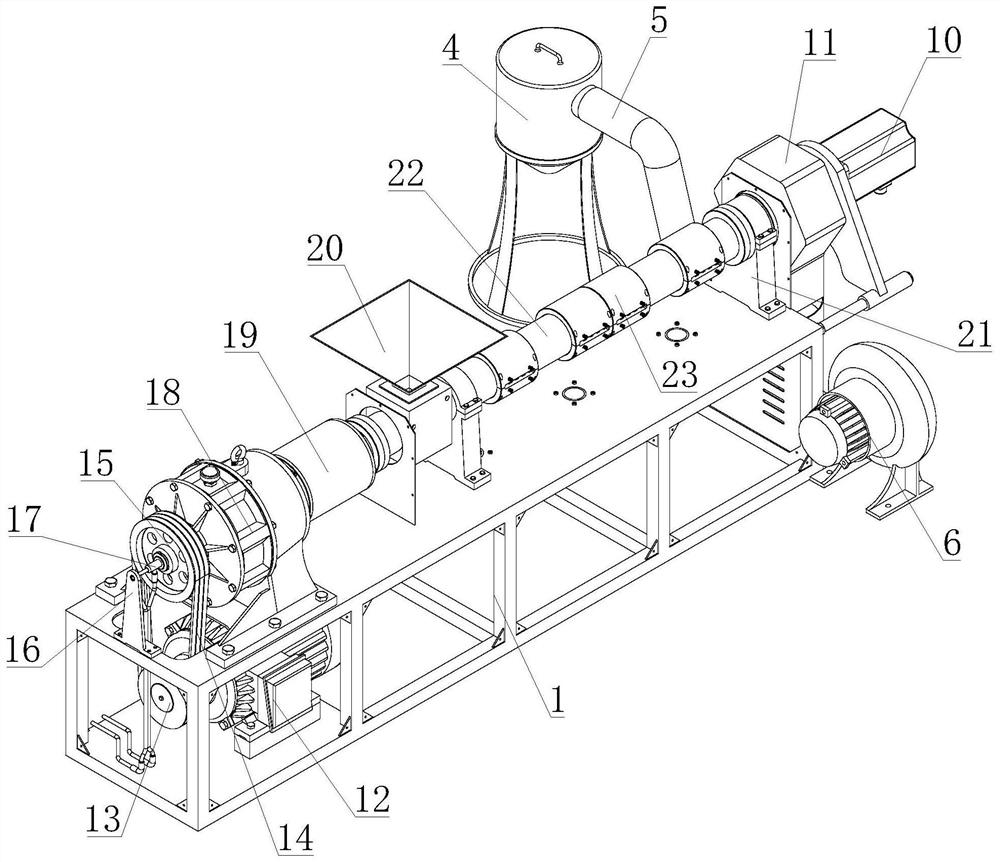

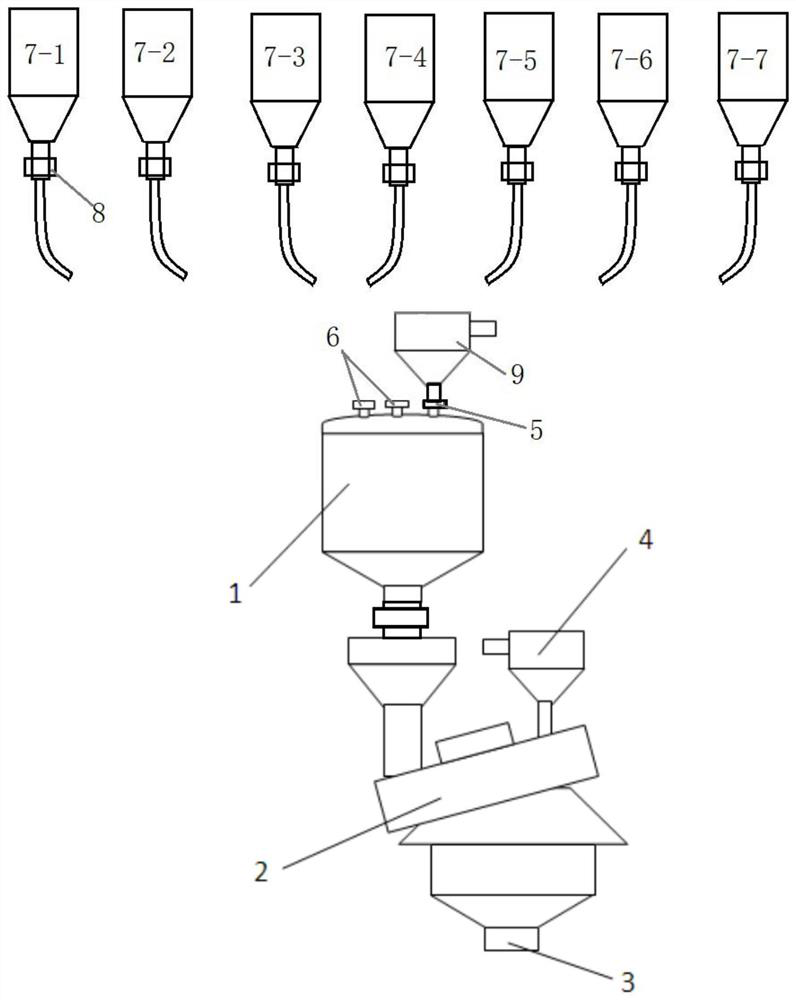

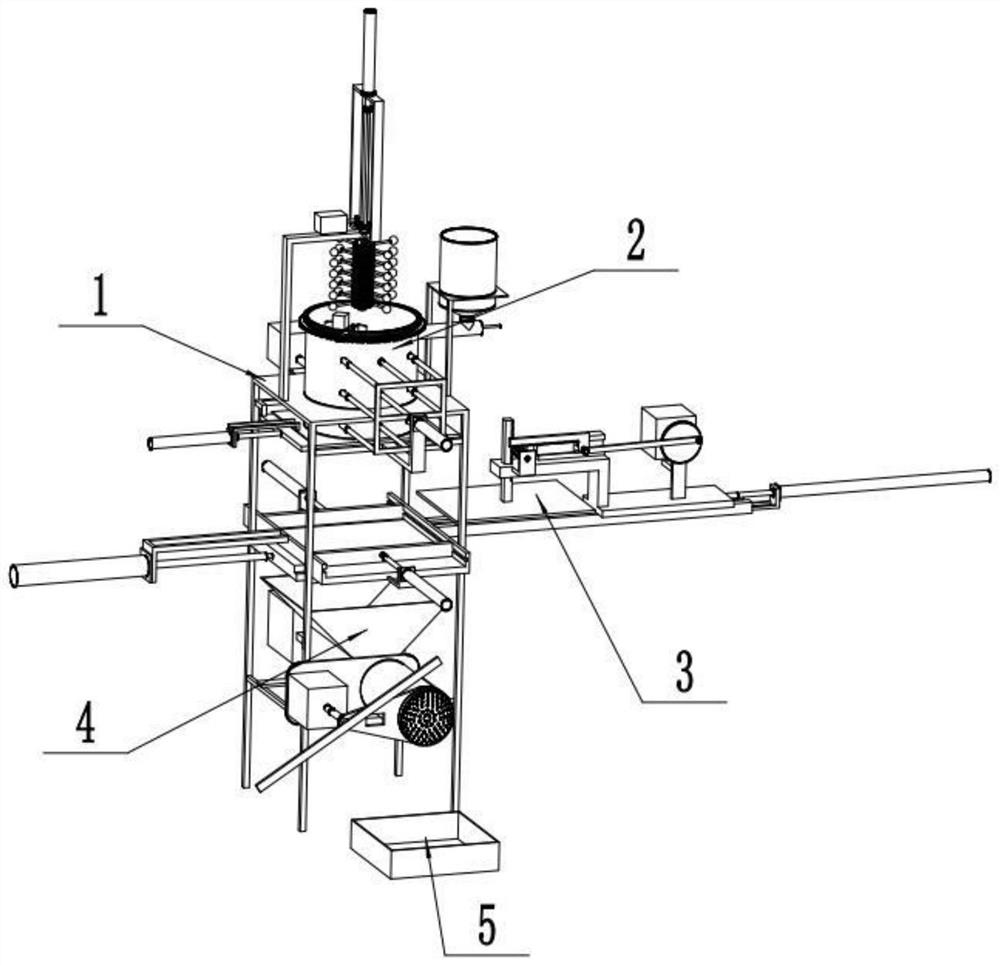

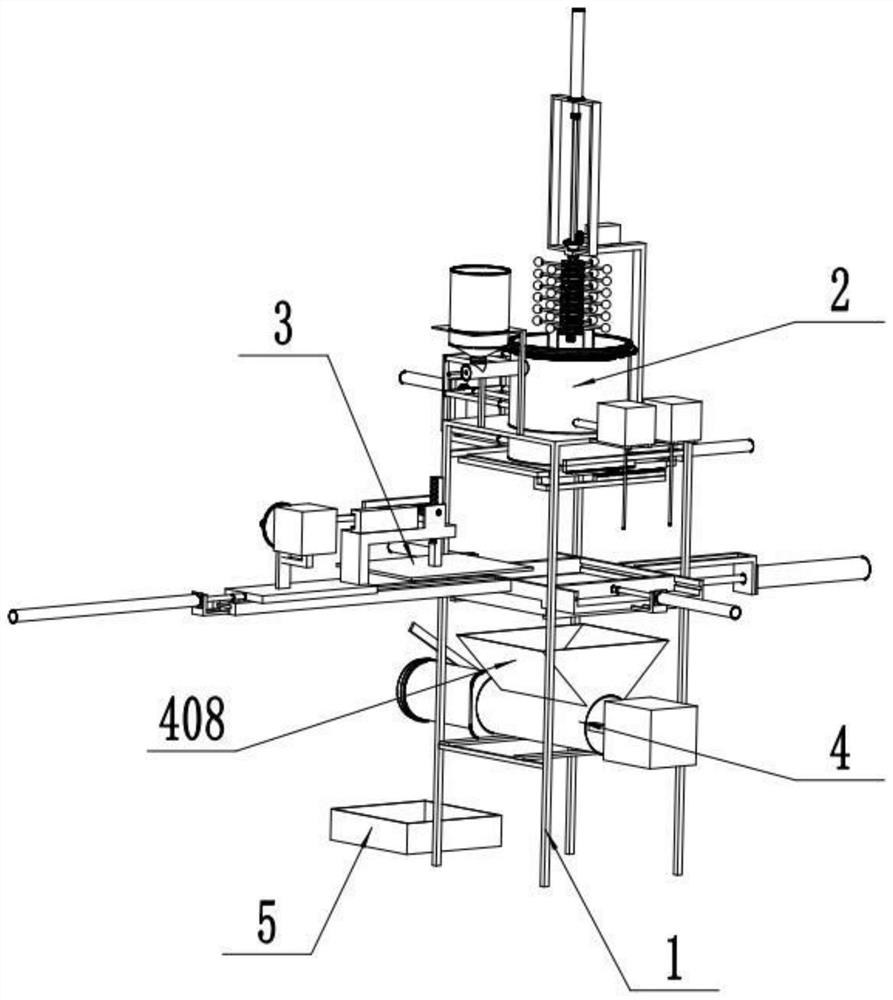

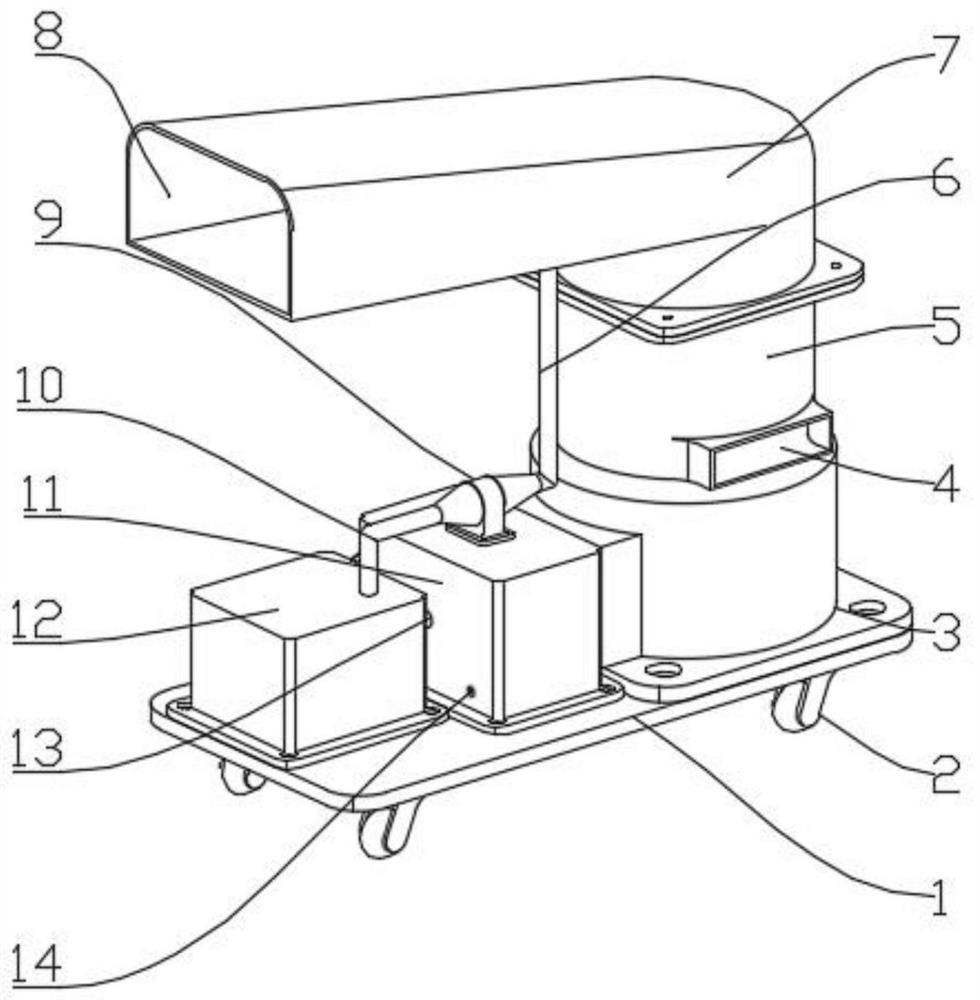

Environment-friendly and efficient tin smelting smoke dust granulating system and method

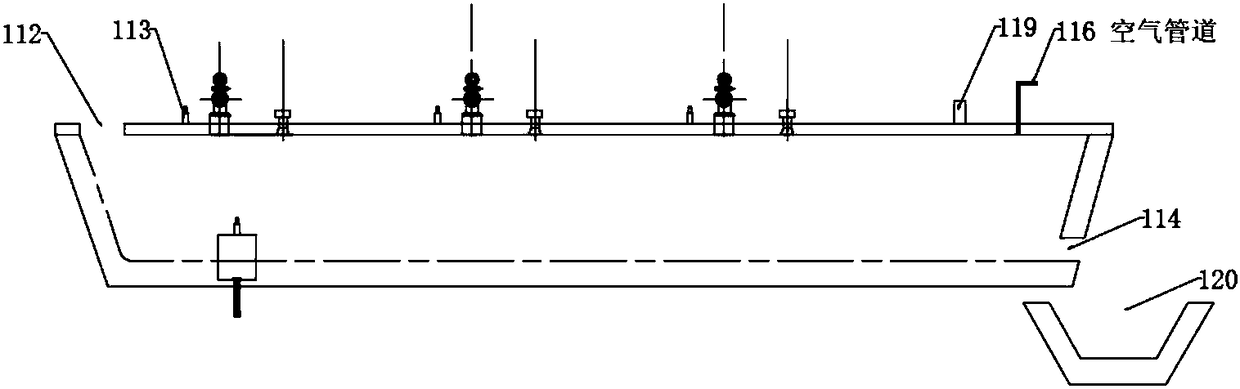

PendingCN111793751AFlexible mixRealize automatic granulationDispersed particle filtrationProcess efficiency improvementControl systemEnvironmental engineering

The invention provides an environment-friendly and efficient tin smelting smoke dust granulating system and method. The system comprises a closed stock bin (1) for storing smoke dust, a granulator (2)and a bag-type dust remover (4), wherein the granulator (2) is positioned below the closed stock bin (1), and the bag-type dust remover (4) is arranged at the tail end of the granulator (4); at leasttwo feeding port (6) and an air outlet (5) are formed in the closed stock bin, each feeding port is correspondingly connected with different tin smoke dust bins through pneumatic conveying pipelines,a gasification jet bin type pump is arranged at a discharge port of each tin smoke dust stock bin, and the gasification jet bin type pumps are controlled to be started by a DCS control system; a topfeed hopper of the granulator is positioned below a discharge port at the bottom of the closed stock bin; and smoke dust particles prepared by the granulator are discharged from a bottom discharge port (3). According to the environment-friendly and efficient tin smelting smoke dust granulating system, the granulating balling rate of tin smelting smoke dust is improved, the labor intensity is reduced, the operating environment is improved, and the cleaning, environmental protection and efficient granulation of the tin smelting smoke dust are realized.

