Nano-modified magnesium-aluminum composite flame retardant and its preparation method and application

A technology of nano-modification and aluminum compounding, which is applied in the field of flame retardants, can solve the problems of difficulty in controlling the degree of reaction and molecular weight distribution, adverse effects of subsequent application of preparation, and great damage to the human body, and achieve excellent compatibility, low raw material cost, Effects of improving heat resistance and electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Slowly add 0.2mol / L magnesium nitrate and 0.1mol / L aluminum nitrate mixed solution (100ml) dropwise into 500mL sodium dodecylbenzenesulfonate solution with a concentration of 0.1mol / L at room temperature, and keep the pH of the system at 9-11, aging at 60°C for 20 hours after the dropwise addition, filtering and washing, the obtained white powder is the nano-modified flame retardant. The reaction yield was 92%.

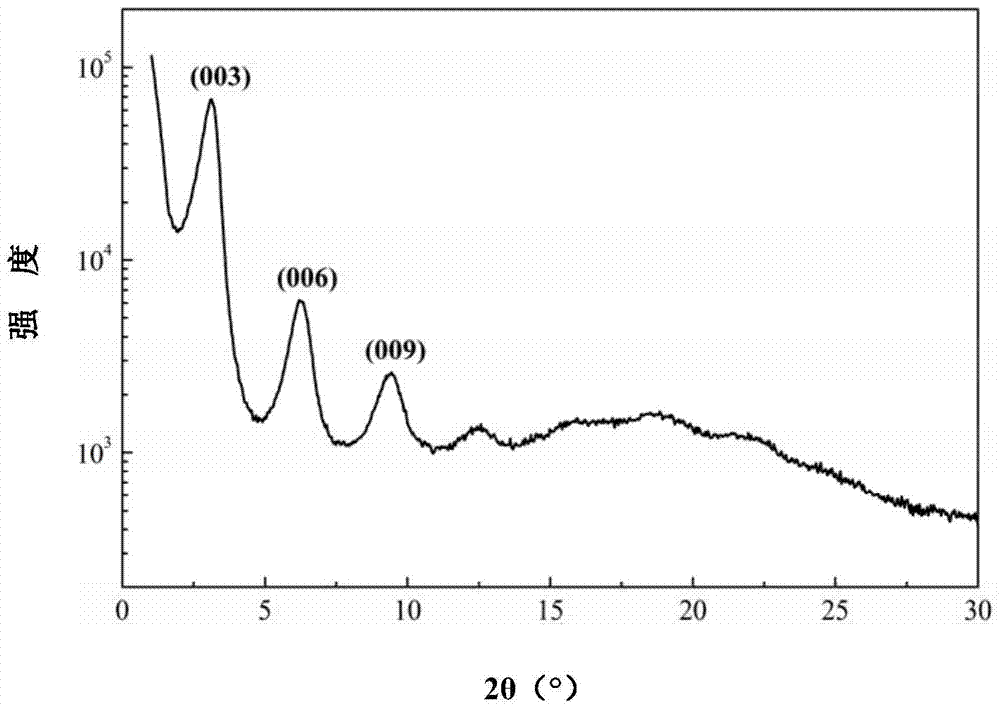

[0031] figure 1 The X-ray diffraction pattern of the nano-modified magnesium-aluminum composite flame retardant prepared for this example, it can be seen from the figure that the first-order diffraction peak (003) appears at 3.10°, and the corresponding layer spacing is 2.84nm, which is indeed Modifiers at the nanoscale.

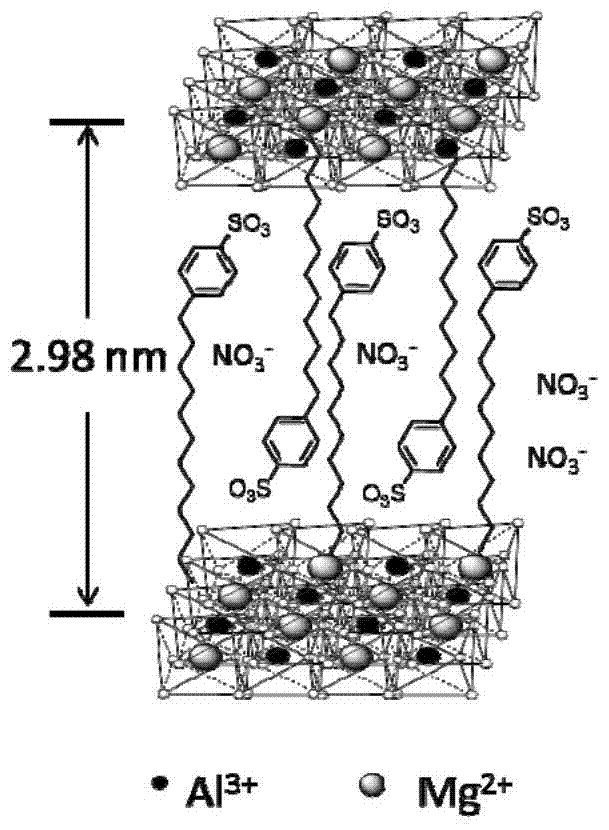

[0032] figure 2 Schematic diagram of the structure of the nano-modified magnesium-aluminum composite flame retardant prepared for this example, the intercalation agent is mainly sodium dodecylbenzenesulfonate between the sheets, and there...

Embodiment 2

[0035] Slowly add 0.1mol / L magnesium nitrate and 0.05mol / L aluminum nitrate mixed solution (50ml) dropwise into 500mL sodium dodecylbenzenesulfonate solution with a concentration of 0.05mol / L at room temperature to keep the pH of the system at 9-11, aging at 80°C for 15 hours after the dropwise addition, filtering and washing, the obtained white powder is the nano-modified flame retardant. The reaction yield was 95%.

[0036] Melt blend 20 grams of the nano-modified flame retardant prepared in this example with 180 grams of thermoplastic phenolic resin on a three-roll machine (drum temperature 90-120°C), and mix thoroughly for 30 minutes to obtain a nano-modified flame retardant Thermoplastic phenolic resin B.

Embodiment 3

[0038] Slowly add 0.2mol / L magnesium nitrate and 0.1mol / L aluminum nitrate mixed solution (200ml) dropwise into 1000mL sodium dodecylbenzenesulfonate solution with a concentration of 0.1mol / L at room temperature to keep the pH of the system at 10-11, aging at 60°C for 18 hours after the dropwise addition, filtering and washing, the obtained white powder is the nano-modified flame retardant. The reaction yield was 95%.

[0039] Melt blend 20 grams of the nano-modified flame retardant prepared in this example with 180 grams of thermoplastic phenolic resin on a three-roll machine (drum temperature 90-120°C), and mix thoroughly for 30 minutes to obtain a nano-modified flame retardant Thermoplastic phenolic resin C.

[0040] The modified flame-retardant thermoplastic phenolic resin prepared according to Examples 1-3, respectively, and the common thermoplastic phenolic resin (comparative example) were prepared using the formula in Table 1 to prepare a phenolic molding compound, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com