Method for preparing spherical molecular sieve

A molecular sieve and spherical technology, which is applied in the field of spherical molecular sieve preparation, can solve the problems of granulation and return system flow fluctuation, inapplicability to granulation production, and strict requirements on blade speed, so as to improve the spheroid formation efficiency, Improve the production environment, the effect of round appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

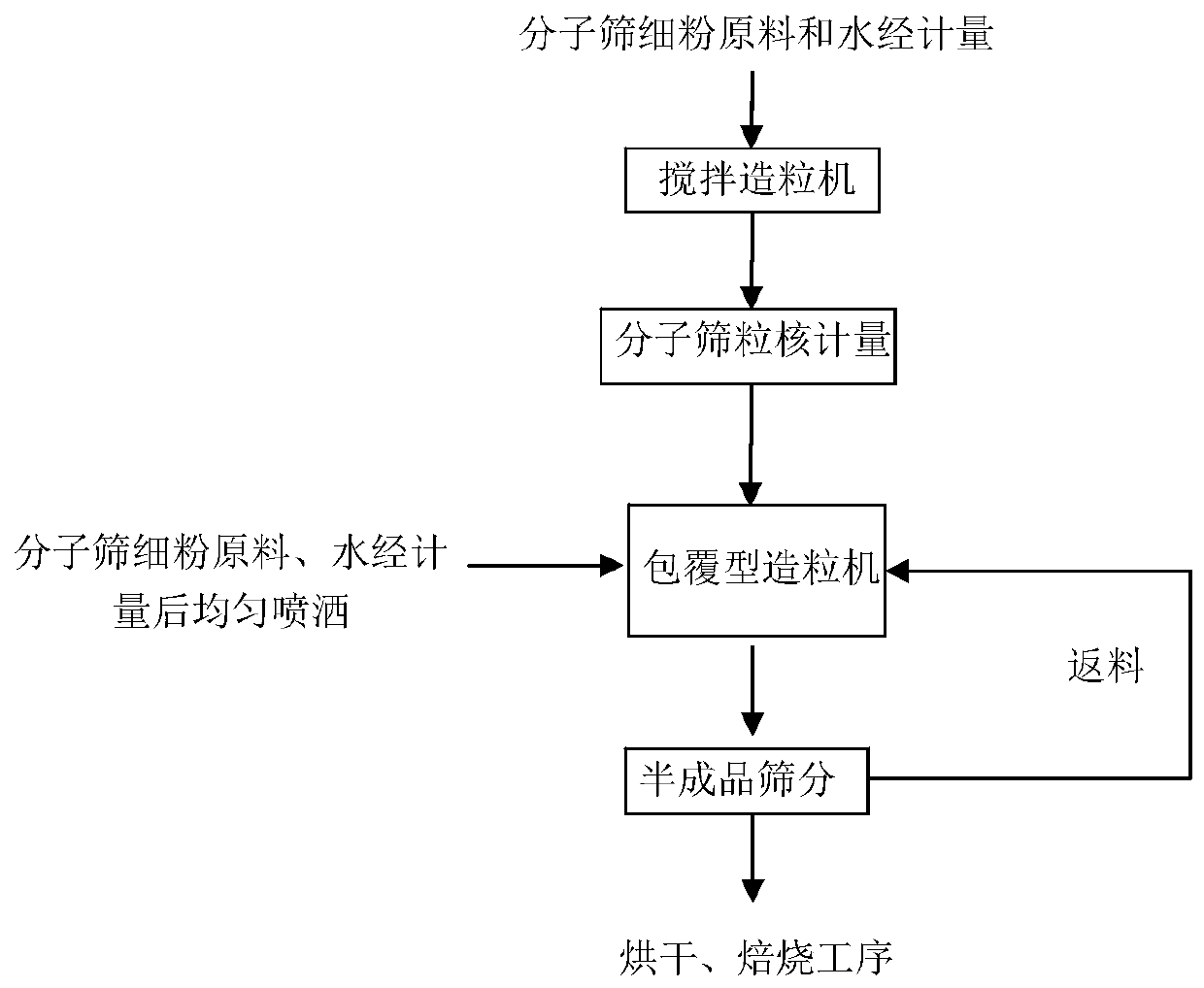

[0041] A kind of preparation method of spherical molecular sieve, its preparation process is as follows figure 1 shown, including the following steps:

[0042] (1) Preparation of small nuclei

[0043] Add 100 parts by weight of zeolite powder raw materials and 15 parts by weight of water into the stirring granulator, and granulate in the stirring granulator for 8 minutes to obtain a small particle nucleus with a particle diameter of 1.5 mm. The stirring granulator includes a cylinder and a device For the stirring blades in the cylinder, the rotation direction of the cylinder and the stirring blades is opposite, and the rotation speed of the paddles is greater than that of the mixing disc, the tangential velocity of the end of the paddles is 10 m / s, and the rotation of the cylinder wall The tangential speed is 3 m / s, and the fineness of the fine powder material used in the preparation process is greater than 100 mesh.

[0044] The process uses a stirring granulator for granul...

Embodiment 2

[0049] A kind of preparation method of spherical molecular sieve, comprises the following steps:

[0050] (1) Preparation of small nuclei

[0051] Add 100 parts by weight of bentonite and 20 parts by weight of water into the stirring granulator, and granulate in the stirring granulator for 4 minutes to obtain a small particle nucleus with a particle diameter of 0.8mm. The stirring granulator includes a cylinder and a The stirring blades in the cylinder, the rotation direction of the cylinder and the stirring blades are opposite, and the rotation speed of the blades is greater than the rotation speed of the mixing disc, the tangential velocity of the end of the blades is 15 m / s, and the rotation of the cylinder wall is tangential The speed is 6 m / s, and the fineness of the fine powder material used in the preparation process is greater than 100 mesh.

[0052] (2) Preparation of molecular sieve spherical particles

[0053] Take out the core and put it into a water chestnut typ...

Embodiment 3

[0056] (1) Preparation of small nuclei

[0057] Add 100 parts by weight of attapulgite and 22 parts by weight of water into the stirring granulator, and granulate in the stirring granulator for 5 minutes to obtain a small particle nucleus with a particle diameter of 1.2mm. The stirring granulator includes a cylinder and a device For the stirring blades in the cylinder, the rotation direction of the cylinder and the stirring blades is opposite, and the rotation speed of the paddles is greater than that of the mixing disc, the tangential velocity of the end of the paddles is 15 m / s, and the rotation of the cylinder wall The tangential velocity is 2.5 m / s, and the fineness of the fine powder material used in the preparation process is greater than 100 mesh.

[0058] (2) Preparation of molecular sieve spherical particles

[0059] Then transfer 0.5 tons of grain core to the disc granulator, the attapulgite raw material is continuously added at a speed of 20 kg / min through the mete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com