Owner:YUNNAN TIN CO LTD TIN BRANCH

Screening machine for feed granulation

InactiveCN106473209AUniform granulationImprove work efficiencyFeeding-stuffRadial distributionEngineering

The present invention discloses a screening machine for feed granulation. The screening machine comprises a rotary drive mechanism, a rotating mandrel, pressing plates, nail rakes, a screening net and a material collecting tank. The screening net covers a tank mouth of the material collecting tank, and the rotating mandrel is hingedly arranged on the material collecting tank and located above the screening net. The nail rakes and the pressing plates are multiple, use the rotating mandrel as the center, and are fixedly arranged at the outer circumference of the rotating mandrel in a radial distribution. The pressing plates are in gap cooperation with the screening net, the nail rakes are in slide cooperation with the screening net, and the rotary drive mechanism is in a synchronized driving with the rotary mandrel and is used to drive the rotation of the rotating mandrel. The screening machine can enable the feed to be efficiently, automatically and uniformly granulated.

Owner:广州普熙达生物科技有限公司

Automatic hammering device and process for ultrahigh-elasticity rubber production

PendingCN114227968AIncrease elasticityEnhanced compression and shock absorption performanceProcess engineeringMachining process

The invention discloses an automatic hammering device and process for ultrahigh-elasticity rubber production, and relates to the technical field of rubber production, the automatic hammering device comprises a supporting assembly and a program control unit, the supporting assembly is provided with a hammering assembly, a hammering assembly and a granulation assembly, the hammering assembly is arranged between the hammering assembly and the granulation assembly, and the program control unit is connected with the hammering assembly; the hammering assembly comprises a hammering barrel, a feeding unit, a hammering unit, a material cleaning unit, a heating unit and a discharging control unit, the hammering assembly comprises a discharging control unit and a hammering unit, the granulation assembly comprises a feeding unit and a granulation unit, a foaming assembly is arranged below the granulation unit, a standing chamber is arranged on the side face of the foaming assembly, and the foaming assembly is arranged in the standing chamber. The machining process is accurate, the machining efficiency is high, and the machined material has the beneficial effects of being ultrahigh in elasticity and good in compression resistance and damping effect.

