Ultramicro powder trapping device for fluidized bed granulation system

A fluidized bed granulation and ultra-fine powder technology, applied in the direction of powder suspension granulation, special binder granulation, etc., can solve the problems of low granulation efficiency, material consumption, low granulation rate, etc. The effect of material balance yield, improving granulation efficiency and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

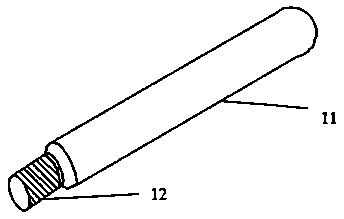

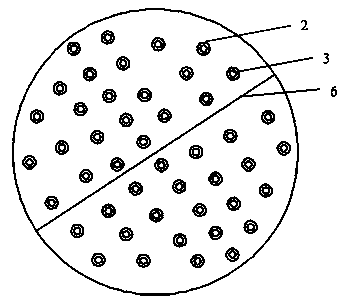

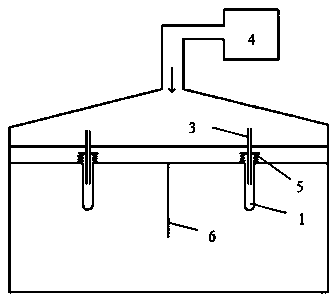

[0021] A dust collection device, which has a hole 2 on the top of the spray fluidization chamber, a titanium rod filter 1 is placed on the hole 2 and fixed to the top of the fluidization chamber, and a nozzle 3 is arranged in the center of the hole 2, The other end of the nozzle 3 is connected to a compressed air pulse blowback device 4 .

[0022] In this embodiment, the rod body 11 of the titanium rod filter 1 is hollow and contains an external thread end 12, the external thread end of the titanium rod filter 1 matches the internal thread 5 on the hole 2, The titanium rod filter 1 is thus connected to the hole 2 . In particular, the nozzle 3 goes deep into the rod body of the titanium rod filter 1 .

[0023] During the one-step granulation process, the titanium rod filter 1 is fixed on the top of the fluidization chamber, and the compressed air pulse blowback device 4 is turned on at the same time. The titanium rod filter 1 can effectively block the dust carried by the waste...

Embodiment 2

[0025] As a further improvement to Example 1, the powder collection device in this embodiment further includes a partition 6 vertically fixed on the top of the fluidized bed, and the partition 6 evenly divides the nozzles 3 at the top of the fluidized chamber.

[0026] In the one-step granulation process, the titanium rod filter 1 is fixed on the top of the fluidization chamber, and the compressed air pulse blowback device 4 is turned on at the same time. The titanium rod filter 1 can effectively block the dust carried by the waste air, and the partition 6 will be positioned at the fluidization chamber. The nozzles on the top of the chemical chamber are evenly separated, and the compressed air passes through the nozzles located inside the rod body of the titanium rod filter 1 to periodically blow back the titanium rod filters 1 on both sides, further reducing the dust adhesion on the titanium rod filter 1 and improving the powder body pelleting efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com