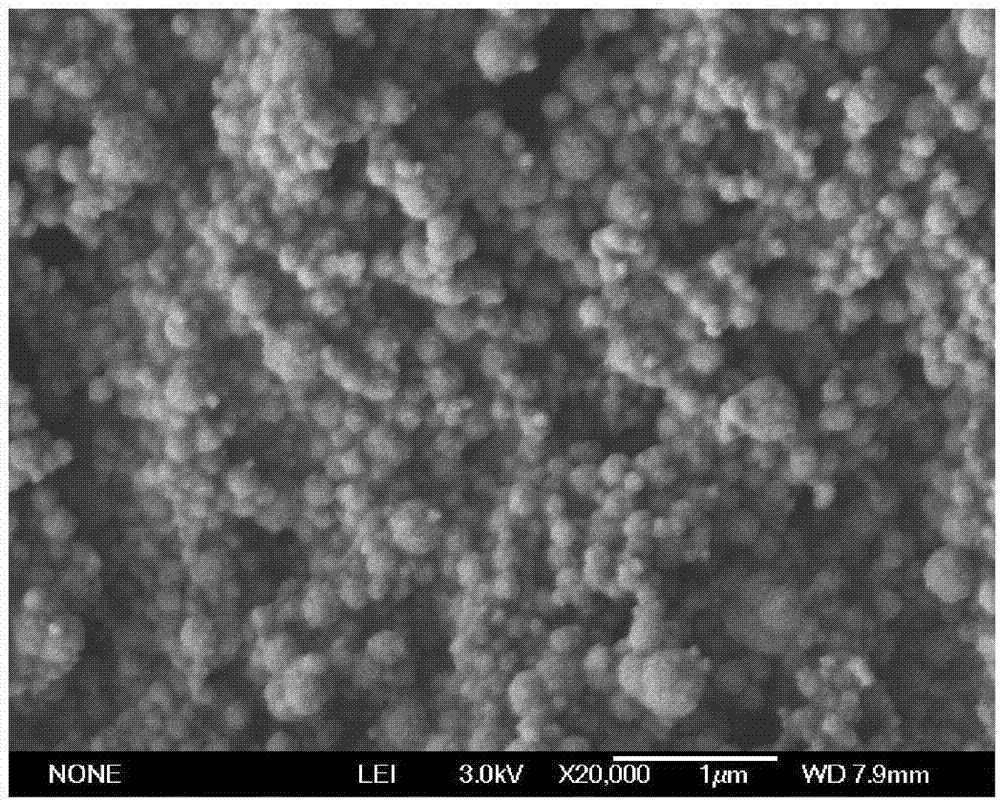

Method for promoting granulation of flocculent activated sludge by applying nano magnet

A nano-magnet and activated sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the cumbersome preparation method of modified nanospheres and the large amount of modified nanospheres , Magnetite consumption and other problems, to achieve the effect of shortening the sludge granulation time, promoting the granulation process, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