Owner:福建省莆田市联盛鞋业有限公司

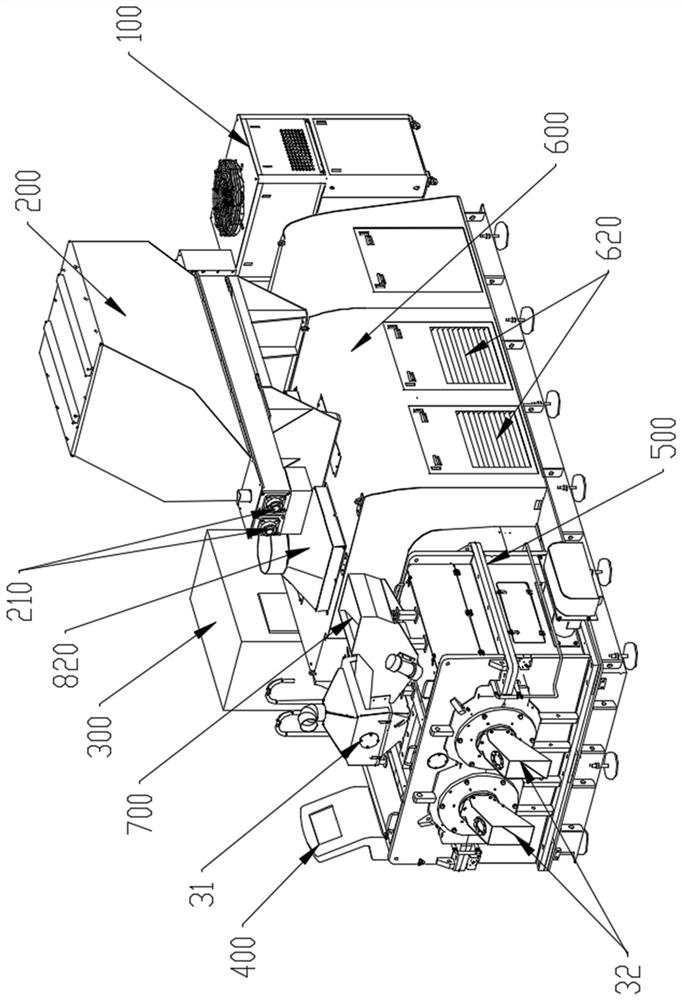

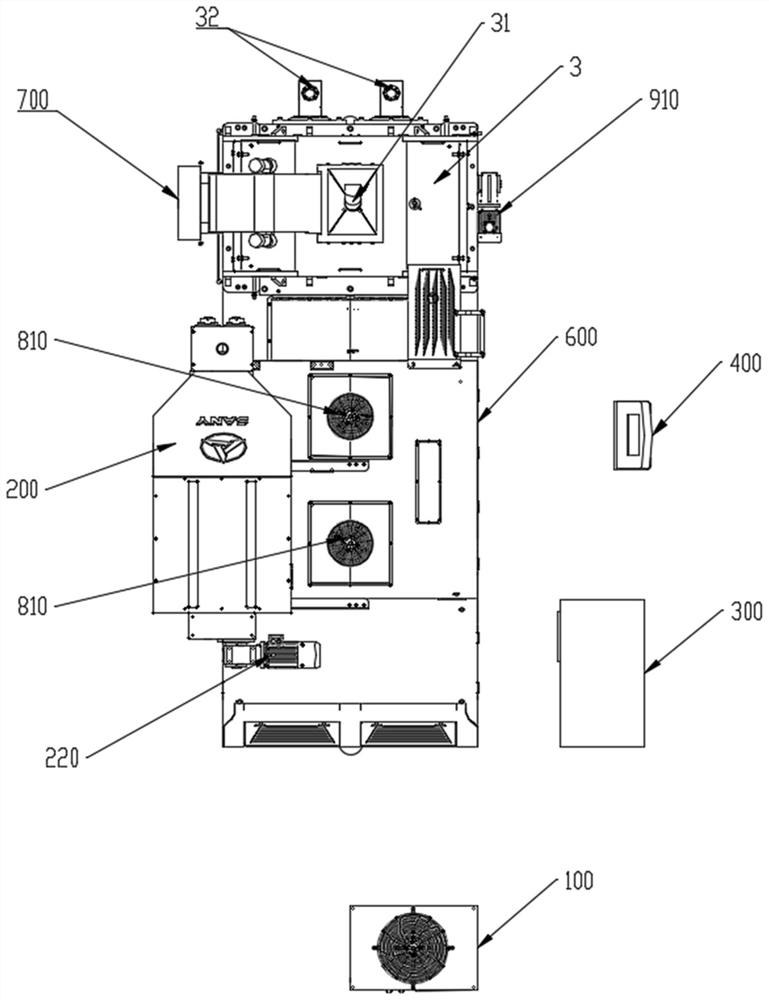

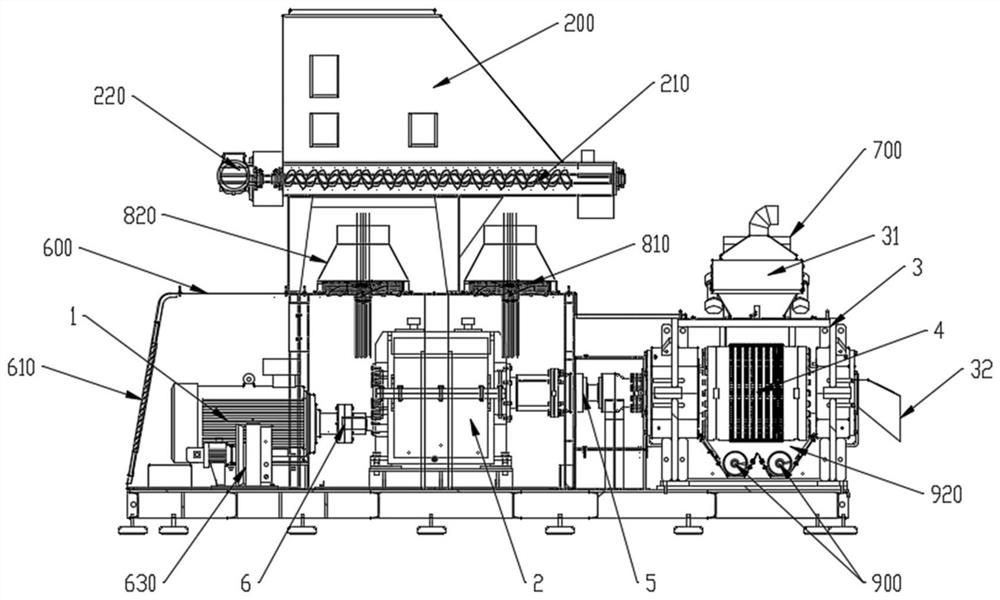

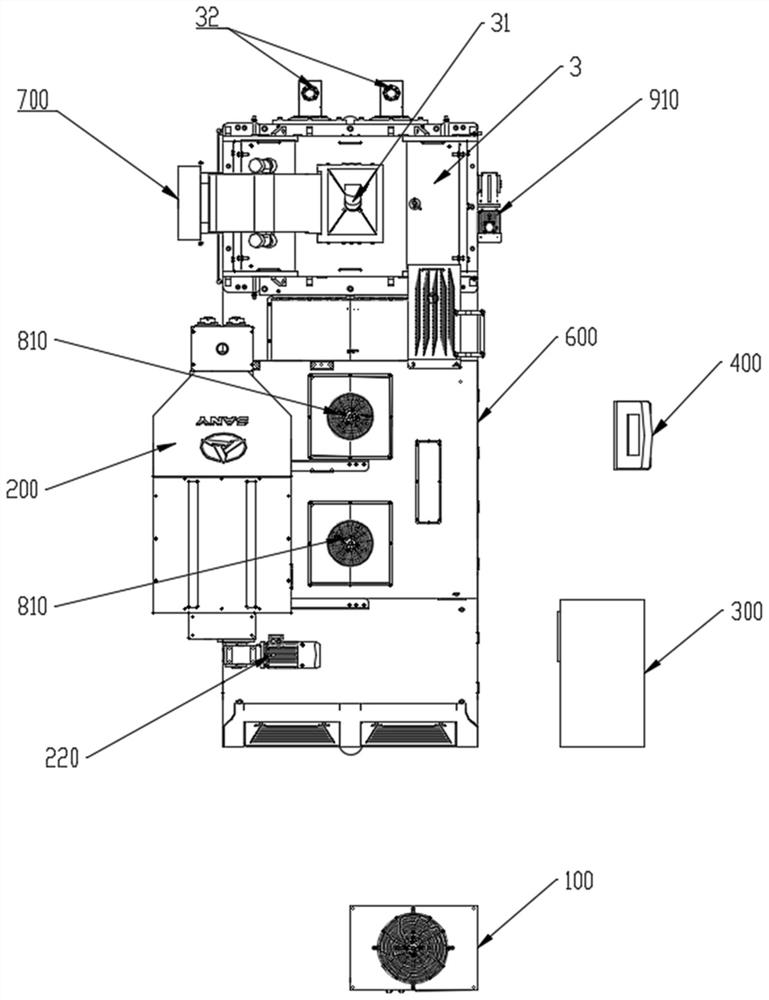

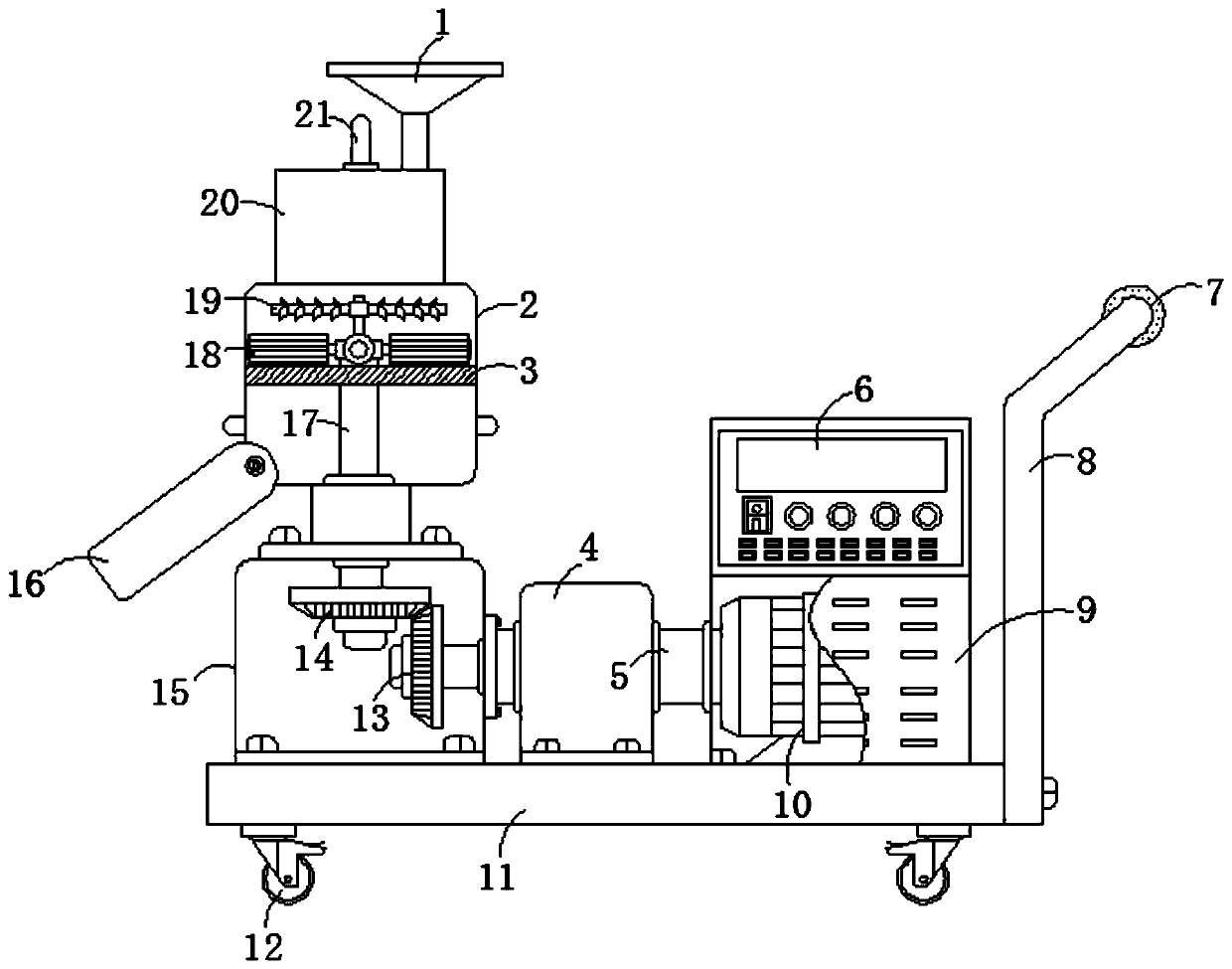

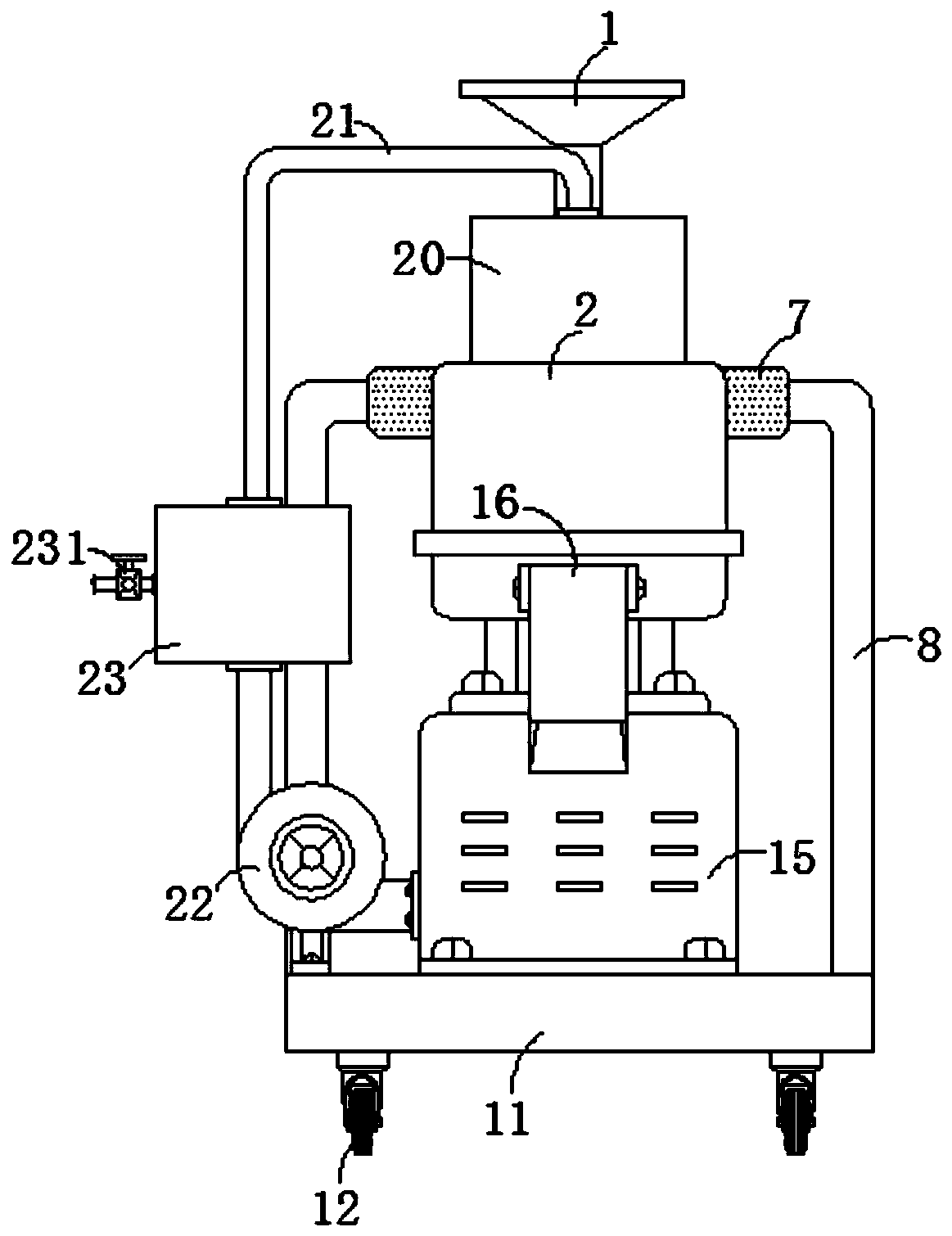

Intelligent biomass particle manufacturing system and granulation method

ActiveCN112844229AEfficient granulationImprove adaptabilitySievingScreeningProcess engineeringManufacturing systems

