Environment-friendly and efficient tin smelting smoke dust granulating system and method

A smoke-dust and high-efficiency technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as low degree of automation control, poor operating environment, and difficulty in setting up dust collection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

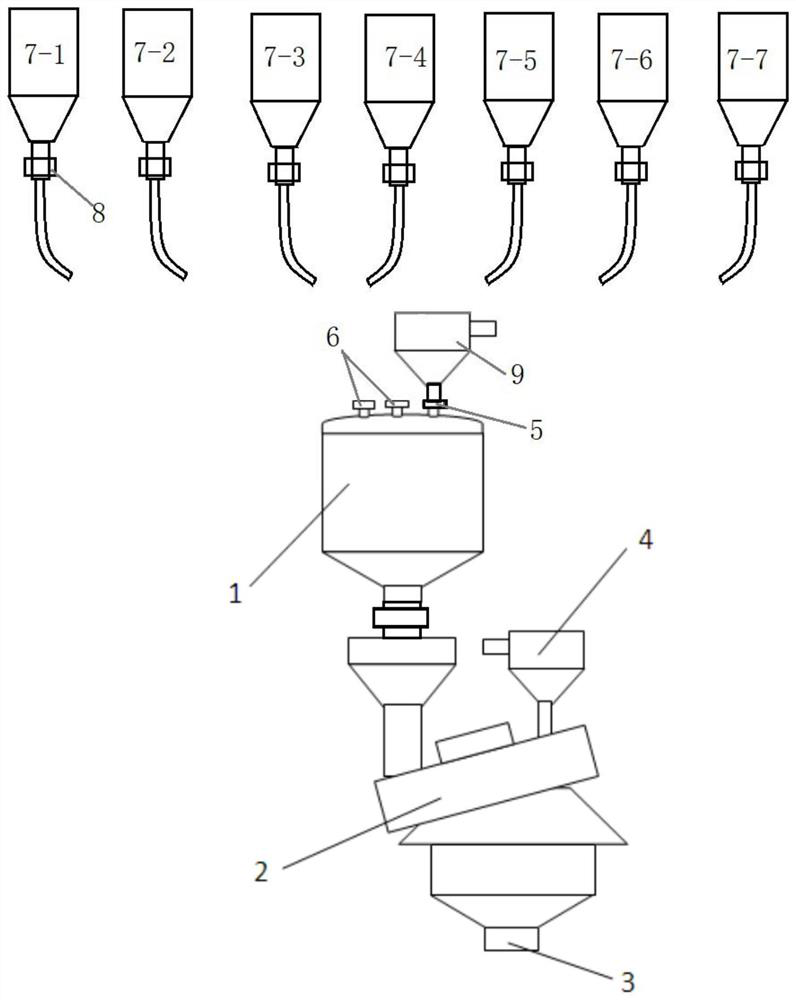

[0010] Such as figure 1 As shown, an environmentally friendly and efficient tin smelting dust granulation system includes a closed silo 1 for storing soot, a granulator 2 located below the closed silo, and a cloth bag connected to the inner cavity of the granulator at the end of the granulator Dust collector 4. The top of the airtight silo 1 is provided with at least two feed ports 6 and air outlets 5, and each feed port is connected to a different tin fume and dust silo through a pneumatic conveying pipeline to receive tin smelting from different tin smelting equipment. For smoke and dust, a gasification injection chamber pump 8 is arranged at the discharge port of each silo, and the gasification injection chamber pump is controlled and opened by the DCS control system. The top feed hopper of the granulator 2 is located below the bottom outlet of the closed silo, and the soot particles prepared by the granulator are discharged from the bottom outlet 3 . The tin smelting dus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com