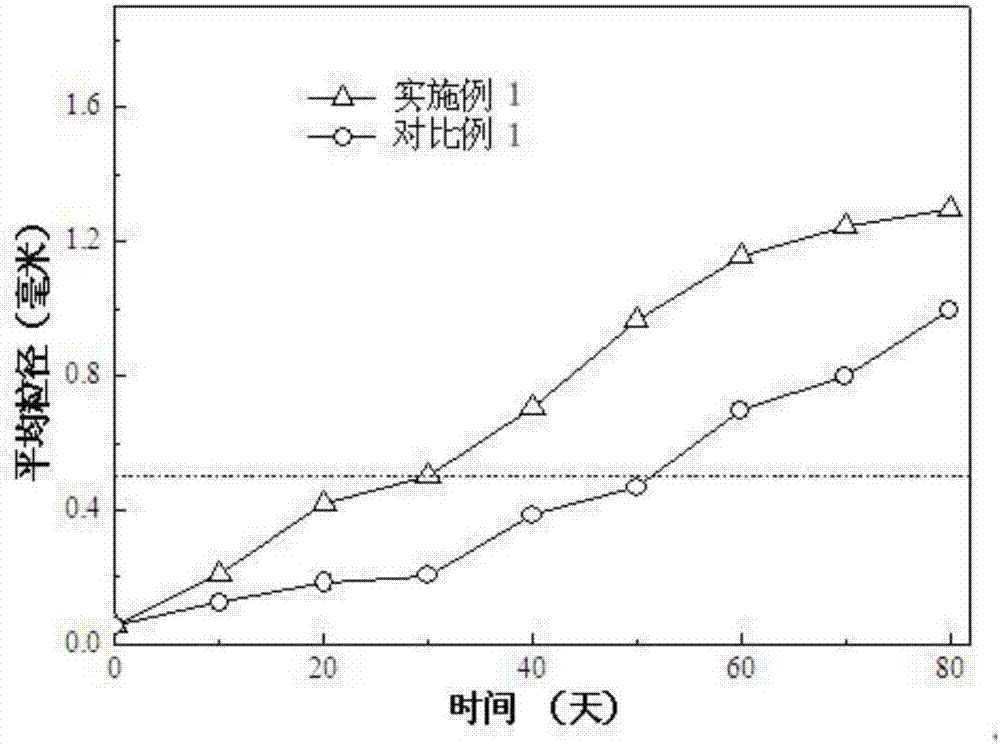

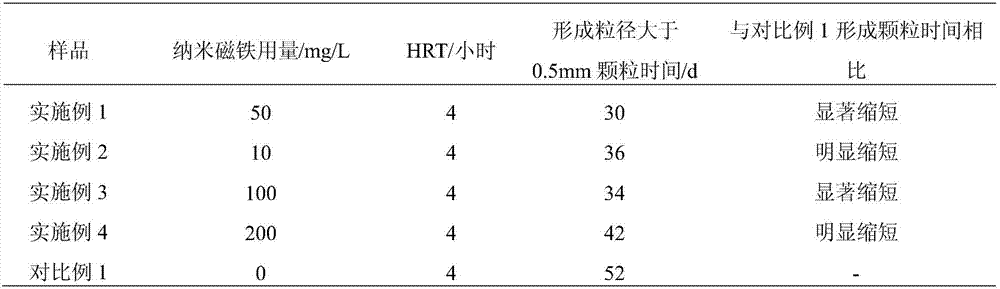

Embodiment 1

[0044] A method for promoting the granulation of flocculent activated sludge by applying nano magnets, comprising the following steps:

[0045] The flocculent activated sludge is inoculated into the sequencing batch reactor, and 5L of the mixed solution (the concentration of the nano magnet in the mixed solution is 50 mg / L) is passed into the urban domestic sewage and the nano magnet, so that the sludge in the sequencing batch reactor The concentration of the nano-magnet is 4000mg / L, and the concentration of the nano-magnet is 50mg / L; the reactor operates periodically at a temperature of 25°C, and the operation conversion of each stage in the reactor cycle is controlled by a time relay. It runs 6 cycles a day, hydraulic The residence time (HRT) is 8 hours, and each cycle is 4 hours, including 6 minutes of water inlet time, 218 minutes of aeration time, 12 minutes of resting time, and 4 minutes of water outlet time; in each cycle, an air compressor is used for aeration , the ae...

Embodiment 2

[0048] A method for promoting the granulation of flocculent activated sludge by applying nano-magnets, the steps are as described in Example 1, except that the concentration of nano-magnets in the sequencing batch reactor is 10 mg / L.

Embodiment 3

[0050] A method for promoting the granulation of flocculent activated sludge by applying nano-magnets, the steps are as described in Example 1, the difference is that the concentration of nano-magnets in the sequencing batch reactor is 100 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com