The invention provides an intelligent biomass particle manufacturing system and a granulation method. The intelligent biomass particle manufacturing system comprises a core shell; a granulator comprising a granulation mold and a driving unit, wherein the driving unit is assembled in the core machine shell, and the granulation mold is arranged at the front end of the core machine shell and connected with the driving unit; a buffer stock bin installed at the top of the core machine shell, wherein a discharging port of the buffer stock bin is connected to a feeding port of the granulation mold through a vibrating screen; and an intelligent control mechanism connected to the granulator and the buffer stock bin and used for calibrating various parameters of the granulator and the buffer stock bin and monitoring the working process of the granulator and the buffer stock bin. The system can intelligently monitor the granulation process of the granulator, and can reasonably calibrate the size, moisture and other parameters of raw materials entering the granulator from the buffer stock bin, so that the adaptability of the system to the raw materials is improved, the fine powder technological process in a traditional granulation system can be omitted, and dust pollution and noise pollution in the granulation process are reduced.

Owner:JIANGSU SANY ENVIRONMENTAL TECH LTD

Toner manufacturing method

InactiveUS7781139B2Suppressing in compositionSuppressing in dispersibilityDevelopersEngineeringAqueous medium

A toner manufacturing method that allows production of toner having desired characteristics with stability in accordance with fusion emulsification technique for obtaining a toner by granulating a resin kneaded product while dispersing it in an aqueous medium. A resin kneaded product containing at least a binder resin and a colorant is mixed with a dispersant / water-containing aqueous medium. The resultant admixture is stirred by an stirring apparatus including a screen with an admixture discharge hole disposed internally of a vessel and a rotor disposed in an stirring space created by the screen.

Owner:SHARP KK

Biomass particle intelligent manufacturing system and granulation method

ActiveCN112844229BEfficient granulationImprove adaptabilitySievingScreeningProcess engineeringIntelligent manufacturing system

The invention provides a biomass particle intelligent manufacturing system and a granulation method. The biomass granule intelligent manufacturing system includes: a core casing; a granulator, including a granulation die and a driving unit, the driving unit is assembled in the core casing, and the granulation die is arranged at the front end of the core casing and is connected with the driving unit; The buffer silo is installed on the top of the core casing. The discharge port of the buffer silo is connected to the feed port of the pelletizing die through the vibrating screen; the intelligent control mechanism is connected to the pellet machine and the buffer silo for calibrating the pellet machine. and various parameters of the buffer silo, and monitor the working process of the pellet machine and the buffer silo. The system can intelligently monitor the granulation process of the granulator, and can reasonably calibrate parameters such as the size and moisture of the raw materials entering the granulator from the buffer silo, thereby improving the adaptability of the system to raw materials, and can omit the traditional granulation system. The fine powder process can reduce the dust pollution and noise pollution in the granulation process.

Owner:JIANGSU SANY ENVIRONMENTAL TECH LTD

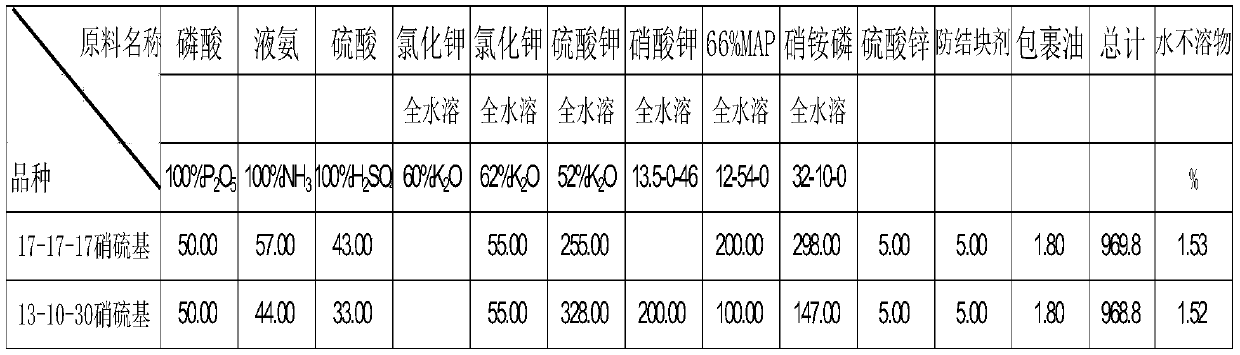

Production device and process of nitro-sulfur-based water-soluble fertilizer

PendingCN111393210AImprove liquidityReduce process waterAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphatePhosphoric acid

The invention provides a production device and process of a nitro-sulfur-based water-soluble fertilizer. A mixing tank, a phosphoric acid pipeline, a sulfuric acid pipeline, a liquid ammonia pipeline,a washing liquid pipeline and a medium-pressure steam pipeline are respectively connected with a tubular reactor through pipelines, the tubular reactor is arranged in a granulator, and the granulatoris connected to a nitro-sulfur-based water-soluble fertilizer storage device. The preparation process comprises the following steps: feeding a mixture of potassium salt, ammonium nitrate phosphate and a chelating agent as a solid raw material from a raw material system, and adding the mixture into a granulator; pumping monoammonium phosphate, ammonium nitrate phosphate, process water and low-pressure steam into a slurry storage tank to form monoammonium phosphate slurry; and forming blended slurry from the monoammonium phosphate slurry, ammonium nitrate phosphate, a washing solution and concentrated phosphoric acid, pumping the blended slurry into a mixing tank, pumping the blended slurry into a tubular reactor after the blended slurry is formed, pumping sulfuric acid, liquid ammonia andsteam into the tubular reactor, spraying the slurry into the granulator for granulating, and performing drying to obtain the nitro-sulfur-based water-soluble fertilizer. The mass fraction of water-insoluble substances of the prepared nitro fertilizer can be stabilized to 0.2-0.3%.

