One-step granulation system for ultrafine powder

A fluidization chamber and fan blade technology, applied in the field of one-step granulation, can solve the problems of low granulation efficiency, large material loss, and easy to generate electrostatic adsorption, etc., to achieve uniform fluidization, improve granulation efficiency, and improve balance Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

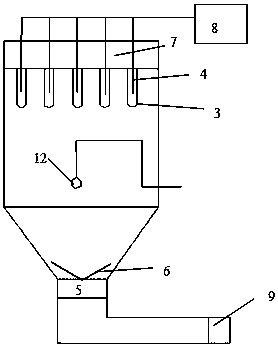

[0034] A one-step granulation system, the main structure diagram is as follows figure 1 .

[0035] The main body of the one-step granulation system includes, from top to bottom, an induced air cavity 7, a spray fluidization chamber 13, an atomization nozzle 12, a pneumatic stirring blade 6, a screen, and an air flow dividing plate 5. The atomization nozzle 12 is located at In the center of the cavity of the spray fluidization chamber 13, the atomization nozzle 12 is connected with the liquid feed pipe placed on the side of the cavity of the spray fluidization chamber 13, and the top of the spray fluidization chamber 13 is provided with the air induction cavity 7 The through hole 10 is connected with a titanium rod filter 3, and the center of the through hole 10 is provided with a nozzle 4, which has a vertical tubular structure and extends to the cavity of the spray fluidization chamber 13, when When the titanium rod filter 3 is connected to the through hole 10, the nozzle 4 is l...

Embodiment 2

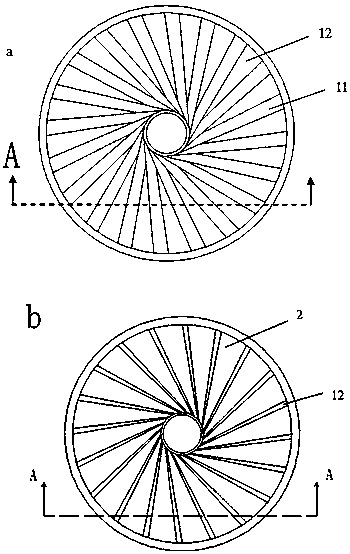

[0042] The bottom view and the top view of the air flow divider plate 5 in Example 1 are respectively figure 2 a and 2b, the A-A line cross-sectional view is as image 3 .

[0043] The air flow distribution plate 5 includes two hollow cylinders inside and outside. The two ends of the first fan blade 1 are mounted on the two hollow cylinders, which are in a fan-like structure. The first fan blade 1 includes a first blade surface 11 and a first blade surface. Two blade surfaces 12, one end of the first blade surface 11 is at the air inlet position, the other end is connected with the second blade surface 12, one end of the second blade surface 12 is at the air outlet position, and the other end is connected with the first blade surface 11 The included angle between the first blade surface 11 and the second blade surface 12 of the first fan blade 1 is an obtuse angle; the first fan blade 1 is spaced between 0.5 cm and 1.5 cm, and is evenly distributed in two Hollow cylinder. The i...

Embodiment 3

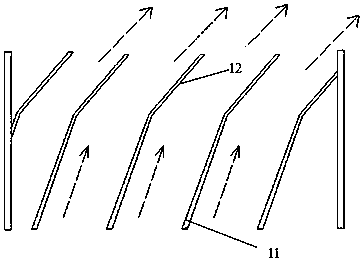

[0046] This embodiment is improved on the basis of Embodiment 2. The bottom view and the top view of the air distribution plate 5 of this embodiment are the same as those of Embodiment 2, and the cross-sectional view along line A-A is as Figure 4 .

[0047] In this embodiment, in the second blade surface 12 of the first fan blade 1 described in the second embodiment, a second fan blade 2 is installed at the end close to the air outlet; the second fan blade 2 and the first fan blade 1 have the same Length, there is an angle between the second fan blade 2 and the first fan blade 1, and a distance from the outer surface of the first fan blade 1 arranged adjacently.

[0048] The working principle of the air distribution plate: the purified hot air blown from below the air distribution plate enters the air distribution plate 5 through the first leaf surface 11 along the way, and the hot air passes through the first leaf surface 11 and the second leaf surface 12 The angle between the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com