Vertical mixer for stirring sewage

A vertical mixer and sewage technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve problems such as unsatisfactory mixing effects, achieve simple structure, convenient use, and improve mixing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

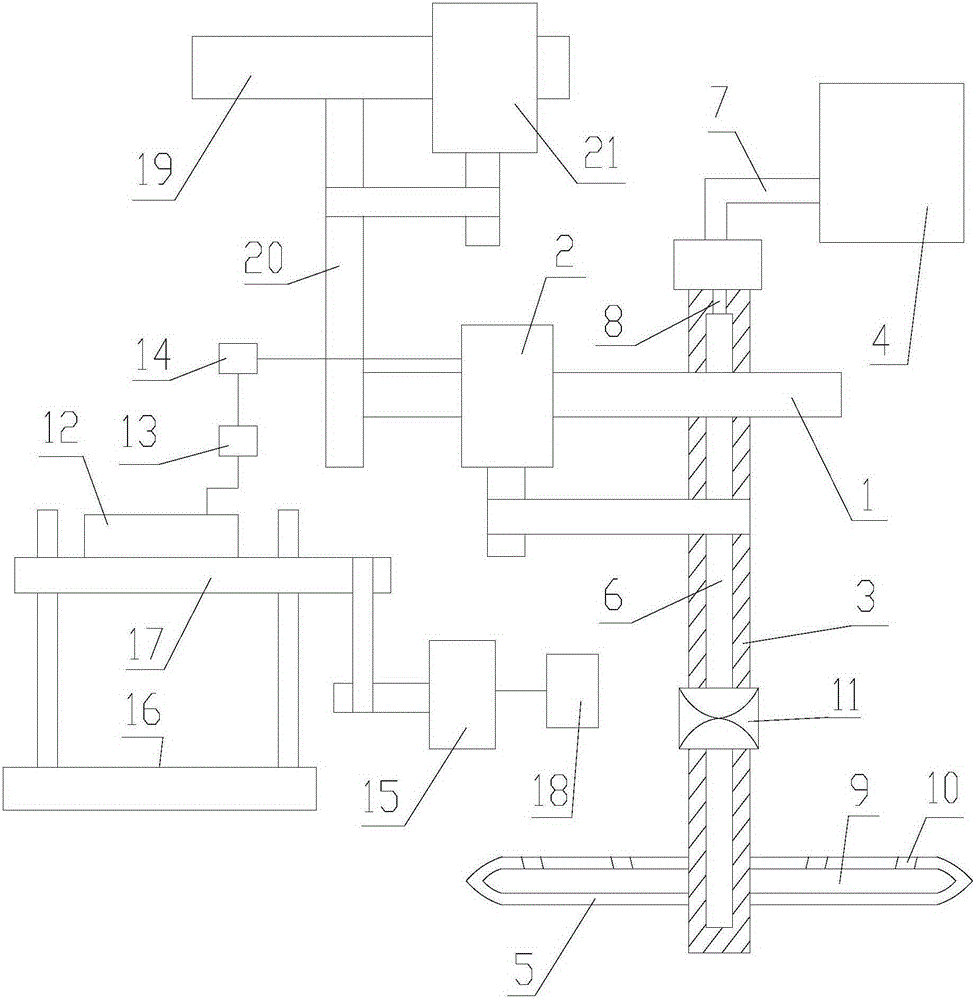

[0022] refer to figure 1 , 2 :

[0023] A vertical mixer for mixing sewage proposed by the present invention includes a support plate 1, a first motor 2, a transmission shaft 3, and a container 4 for feeding medium into the area to be stirred. The first motor 2 is installed on the support On the plate 1, the transmission shaft 3 is rotationally connected with the support plate 1, and the first motor 2 is transmission-connected with the transmission shaft 3;

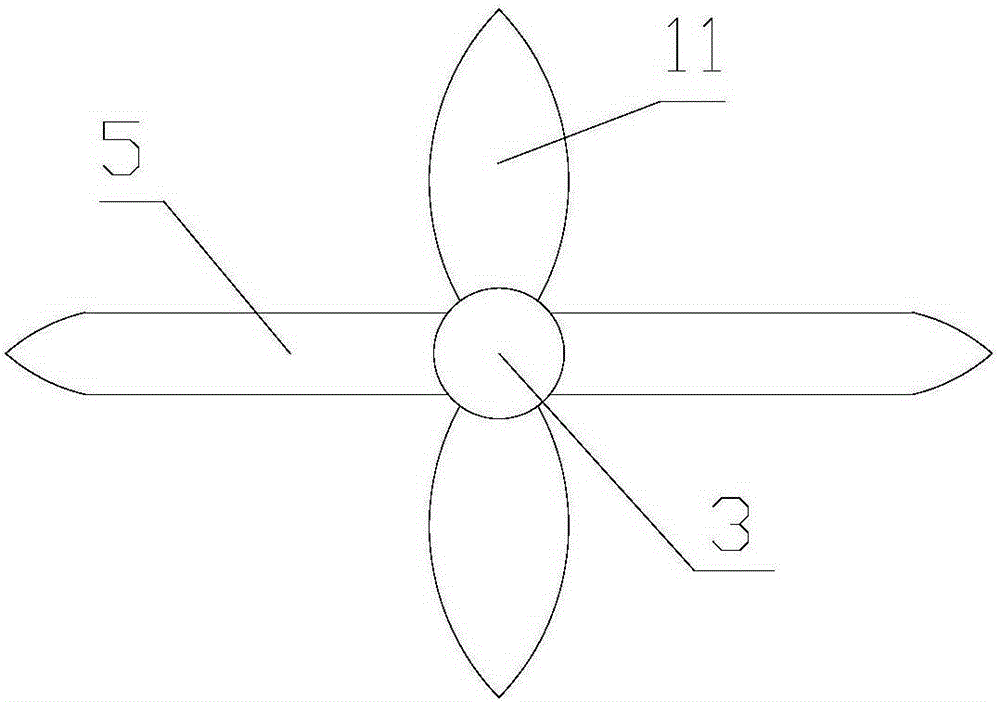

[0024] The end of the drive shaft 3 away from the support plate 1 is provided with N first stirring blades 5;

[0025] The middle part of the transmission shaft 3 is axially provided with a first storage space 6 for storing medium, and the container 5 is rotationally connected with the end of the transmission shaft 3 away from the first stirring blade 5 through a pipe 7, and the transmission shaft 3 is far away from the first stirring blade. One end of the leaf 5 is provided with a connecting channel 8 for communicatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com