Owner:湖北省黄麦岭磷化工有限责任公司

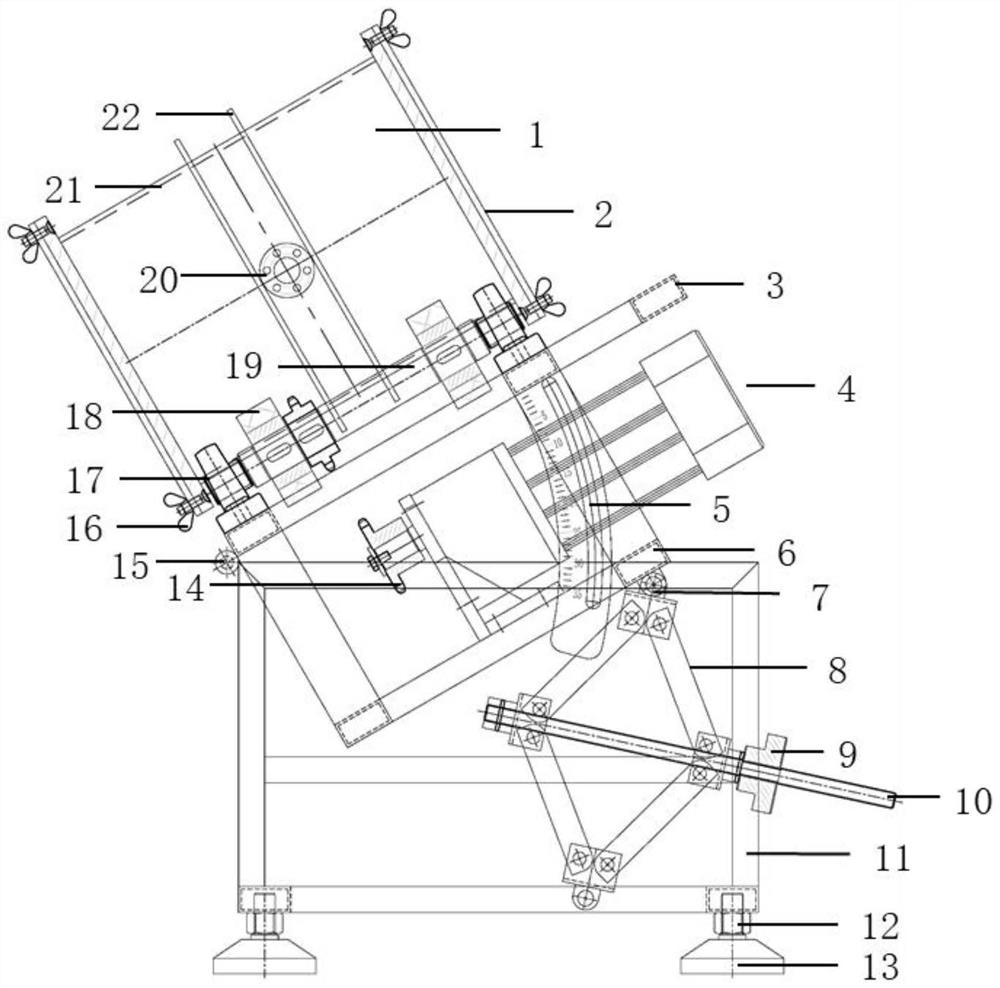

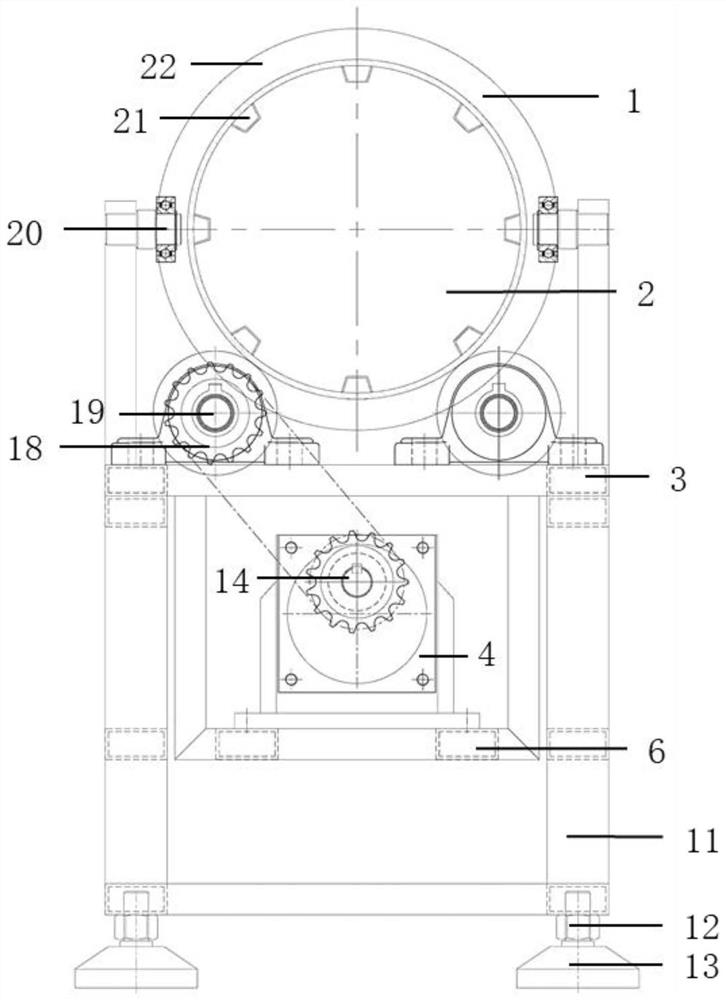

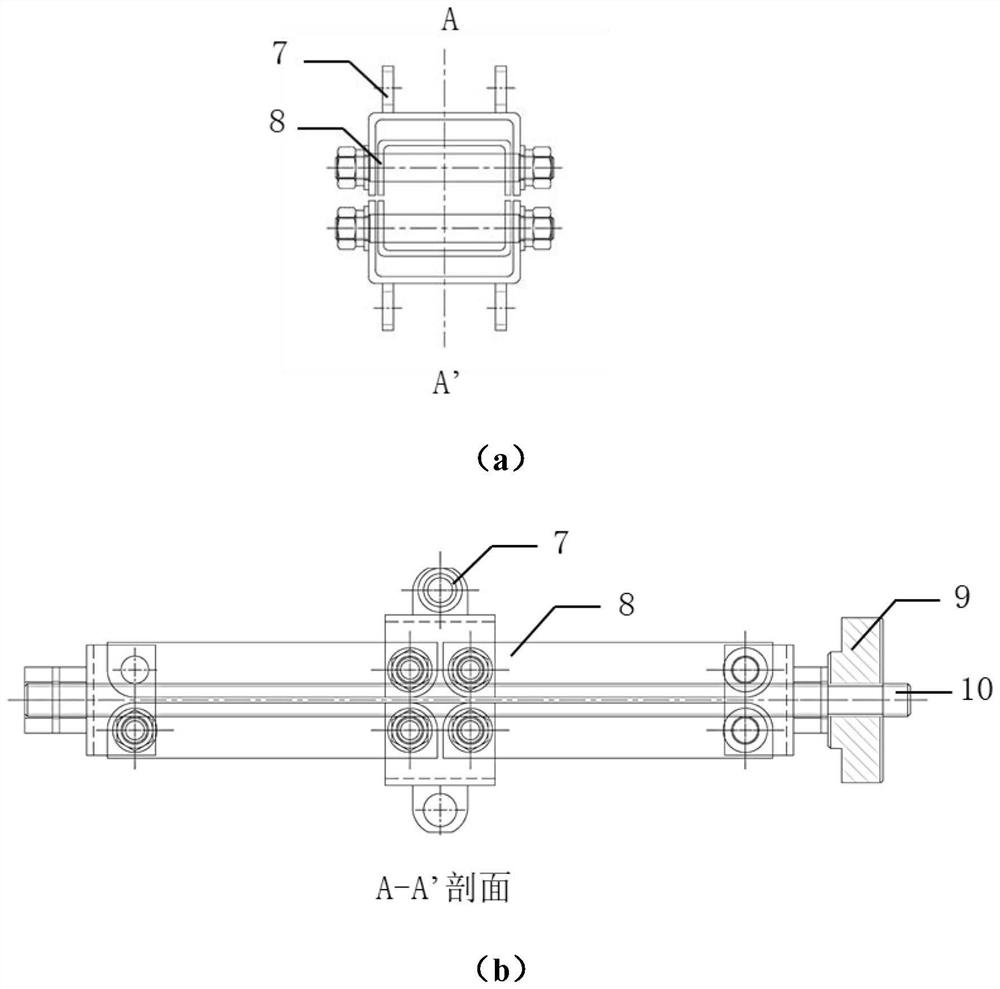

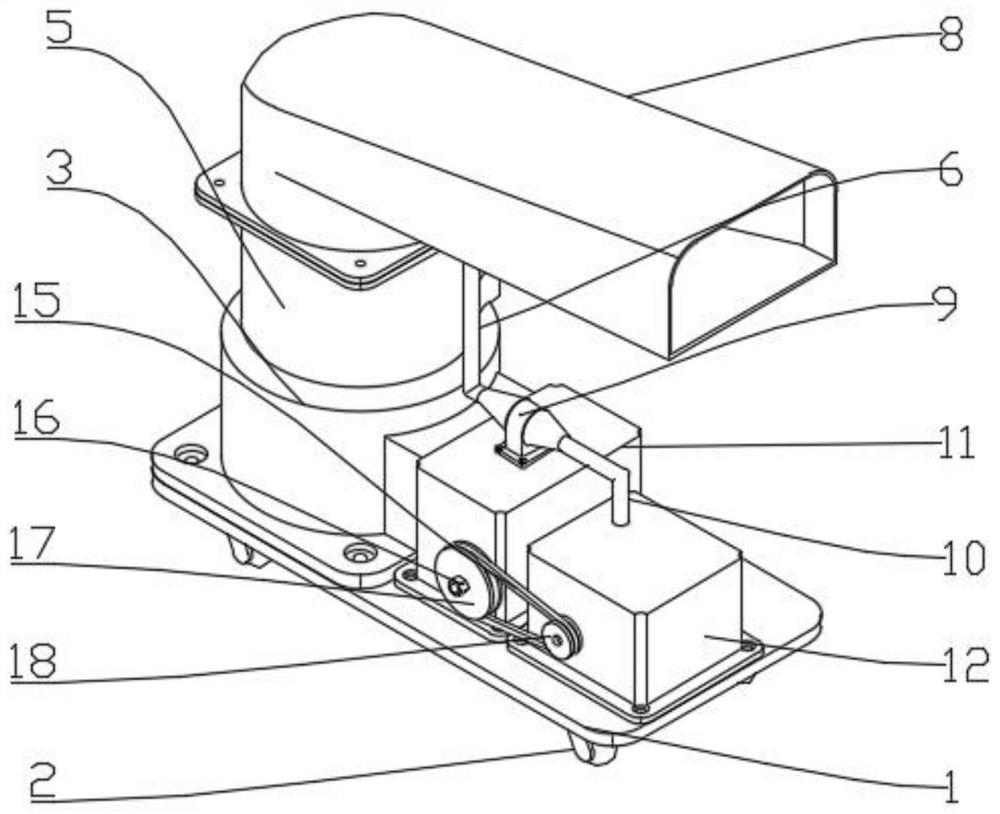

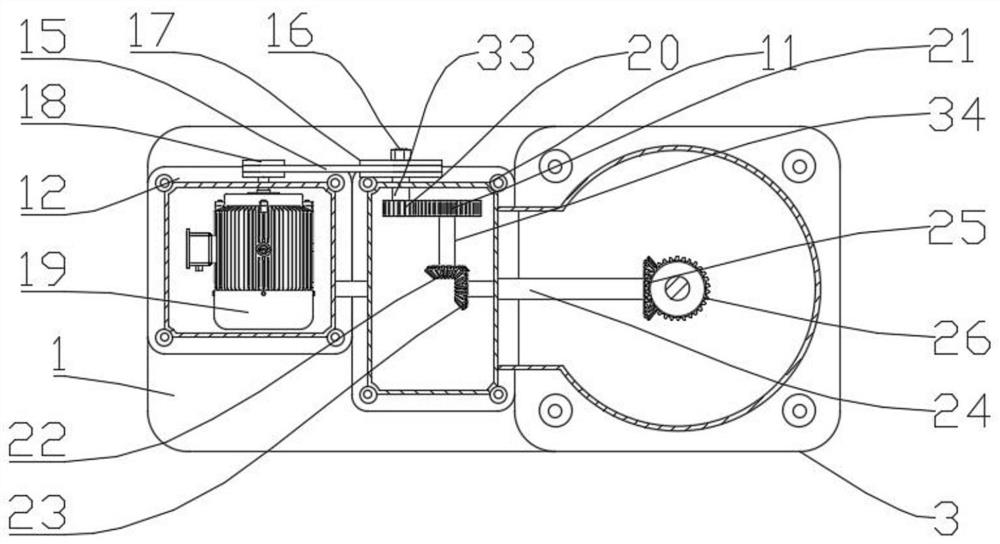

An ore granulation device and method with adjustable inclination angle and rotating speed

ActiveCN111036137BAdjustable inclinationNo axial displacementGranulation in rotating drumsGranulation with special binding agentsAxial displacementKeel

The invention provides an ore granulation device and method with adjustable inclination angle and rotational speed, belonging to the technical field of metal ore granulation. The device includes a granulation drum, a partition, a fixed knob, a trapezoidal keel, a rotating support platform, an angle scale, an angle adjustment bracket, an angle adjustment knob, a threaded screw, a main rotating roller, a slave rotating roller, a variable speed motor, a motor bracket, and a transmission devices, stainless steel brackets, leveling nuts, etc. Rotate the threaded screw to open and close the angle adjustment bracket, use the angle scale to observe and determine the current inclination angle, and realize the adjustable inclination angle of the granulation drum; the variable speed motor is connected with the lateral support roller through the transmission system to drive the granulation drum to rotate ; There is a keel inside the granulation drum to improve the efficiency of granulation rolling and granulation; there is an axial support roller inside the rolling guide to ensure that the granulation drum does not move axially during rotation. The structure of the device is simple, the method is practical and convenient, and it can carry out high-efficiency granulation of ore under actual working conditions such as different inclination angles and different speeds.

Owner:UNIV OF SCI & TECH BEIJING

A method and device for producing tar cracking catalyst by granulating liquid blast furnace slag

ActiveCN106423168BEfficient granulationImprove heat transfer effectCatalytic crackingRecycling and recovery technologiesHigh pressureQuenching

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A high-efficiency and environment-friendly straw processing granulator

ActiveCN108854846BUniform feedingFalling smoothlyGranulation by pressingAgricultural engineeringProcess engineering

The invention discloses a high-efficiency and environment-friendly type straw particle processing machine. The high-efficiency and environment-friendly type straw particle processing machine comprisesa bottom plate, wherein a gear box is fixedly arranged at one side of the upper surface of the bottom plate; a main shaft box is arranged at the top end of the gear box through a fixed seat; a material charge bin is fixedly arranged at the upper surface of the main shaft box; a main shaft is arranged in the middle part of the bottom part of the interior of the main shaft box; a material feed hopper is arranged at one side of the upper surface of the material charge bin; the main shaft penetrates through the main shaft box, and extends into the gear box; a first connecting roll and a second connecting roll are fixedly arranged at one end of the main shaft. The high-efficiency and environment-friendly type straw particle processing machine has the advantages that by arranging a stirrer, a material is uniformly fed, so that the blockage of the equipment by the fed material is prevented, and the processing efficiency is improved; by arranging an energy recycling device, the heat energy ofair can be recycled, the loss of heat energy resources is prevented, and the secondary pollution to environment by the exhaust of hot air is avoided; more energy-saving and environment-friendly effects are realized, the blockage of the equipment is prevented, the straw particles are quickly discharged, and the equipment processing is more efficient.

