Application of ceramic waste in preparation of high-strength light aggregate and prepared high-strength light aggregate

A ceramic waste and light aggregate technology, which is applied in the field of high-strength light aggregate and preparation of high-strength light aggregate, can solve the problems of low waste disposal and utilization, and achieve the effects of reduced energy consumption, high refractoriness, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The raw materials for the preparation of the high-strength lightweight aggregate described in this embodiment include: 30 kg of fly ash, 12 kg of pellet core material, 38 kg of green waste fine powder, 5 kg of plasticizer, 10 kg of foaming agent, and 5 kg of flux.

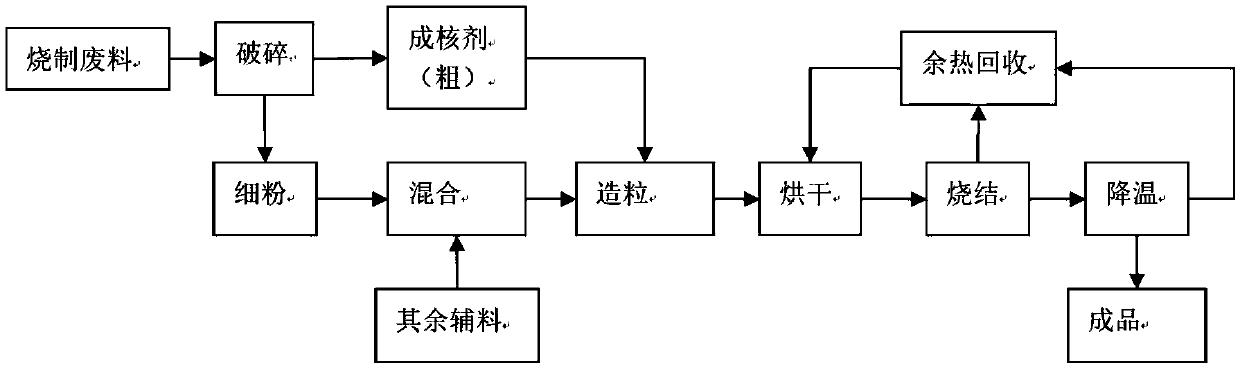

[0037] like figure 1 As shown in the process flow diagram, the preparation method of the high-strength lightweight aggregate described in this embodiment includes the following steps:

[0038] (1) carrying out crushing and ball milling treatment of each raw material according to the selected particle size range, for subsequent use;

[0039] (2) according to the selected proportioning amount, get described fly ash, pelletizing nuclei material, biscuit waste fine powder, plasticizer, blowing agent and fluxing agent to mix;

[0040] (3) Utilize the disc granulator to continuously granulate the obtained mixed material, and add water continuously, the amount of water added is 18wt% of the mixed material amount, ...

Embodiment 2

[0044] The raw materials for the preparation of the high-strength lightweight aggregate described in this embodiment include: 34 kg of fly ash, 9 kg of ball core material, 40 kg of green waste fine powder, 5 kg of plasticizer, 8 kg of foaming agent, and 4 kg of flux.

[0045] The preparation method of the high-strength lightweight aggregate described in this embodiment comprises the following steps:

[0046] (1) carrying out crushing and ball milling treatment of each raw material according to the selected particle size range, for subsequent use;

[0047] (2) according to the selected proportioning amount, get described fly ash, pelletizing nuclei material, biscuit waste fine powder, plasticizer, blowing agent and fluxing agent to mix;

[0048] (3) Utilize the disc granulator to continuously granulate the obtained mixed material, and add water continuously, the amount of water added is 22wt% of the mixed material amount, to obtain the ceramsite green body;

[0049] (4) drying...

Embodiment 3

[0052] The raw materials for the preparation of the high-strength lightweight aggregate described in this embodiment include: 49kg of fly ash, 3kg of ball core material, 38kg of green waste fine powder, 5kg of plasticizer, 2kg of foaming agent, and 3kg of flux.

[0053] The preparation method of the high-strength lightweight aggregate described in this embodiment comprises the following steps:

[0054] (1) carrying out crushing and ball milling treatment of each raw material according to the selected particle size range, for subsequent use;

[0055] (2) according to the selected proportioning amount, get described fly ash, pelletizing nuclei material, biscuit waste fine powder, plasticizer, blowing agent and fluxing agent to mix;

[0056] (3) Utilize the disc granulator to continuously granulate the obtained mixed material, and add water continuously, the amount of water added is 20wt% of the mixed material amount, to obtain the ceramsite green body;

[0057] (4) drying the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com