Owner:宋晴

A system for dry centrifugal granulation and waste heat recovery and utilization of liquid slag

ActiveCN108359756BEfficient granulationEfficient recyclingRecycling and recovery technologiesHandling discharged materialLiquid slagWater vapor

Disclosed is a dry type centrifugal granulation and waste heat recycling and utilization system for liquid molten slag, comprising a molten slag temporary storage and flow rate control module (1), a molten slag centrifugal granulation and waste heat recycling module (2), a molten slag moving bed heat exchange and waste heat recycling module (3), and a high-temperature air waste heat utilization module (4). The system comprises a water vapor procedure, an air procedure, an exhaust gas procedure and a slag procedure and the corresponding devices therefor. By means of the design of the aforementioned modules and the various medium procedures, the efficient granulation of the liquid molten slag and the efficient recycling and utilization of heat can be guaranteed.

Owner:XI AN JIAOTONG UNIV

A urea granulation process without adding formaldehyde

ActiveCN106984243BGet rid of dependenceEfficient granulationUsing liquid separation agentGranulation by liquid drop formationIn vehiclePhysical chemistry

The invention relates to a urea granulation process without adding formaldehyde. When producing large granules of formaldehyde-free urea, 75-99% (wt) urea solution is sent to a granulator without adding formaldehyde solution, and is granulated by an atomized fluidized bed granulation process, and is obtained after drying and cooling Large granular urea. The air containing urea dust discharged during the production process is treated with dry and wet dust removal methods under normal temperature and pressure. The nitrogen content of the formaldehyde-free large-grain urea obtained by the present invention can be as high as 46.5%, which is superior to the national urea standard (GB2440-2001) for high-grade products, can completely meet the industrial and agricultural uses at the same time, and can be directly used for vehicle urea. And the particles are large, uniform, low biuret content, high particle strength, good fluidity, not easy to break and not agglomerate, easy to store and apply.

Owner:CASALE SA

Efficient environment-friendly straw processing granulator

InactiveCN113680281AEasy accessWon't clogGranulation by pressingProcess engineeringMechanical engineering

The invention discloses an efficient environment-friendly straw processing granulator which comprises a bottom plate, four fixed universal wheels are fixed to the bottom end of the bottom plate, the four fixed universal wheels are installed at the four corners of the bottom end correspondingly, and a motor box is fixed to one side of the top end of the bottom plate through four sets of M10 bolts. According to the invention, the feed port is a smooth plane with an inclined angle; meanwhile, the narrow opening deviating to the turning direction of the cutting cutter head is formed, it can be guaranteed that straw can enter a material crushing area more easily without blocking, secondary processing is conducted on the straw through the cutting cutter head and the grinding roller, primary processing is conducted on the straw through the cutting cutter head, and efficient granulation of the equipment is guaranteed. The detachable sieve can be replaced according to the requirement for the particle size, heat generated by the power source and the transmission mechanism is transmitted into the material crushing area and the particle crushing area at the same time, straw is dried, the drying degree of the straw is improved, the storage time of the straw is prolonged, and meanwhile it is guaranteed that the device efficiently and reasonably uses energy.

Owner:黄春燕

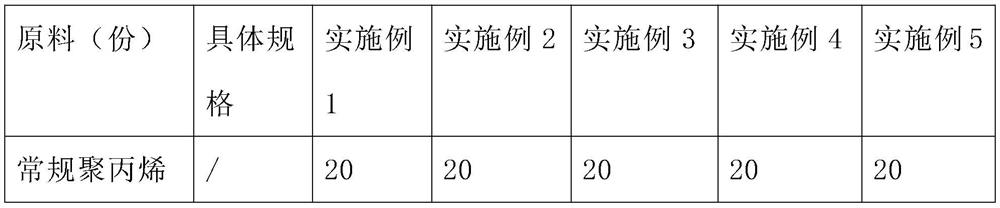

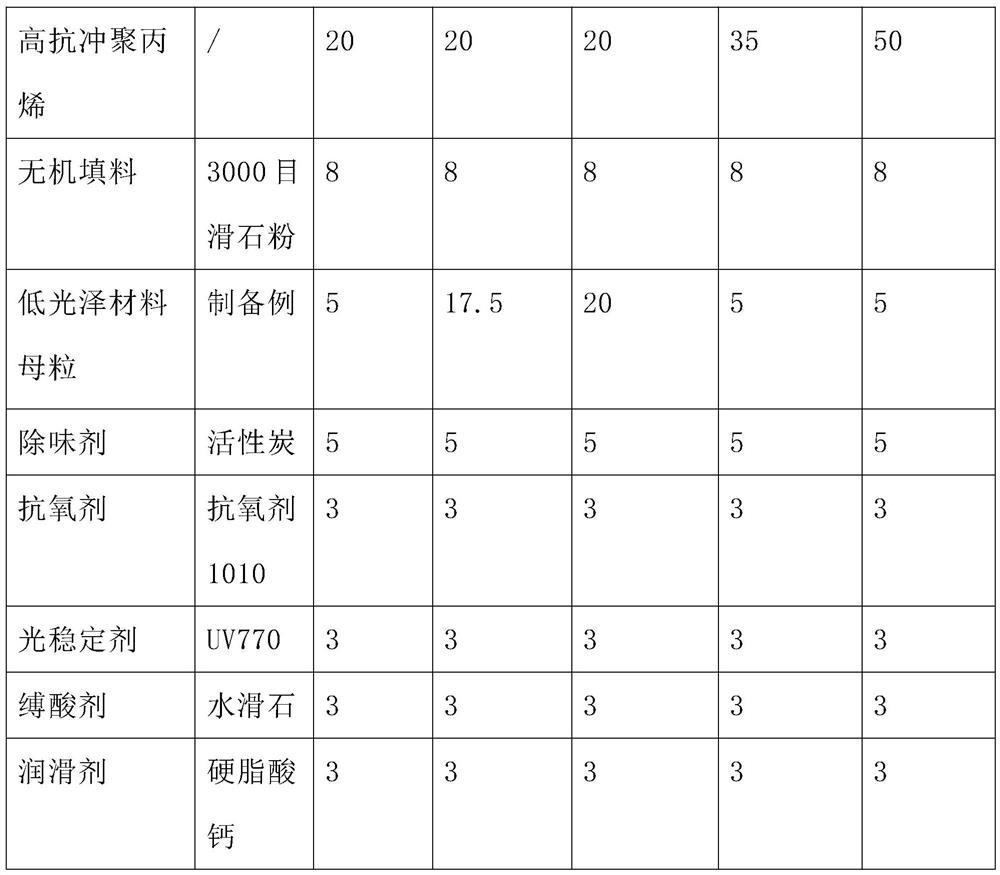

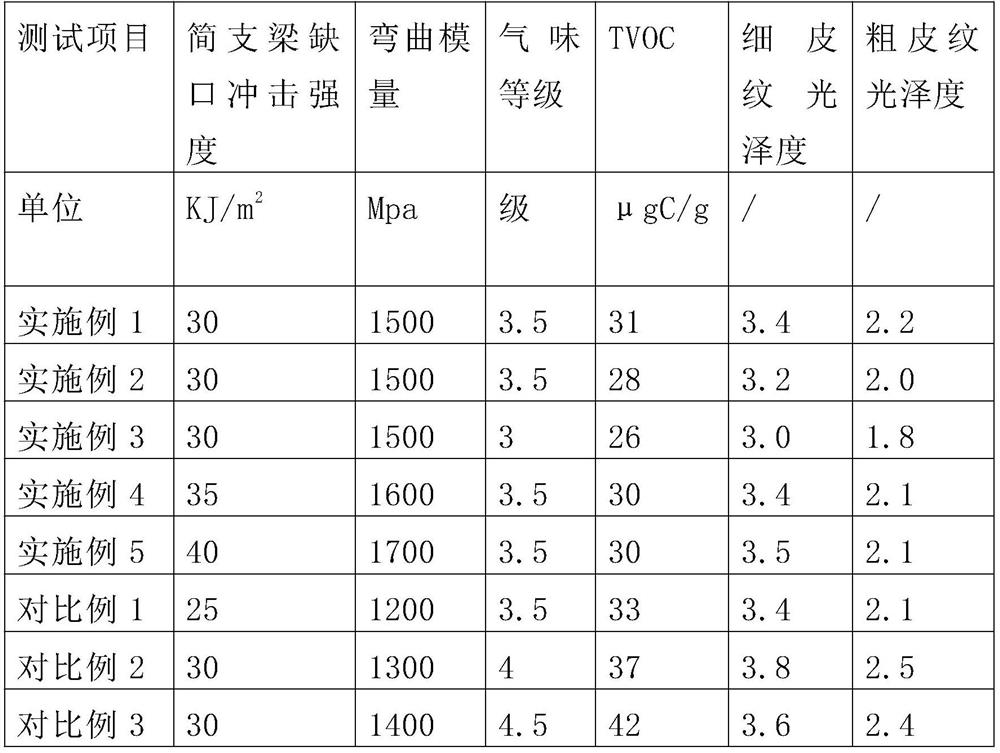

Modified polypropylene for automotive interiors and preparation method of modified polypropylene

The invention relates to modified polypropylene for automotive interiors and a preparation method of the modified polypropylene. The key point of the technical scheme is that the modified polypropylene is prepared from the following components in parts by mass: 20-50 parts of conventional polypropylene, 20-50 parts of high-impact polypropylene, 8-20 parts of inorganic filler, 5-20 parts of low-gloss material master batch, 0-5 parts of a deodorant, 0-3 parts of an antioxidant, 0-3 parts of a light stabilizer, 0-3 parts of an acid-binding agent and 0-3 parts of a lubricant. The modified polypropylene provided by the invention has good stability, and generates less volatile organic compounds in daily use compared with traditional modified polypropylene for automotive interiors.

Owner:QINGDAO GON TECHNOLOGY CO LTD

One-step granulation system for ultrafine powder

ActiveCN105478055BImprove balance yieldImprove granulation efficiencyGranulation in stationary drums/troughsAir velocityEngineering

The invention relates to the technical field of one-step granulation, and discloses a one-step granulation system for ultrafine powder, including a spray fluidization chamber, and an air distribution plate is arranged below the screen at the bottom of the spray fluidization chamber, and the spray The upper part of the fluidization chamber is provided with an air induction chamber, and the top of the spray fluidization chamber is provided with a through hole communicating with the air induction chamber. The through hole is connected with a titanium rod filter, and the center of the through hole is provided with a nozzle. One end is connected to the compressed air blowback device; the air distribution channel formed by the air flow distribution plate and the air flow distribution plate surface of the fluidized bed present a channel angle of 30-60°, thereby changing the direction of the air intake, increasing the wind speed, and simultaneously entering the air The whole is rotating, which is conducive to improving the uniform state of fluidization; the pore size of the titanium rod filter is 0.1-10 µm, which can effectively block ultra-fine dust and reduce leakage of materials; The dust accumulated on the titanium rod filter is dusted off to improve the granulation efficiency of the powder.

Owner:ZHONGSHAN ZHONGZHI PHARMA GRP

Granulating device for cold and heat shrinking material of insulation joint

The invention relates to the technical field of cold and heat shrinking material processing equipment and discloses a granulating device for a cold and heat shrinking material of an insulation joint.The granulating device comprises a granulating rack, wherein a seal cover is mounted at the top end of the granulating rack, a spindle is mounted in the middle of the upper end of the seal cover through a bearing pedestal, a raw material barrel is mounted at the bottom end of the spindle, a plurality of centrifugal holes are formed in the inner wall of the raw material barrel, the spindle is of ahollow structure, an auxiliary shaft is arranged in the spindle, a granulating barrel is mounted at the bottom end of the auxiliary shaft, a plurality of granulating holes are formed in the bottom endof the granulating barrel, a plurality of granulating cutters are mounted on the inner wall of the granulating barrel, a fixed plate is mounted at the bottom end of the inner wall of the granulatingbarrel, a discharge plate is connected to the upper end of the fixed plate through a buffer spring, a plurality of discharge holes are formed in the middle of the discharge plate, the right end of thedischarge plate is connected to a vibrating motor by a vibrating column, and a discharge hopper is mounted at the bottom of the granulating rack. According to the granulating device, the cold and heat shrinking material is granulated efficiently. By matching with the discharge plate, the granulated granules will not block the granulating device internally, so that the granulating quality is improved greatly.

Owner:顾建荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com